INDUSTRIAL CT SCANNING

SERVICES

Digital Radiography & Computed Tomography

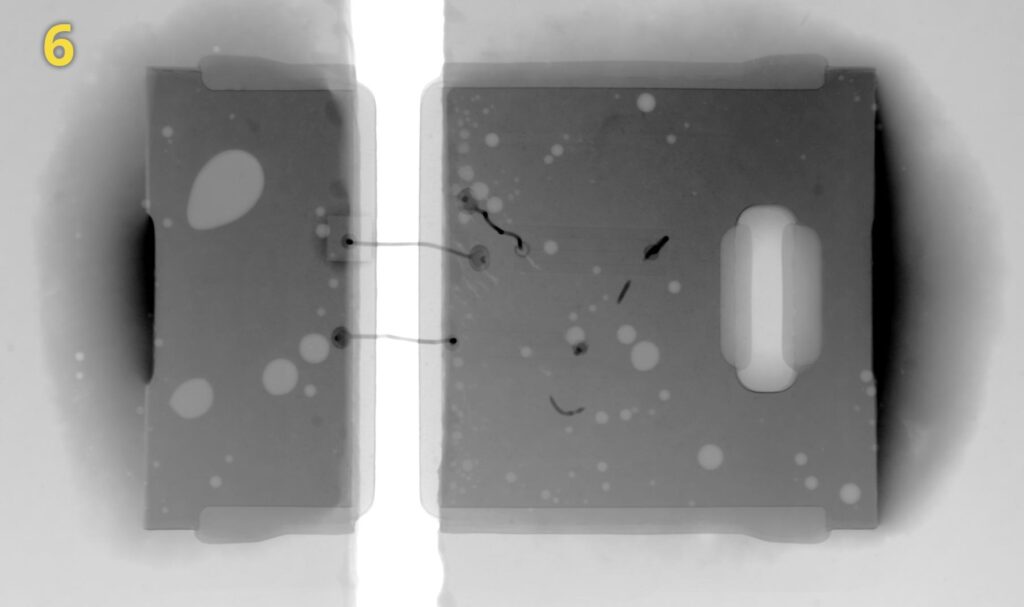

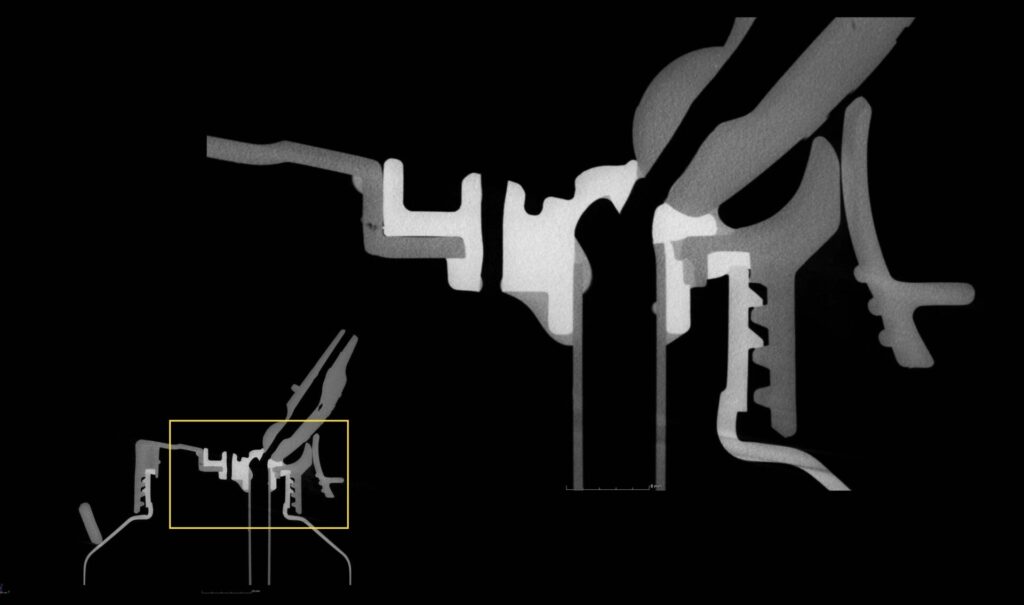

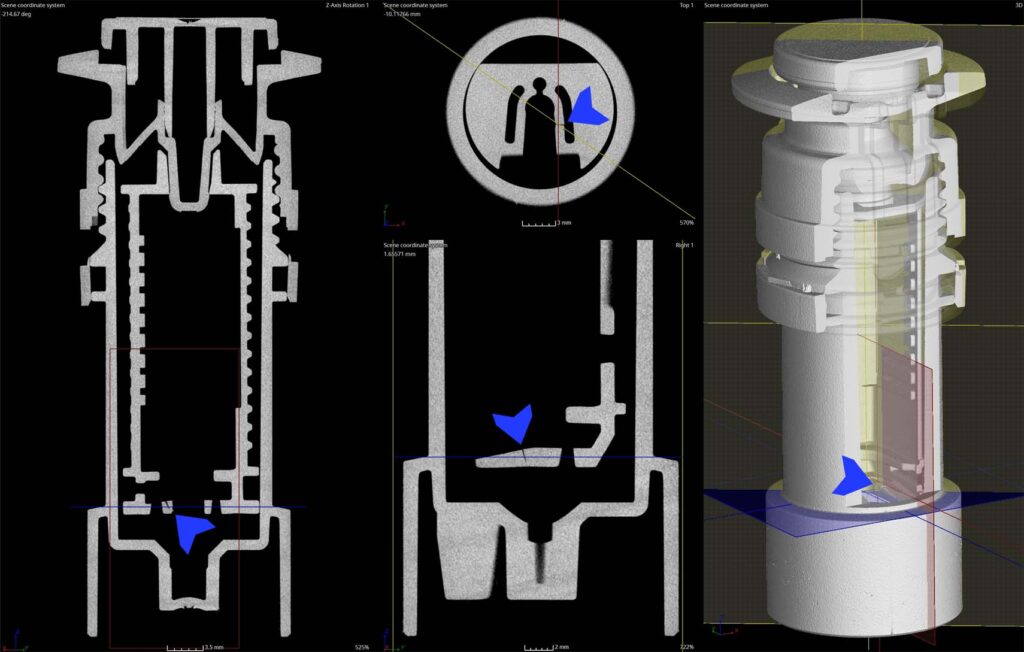

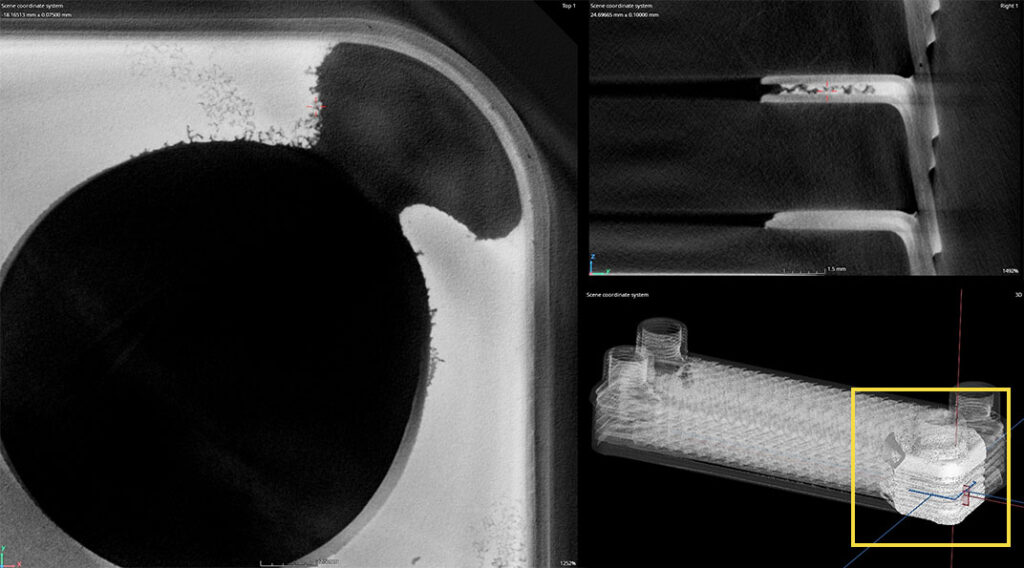

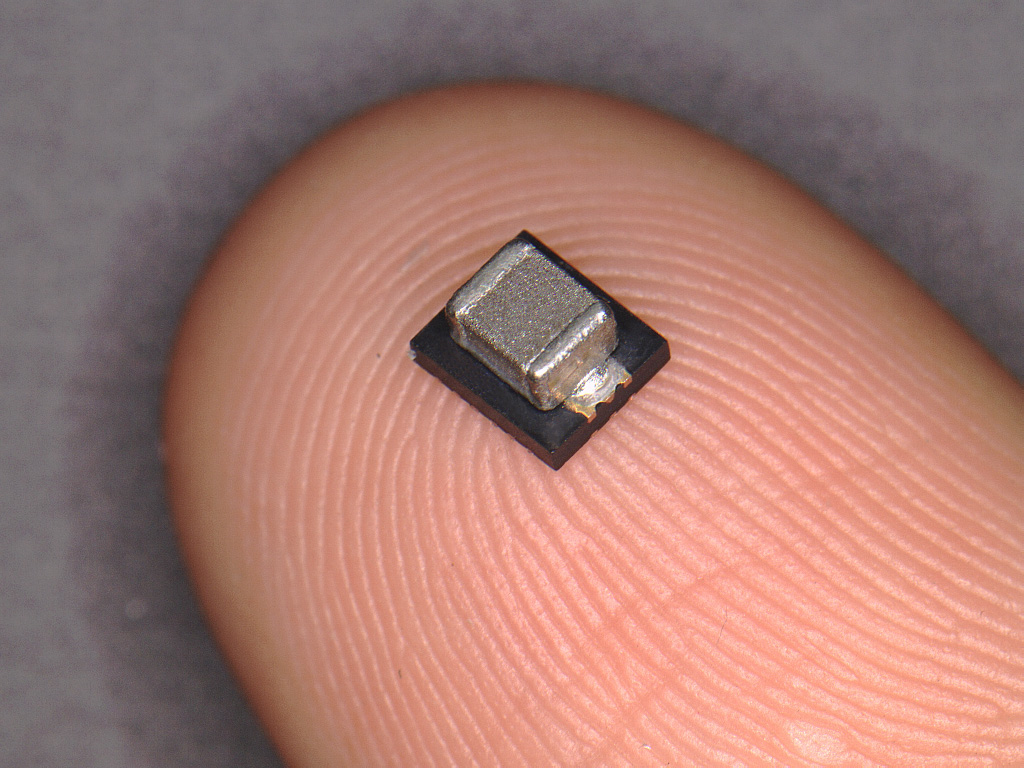

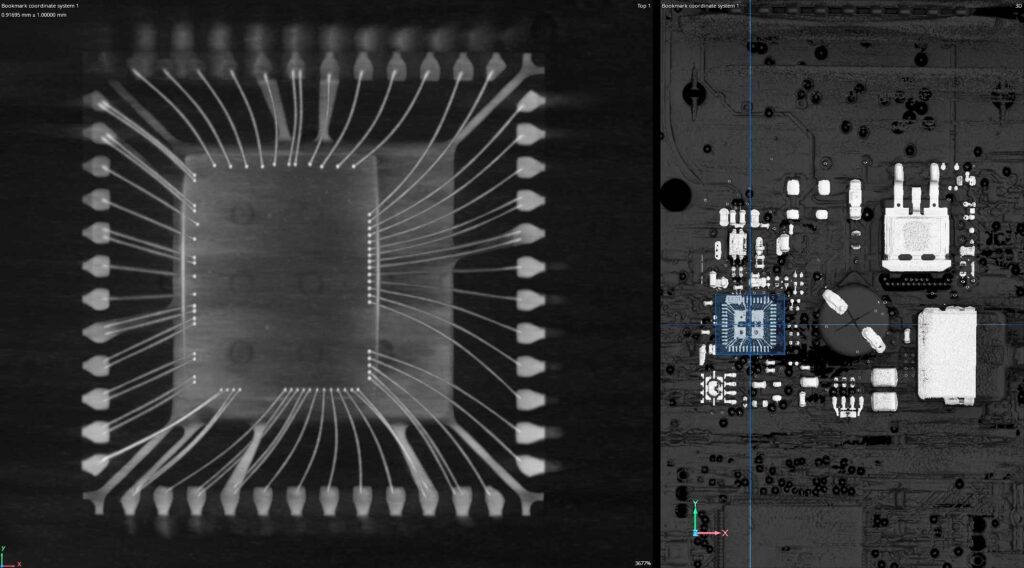

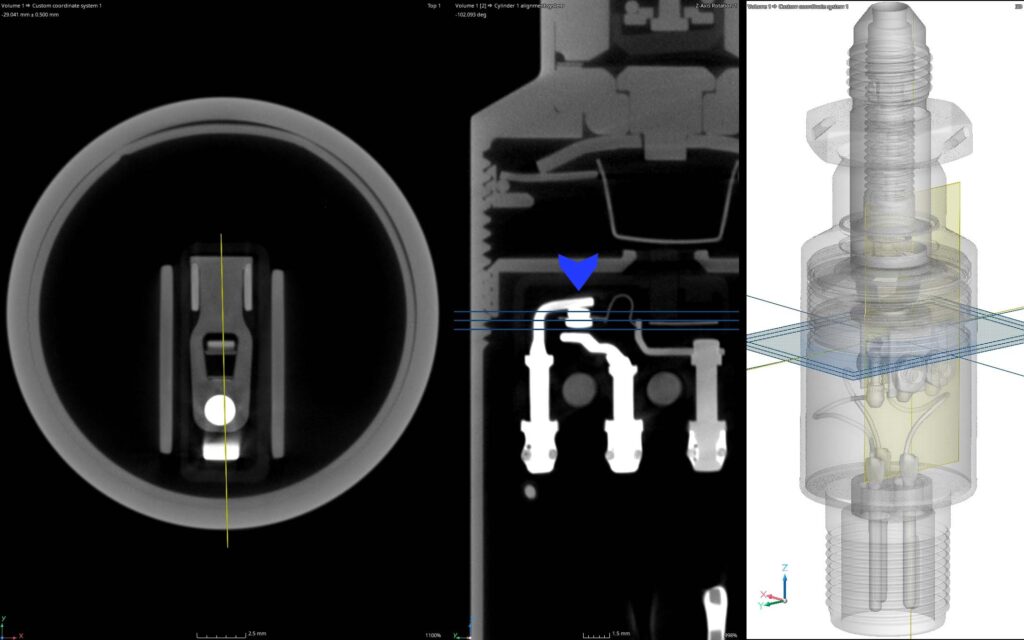

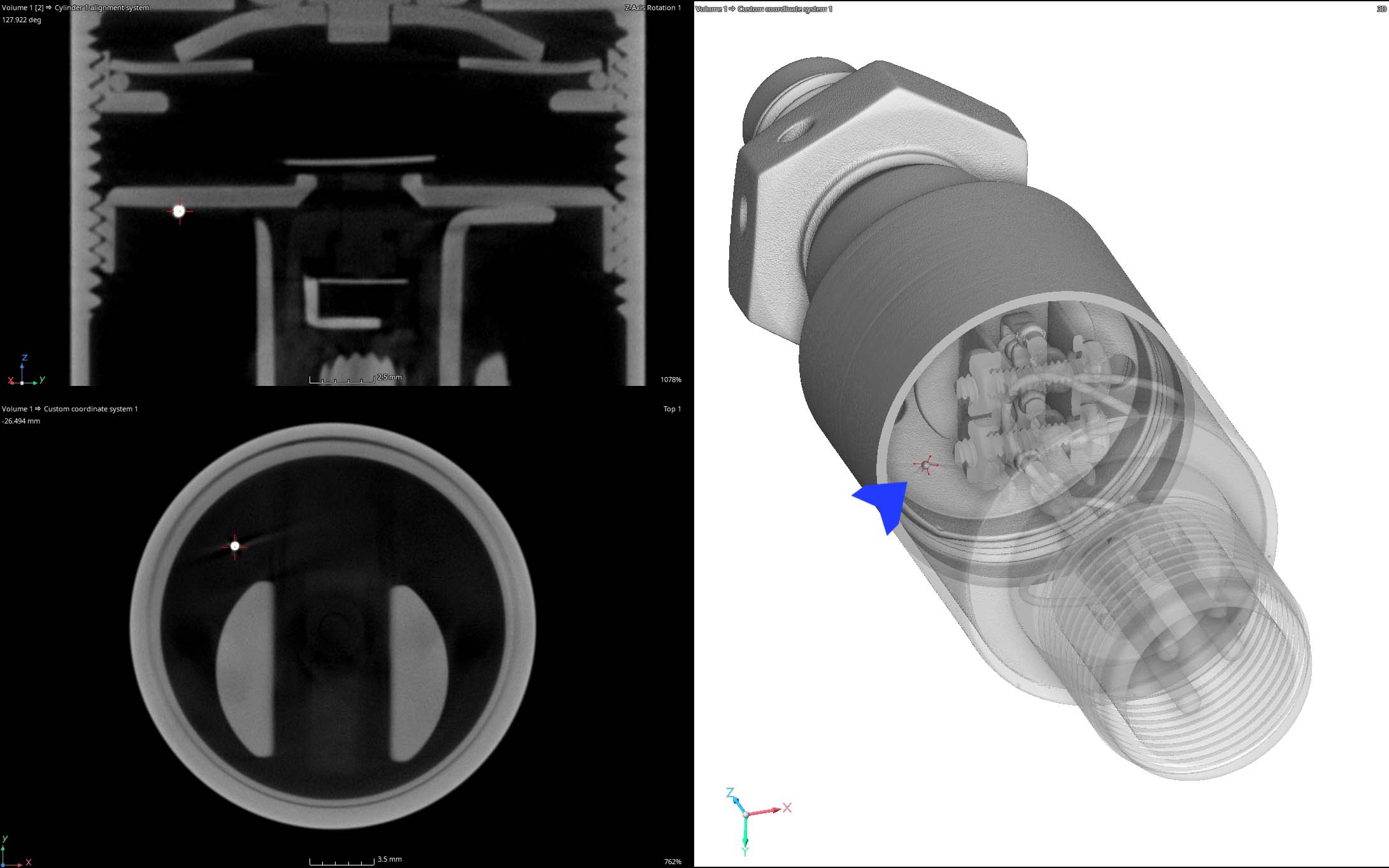

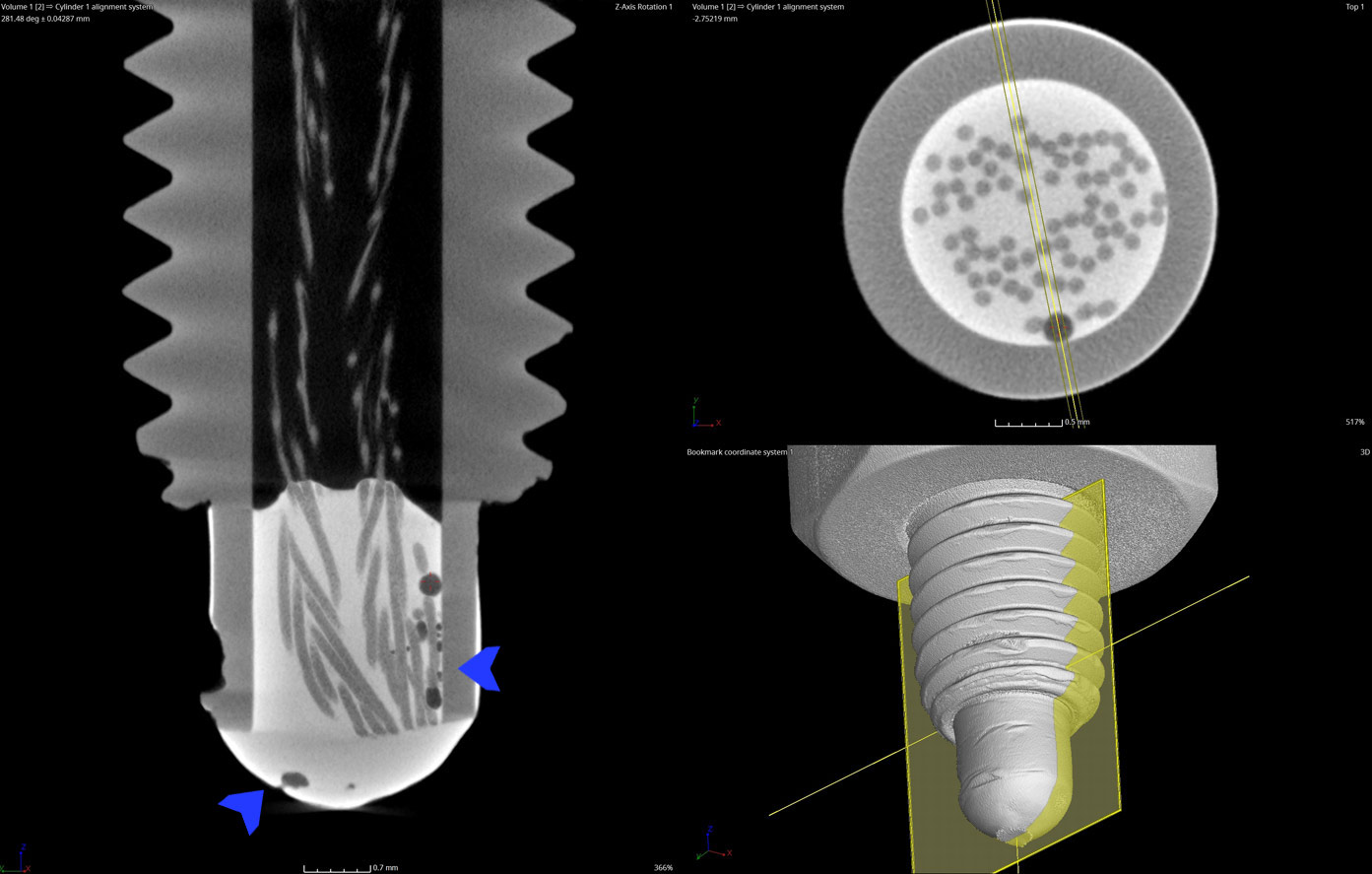

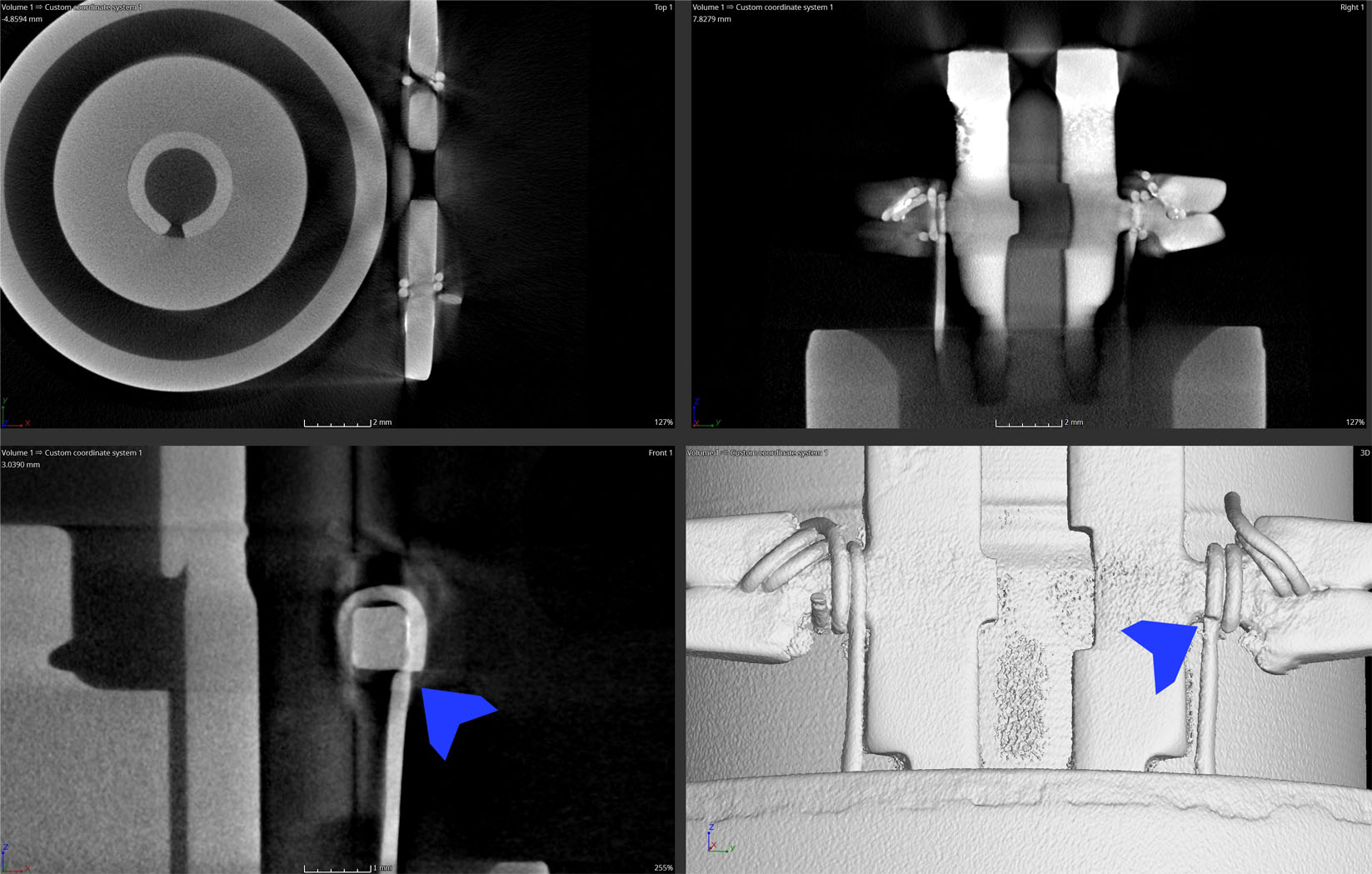

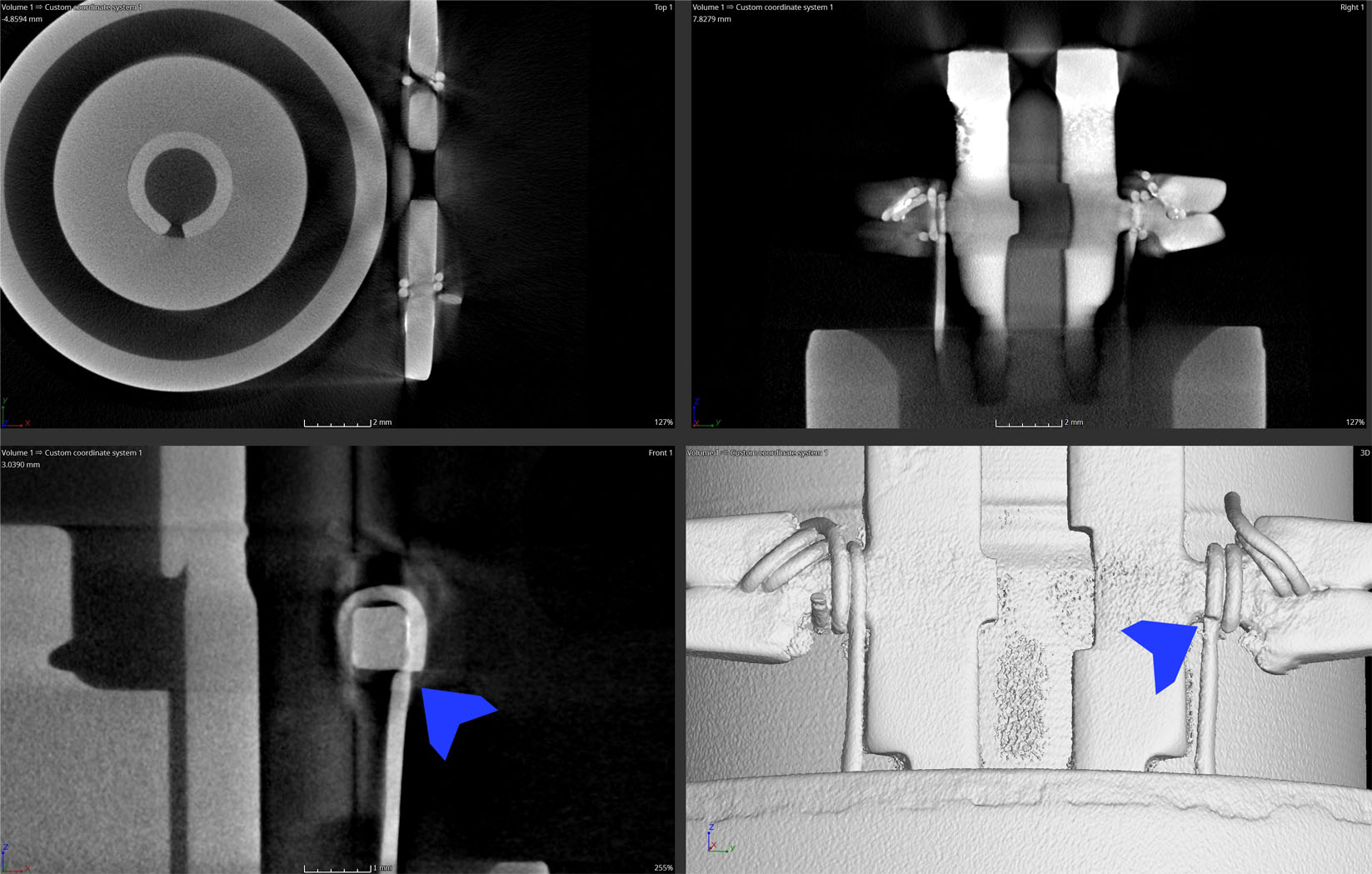

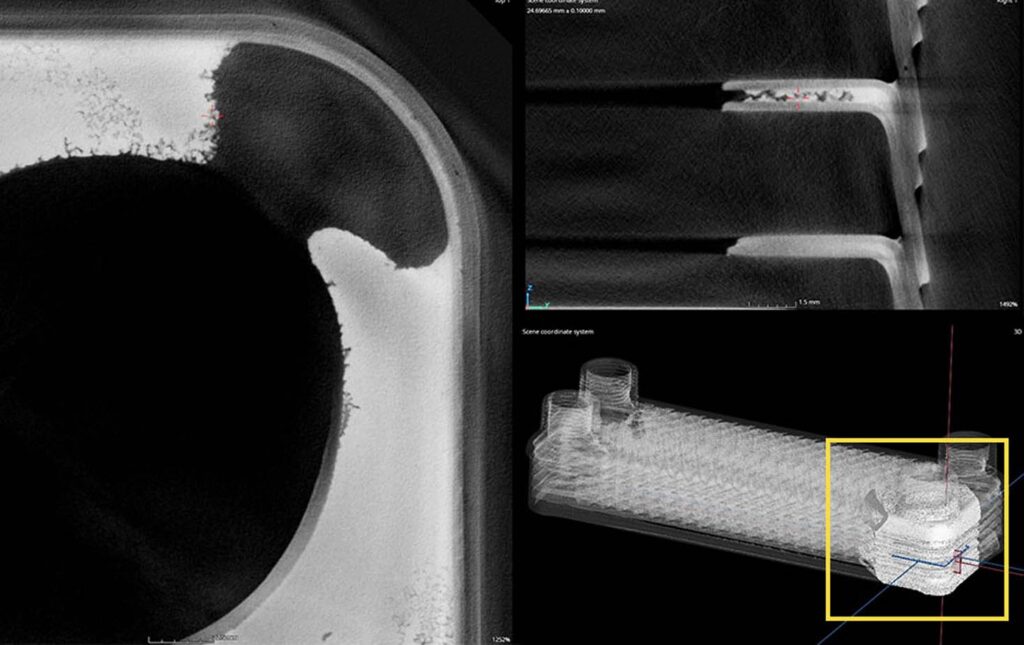

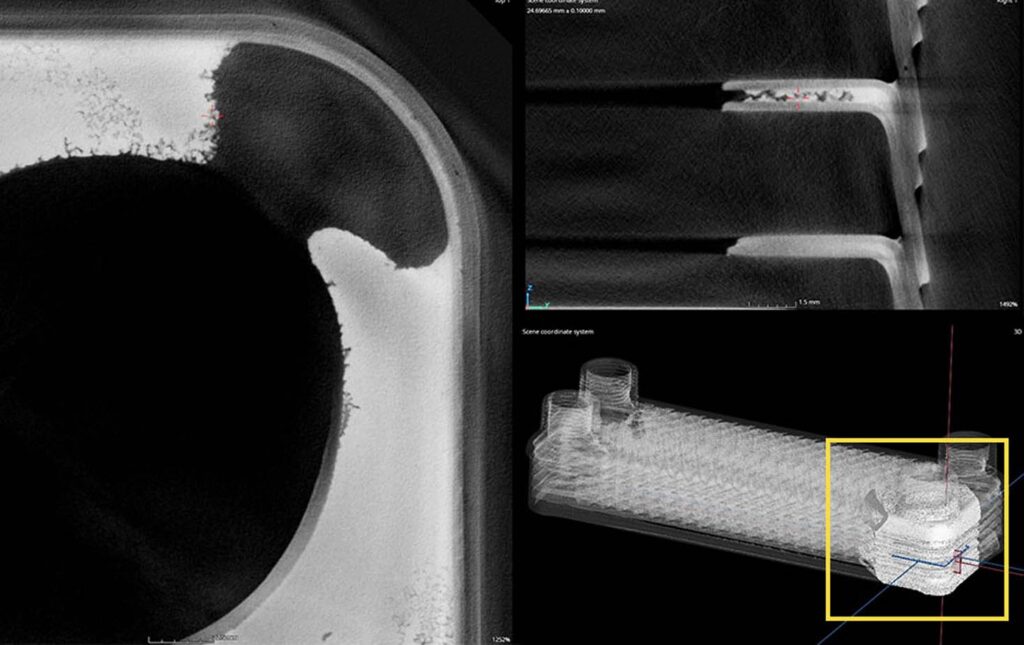

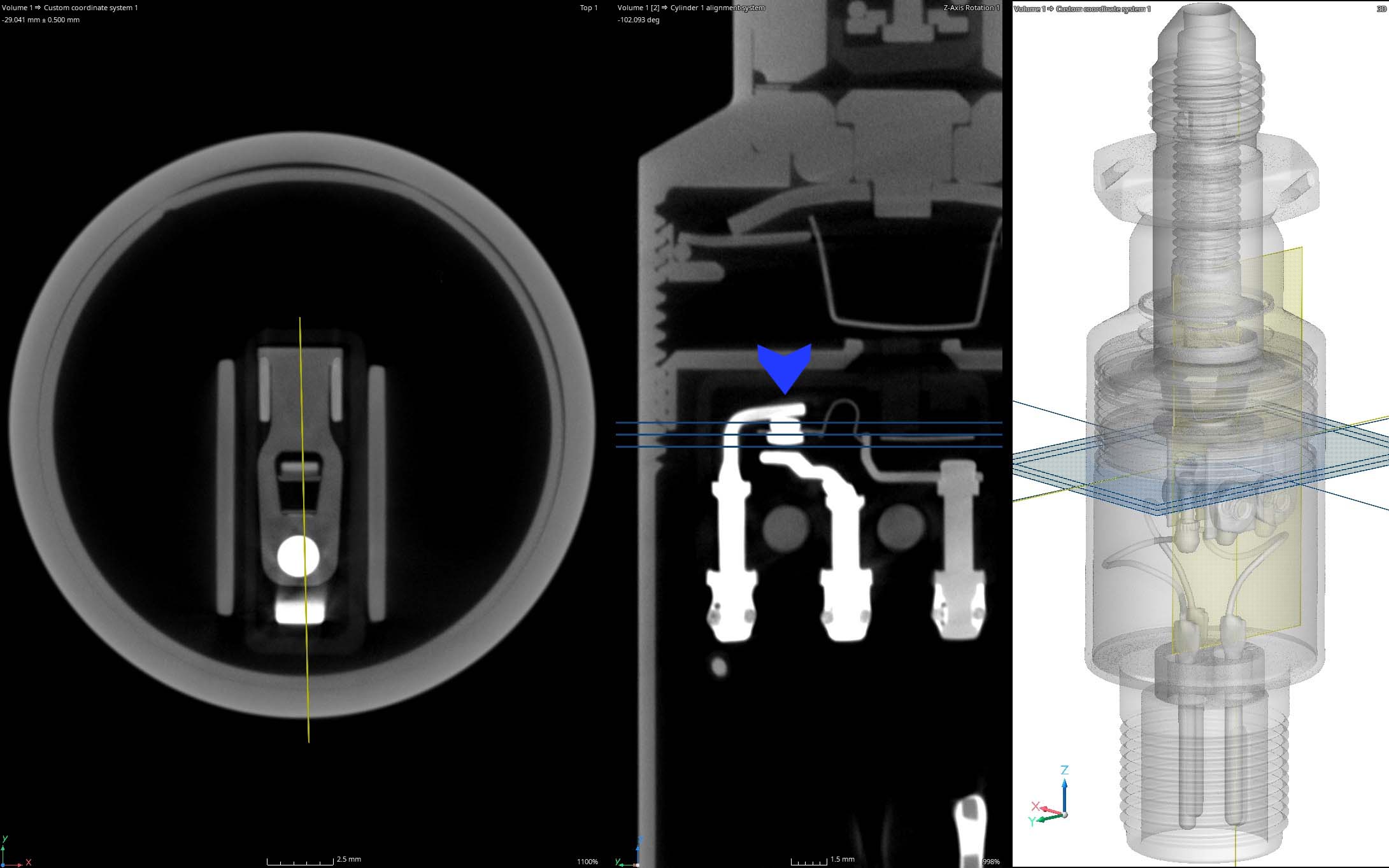

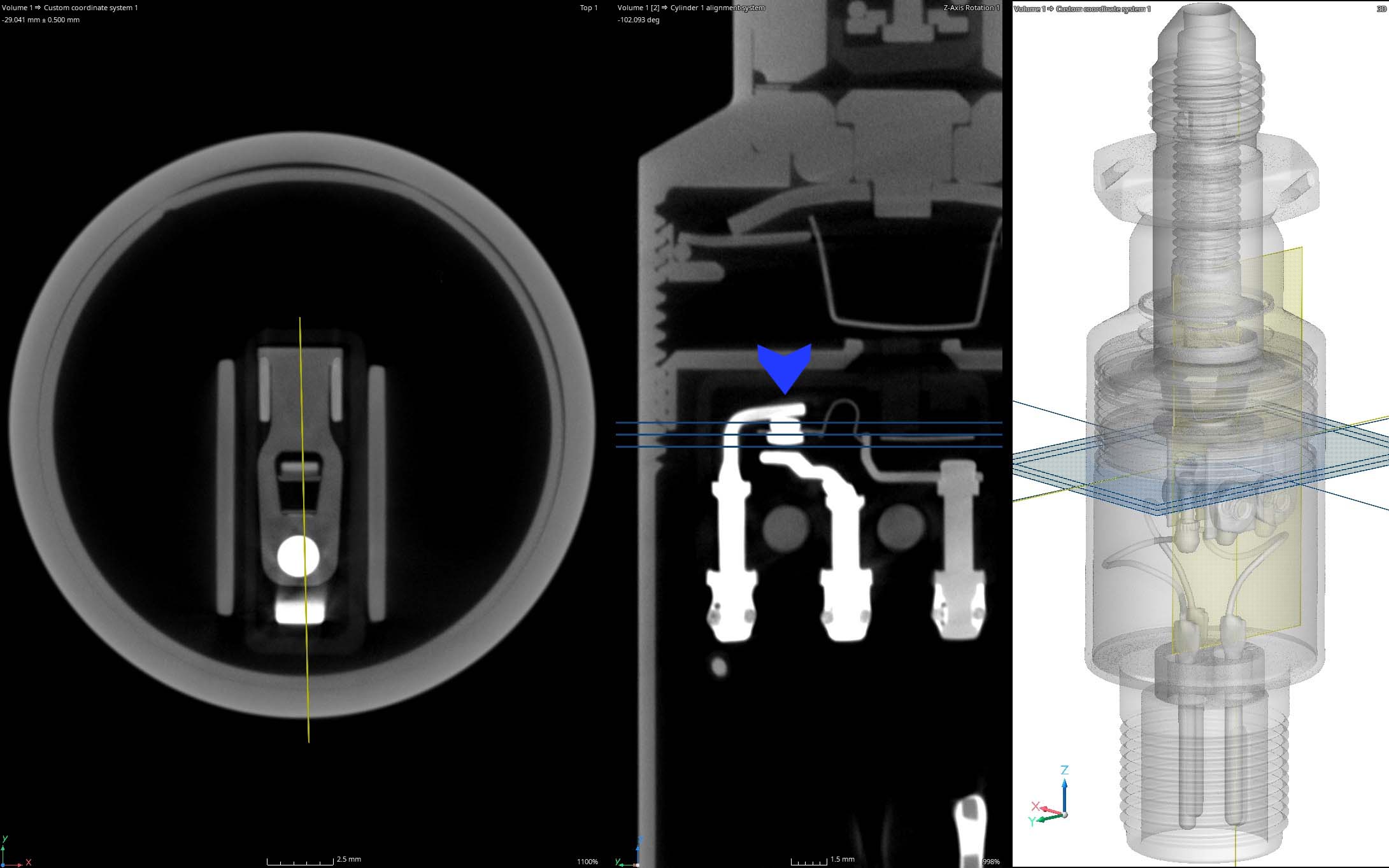

This cube satellite bridges the digital divide by providing essential connectivity to remote and underserved communities in developing countries. A month before launch an unknown component failed. We were tasked to find the point of failure.

DR & CT, two non-destructive testing methods, give unparalleled access to manufactured products. Combining the world’s premier hardwares and softwares, we provide insight into the inside of the the most basic to most complex and critical components. Our clients and work are everywhere – from art exhibits to outer space.

We are involved in some of the most demanding industries like:

rocketry & satellites, defense & armaments, aerospace & aviation, automotive development, nuclear & energy, EV & consumer batteries, additive manufacturing, and medical implants and plastics.

Our certifications and qualified staff will ensure you’ve never done better than with Industrial Inspection.

