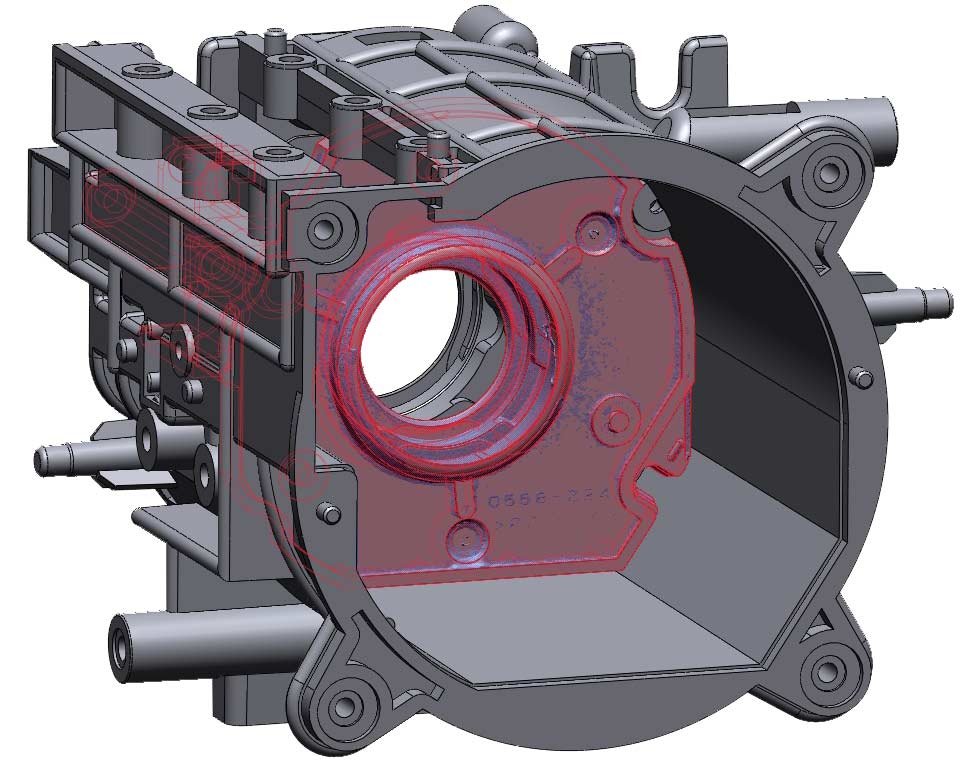

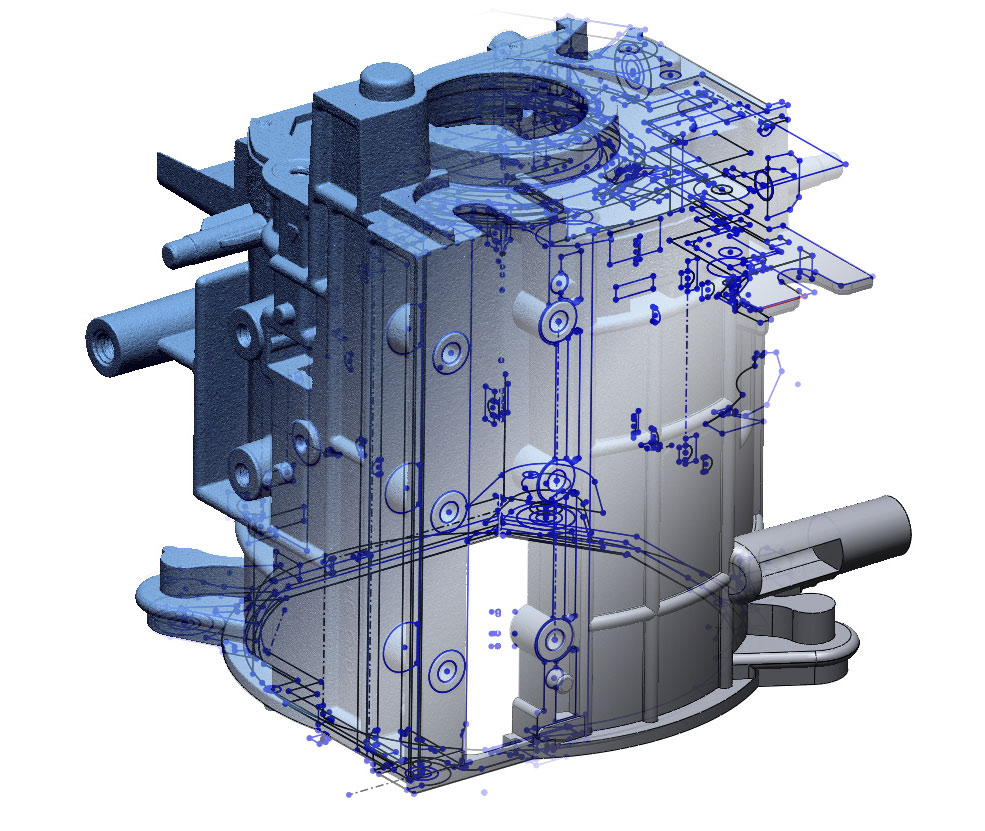

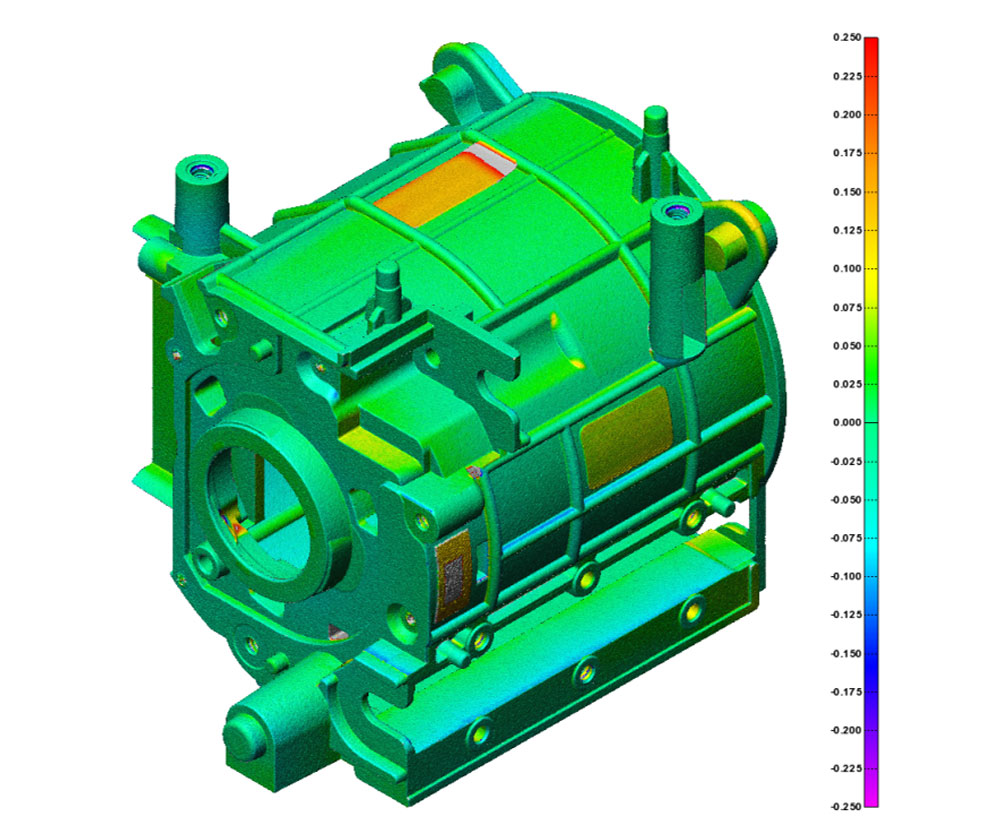

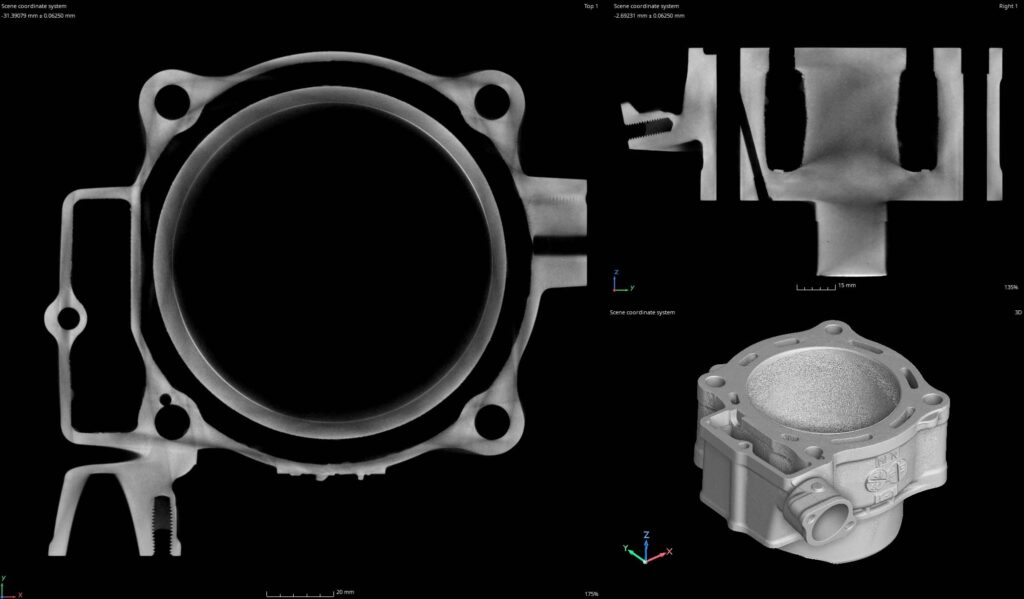

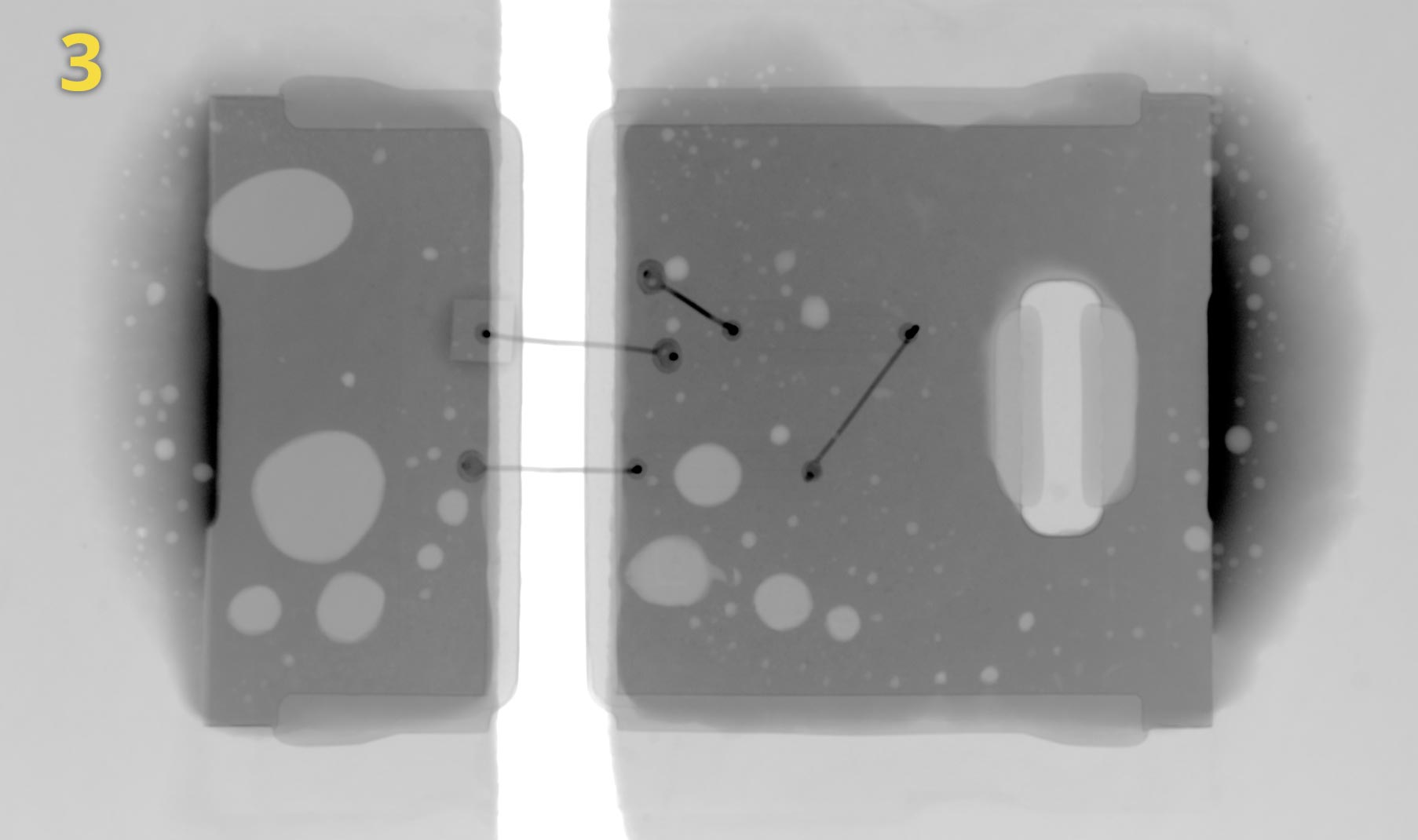

