DIGITAL RADIOGRAPHY

SERVICES

320KV LARGE CAPACITY DR / CT

Industrial Inspection offers ASNT & NAS-410 certified radiography services for all industries like the sciences, aerospace, defense, and automotive.

With our digital and high resolution systems we save our clients on cost (no film or consumables waste), offer shorter lead times (no chargeable and time consuming film exposures), and produce better repeatability by using programmable part manipulators.

Between our two microfocus systems we offer variable penetration from 50 to 320 kv for a range of product inspections like low density plastics and biologics to high density evaluations like thick castings and copper wound stators.

225KV METROLOGY DR / CT

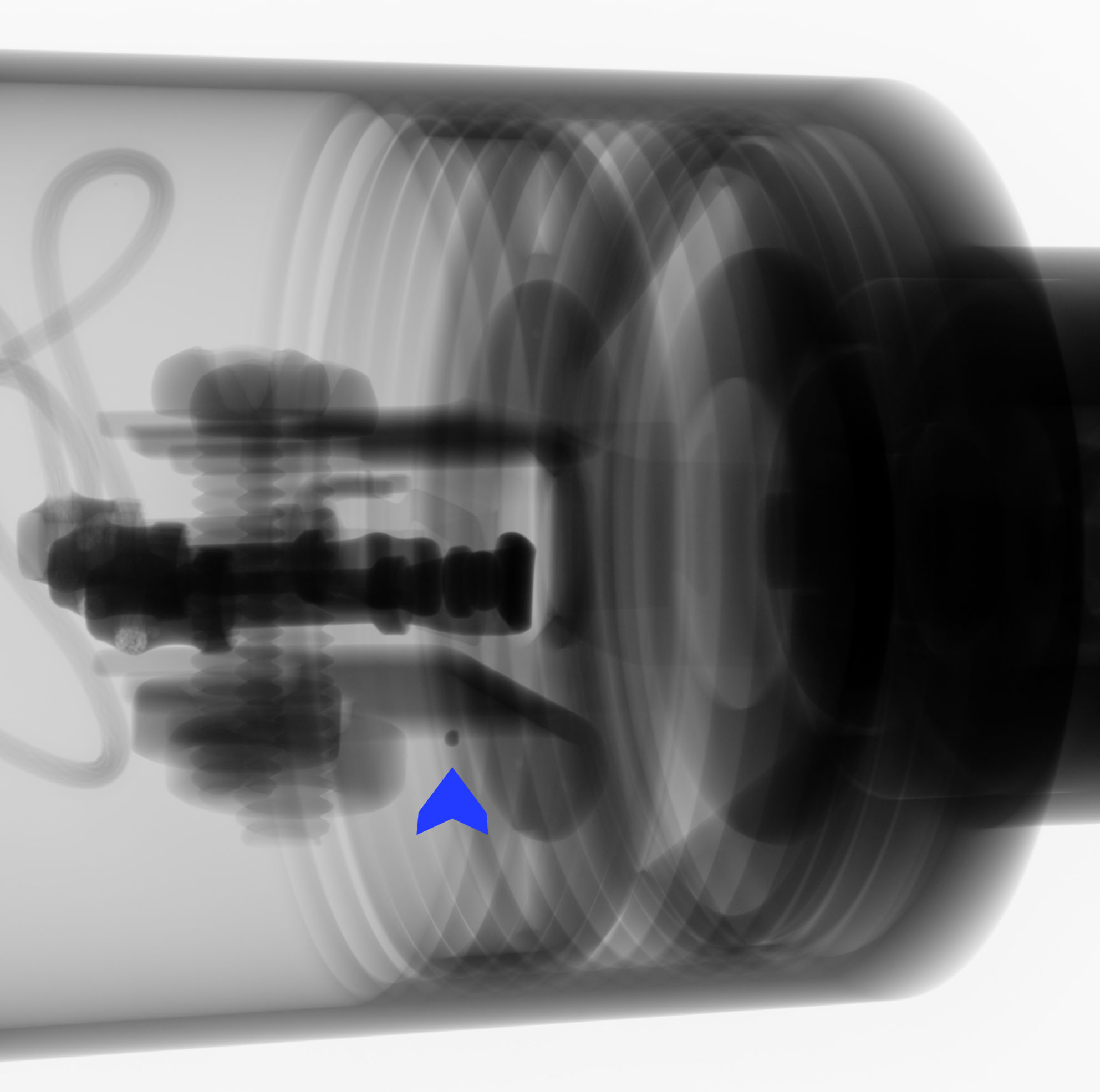

FAILURE PREVENTION & ANALYSIS

X-ray is used to help prevent failure by verifying products are manufactured properly (bolts are present, no FOD, spacing of components). Some manufacturers even require a serialized x-ray of all their parts for documented proof of conformance. It is also used post-failure to look for indications and characterize the sample before deconstruction.