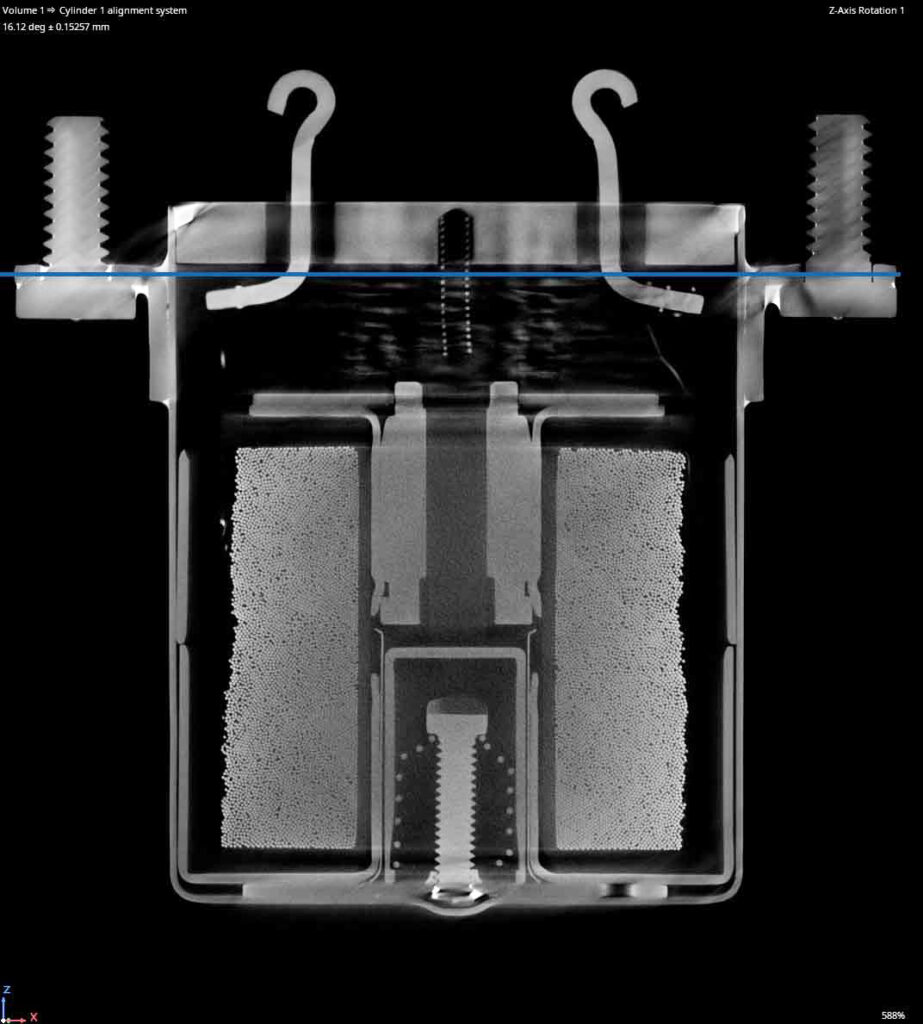

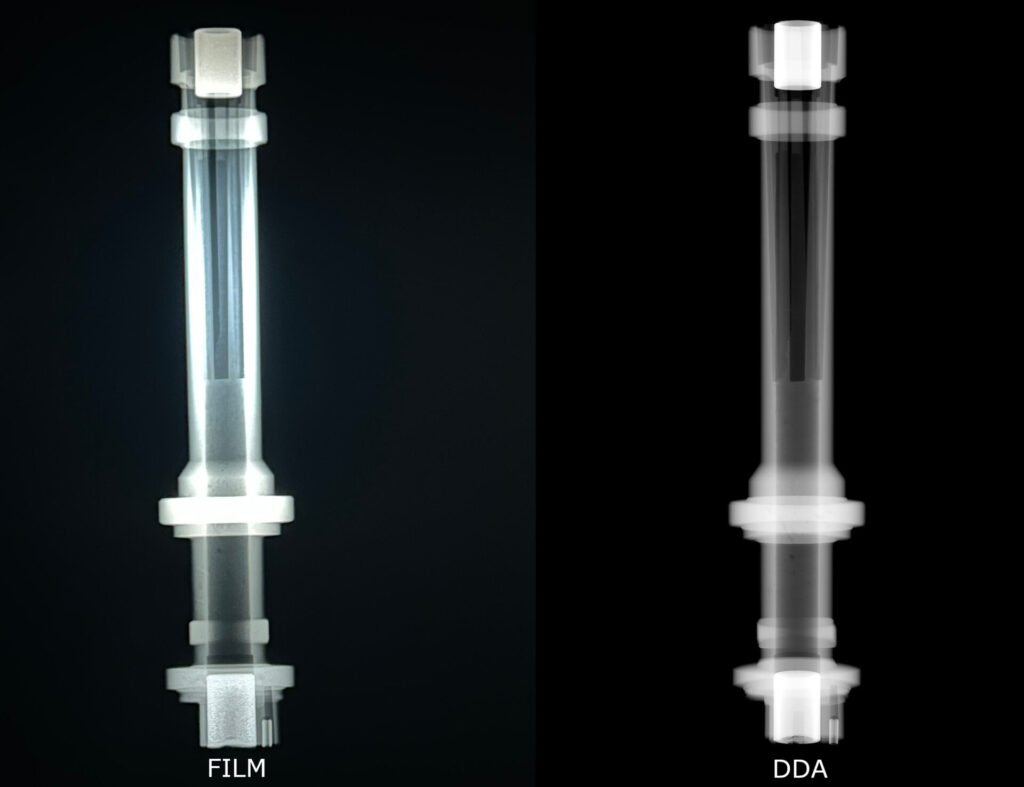

320KV LARGE CAPACITY DR / CT

LARGE CAPACITY

With a weight capacity of 220lbs and working volume of 4.5 x 3.5 feet diametral, most parts that qualify for CT inspection fit in our systems.

HIGH ENERGY

With variable penetration between 50kv and 320kv, we can capture data for most product types and wall thicknesses while keeping noise low.

CERTIFIED SERVICES

Industrial Inspection offers a host of prime audited NAS410 written practices including our Non-Film Digital Radiography & CT Scanning programs.

MULTIPLE SYSTEMS

Multiple systems offer reduced lead times and redundant capabilities during system maintenance and busy scheduling periods.

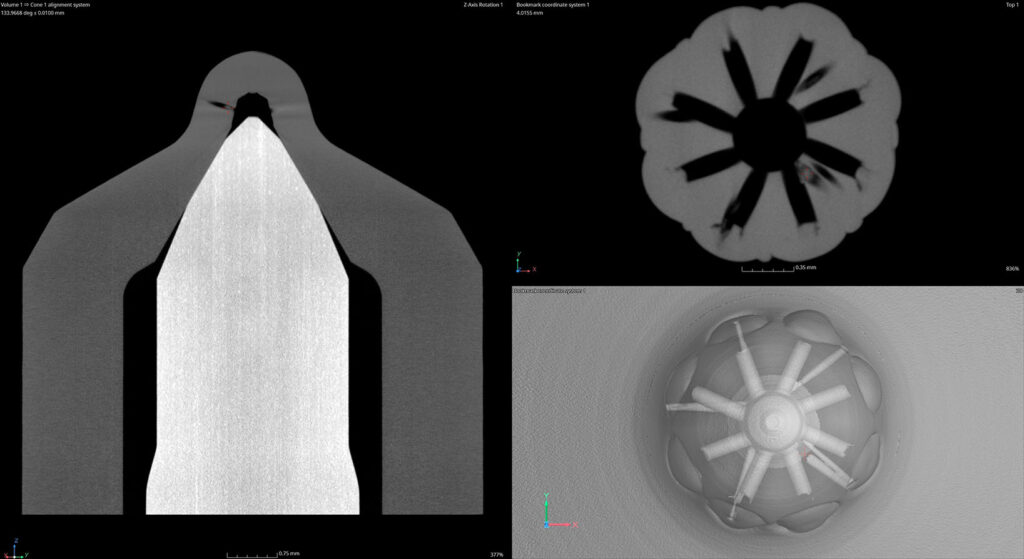

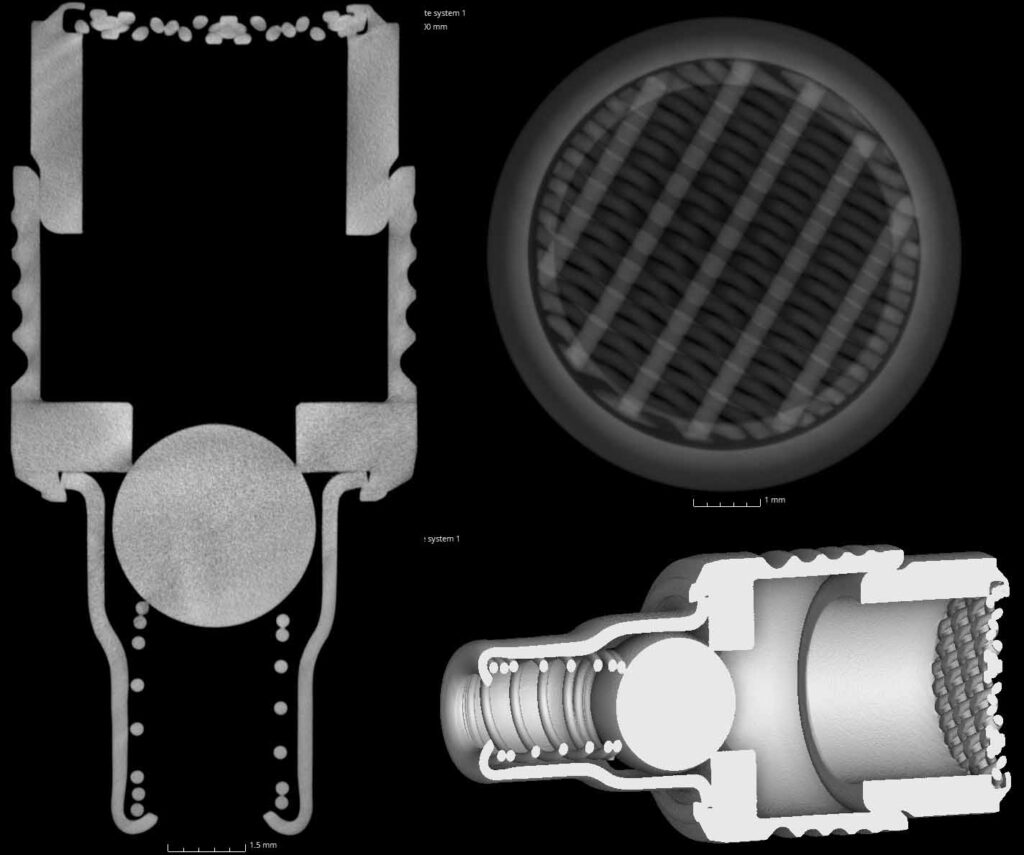

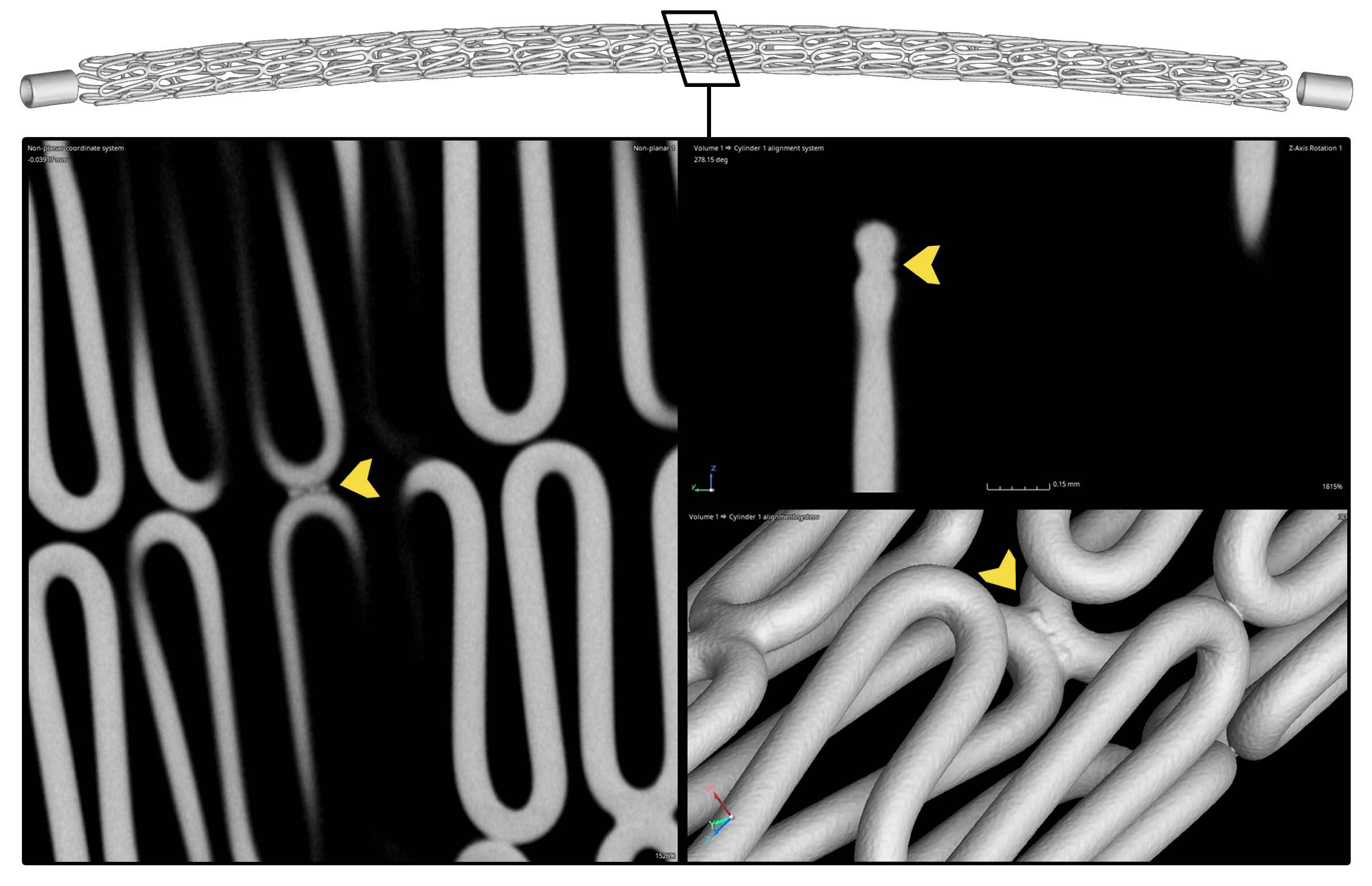

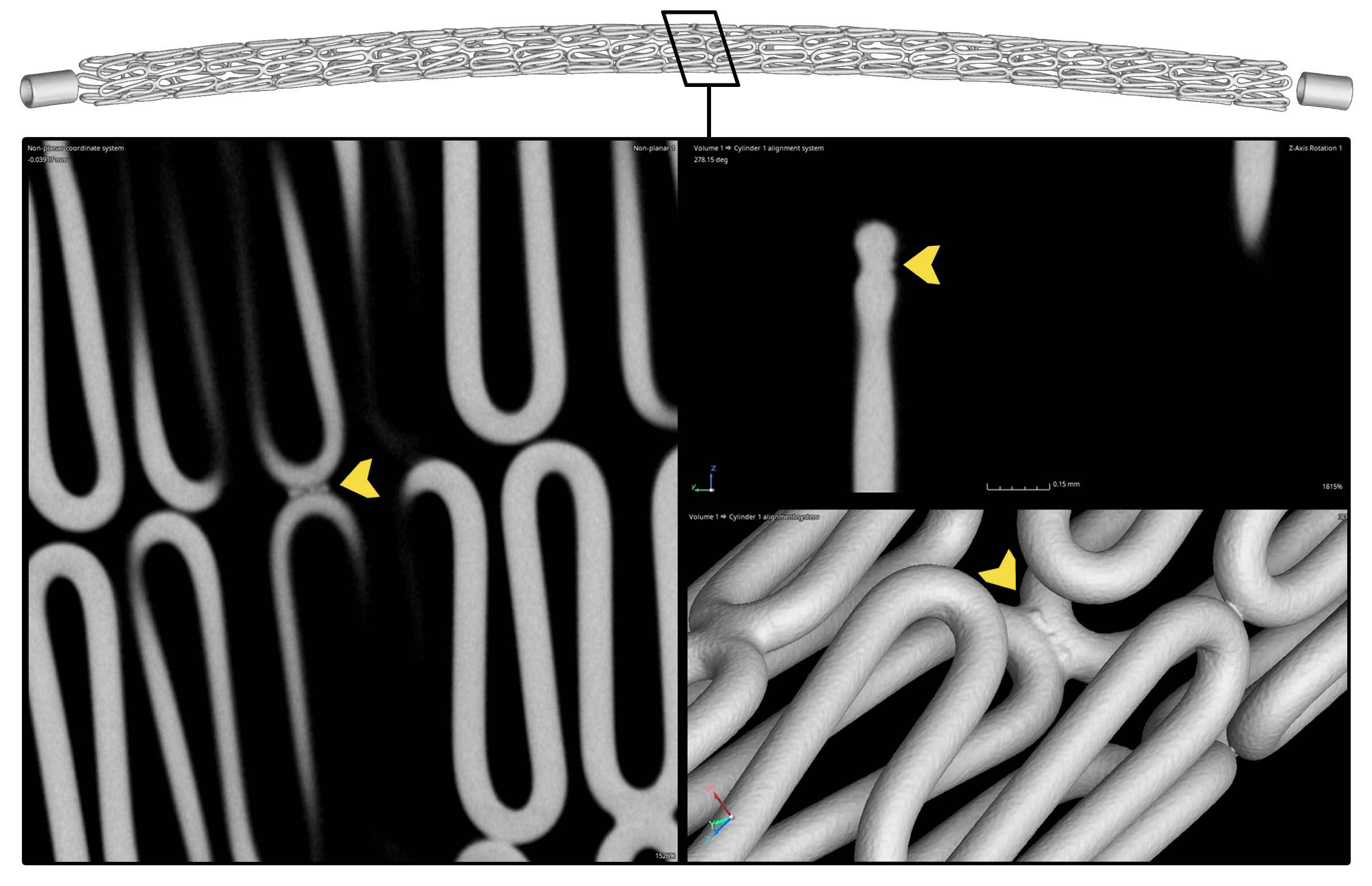

VARIABLE RESOLUTION

Our programmable systems offer the ability to adjust resolution from 3um to 150um, allowing us to image everything from coronary stents to steel castings.

225KV METROLOGY DR / CT

HIGH ACCURACY

Our metrology grade systems use calibrated artifacts to scale datasets to known sizes in order to provide dimensional services with confidence.

HIGH SPEED

Our digital systems and high end processors allow for fast acquisition and processing, providing clients with reduced cost and improved lead times.

Have a question or request for quote regarding CT Scanning?

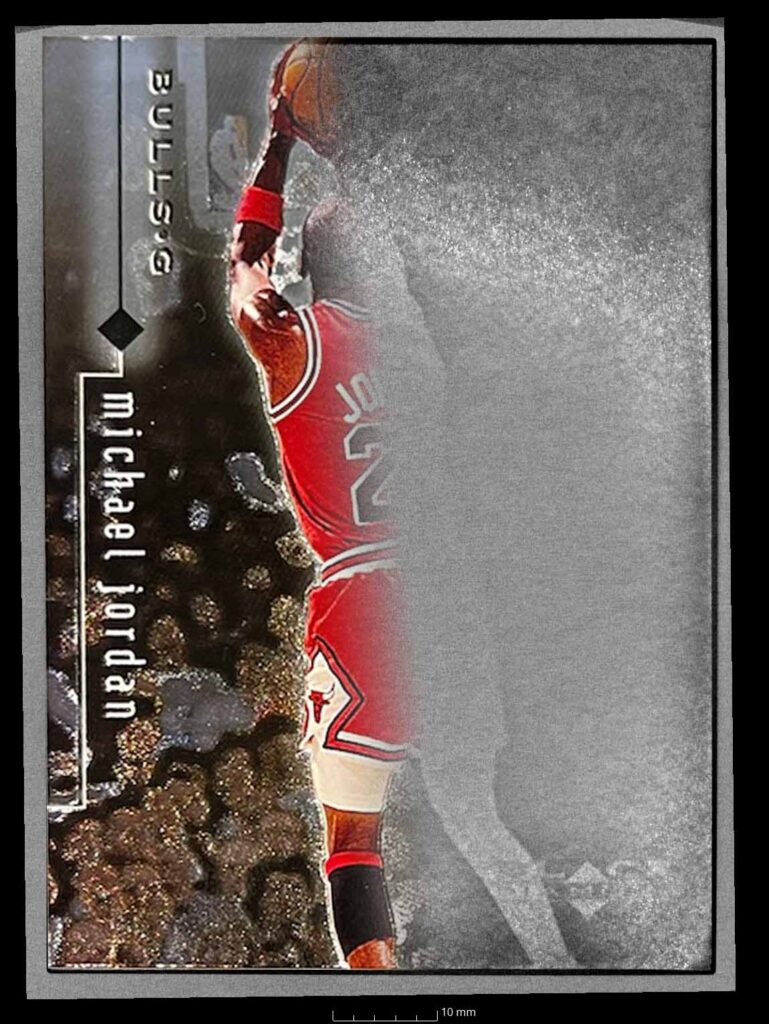

X-RAY & CT SCANNING CASE STUDIES

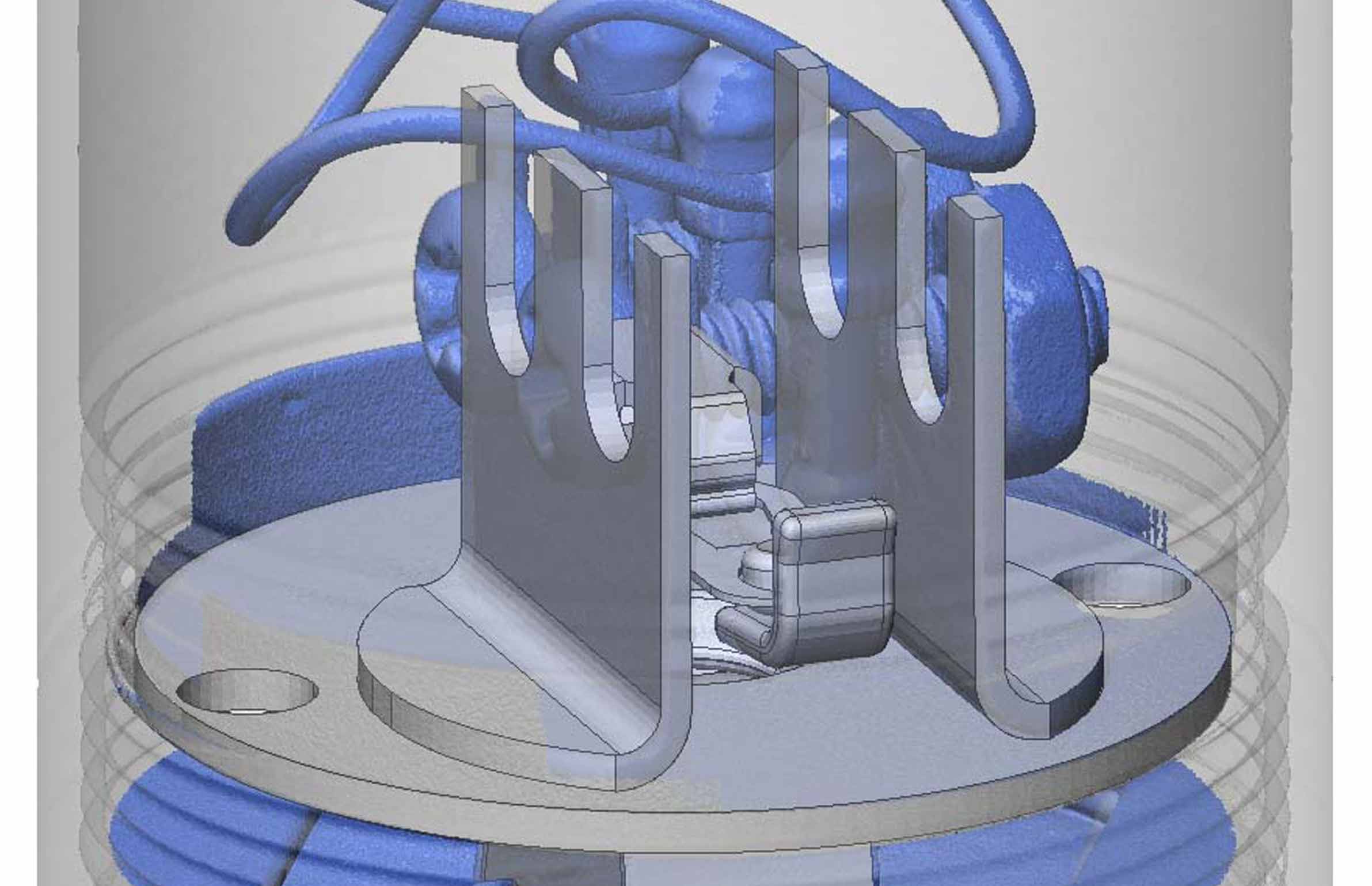

WHAT IS INDUSTRIAL CT DATA USED FOR?