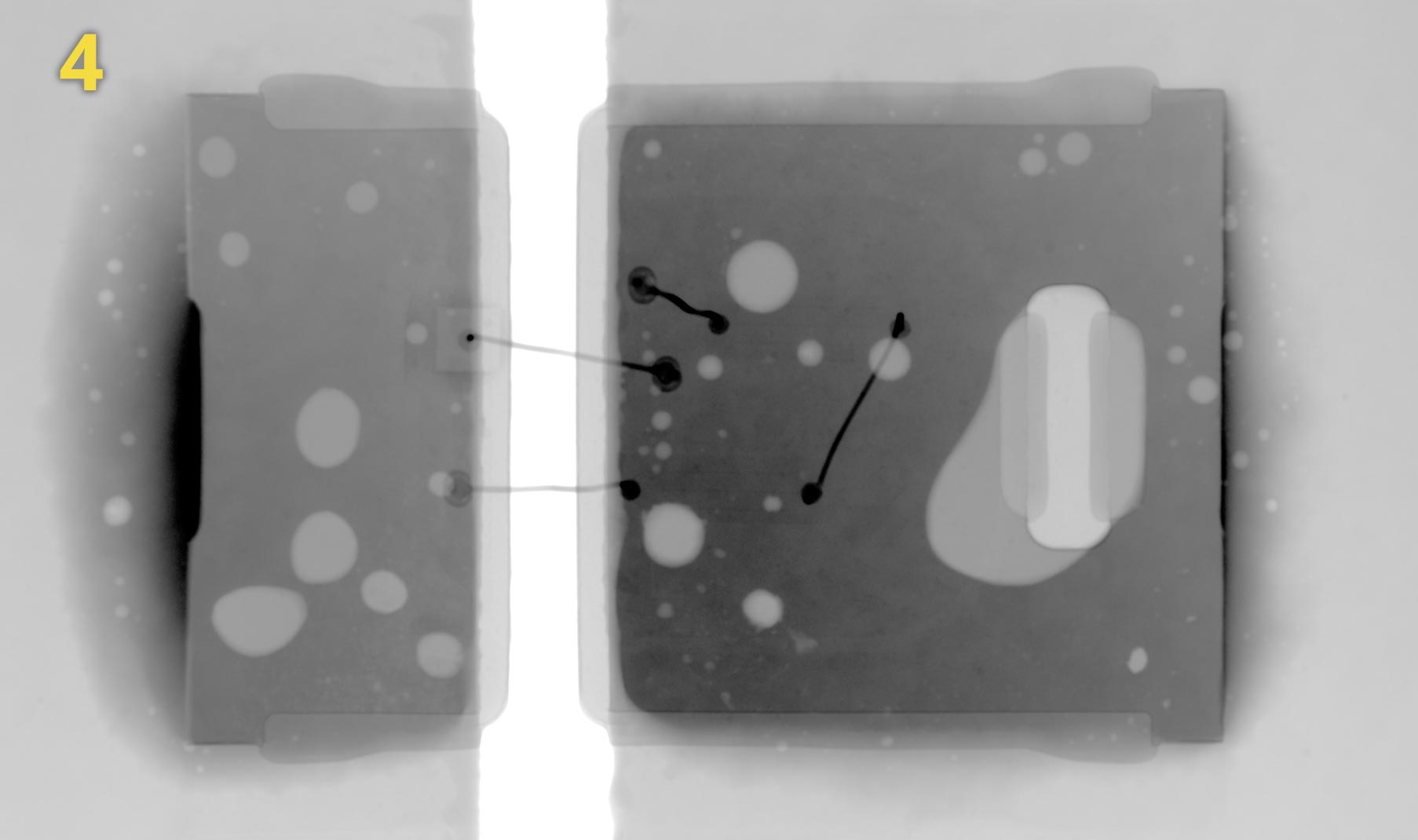

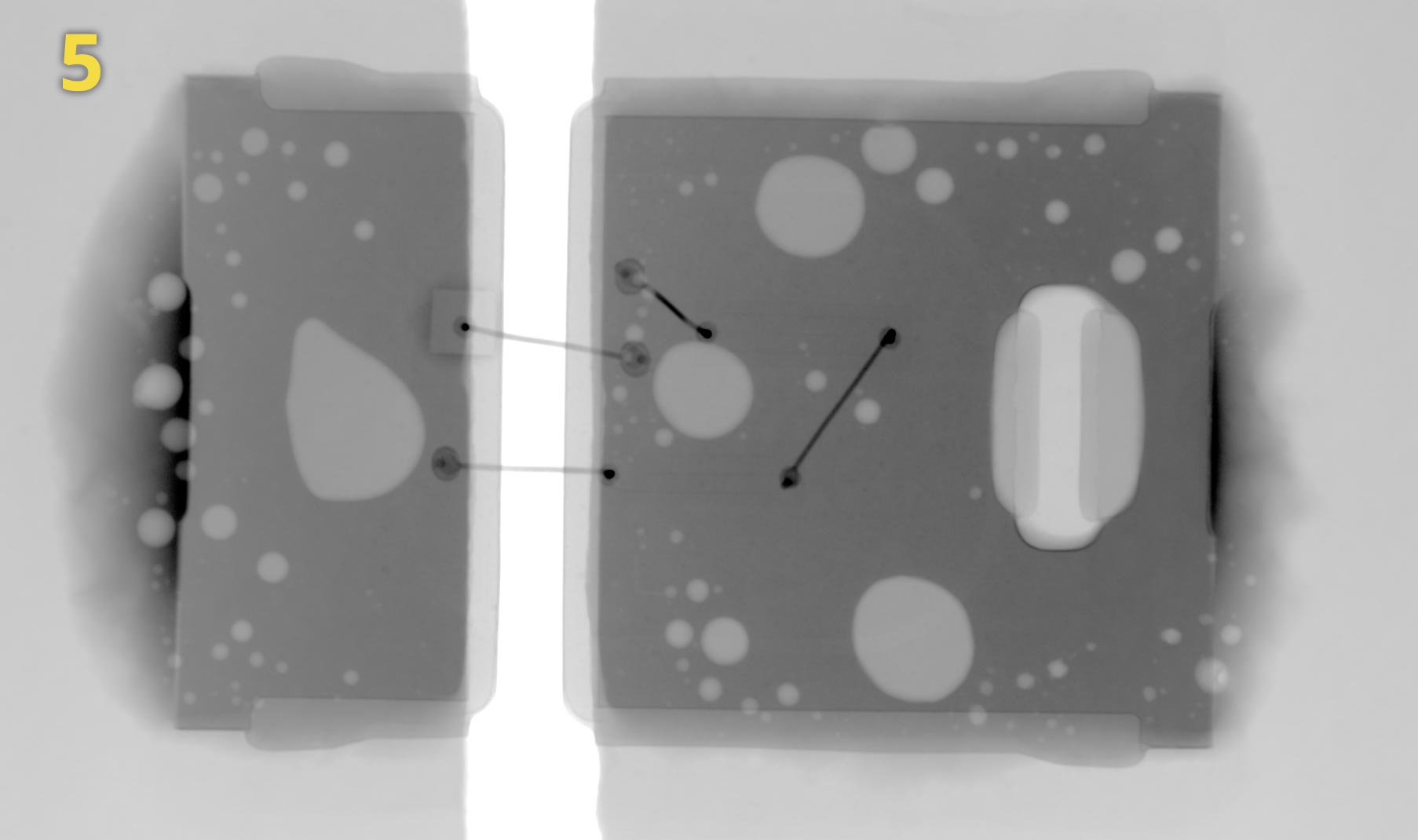

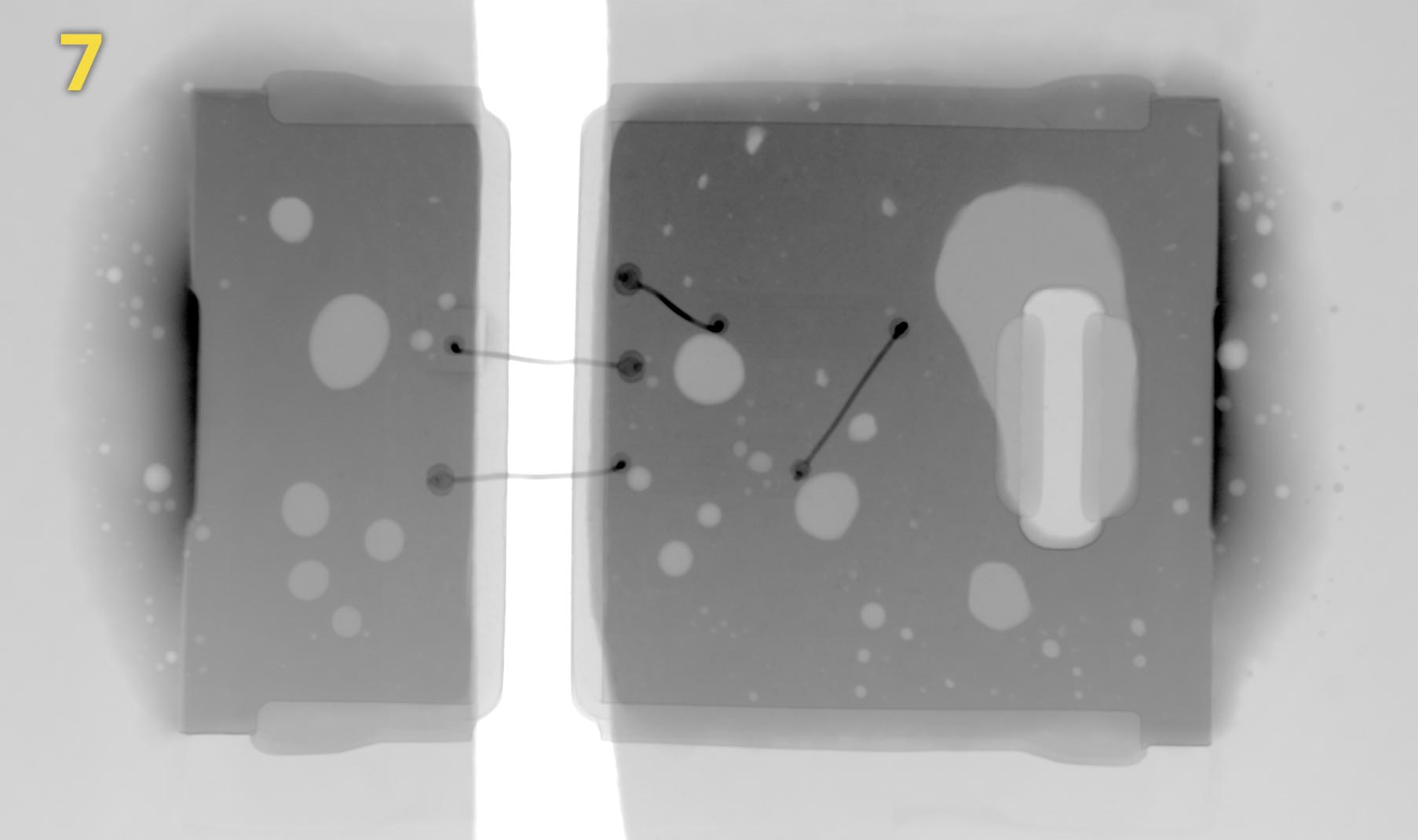

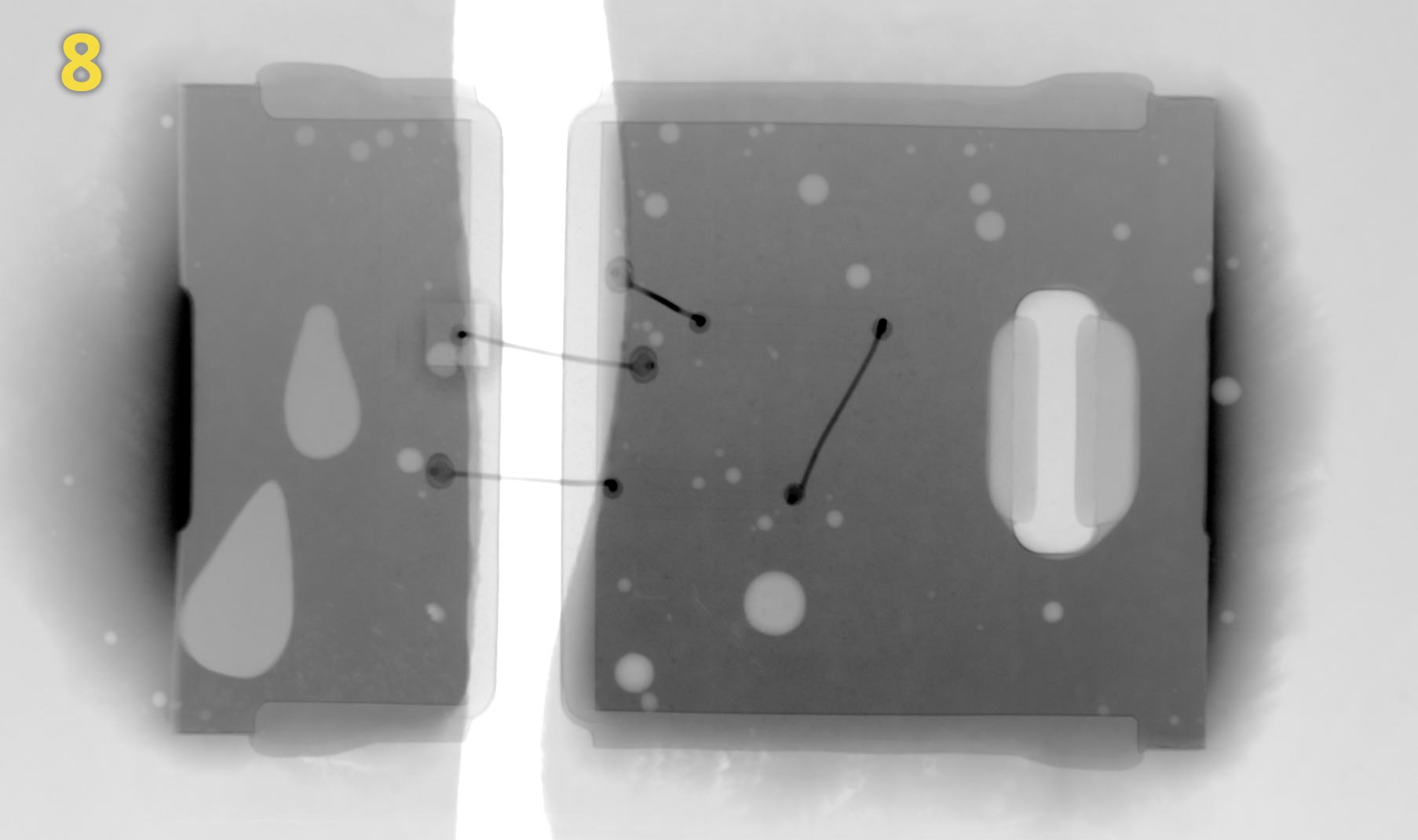

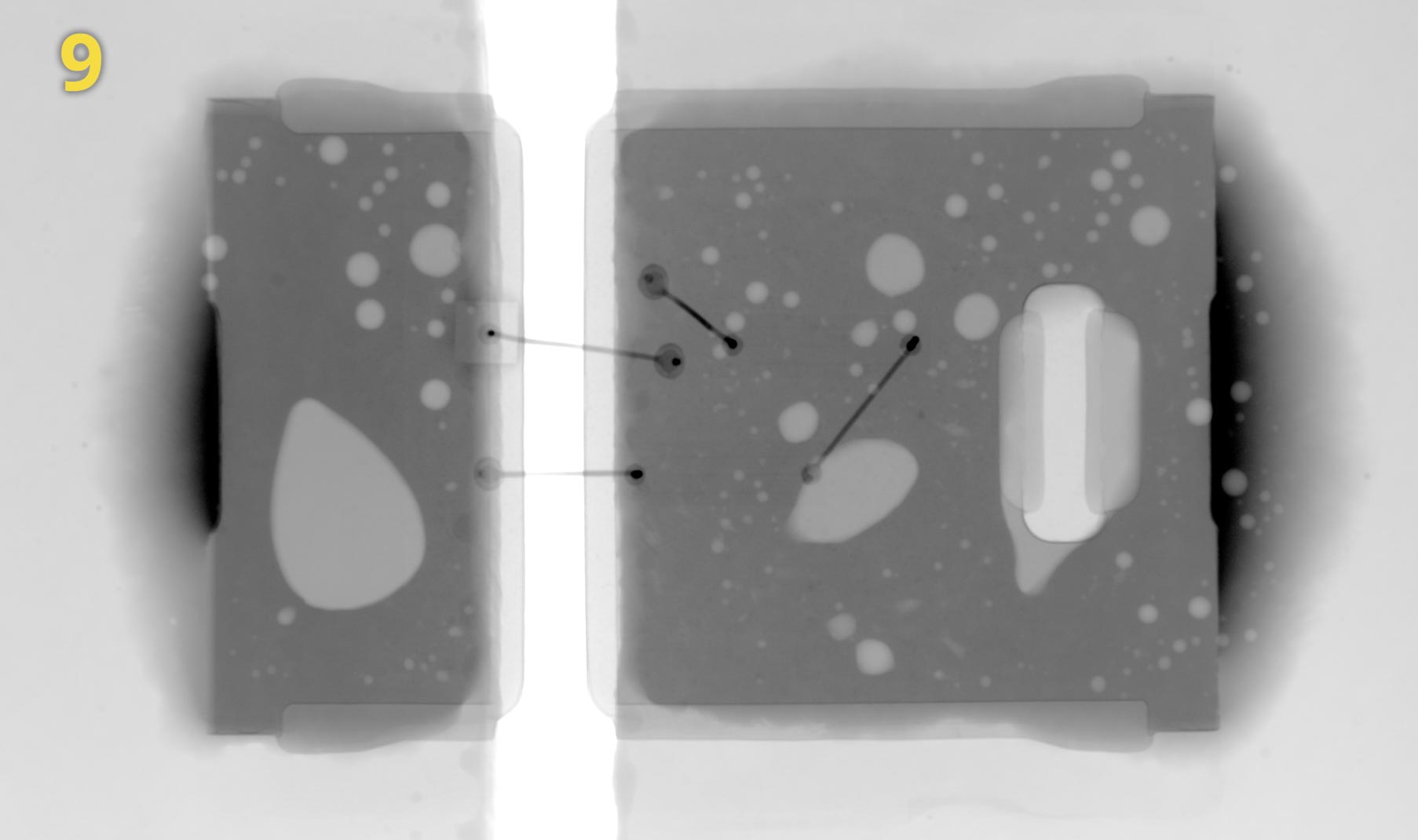