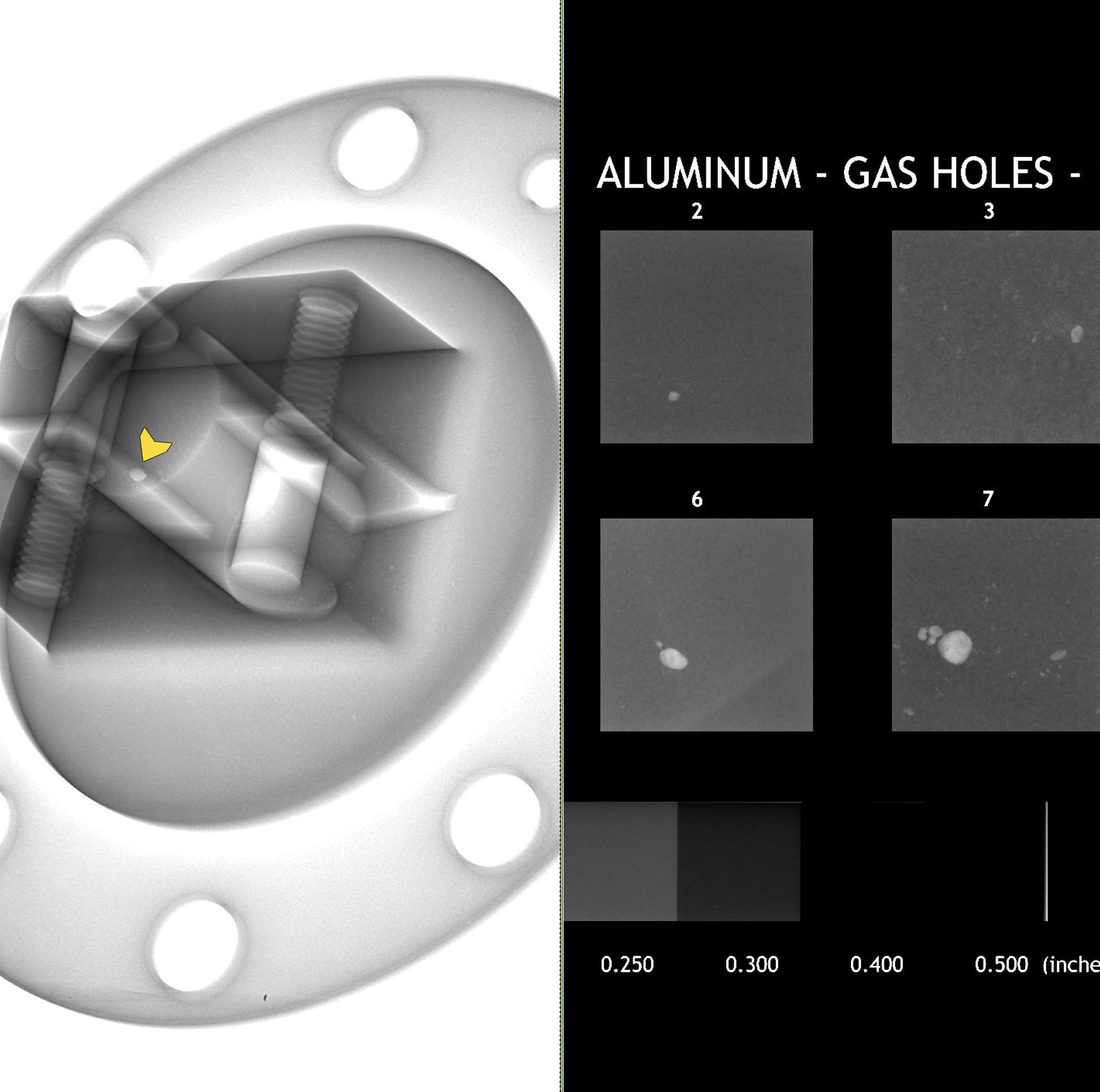

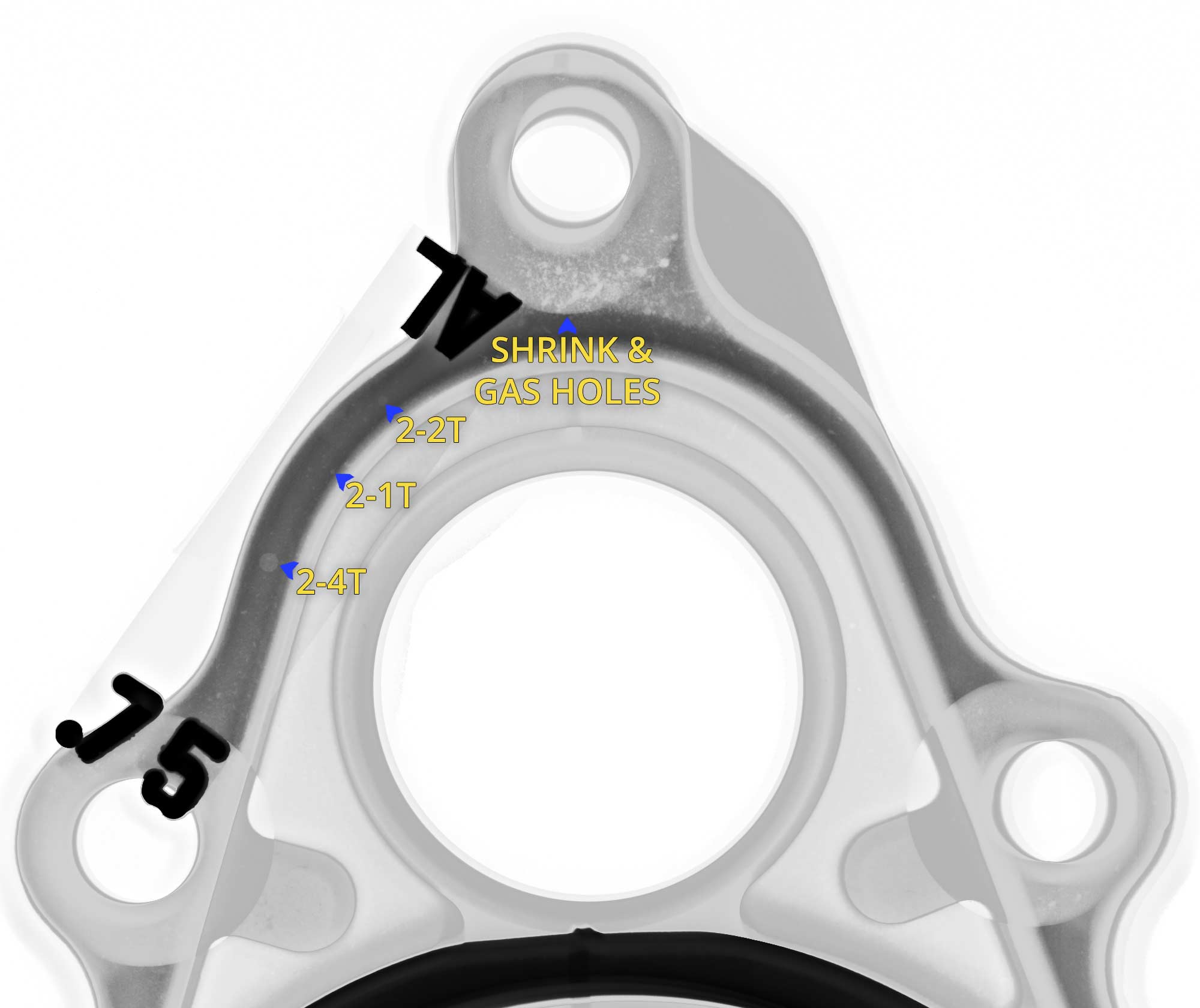

X-RAY SORTING & CASTING GRADING

Structural, functional, and safety critical castings undergo x-ray inspection and can be graded against a variety of specifications. For example, the below aluminum casting is being evaluated against a scaled reference radiograph per ASTM E2422 for gas holes, shrink, and porosity. Industrial Inspection screens castings before they make it to machining or assembly phases.

Have a question or request for quote regarding Digital X-Ray Imaging?