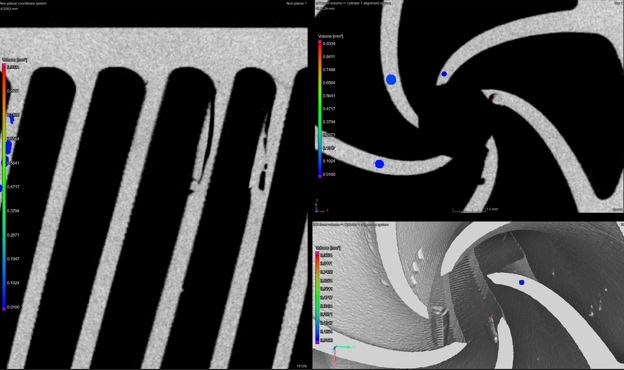

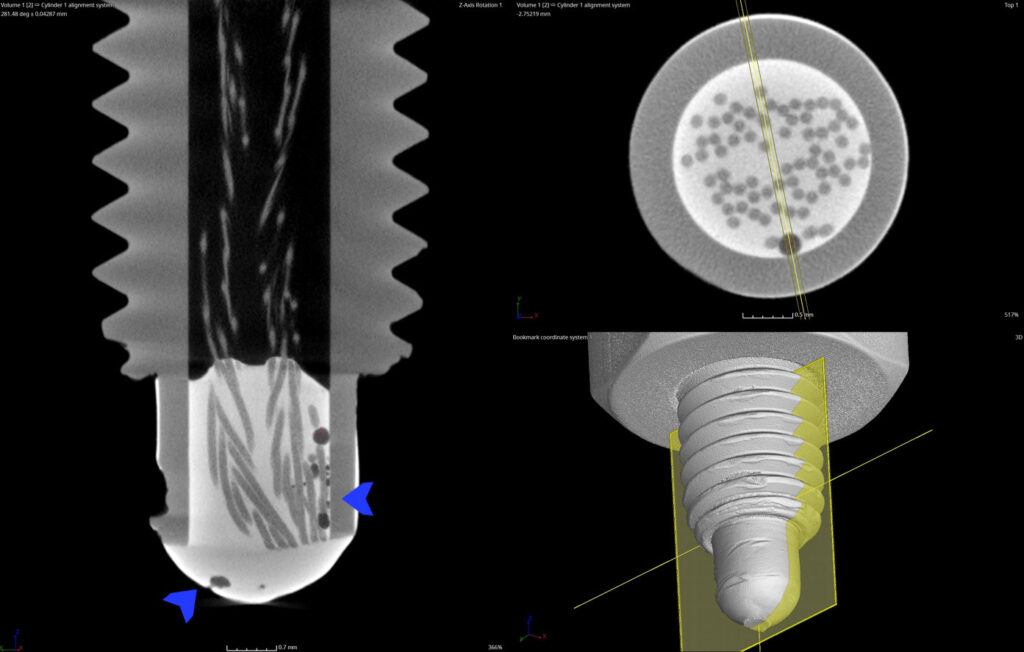

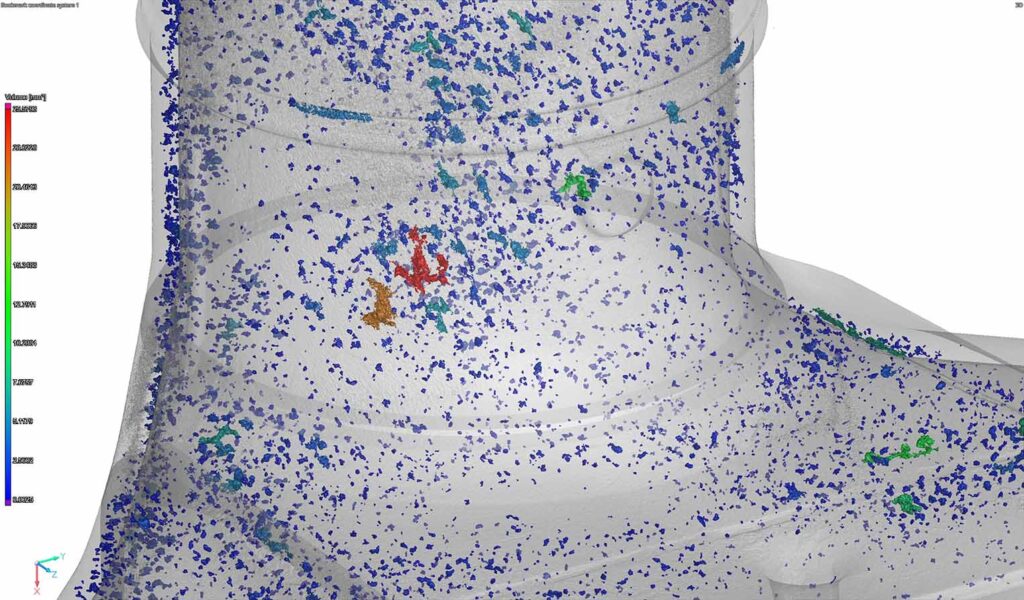

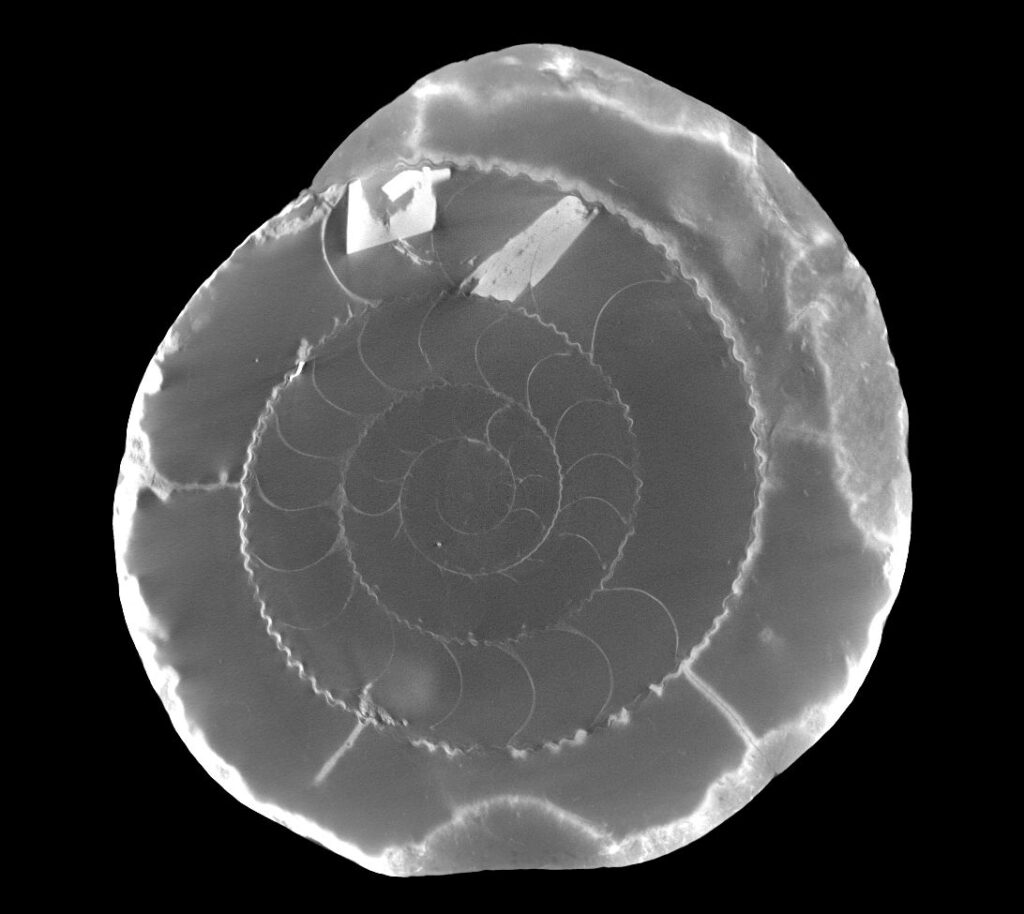

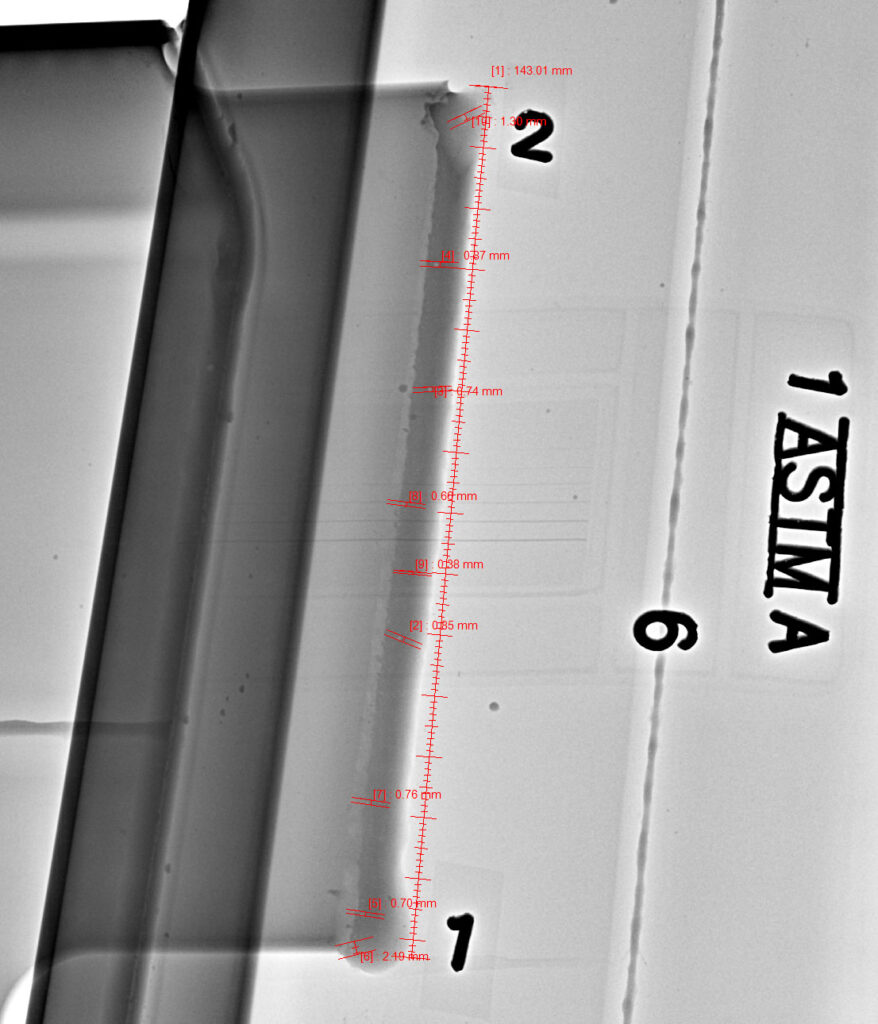

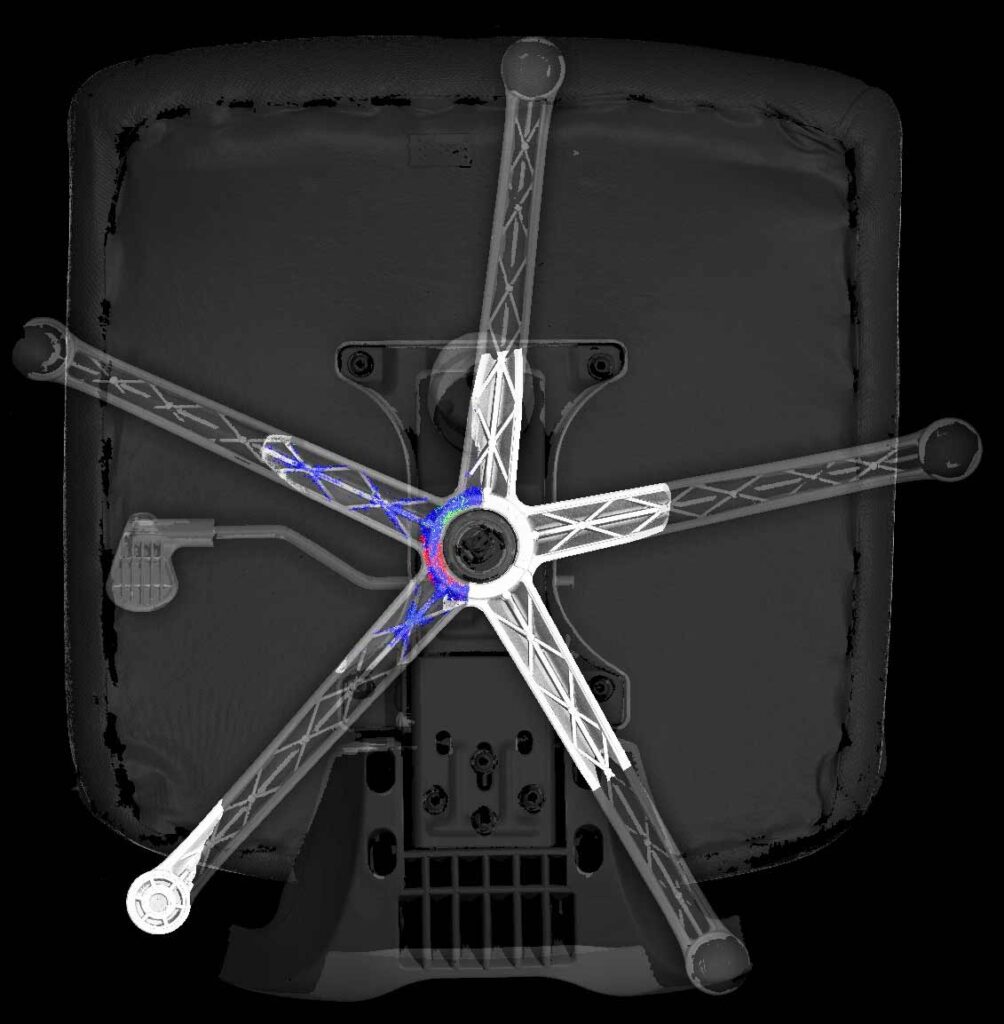

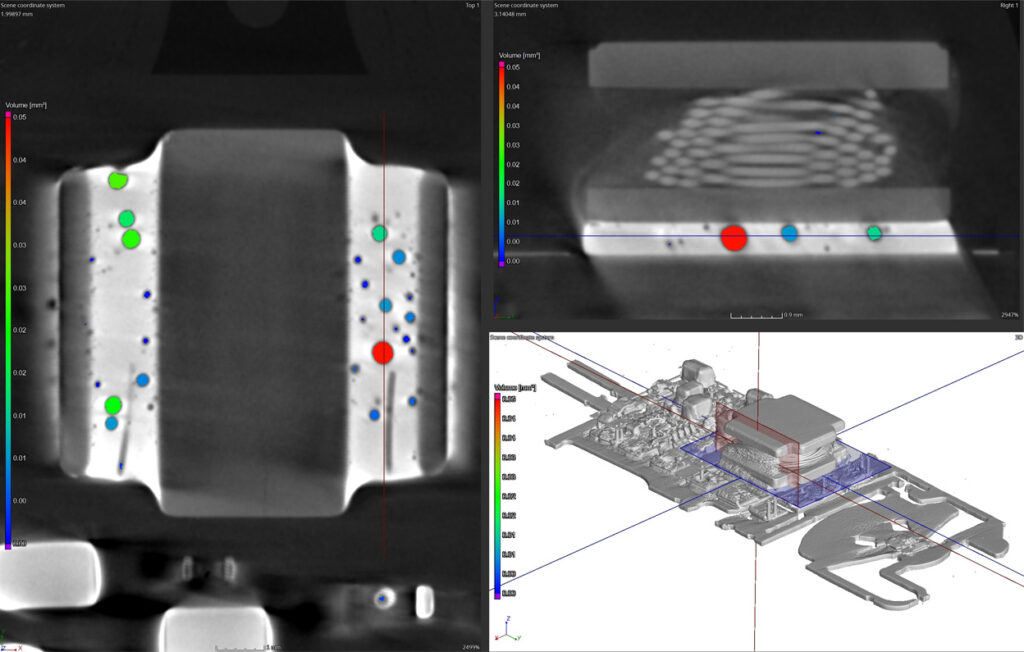

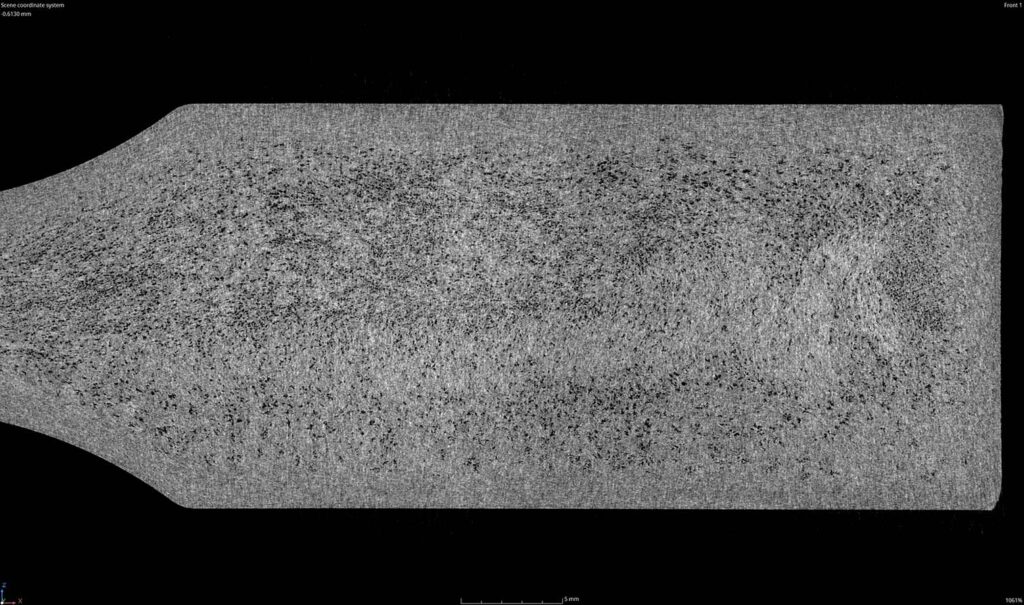

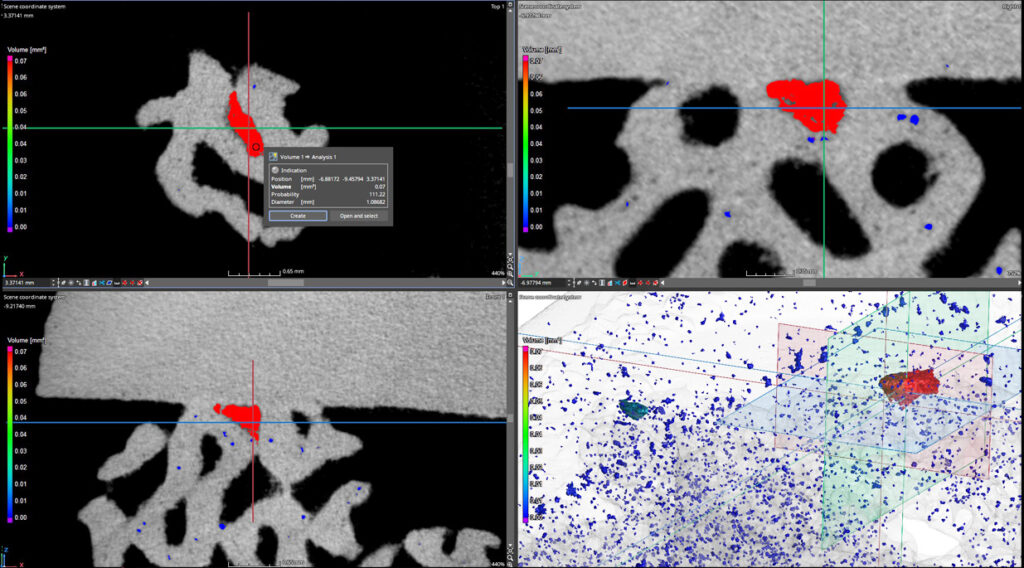

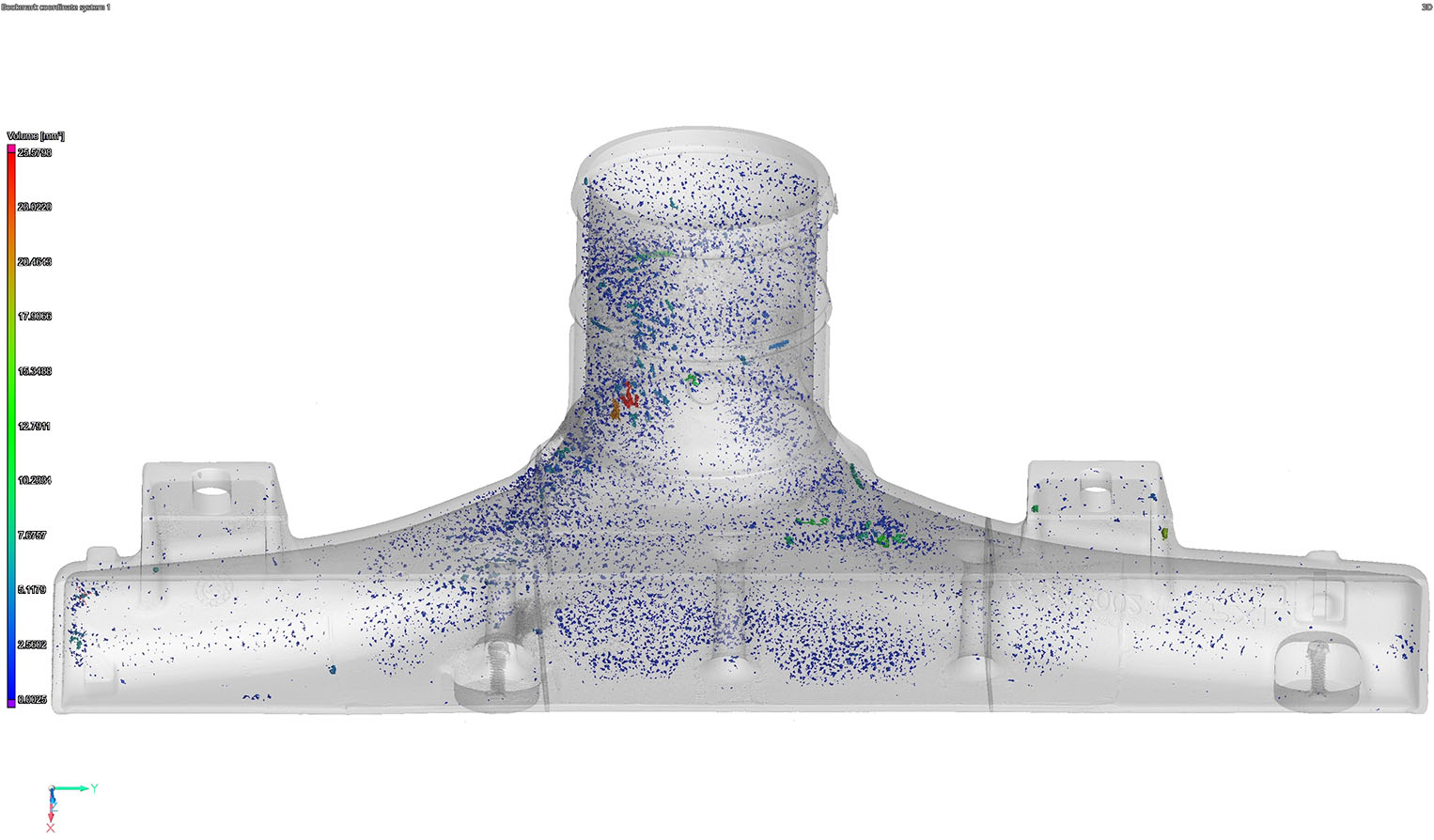