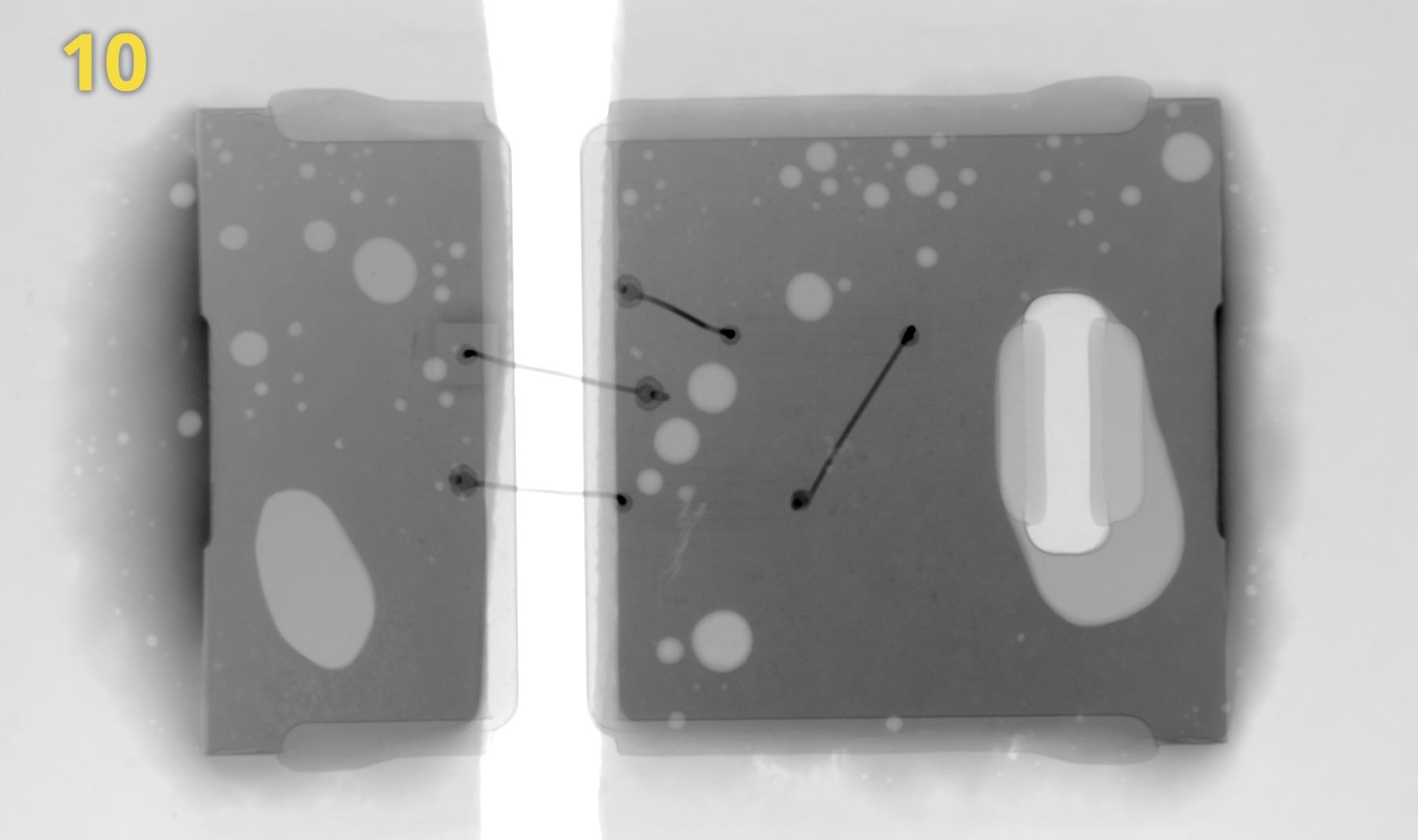

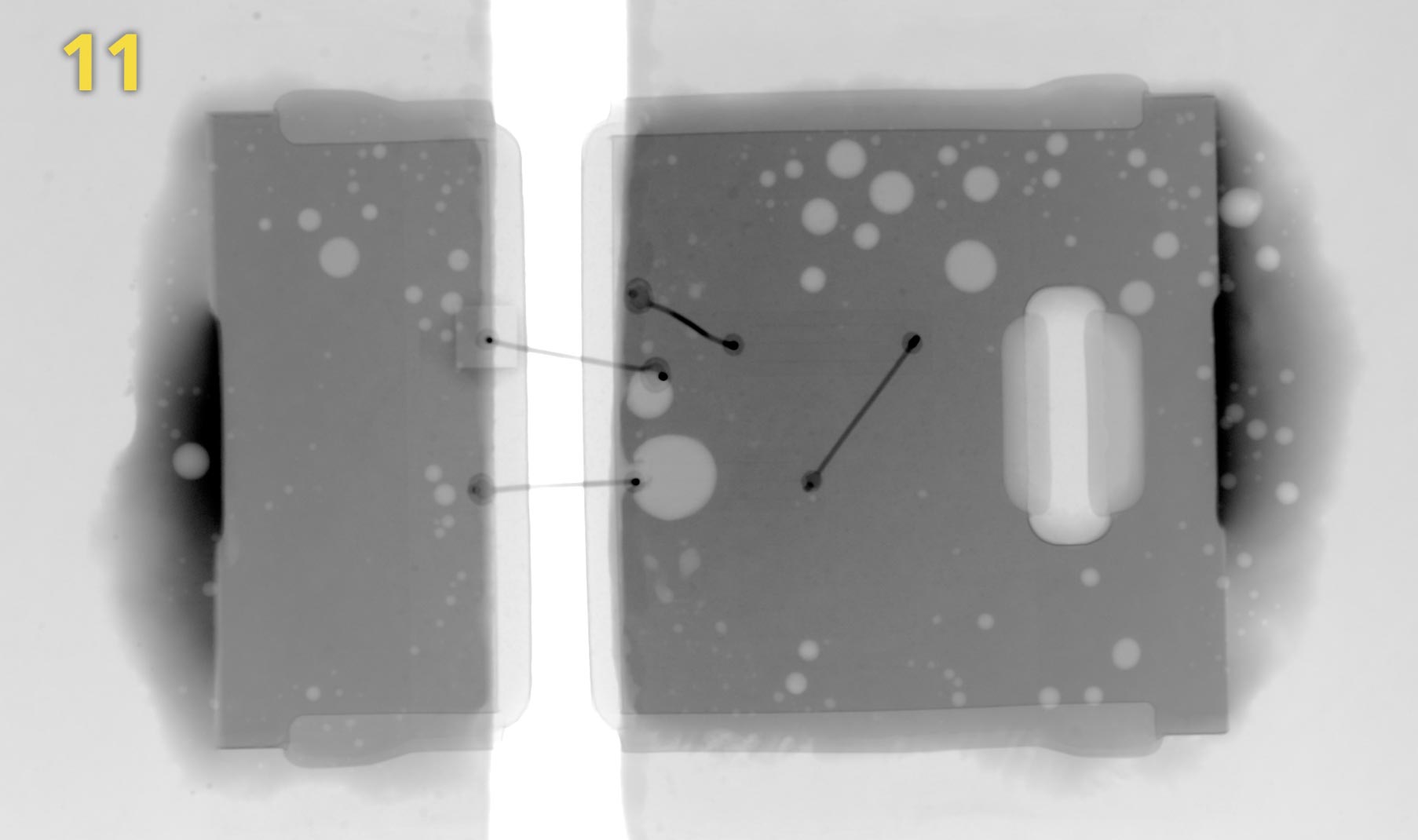

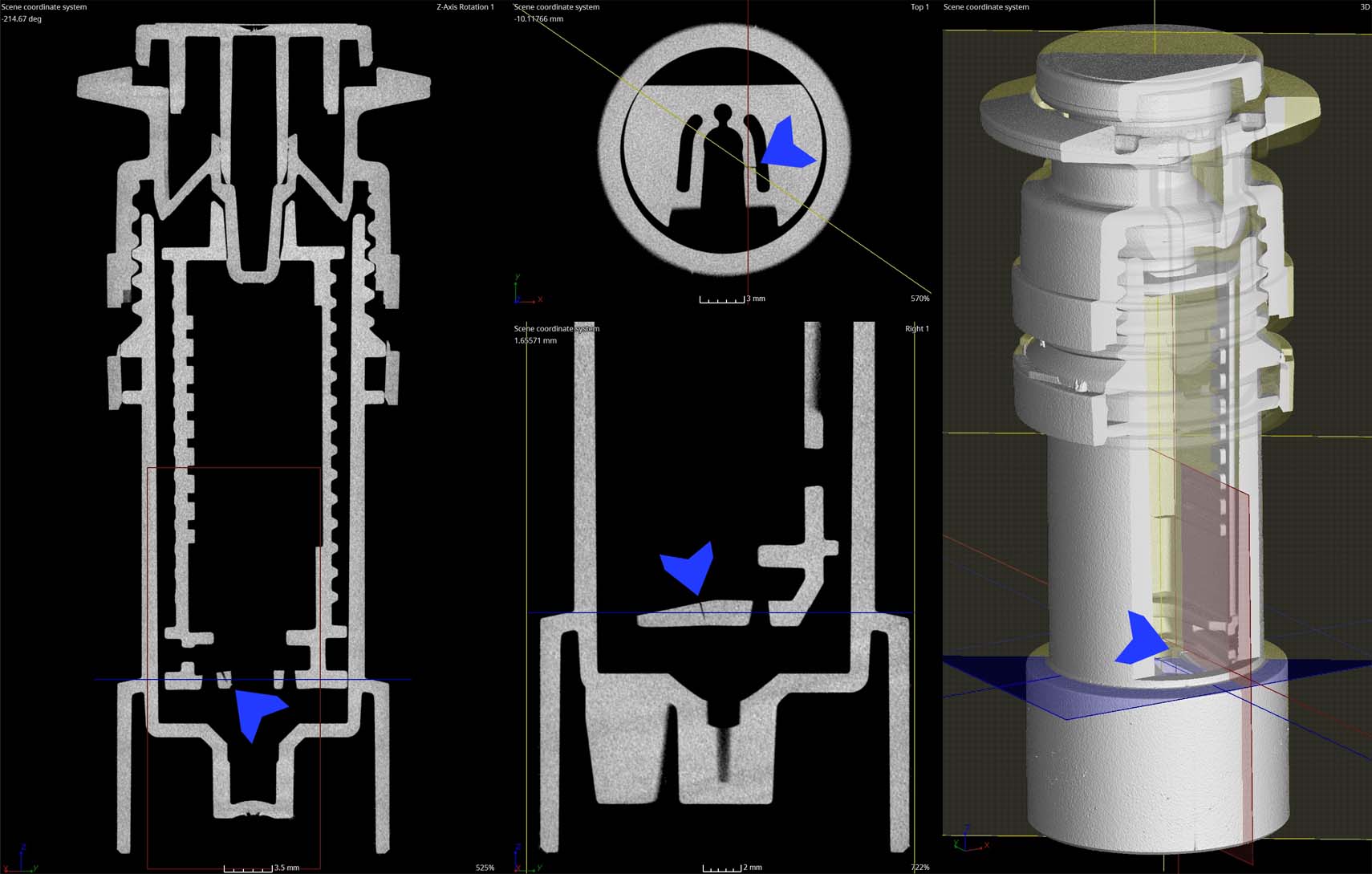

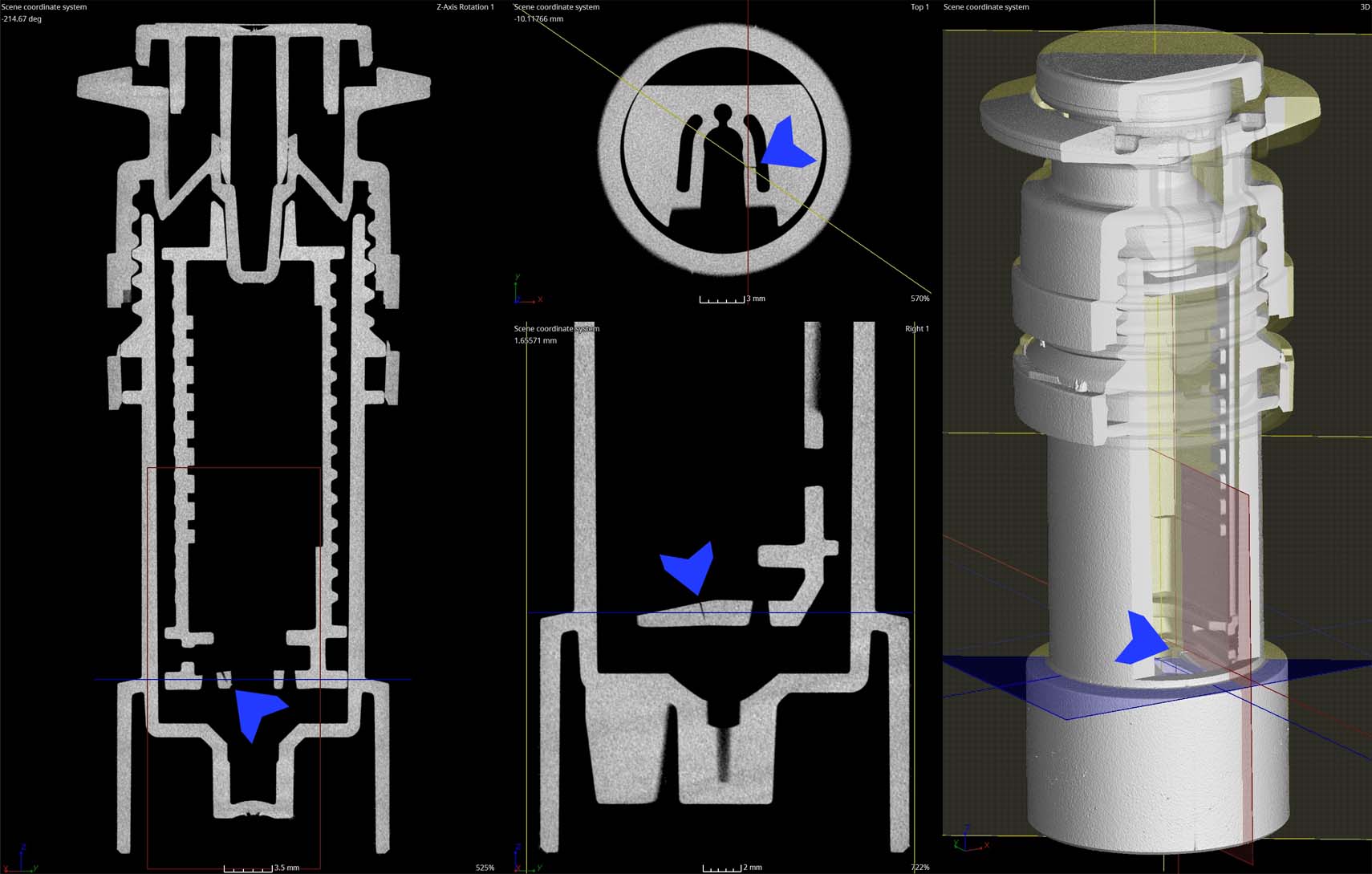

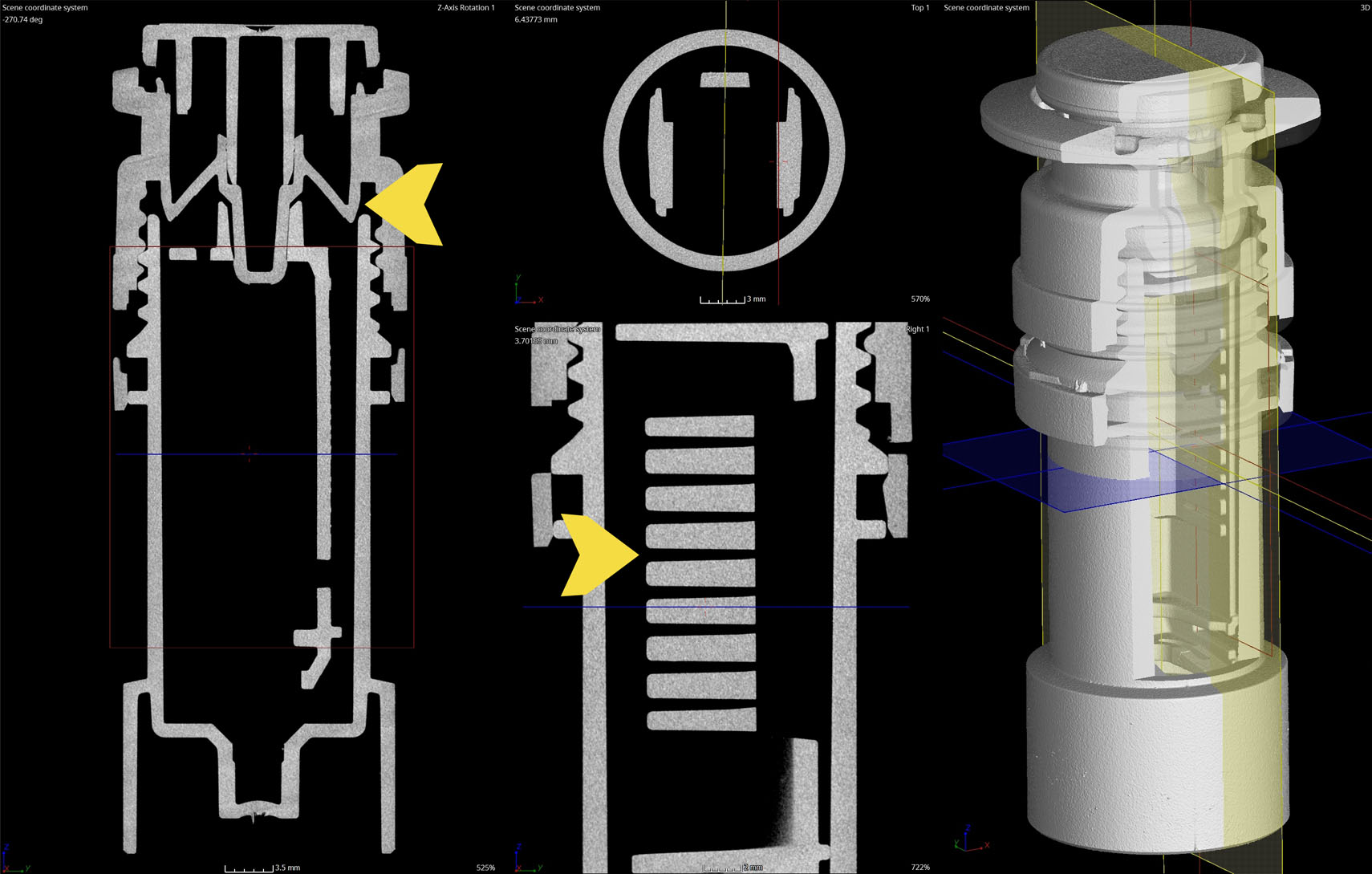