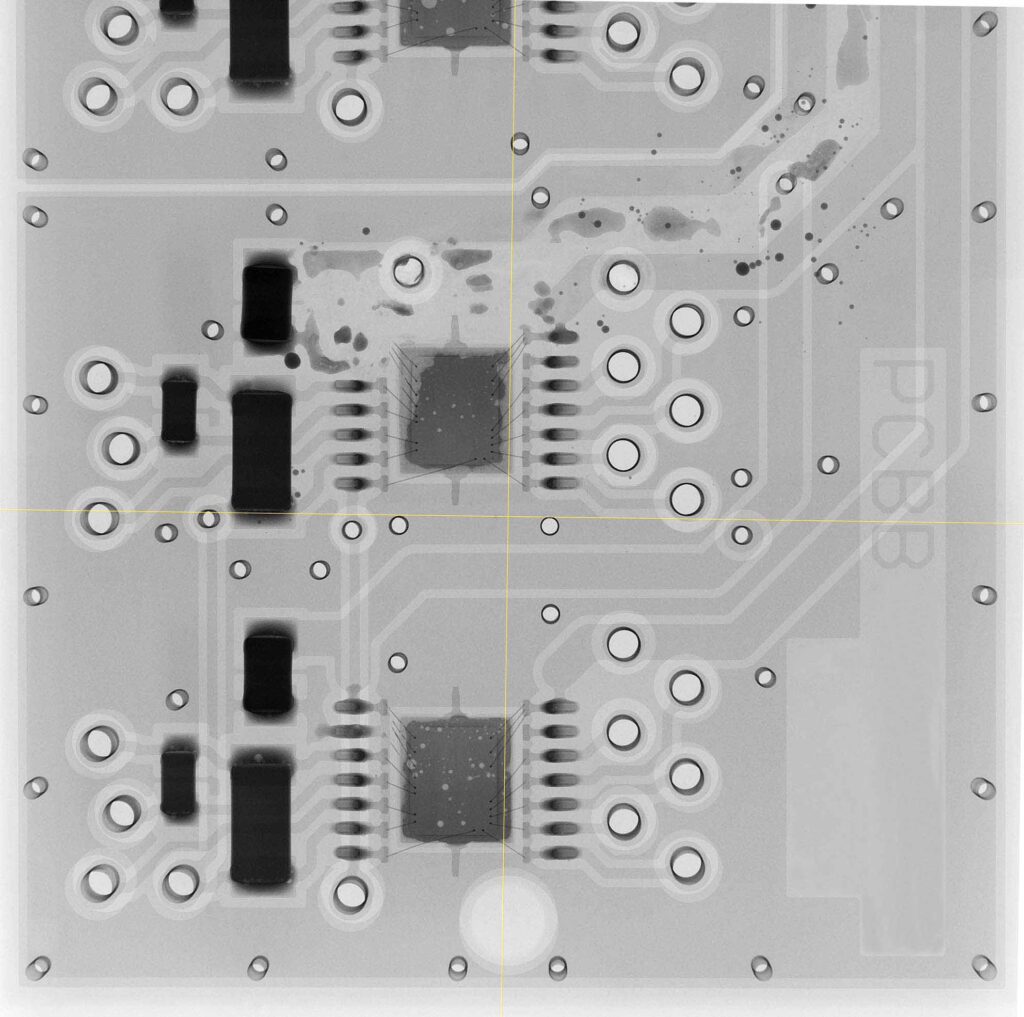

PCB INSPECTION

PCBs are prone to a variety of defects like solder joint porosity, FOD, cracked capacitors, broken traces, and disconnected wires. All of these can be characterized using high resolution x-ray.

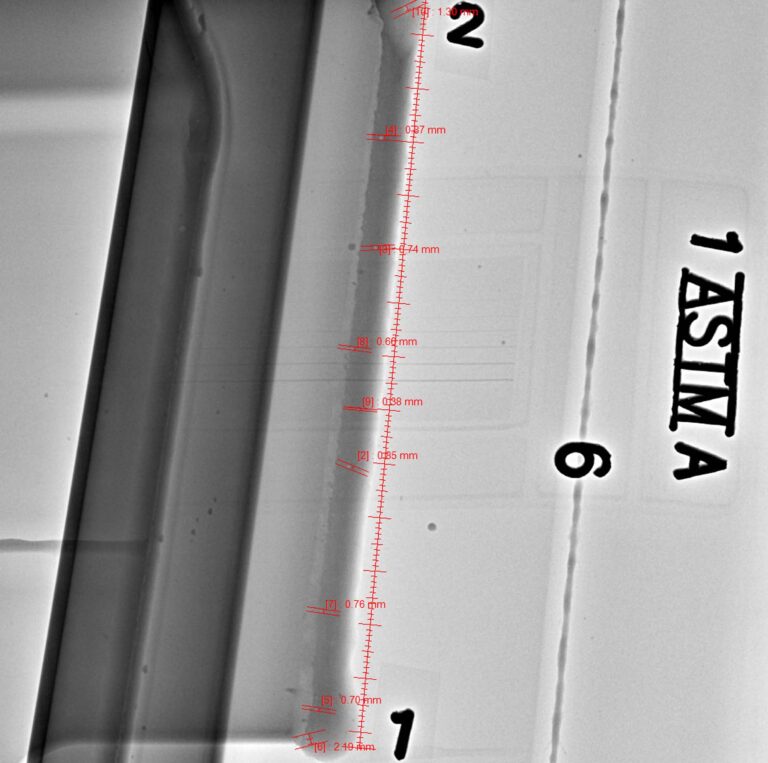

WELDS, BRAZES & BONDS

Industrial inspects and grades joints for rejectable indications like porosity, inclusions, lack of fusion or penetration, undercut, and cracks. Using image review software we provide indicated images along with the report.

When the pinnacle of science and design collide

Industrial Inspection pushes the limits of electronics and accessories by using digital X-ray imaging to provide the highest quality data on the market – like with the Nintendo Switch 2.

Why? Because flawless fit isn’t a guessing game. With our expertise every camera cutout, every vent alignment, and every curve is built on cold, hard data.