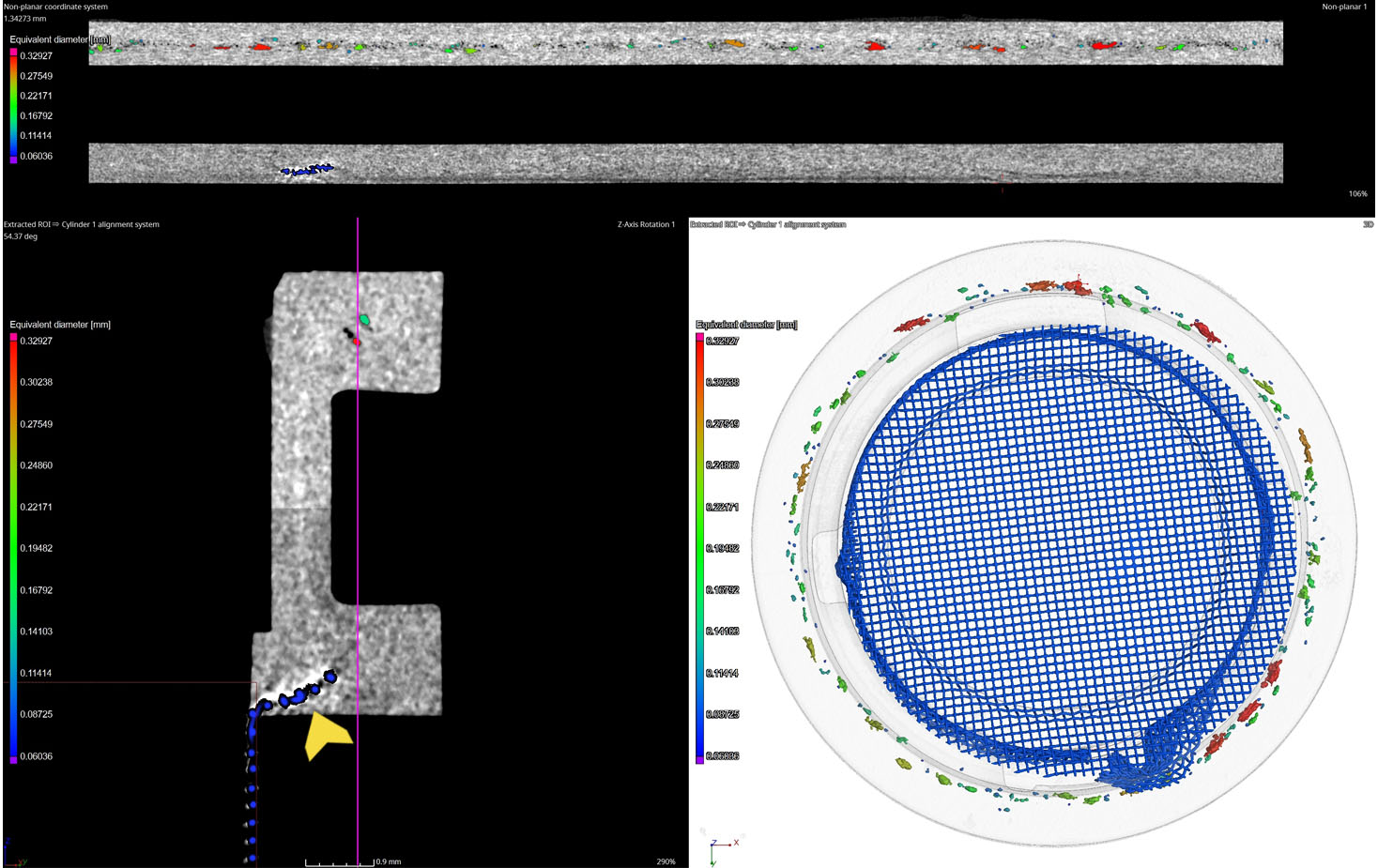

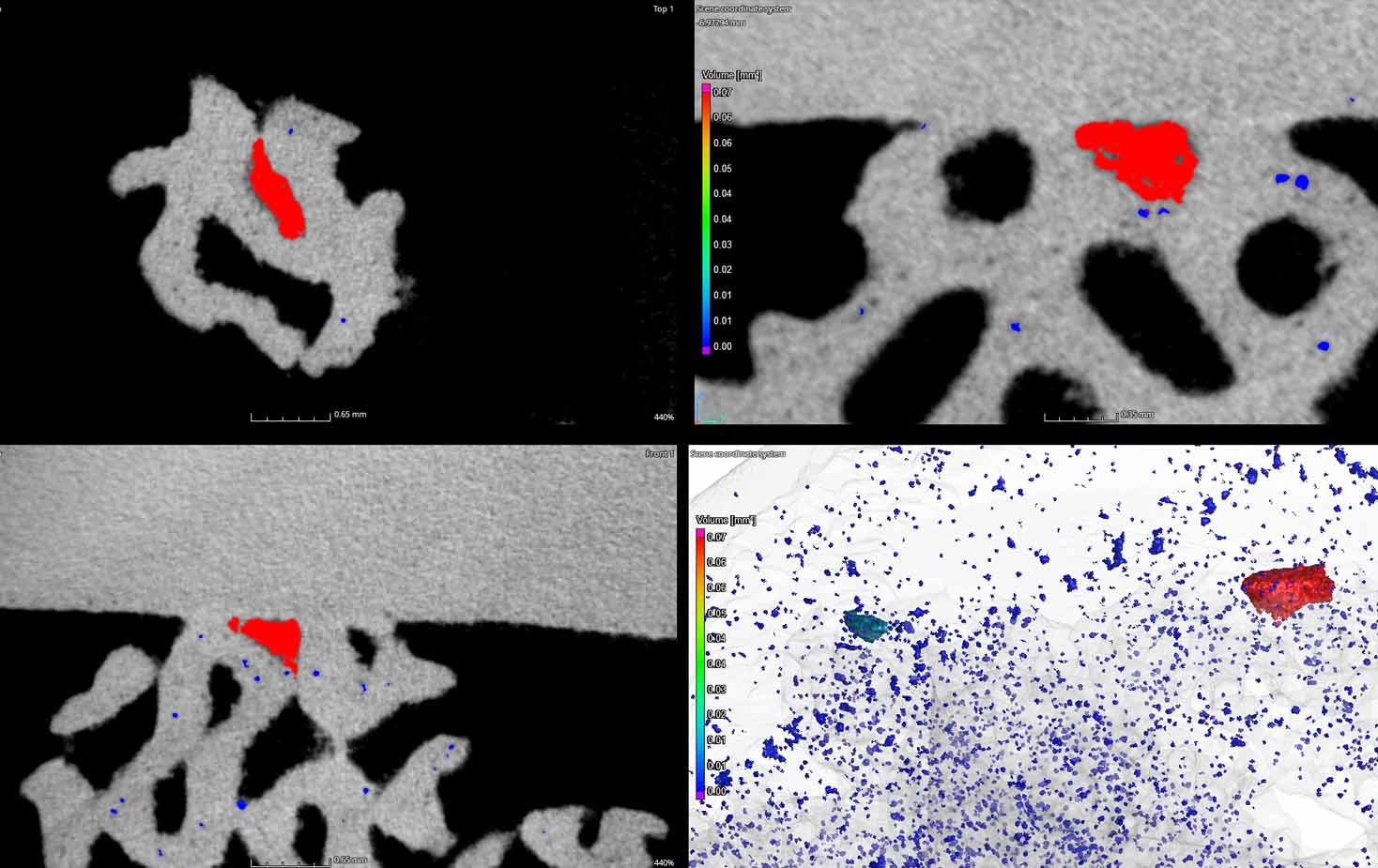

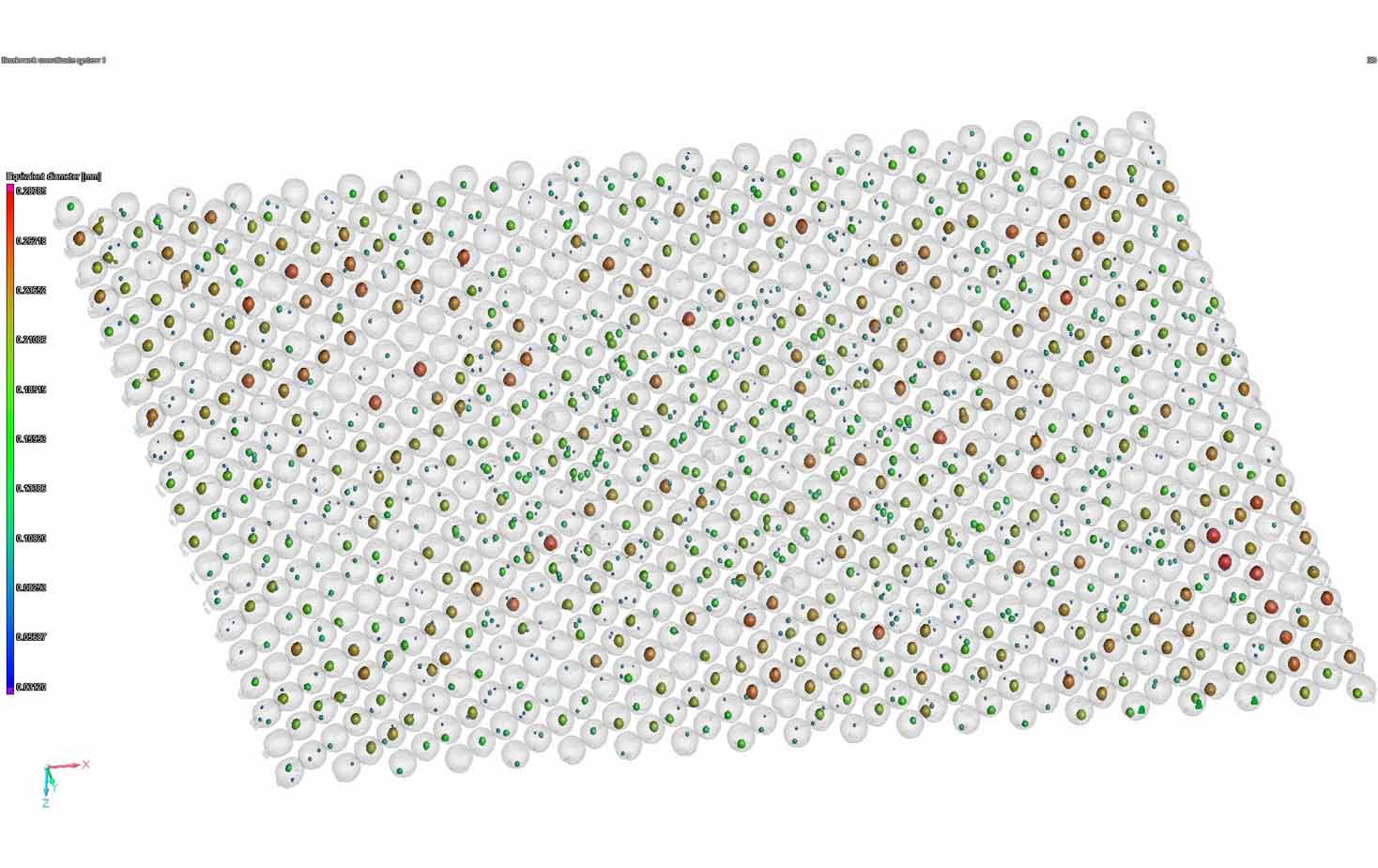

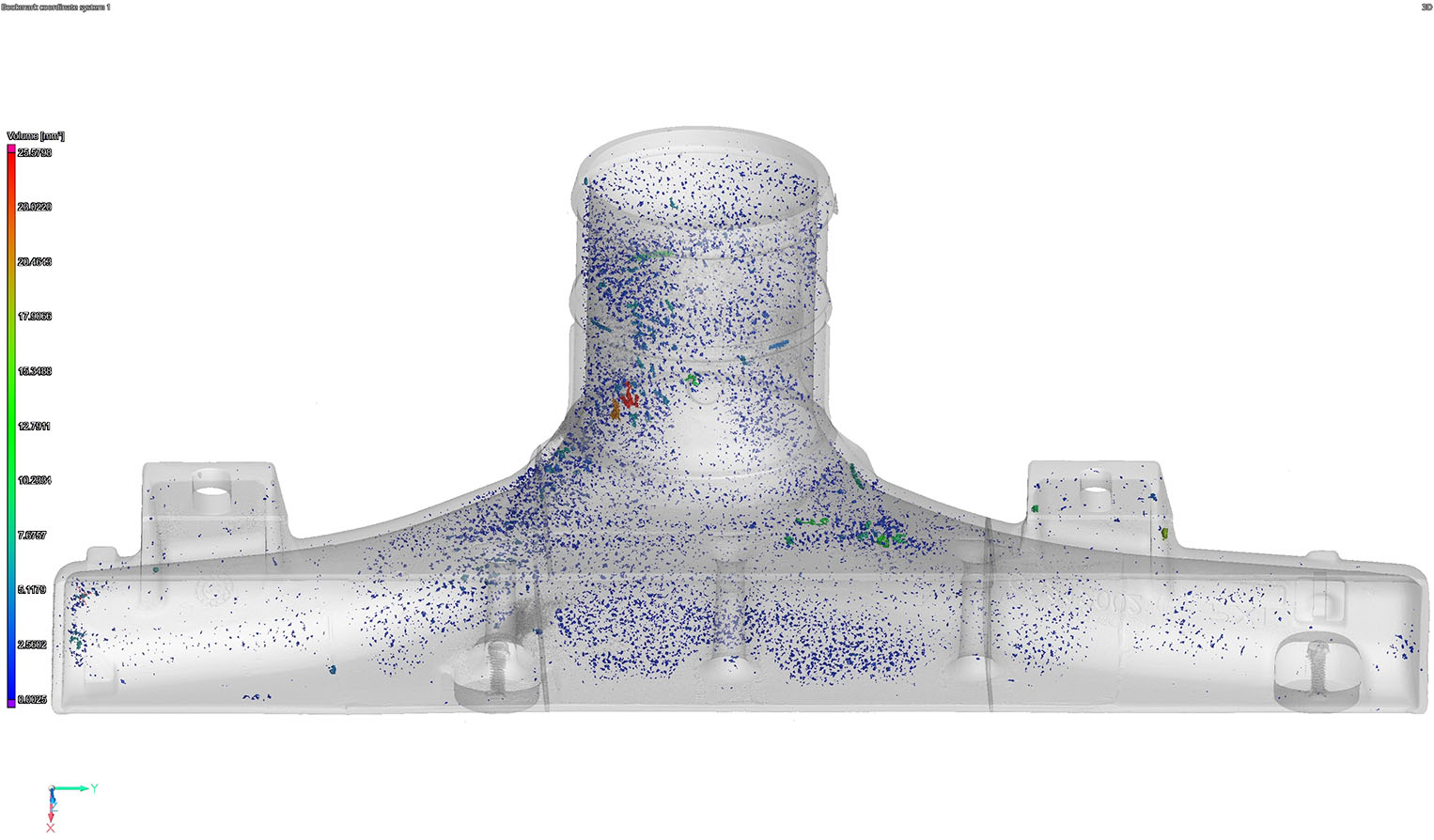

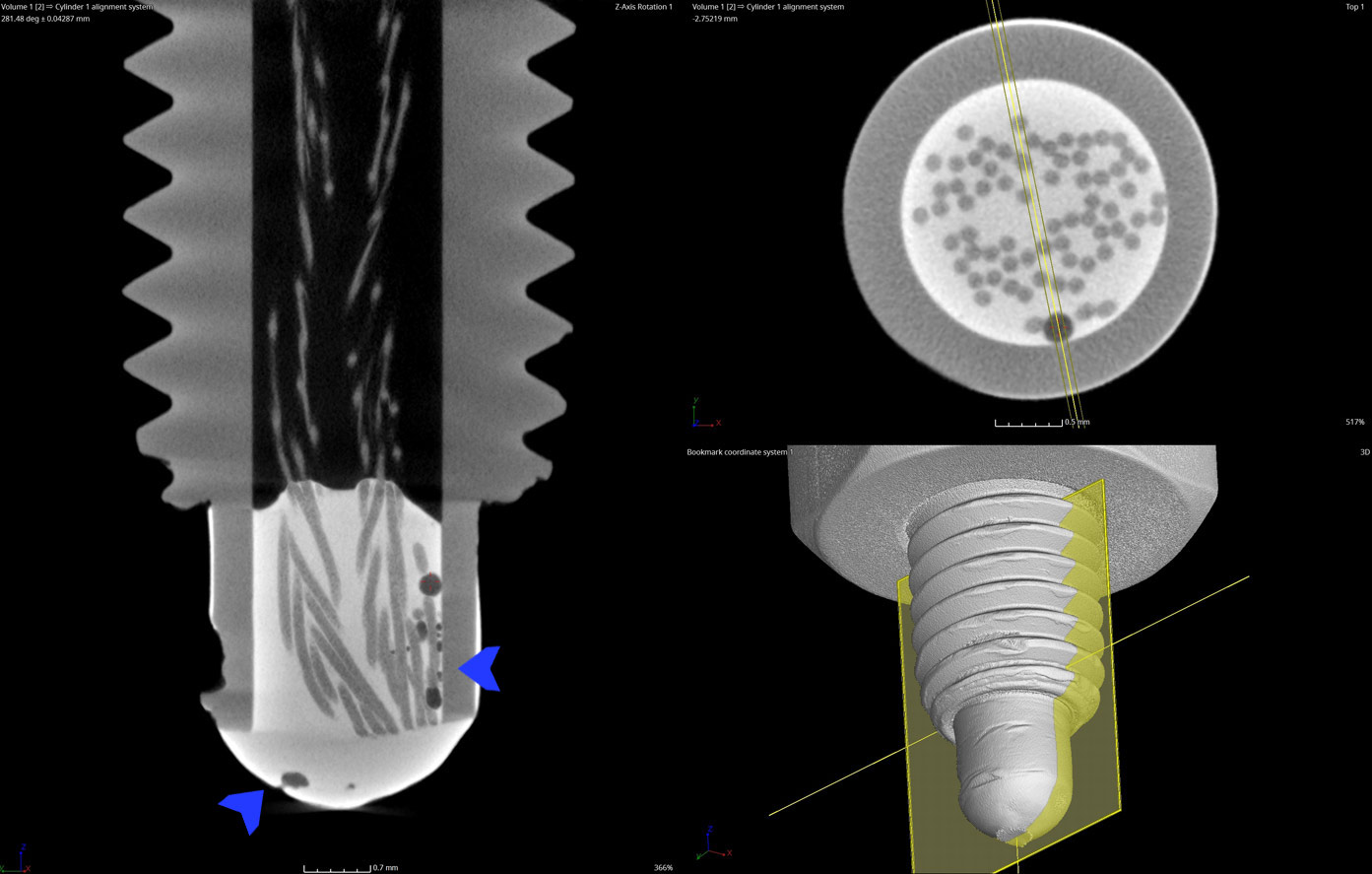

POROSITY, INCLUSIONS, & FRACTURES

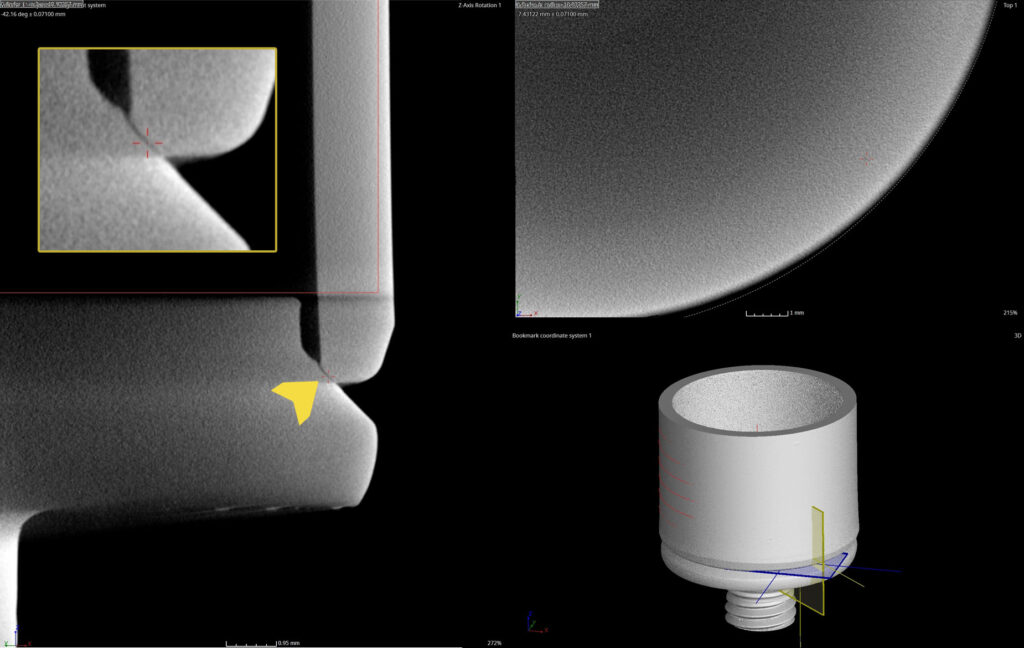

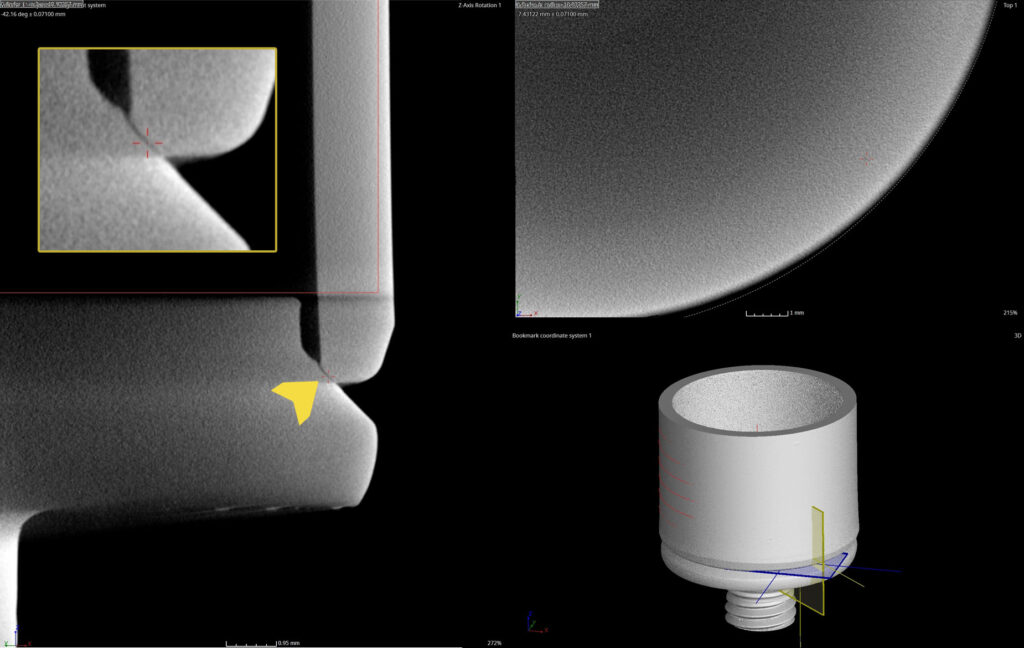

Industrial CT Scanning is used to three dimensionally quantify internal, inaccessible indications like porosity, inclusions, and