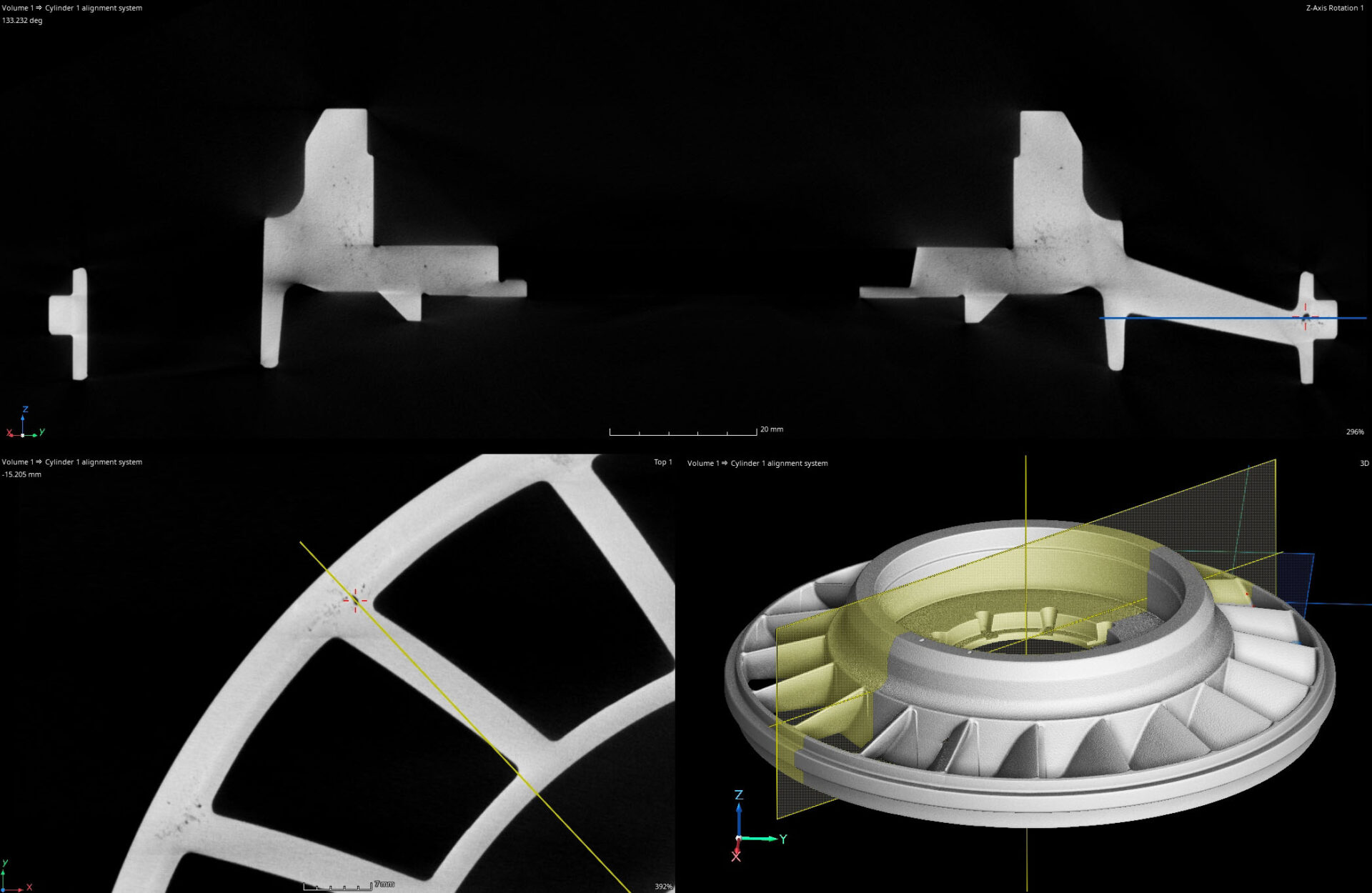

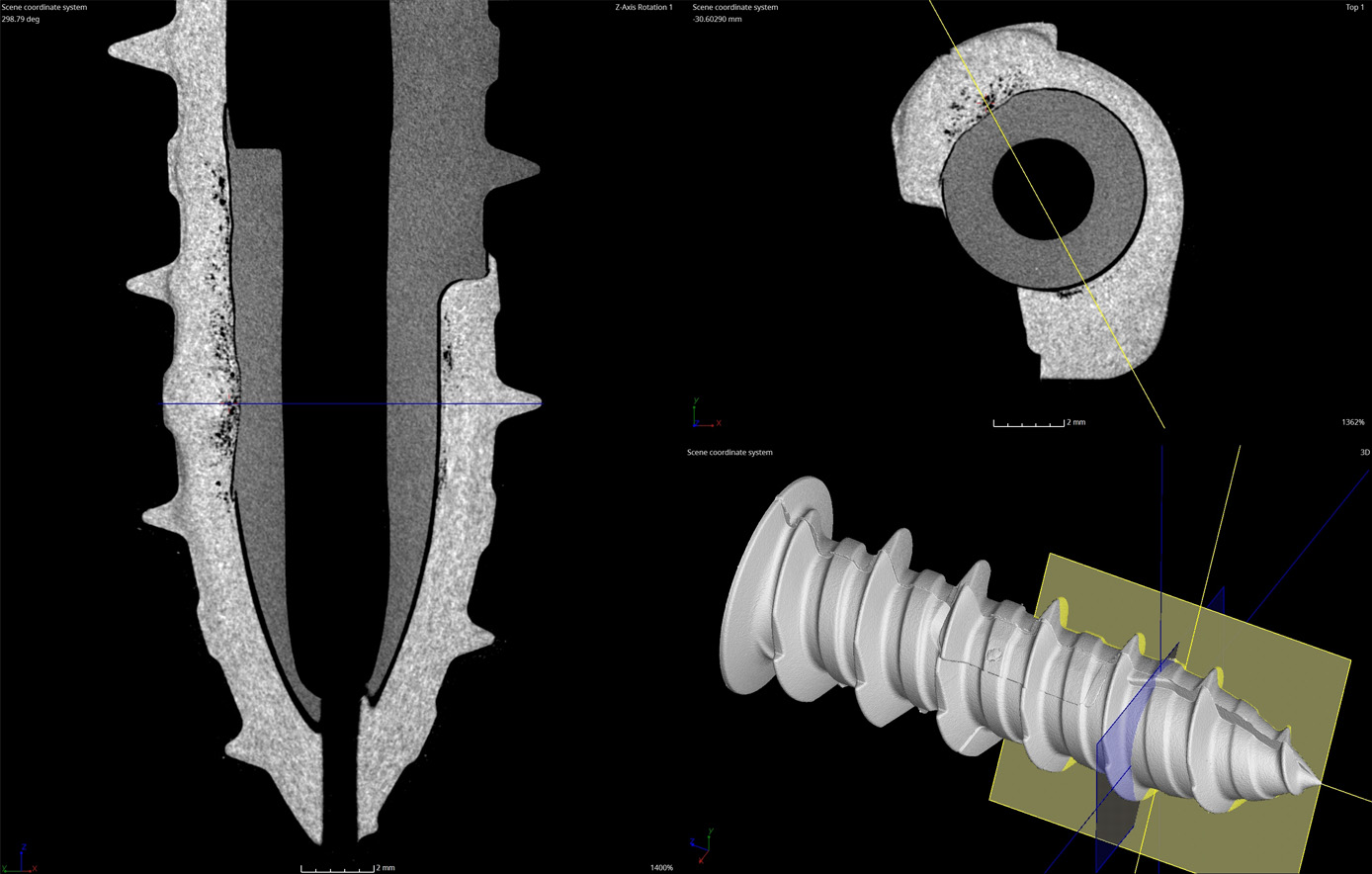

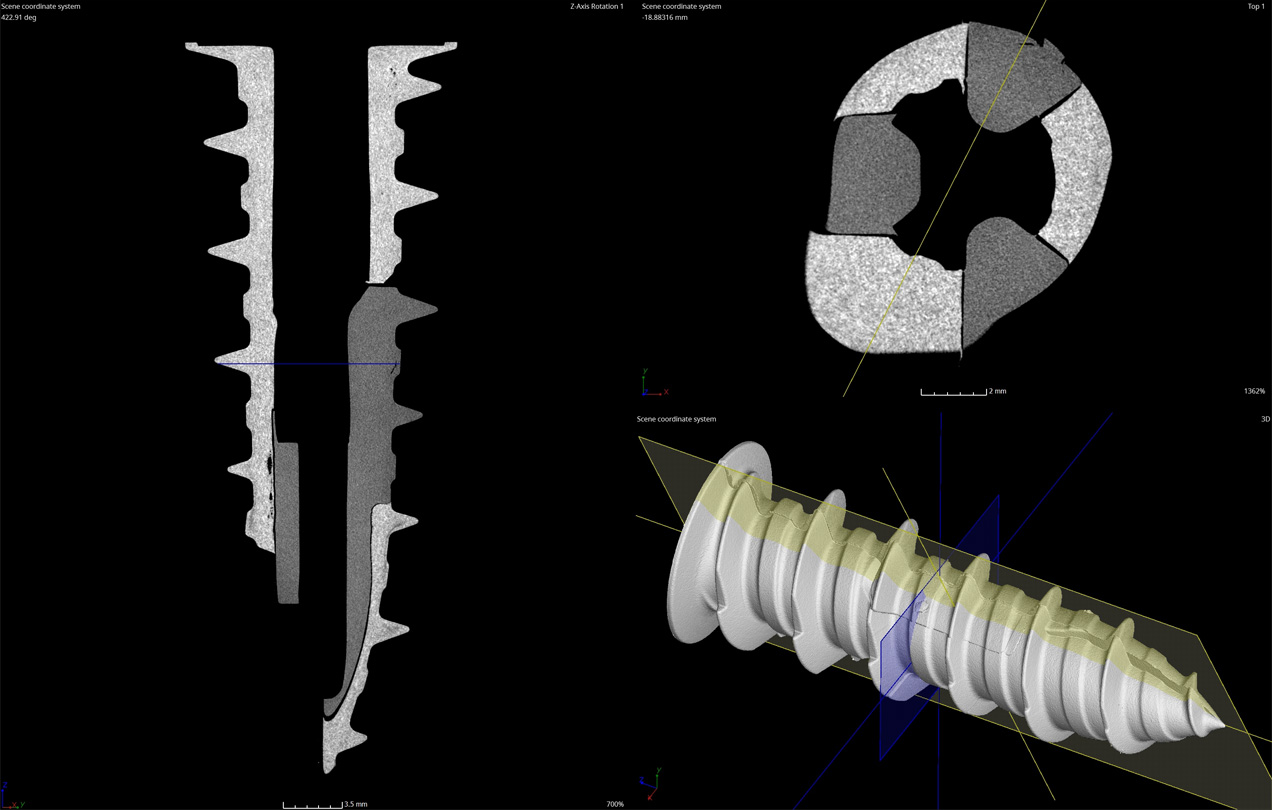

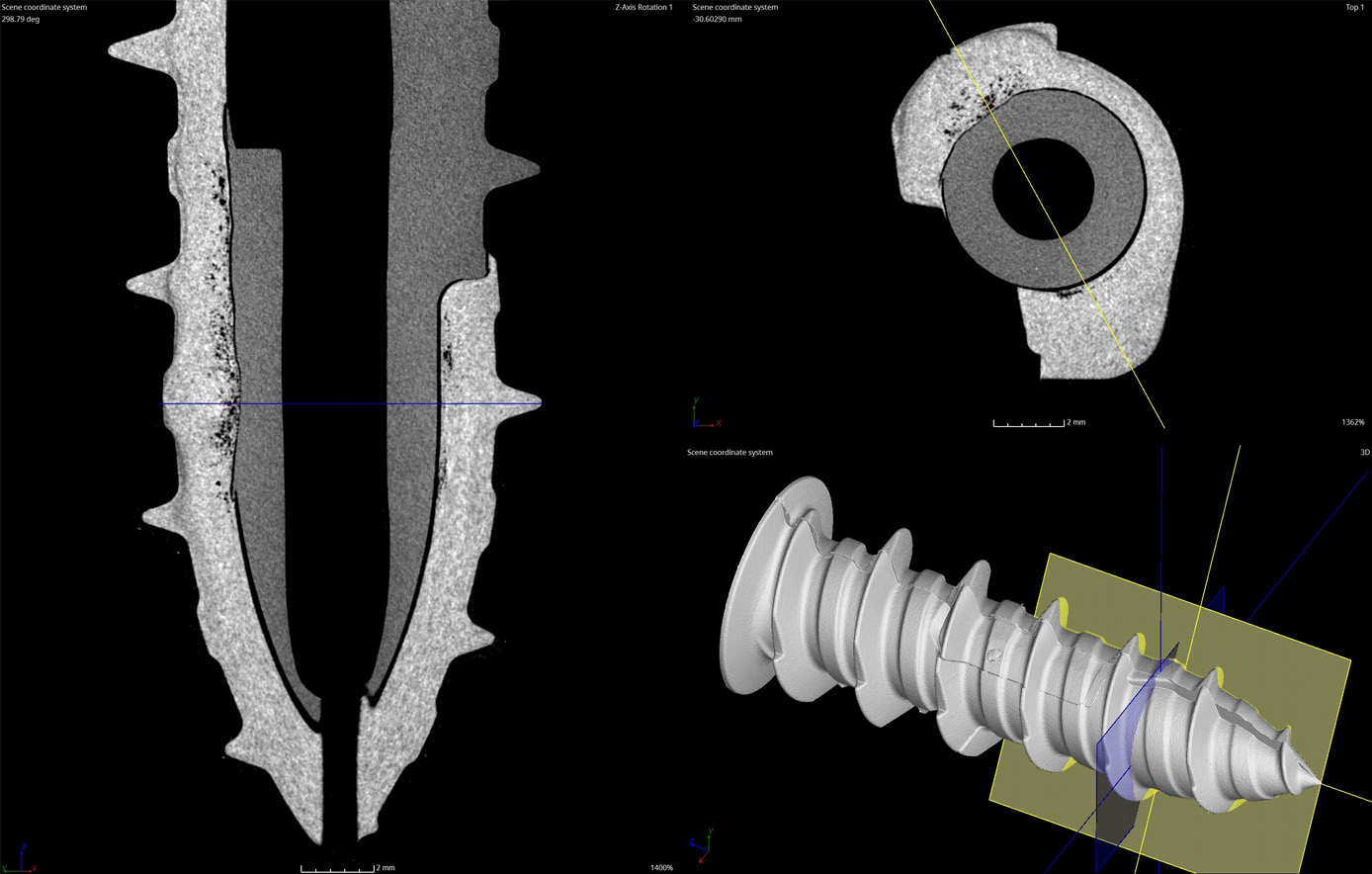

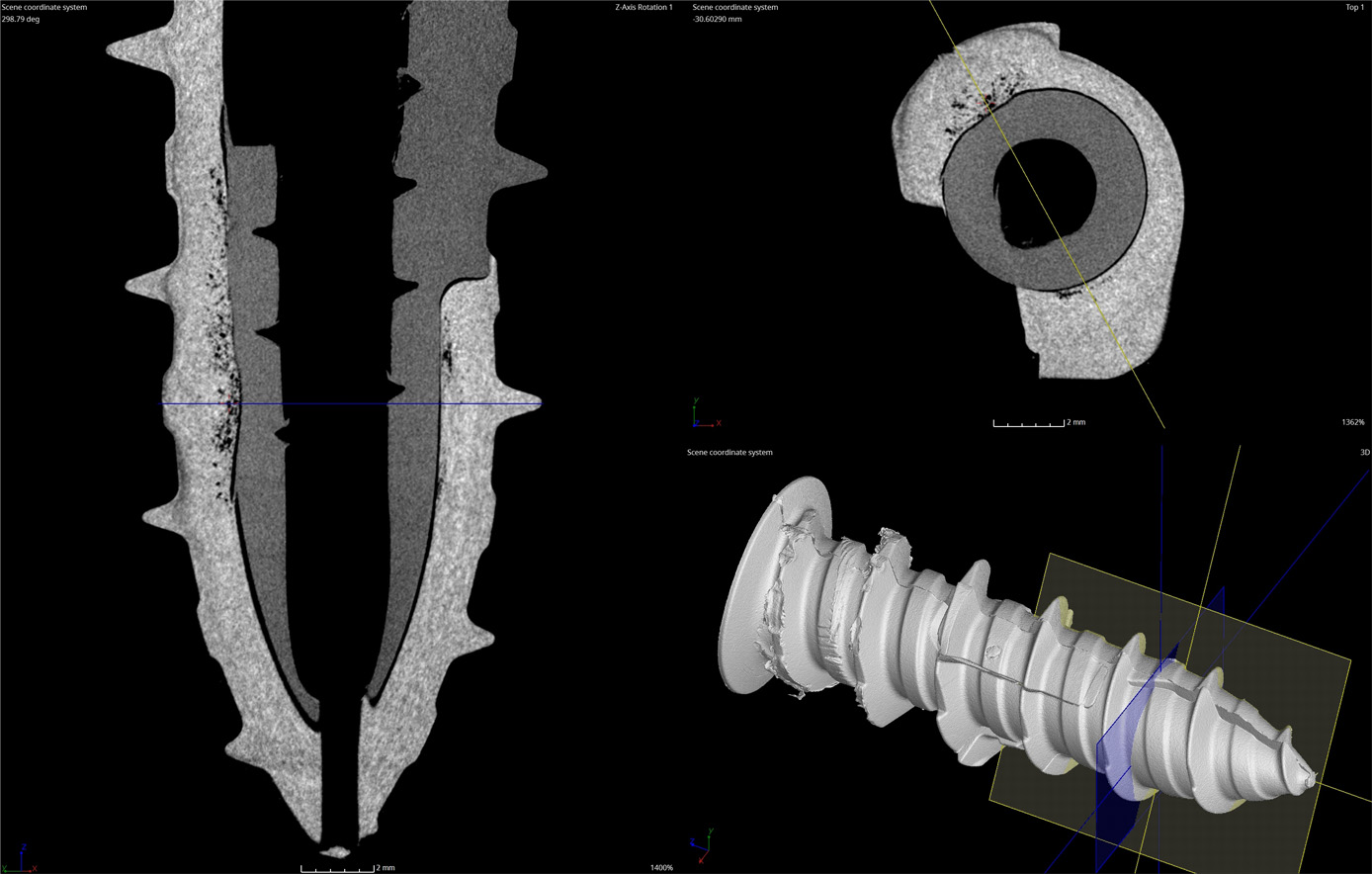