fractures. Exact location and size of the flaw can be determined.

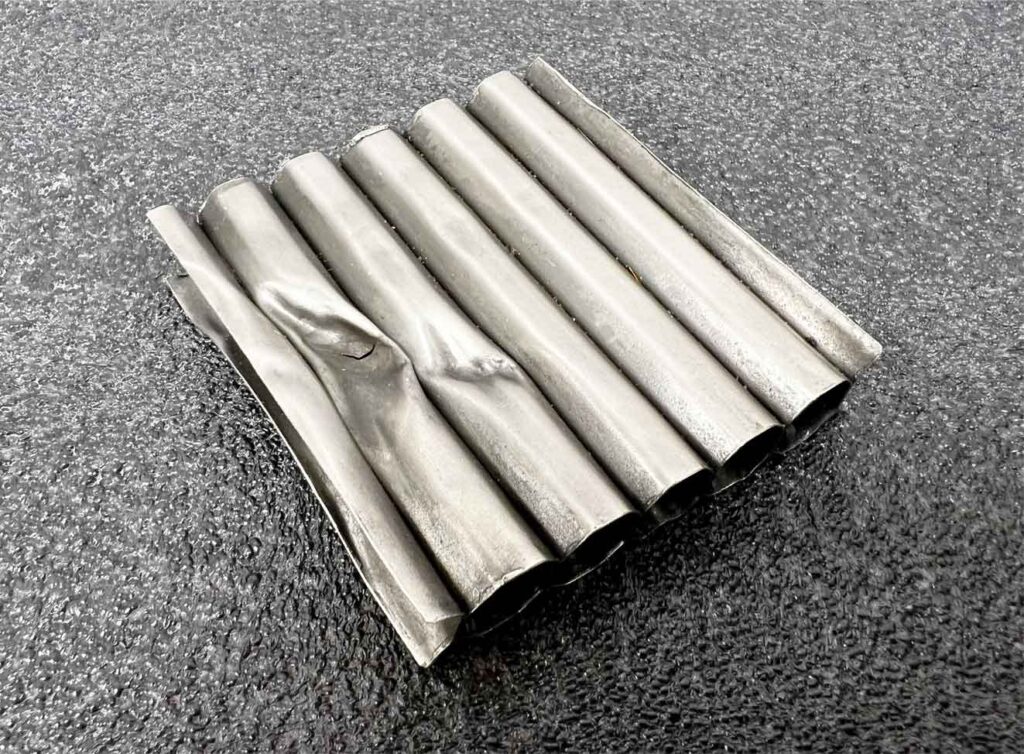

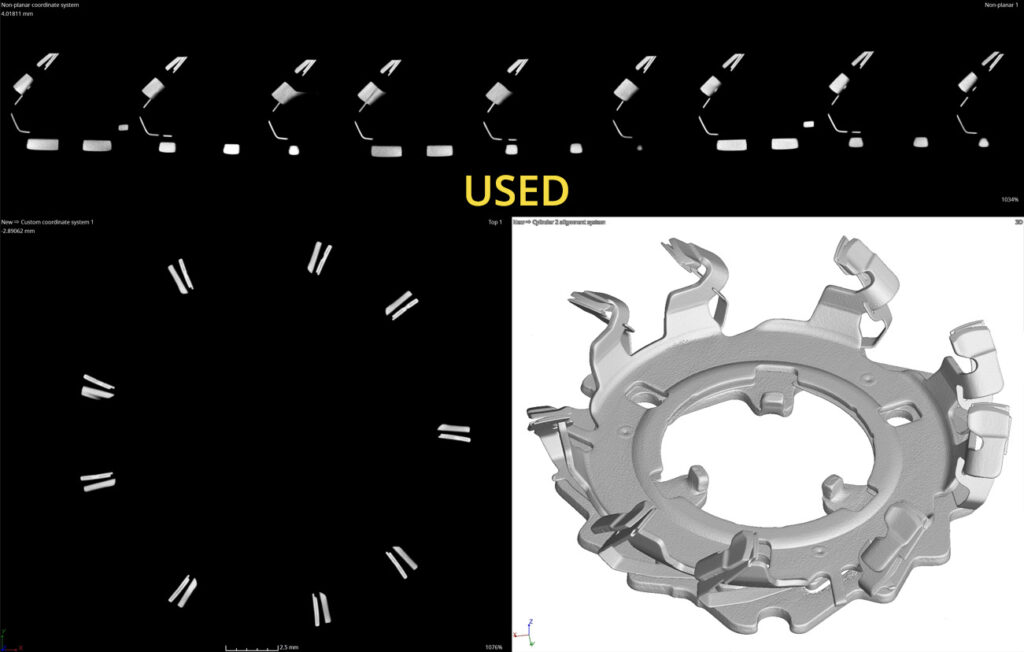

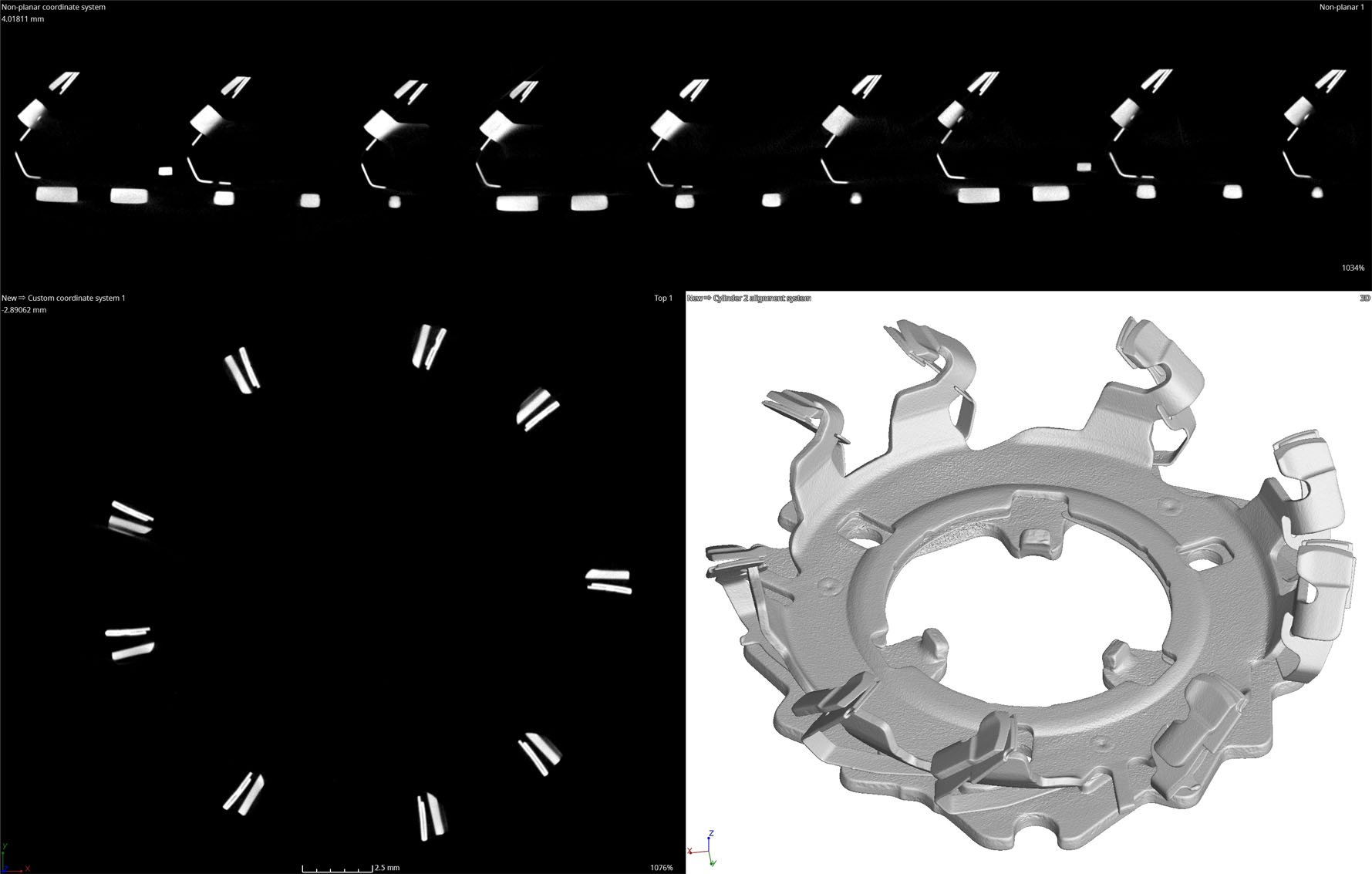

CT SORTING SERVICES - 24/7 AVAILABILITY

X-Ray & CT is used to sort and save product batches that may have rejectable manufacturing defects. High speed detectors and high resolution sources ensure we can locate anything and not break the bank.