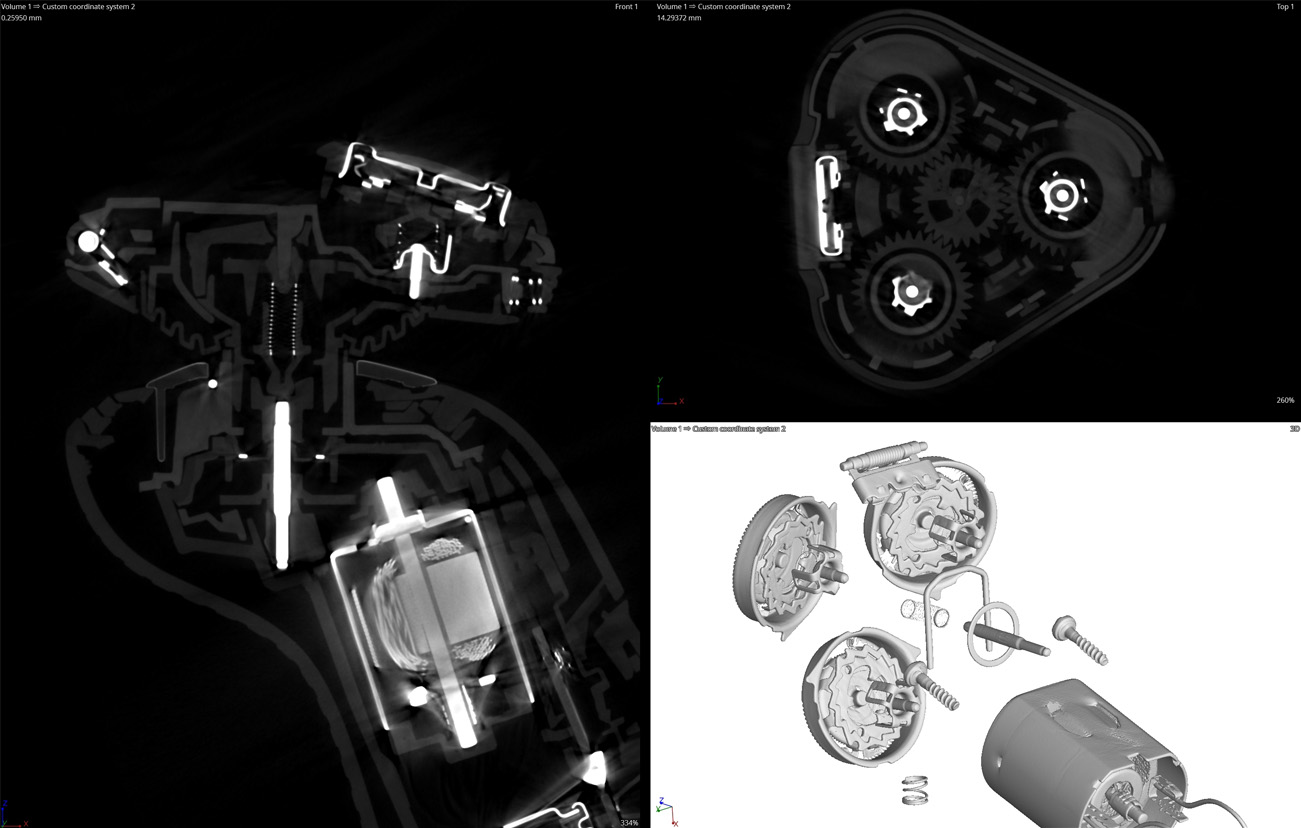

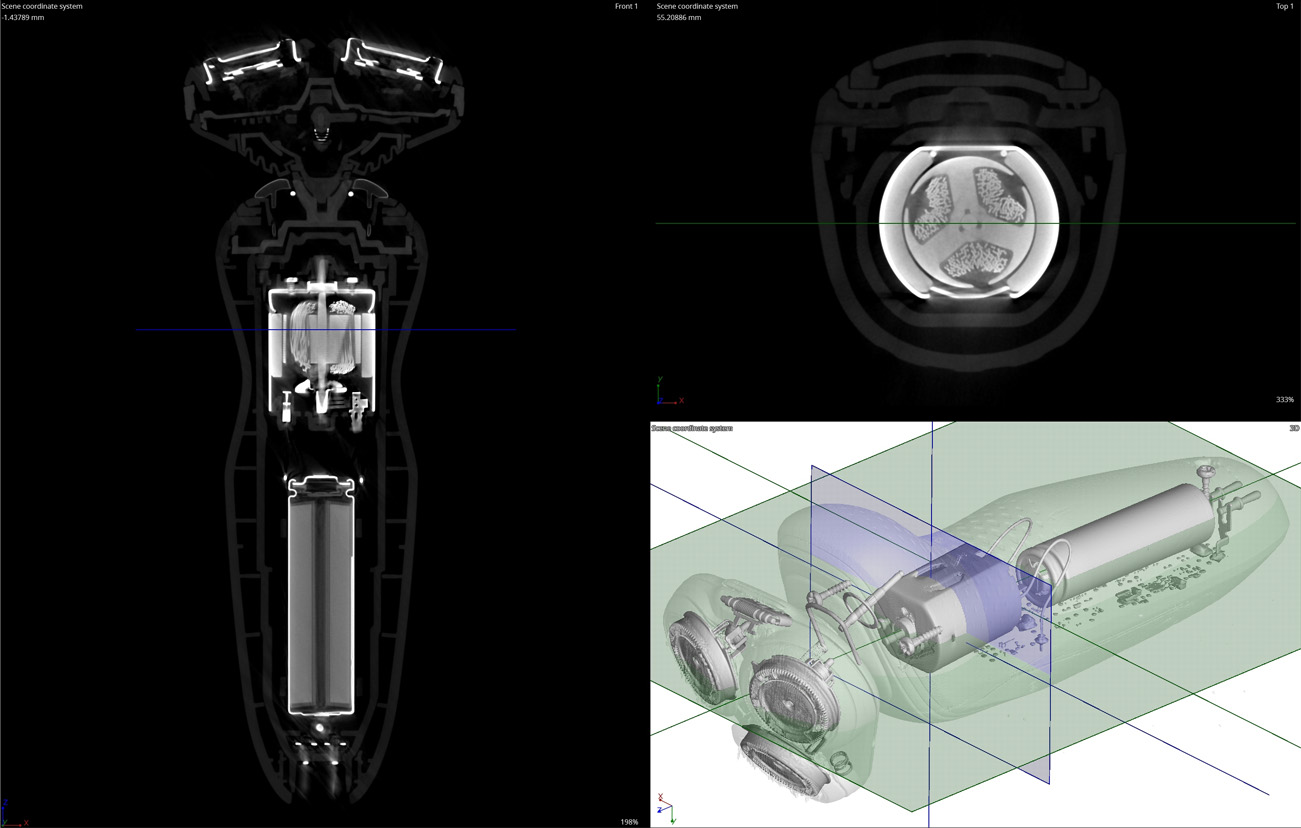

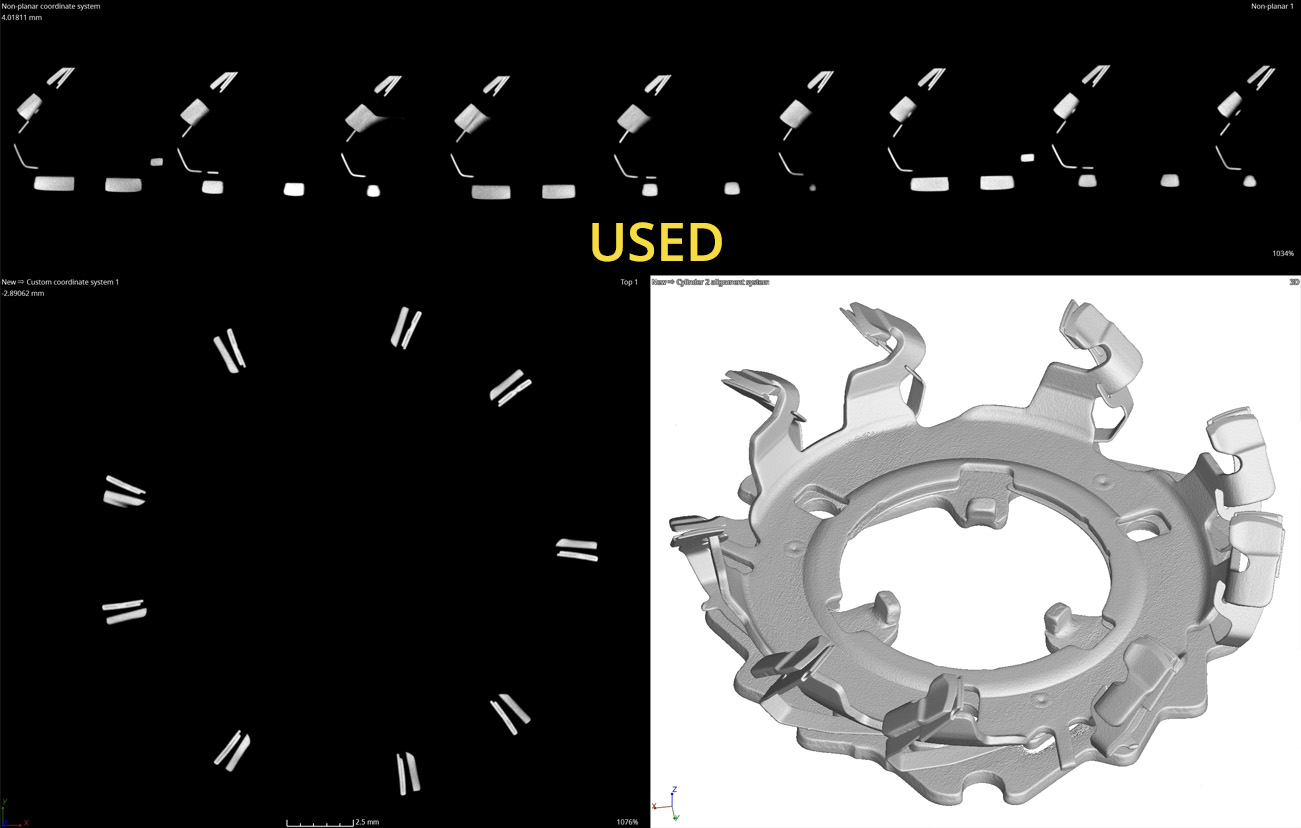

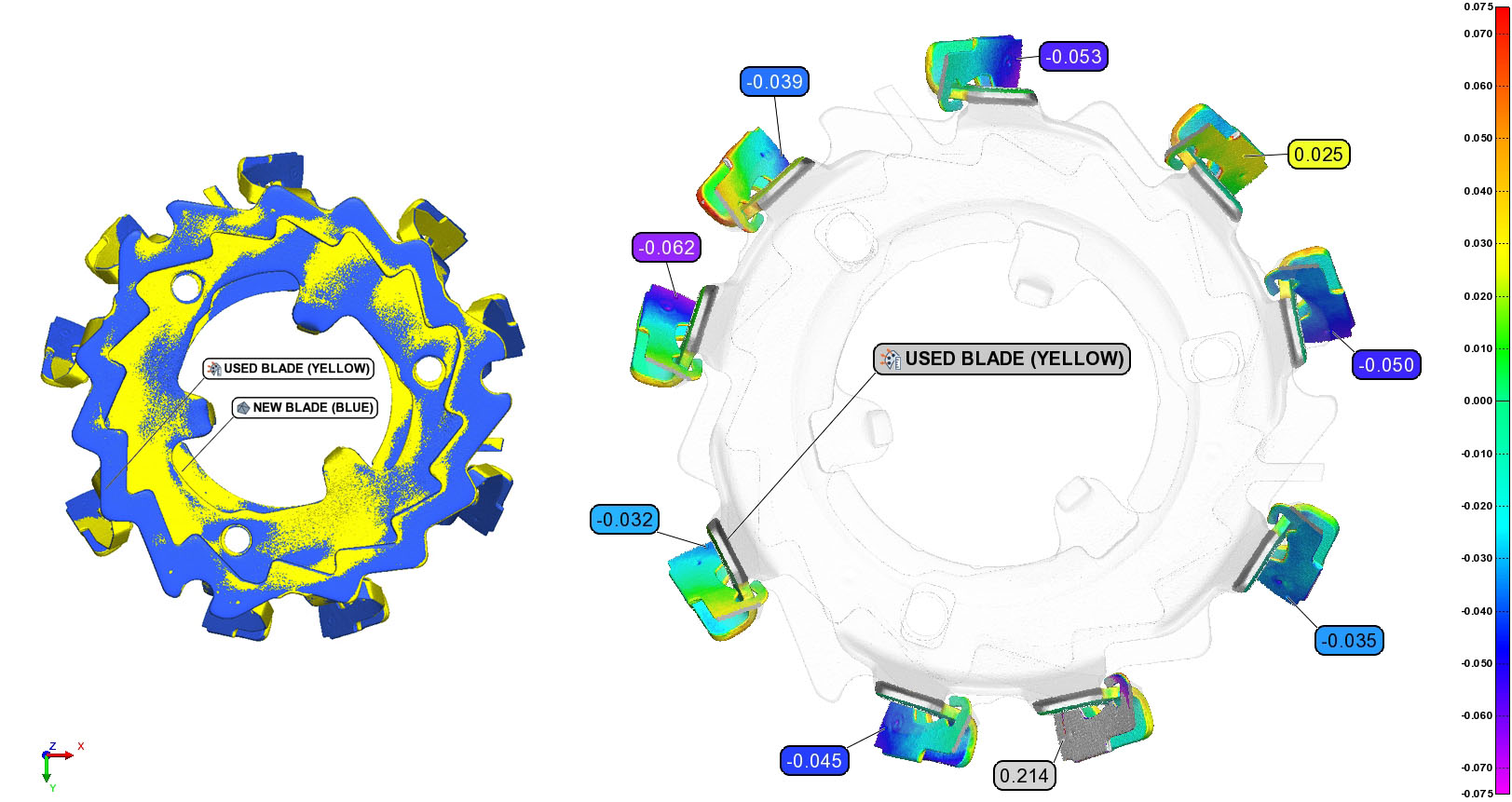

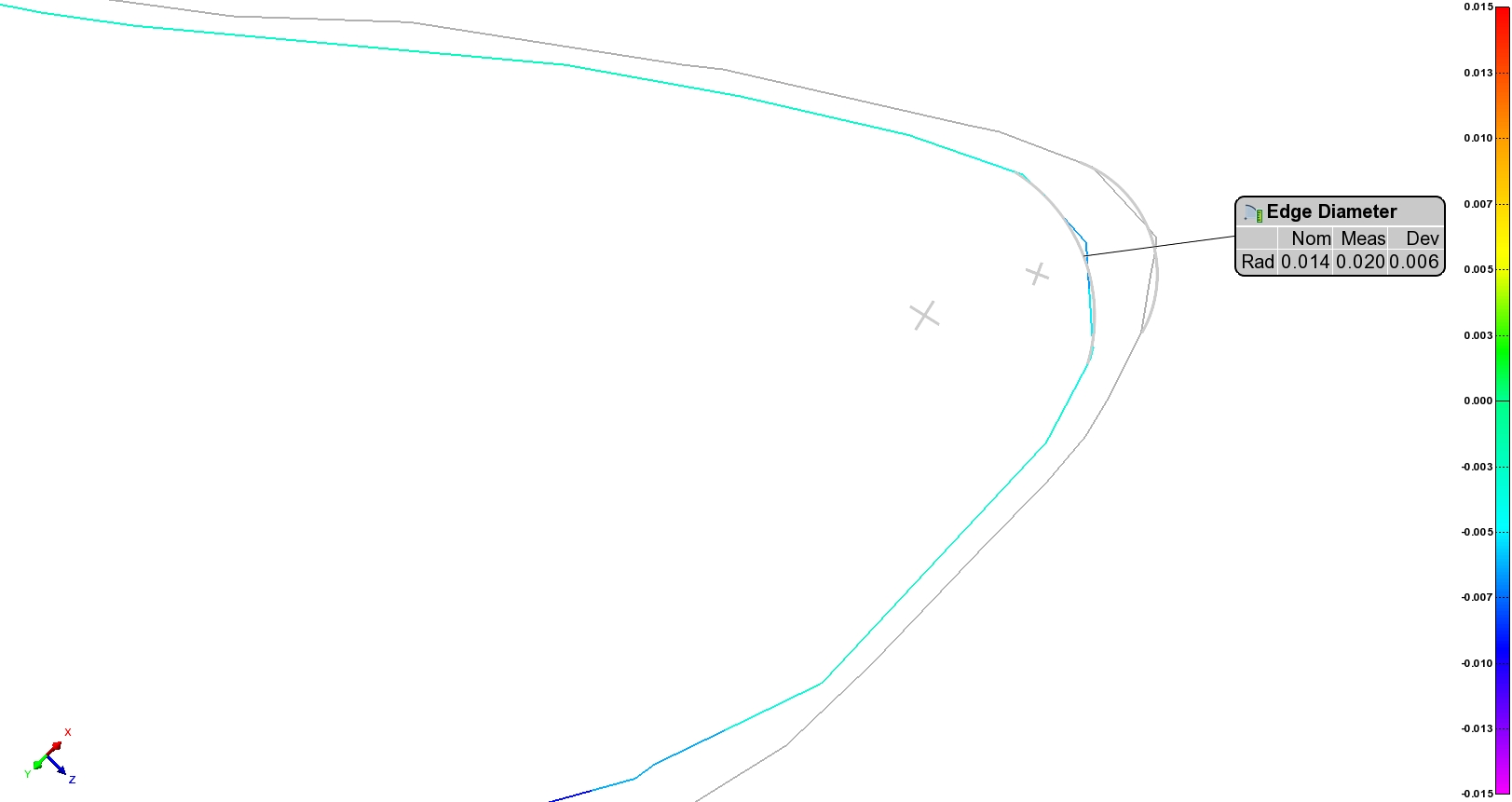

CT Scanning & Reverse Engineering Complex Assemblies

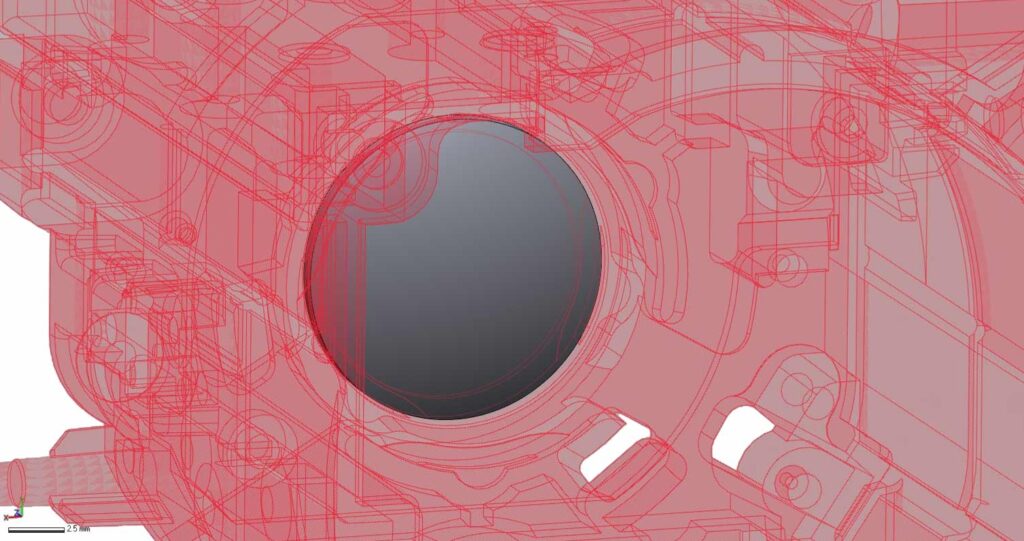

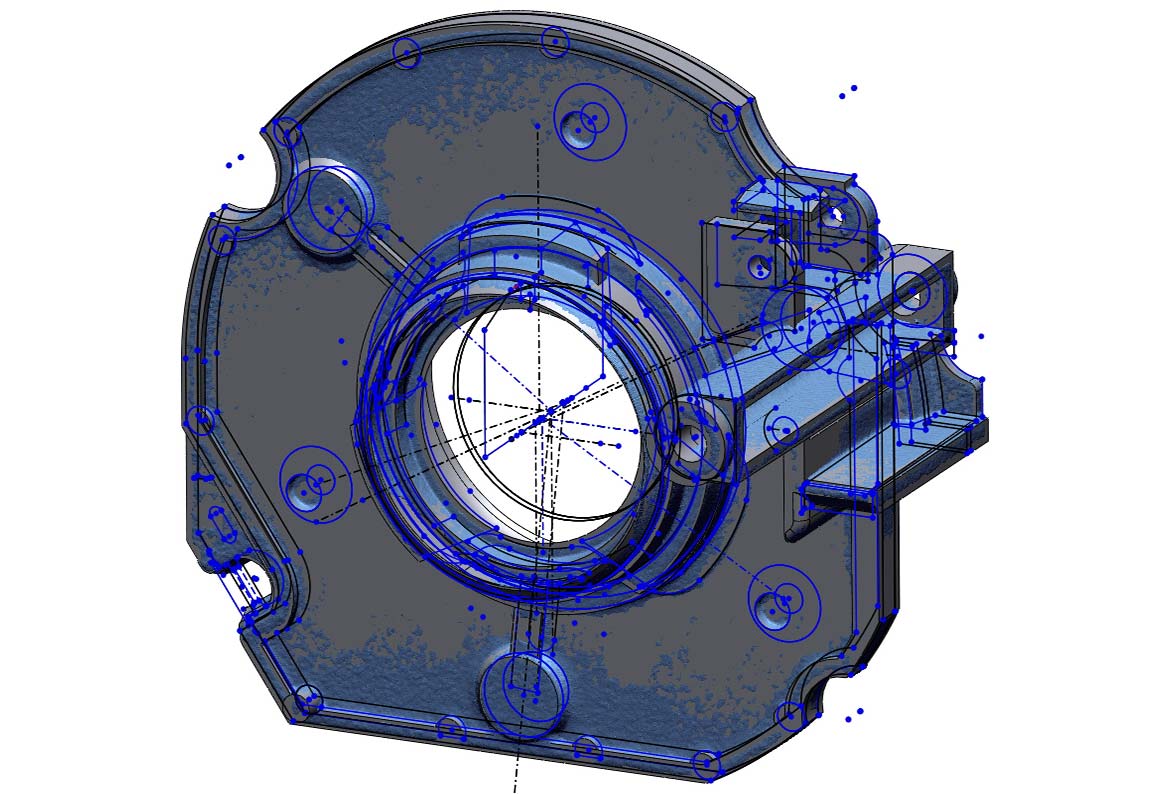

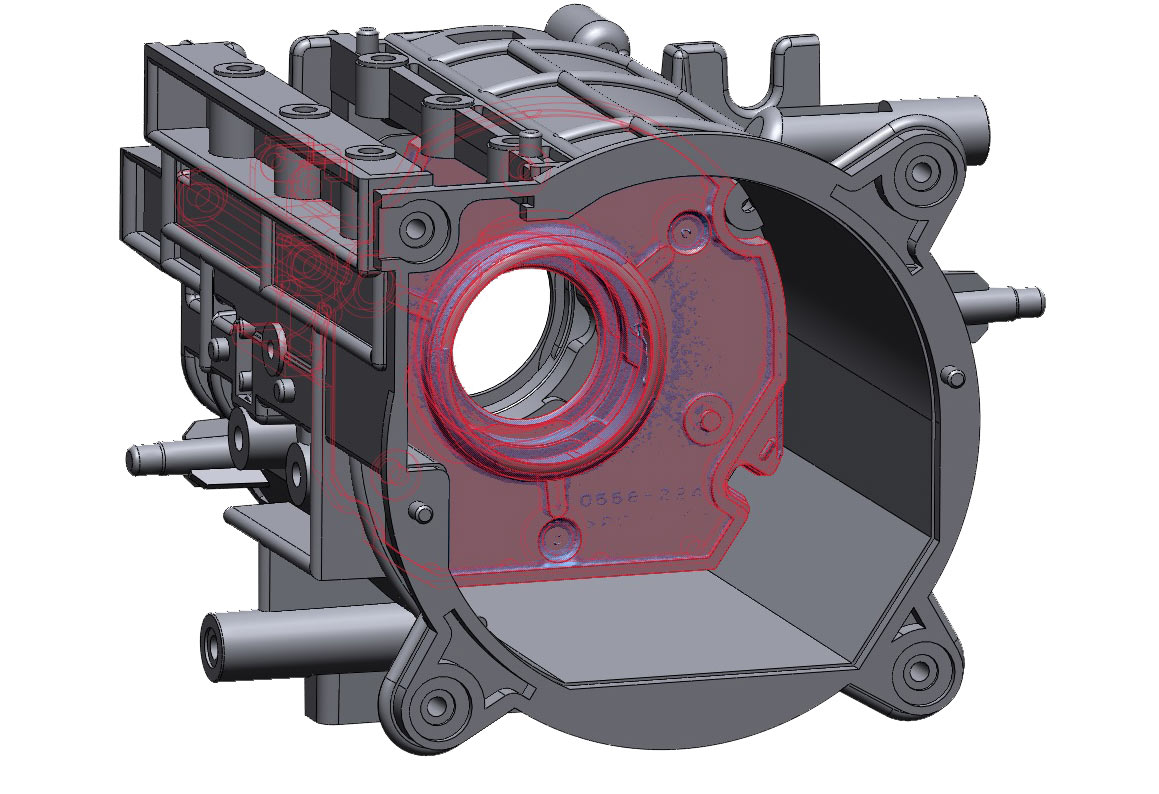