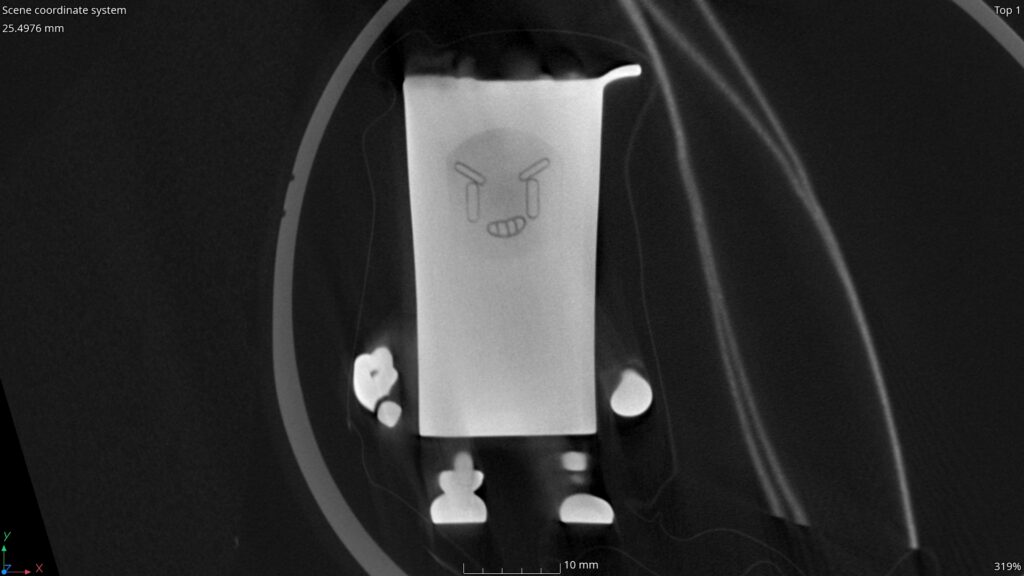

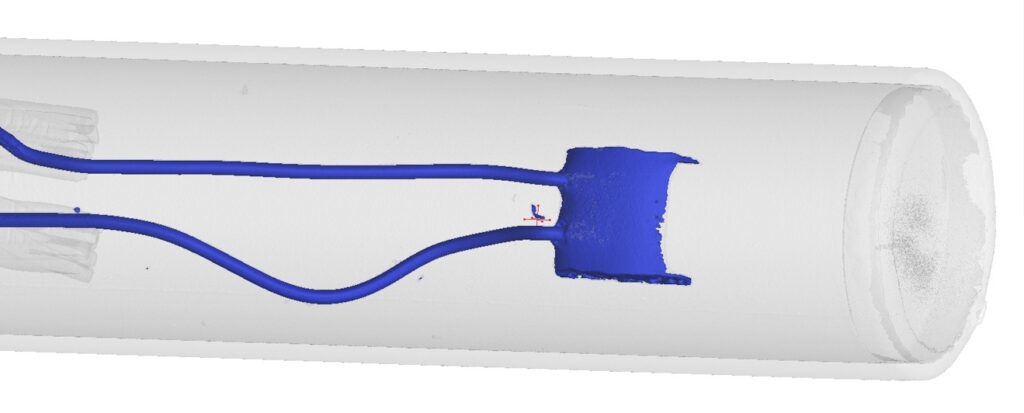

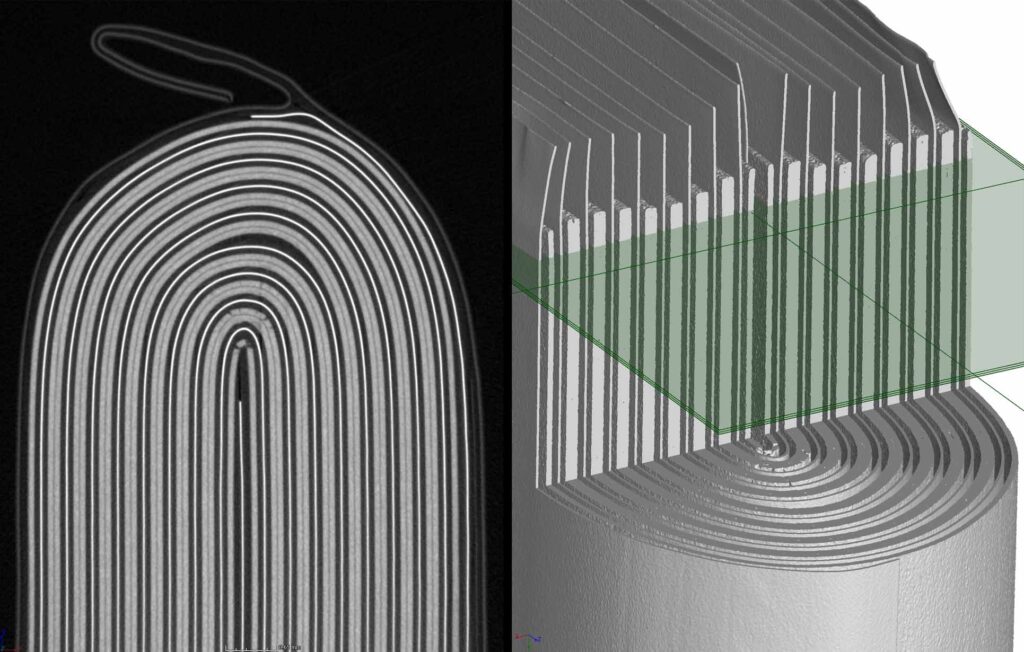

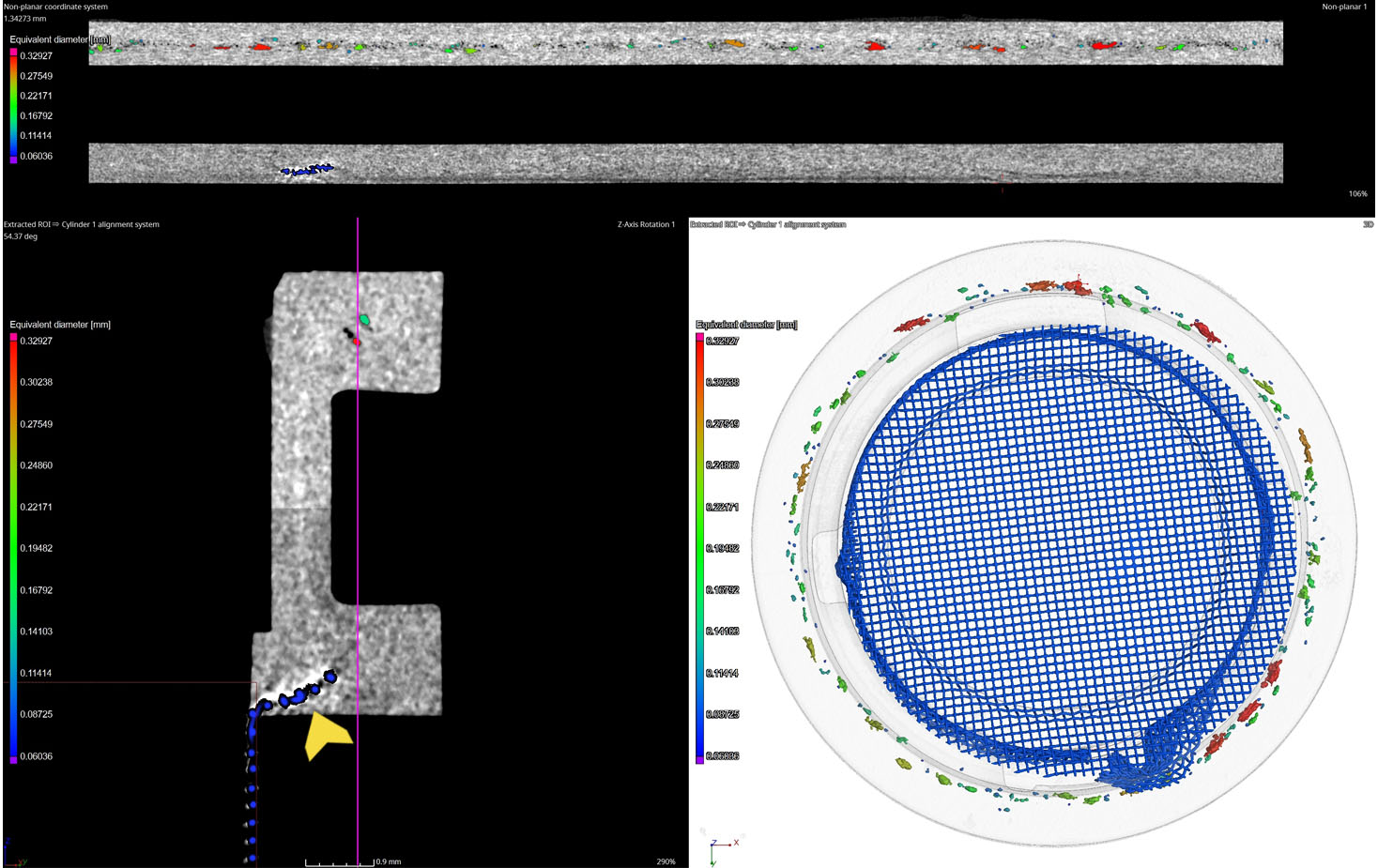

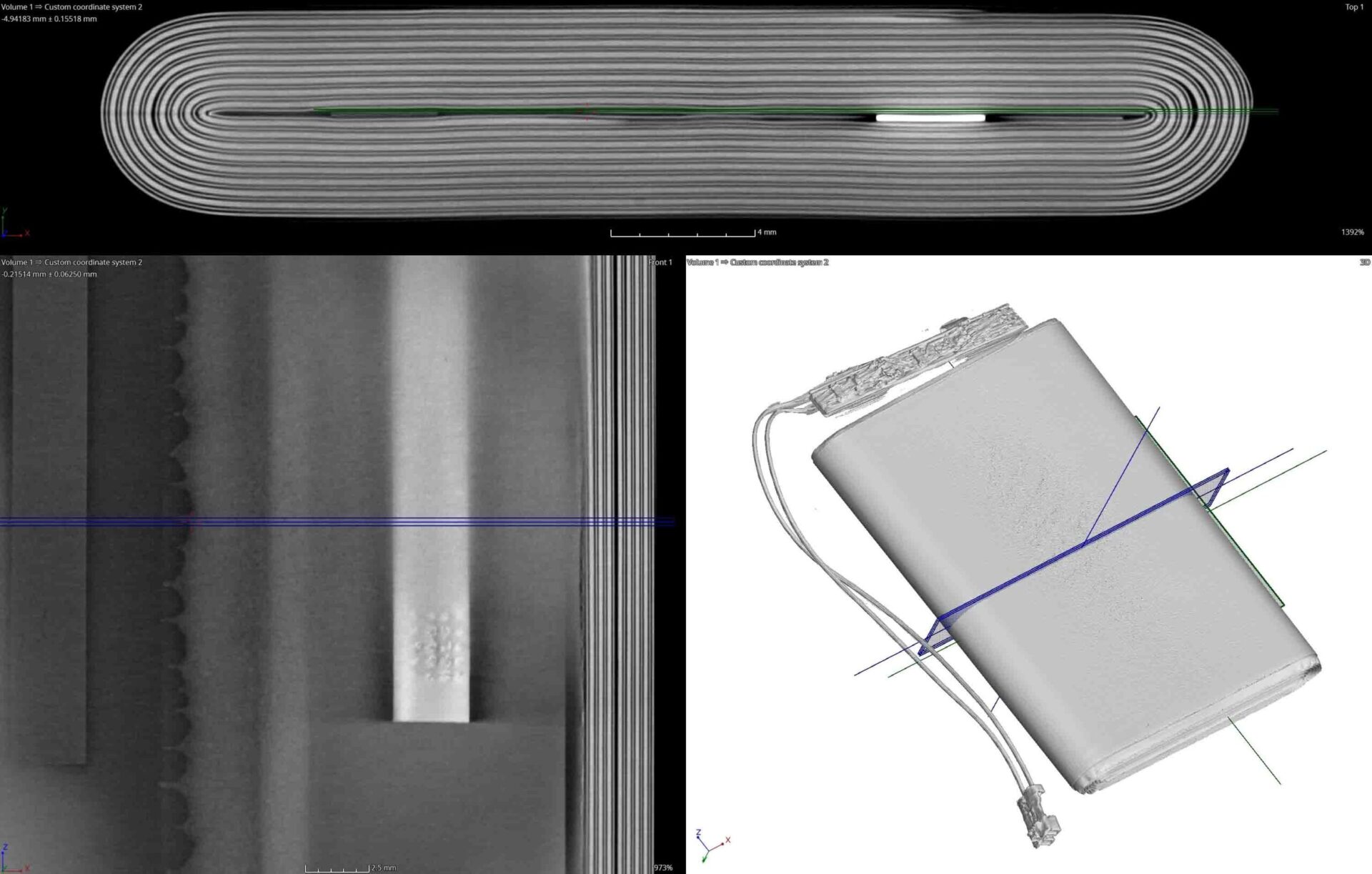

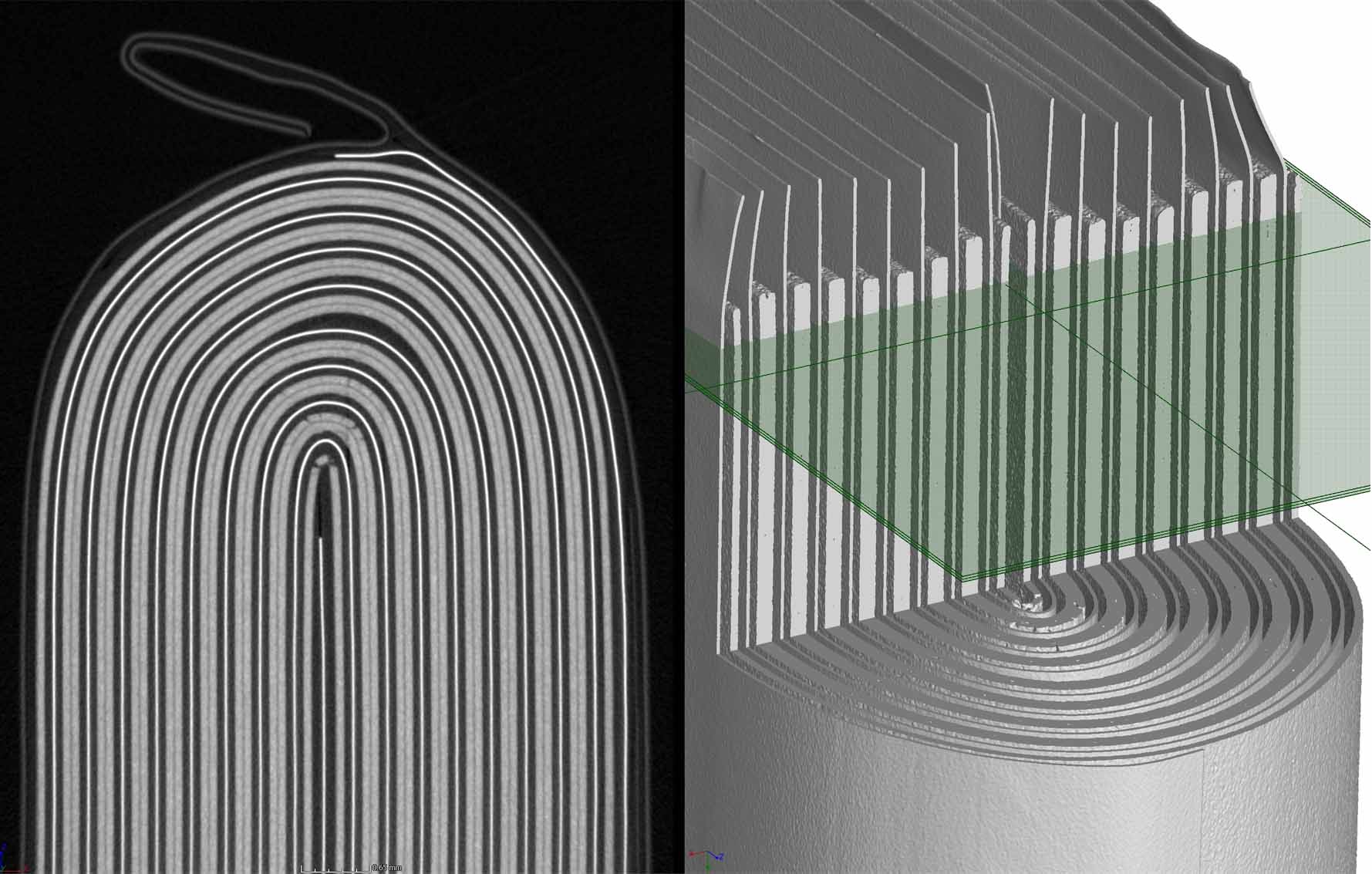

BATTERY INSPECTION

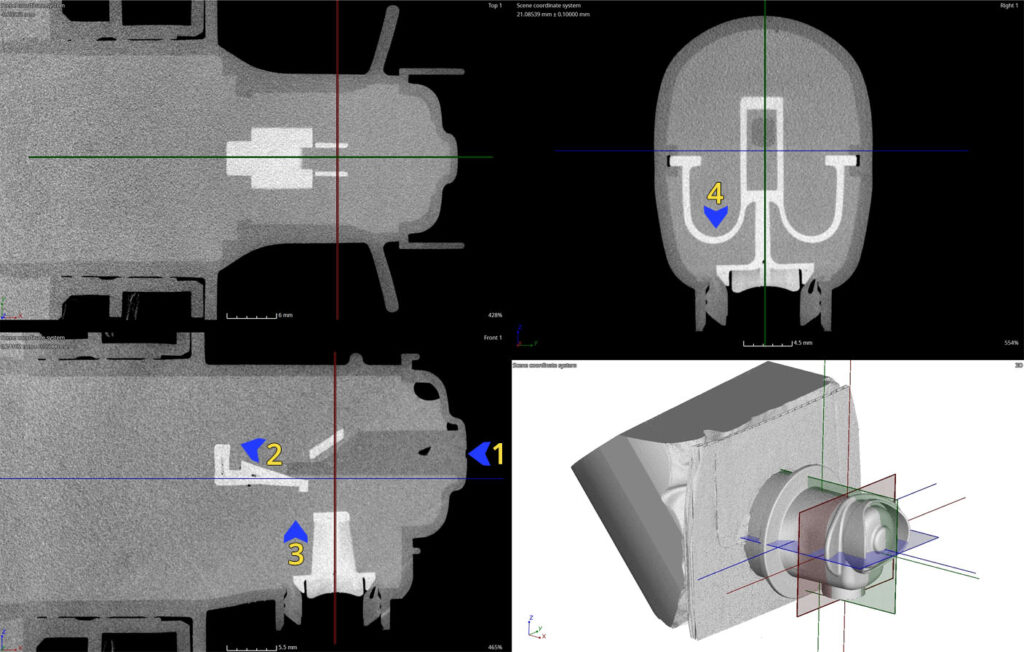

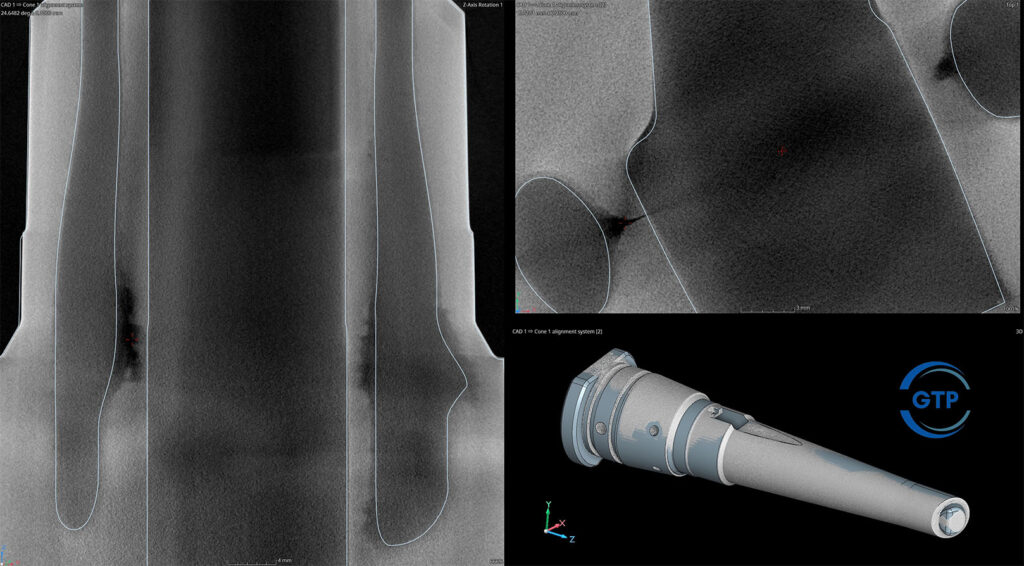

FAILURE ANALYSIS

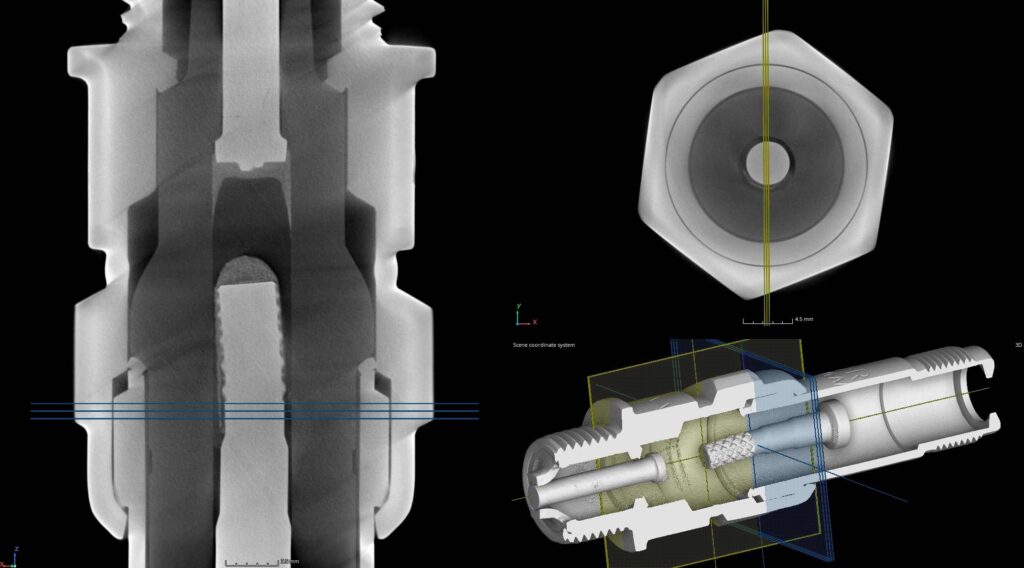

Typically when we receive a part we are on a mission to characterize the unknown, or find the needle in a haystack. Failures could be anything from a missing component, weld crack, or disbonded PCB joint.