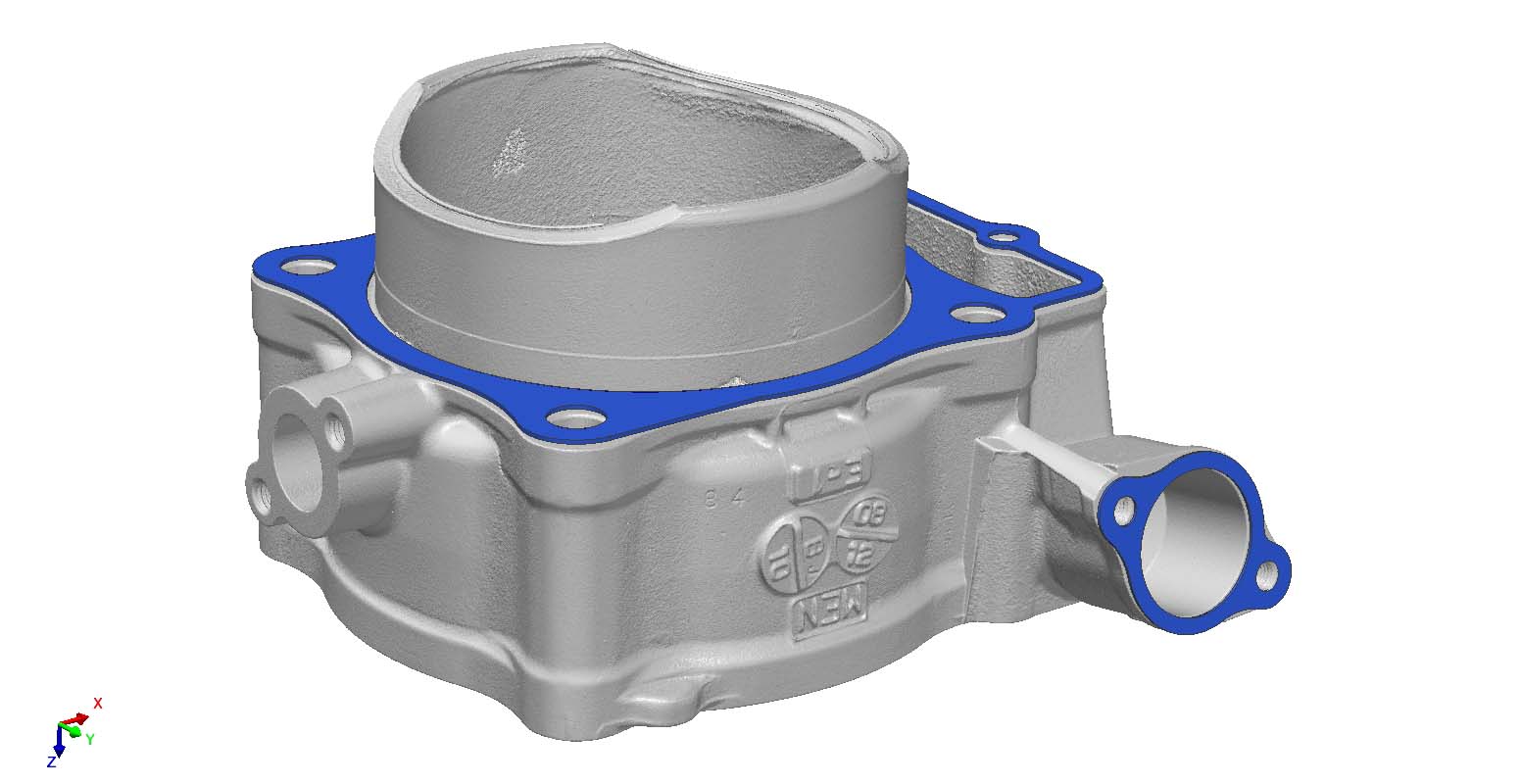

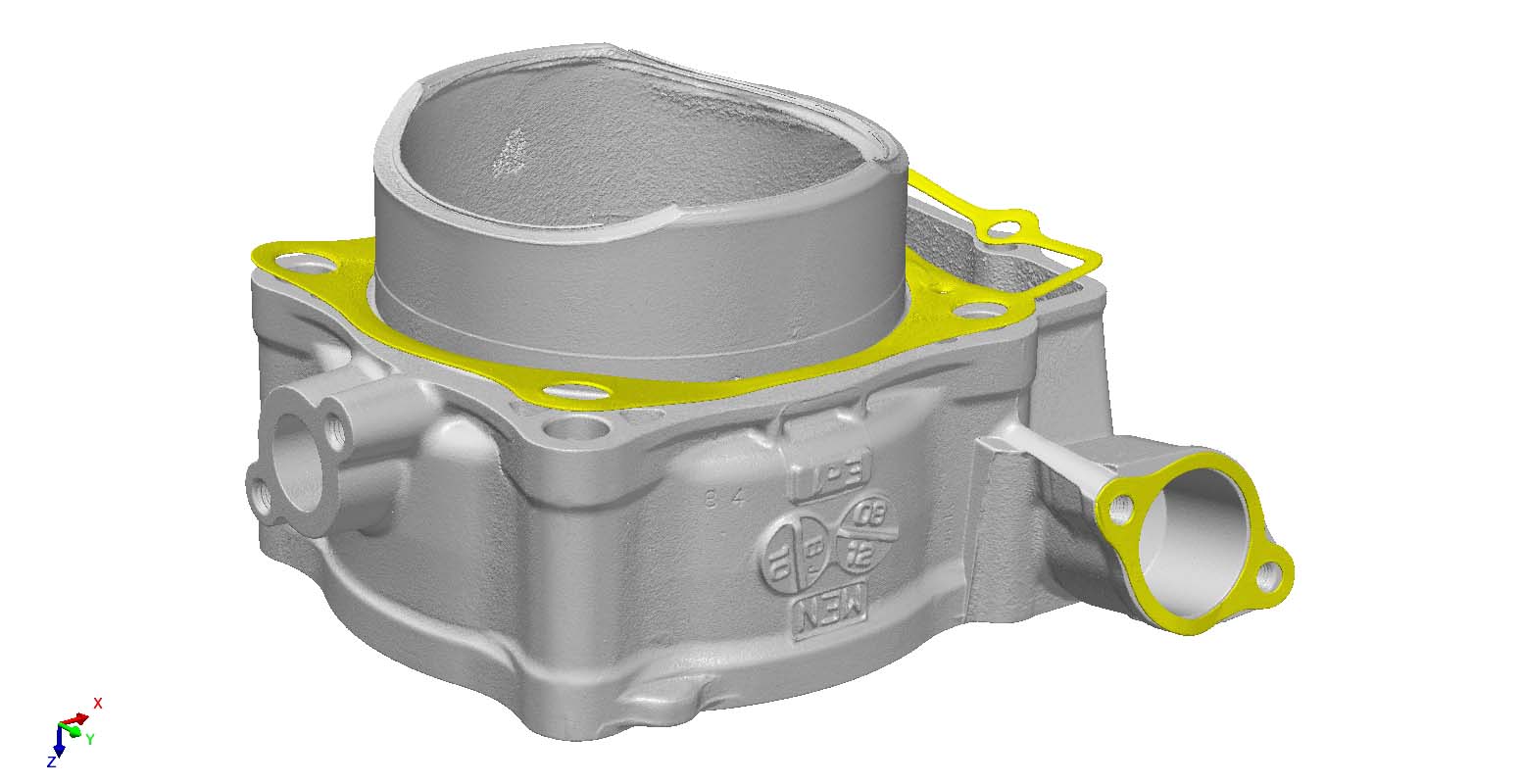

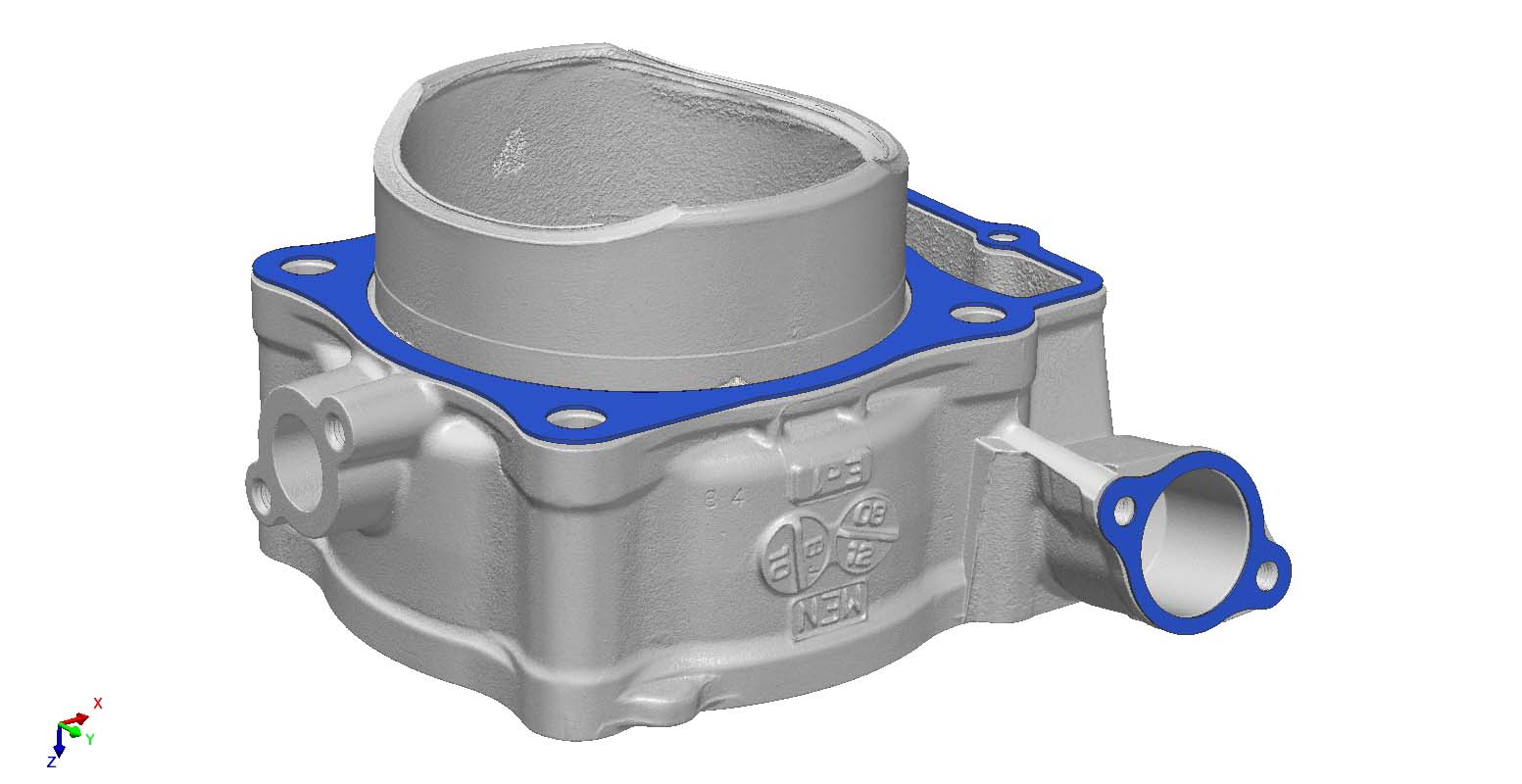

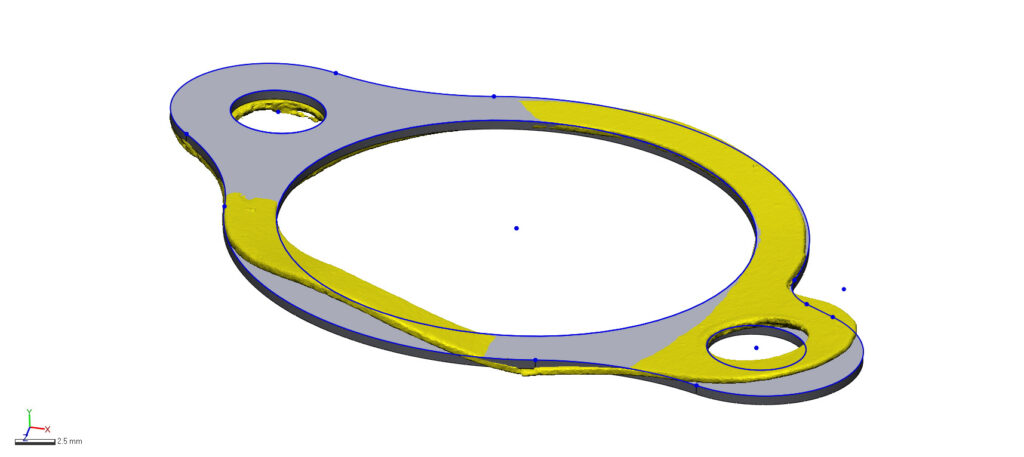

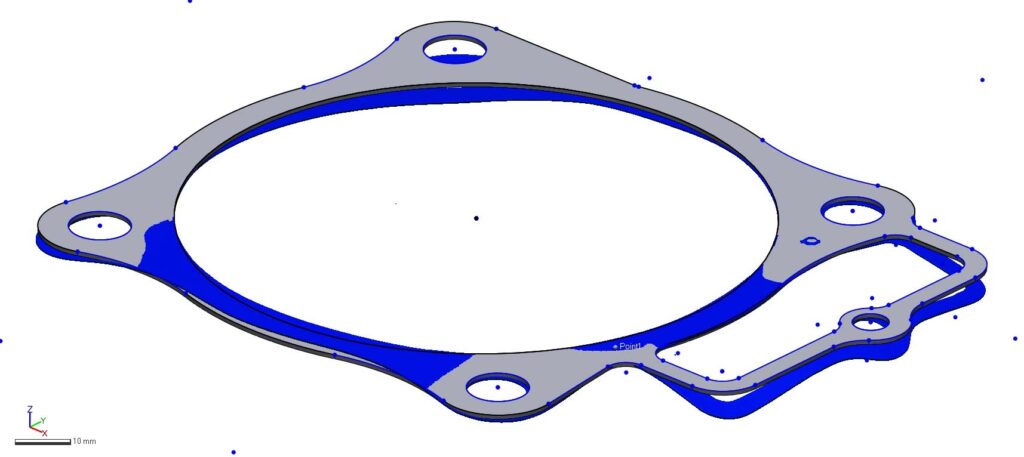