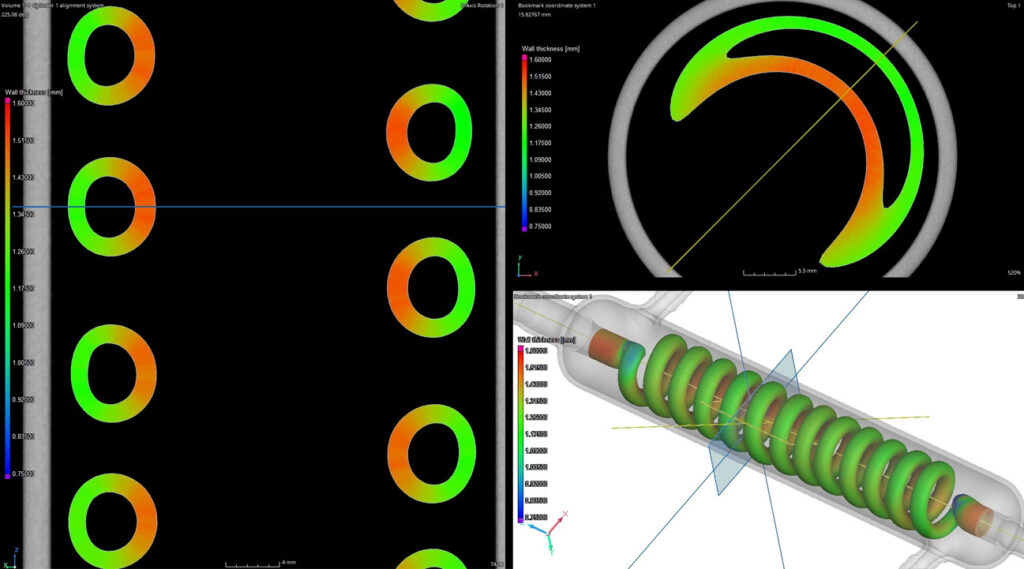

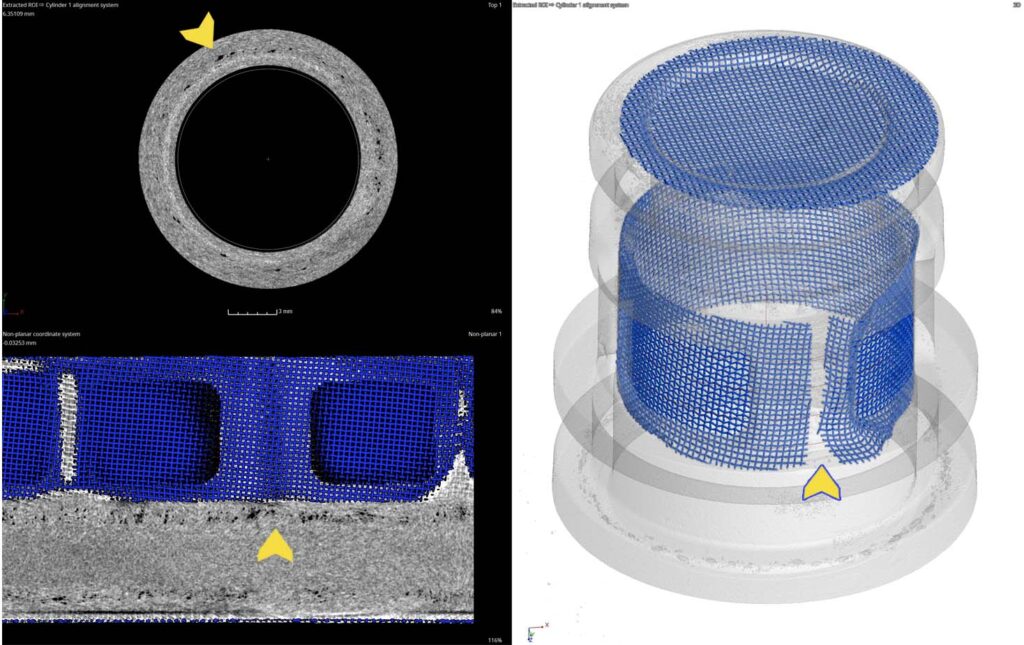

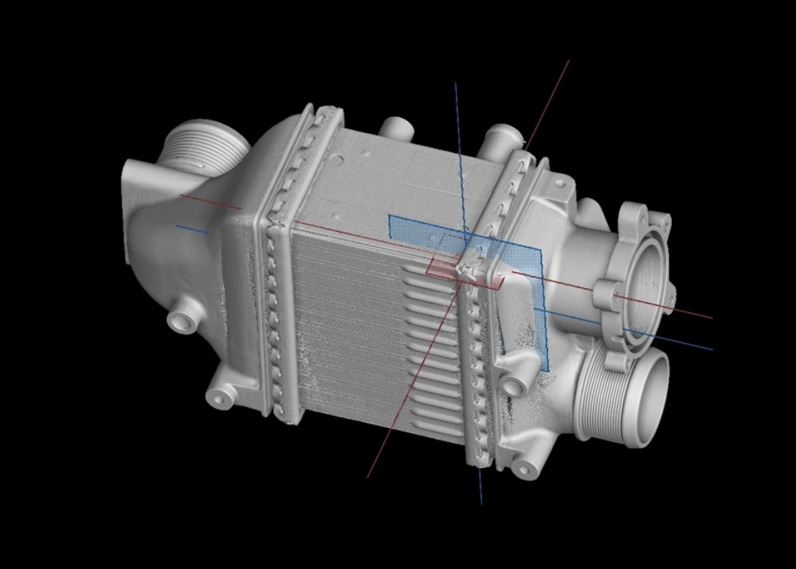

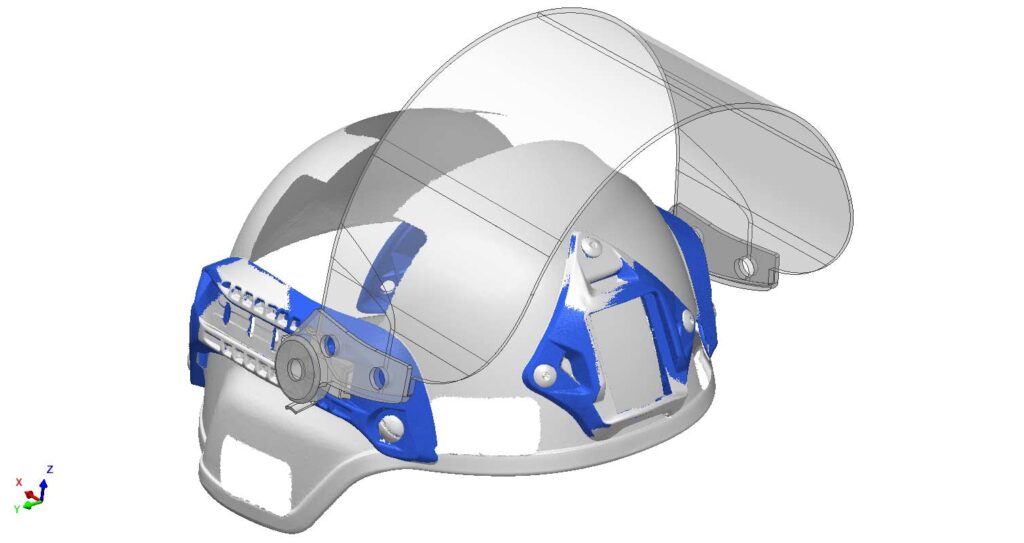

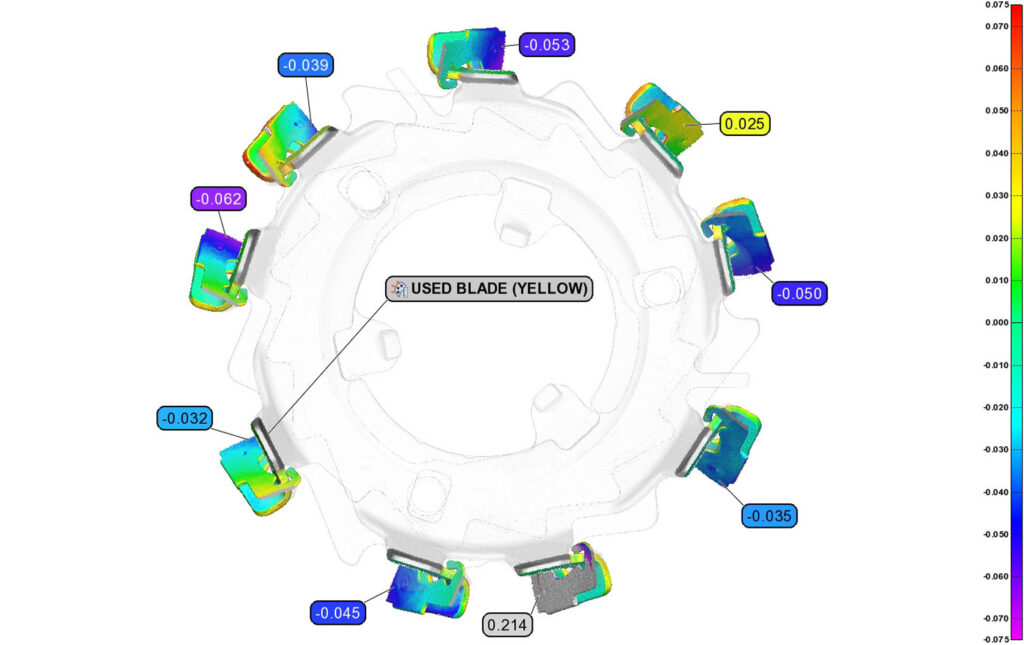

DIMENSIONAL INSPECTION

Industrial CT Scanning is dimensionally accurate by using scaling artifacts. We can measure geometry in Volume Graphics or export .stls for dimensional GD&T programming in PolyWorks.

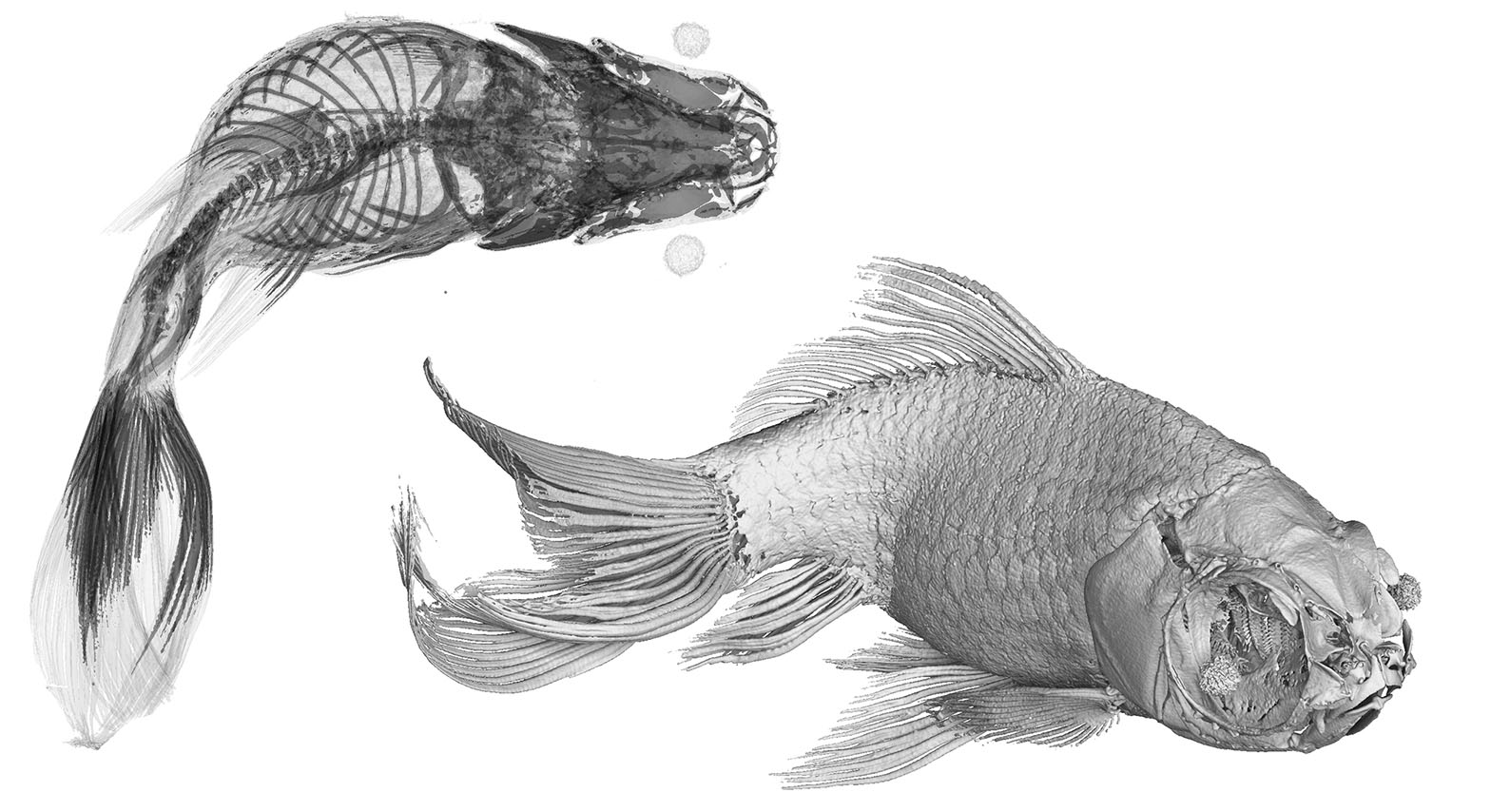

BIOLOGICS, BIOMIMICRY, AND DIGITAL TWIN

This Black Moor goldfish is one of the most difficult scans we’ve completed due to it’s low density, soft tissue, and flowing fins. Perfectly still conditions and a clever holding method are required.

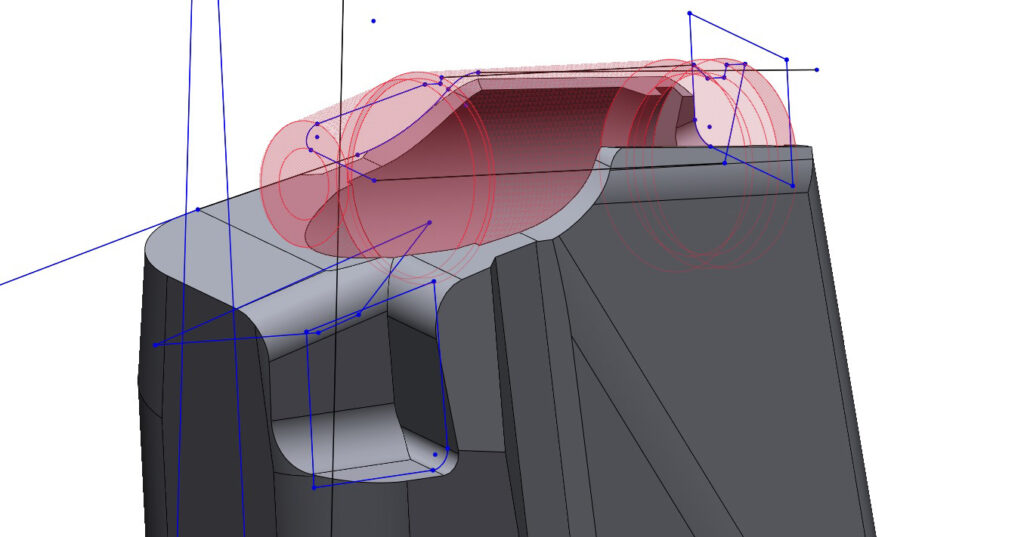

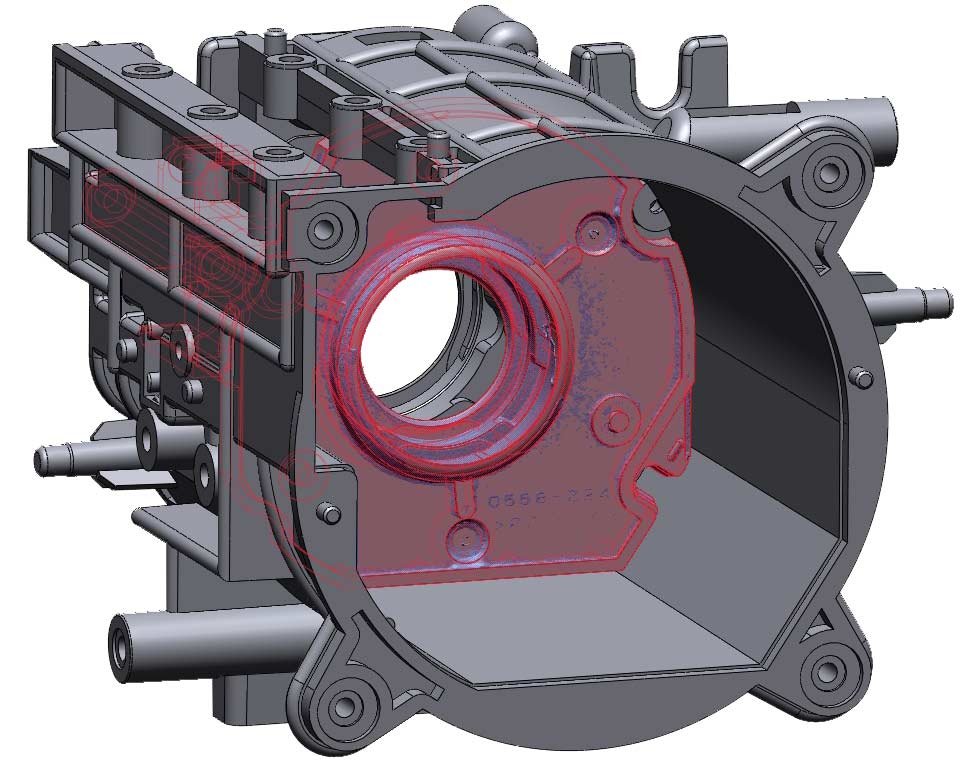

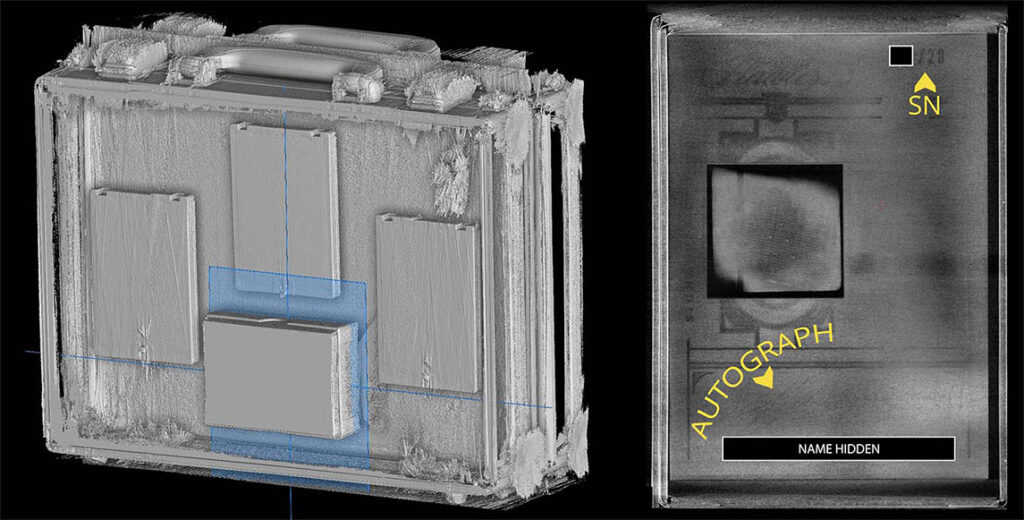

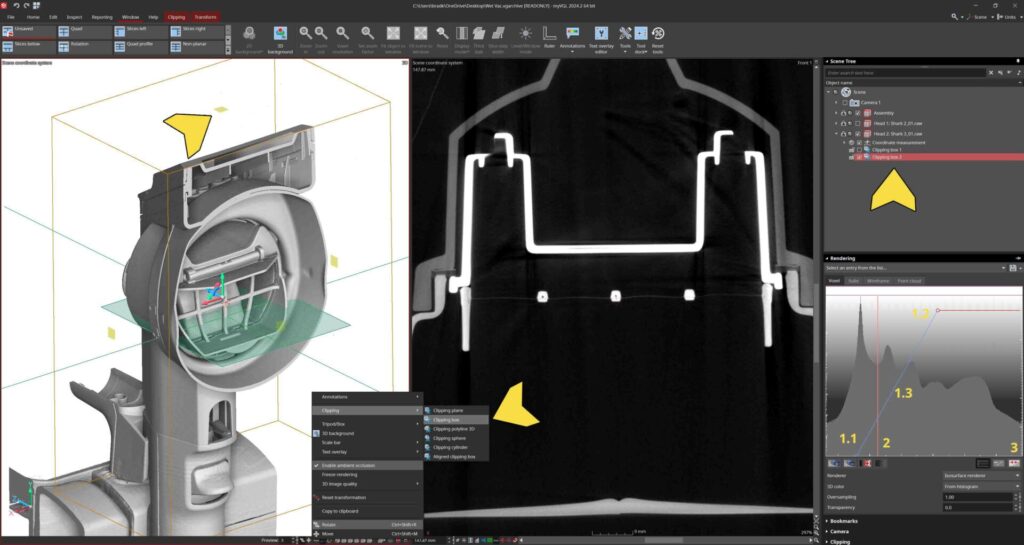

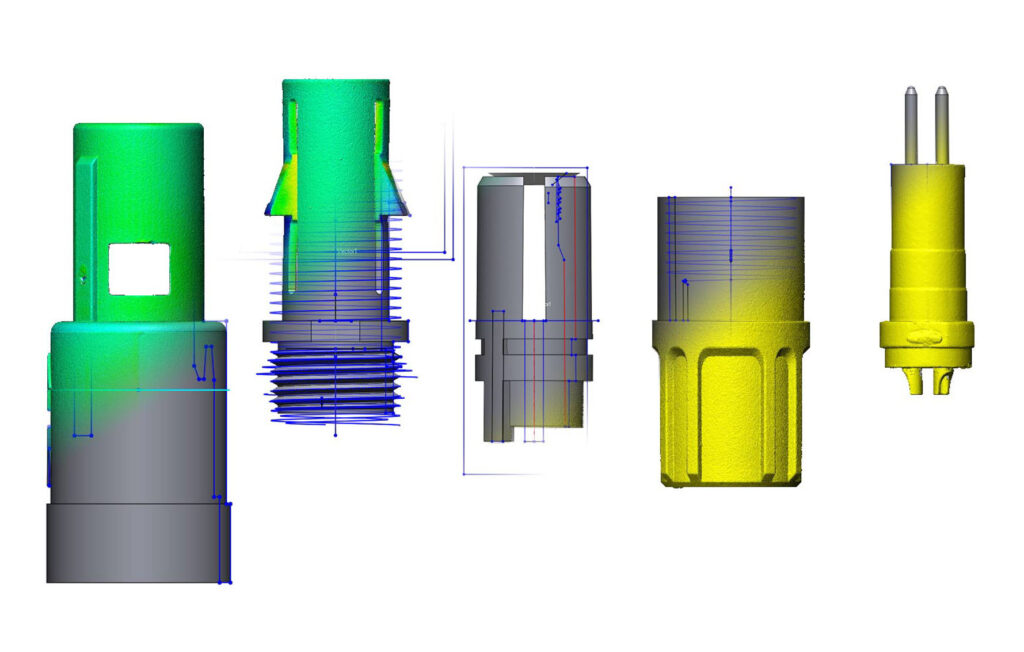

REVERSE ENGINEERING

Scaled and exported .stl files can be imported to Geomagic Design X for reverse engineering to toolable, parametric .STEP CAD models. Visit our reverse engineering page to learn more about this process.

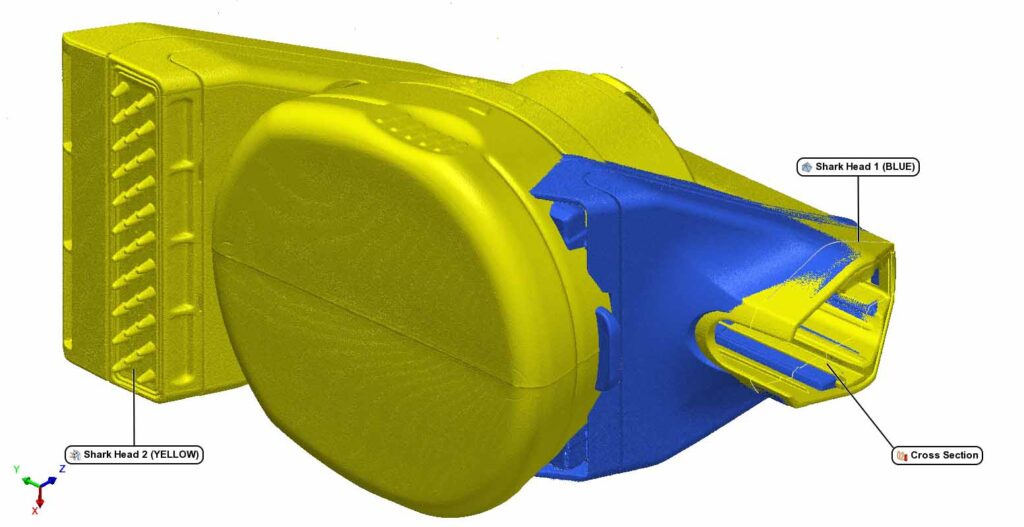

SCAN TO CAD DEVIATION

REVERSE ENGINEERED MODEL

CT SCAN STL

GEOMETRY CHARACTERIZATION & CAD COMPARE

Geometry characterization and CAD comparisons are useful for understanding how a part was manufactured and predicting how it will function. Basic imaging can offer engineers the peace of mind that a part will function properly.

VGSTUDIO Max with Cast & Mold Module

Volume Graphics is the industry leading software for CT volume evaluation. With a suite of modules available, like Cast & Mold for dimensional inspection and porosity and inclusion analysis, we are equipped to ensure you receive all the data required for your inspection.

myVGL Viewing Software

myVGL is the free viewing software. It includes the ability to navigate CT volumes, save images and videos, and perform basic measurements. This option is available for all clients and all projects upon request. Here is the link to view our guide to download and use myVGL.