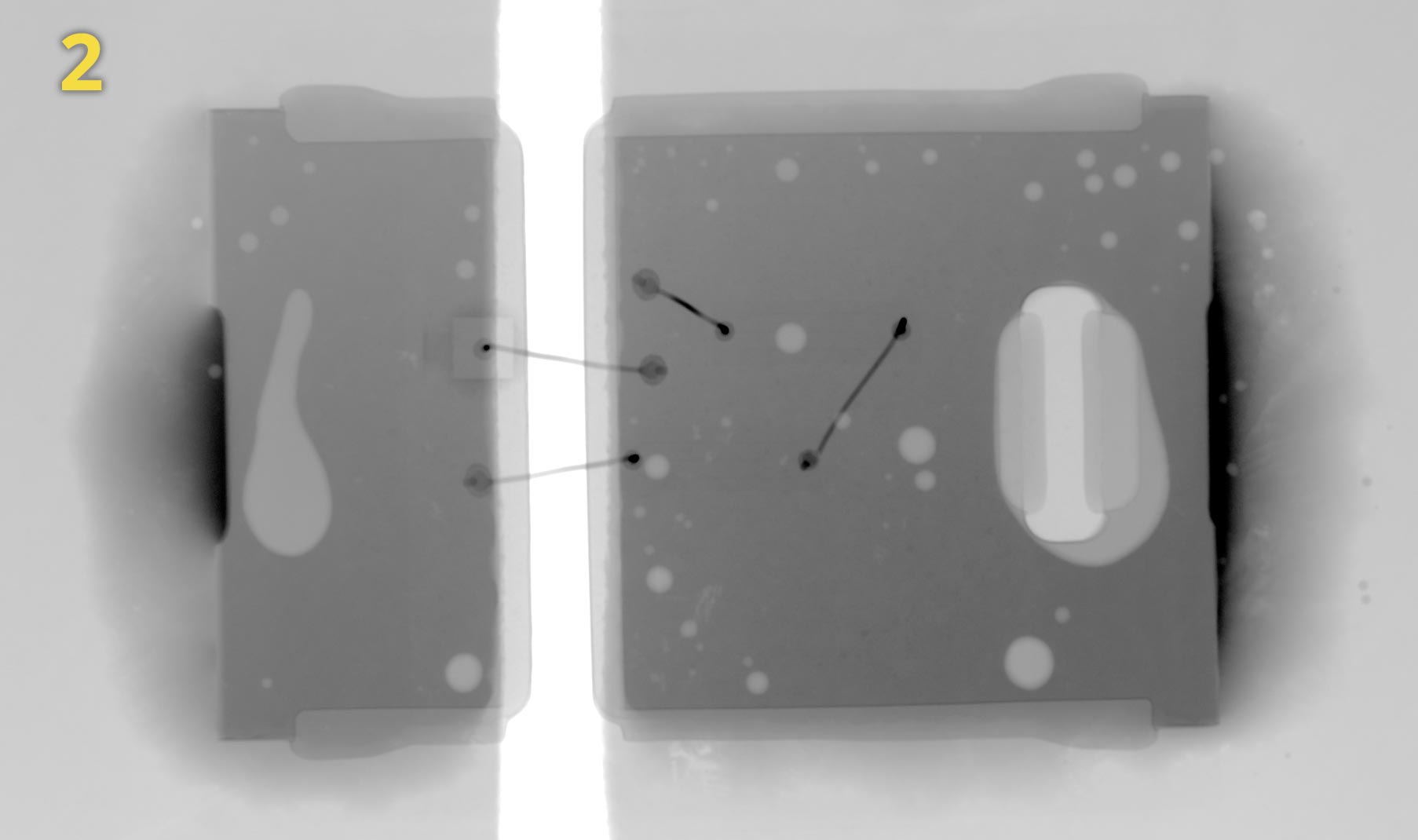

Reverse Engineering Components for Fit & Function

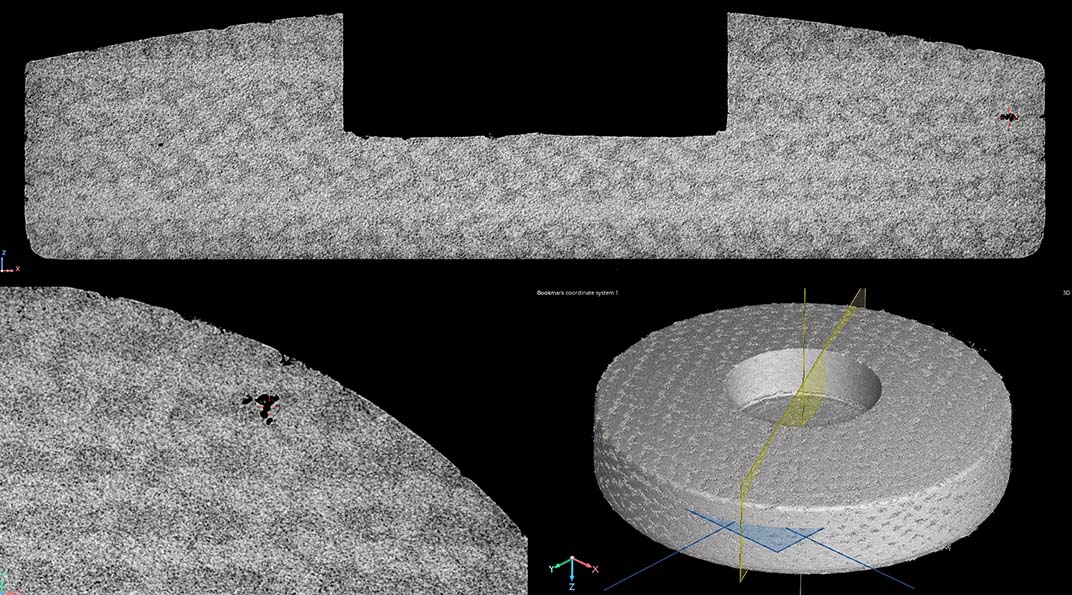

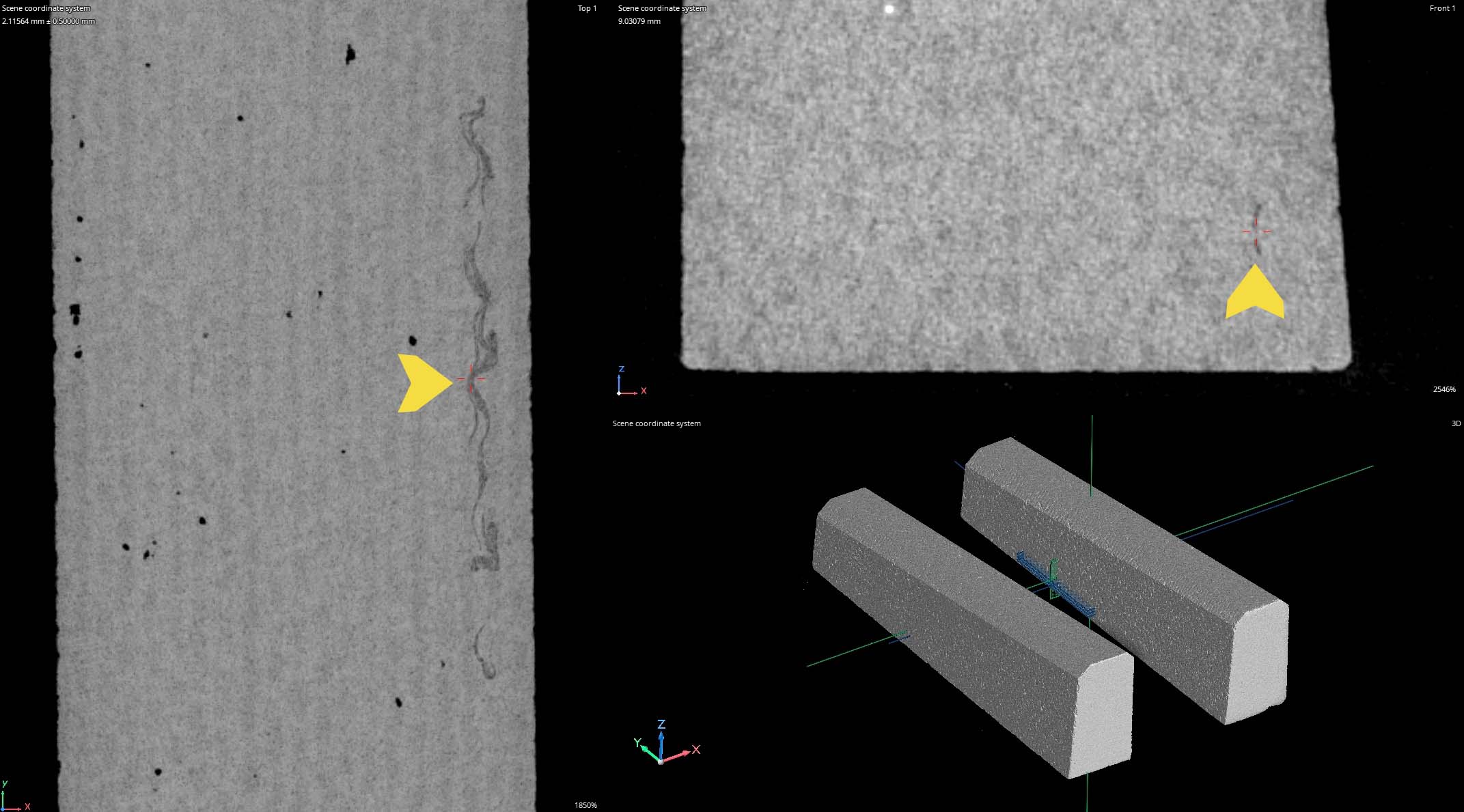

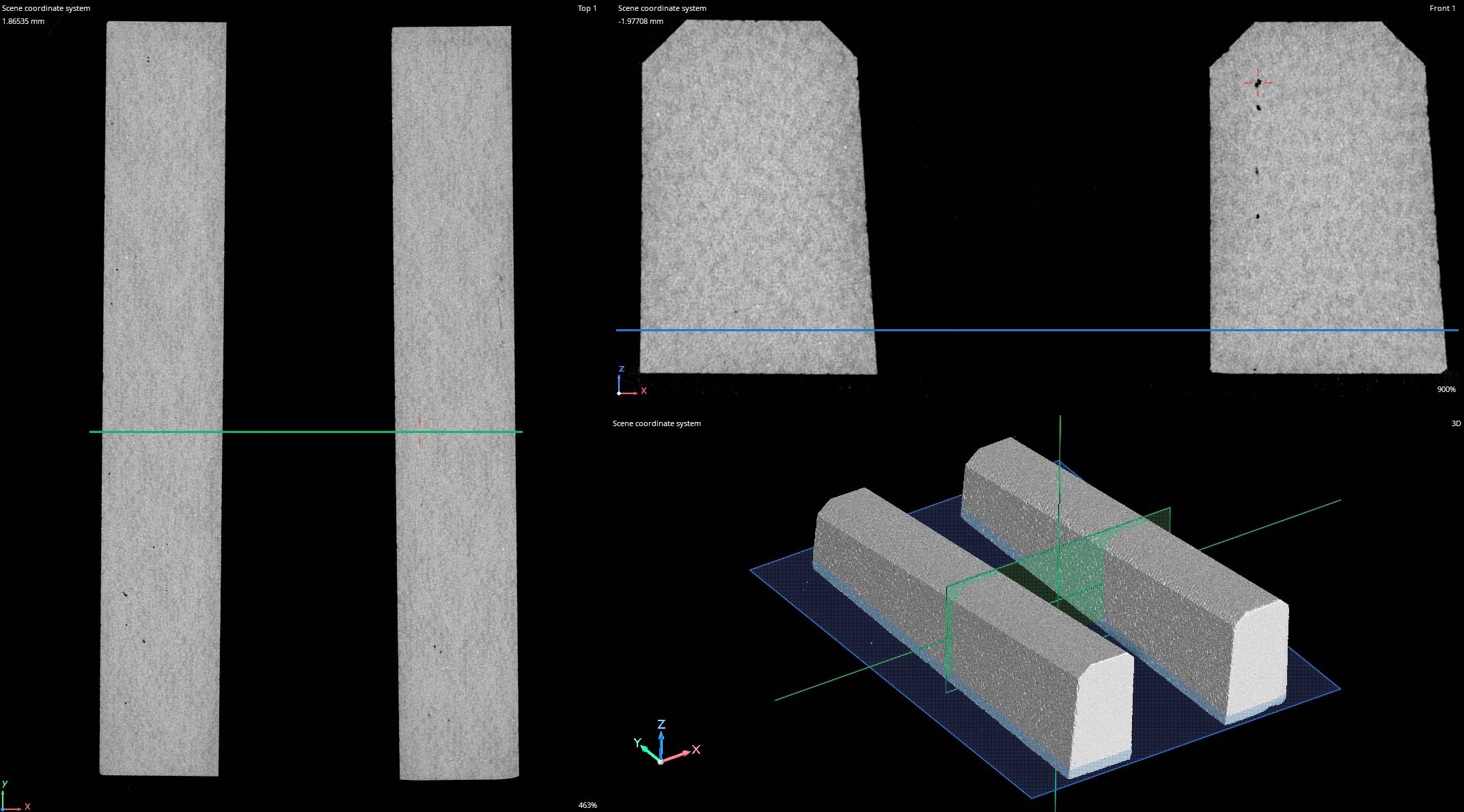

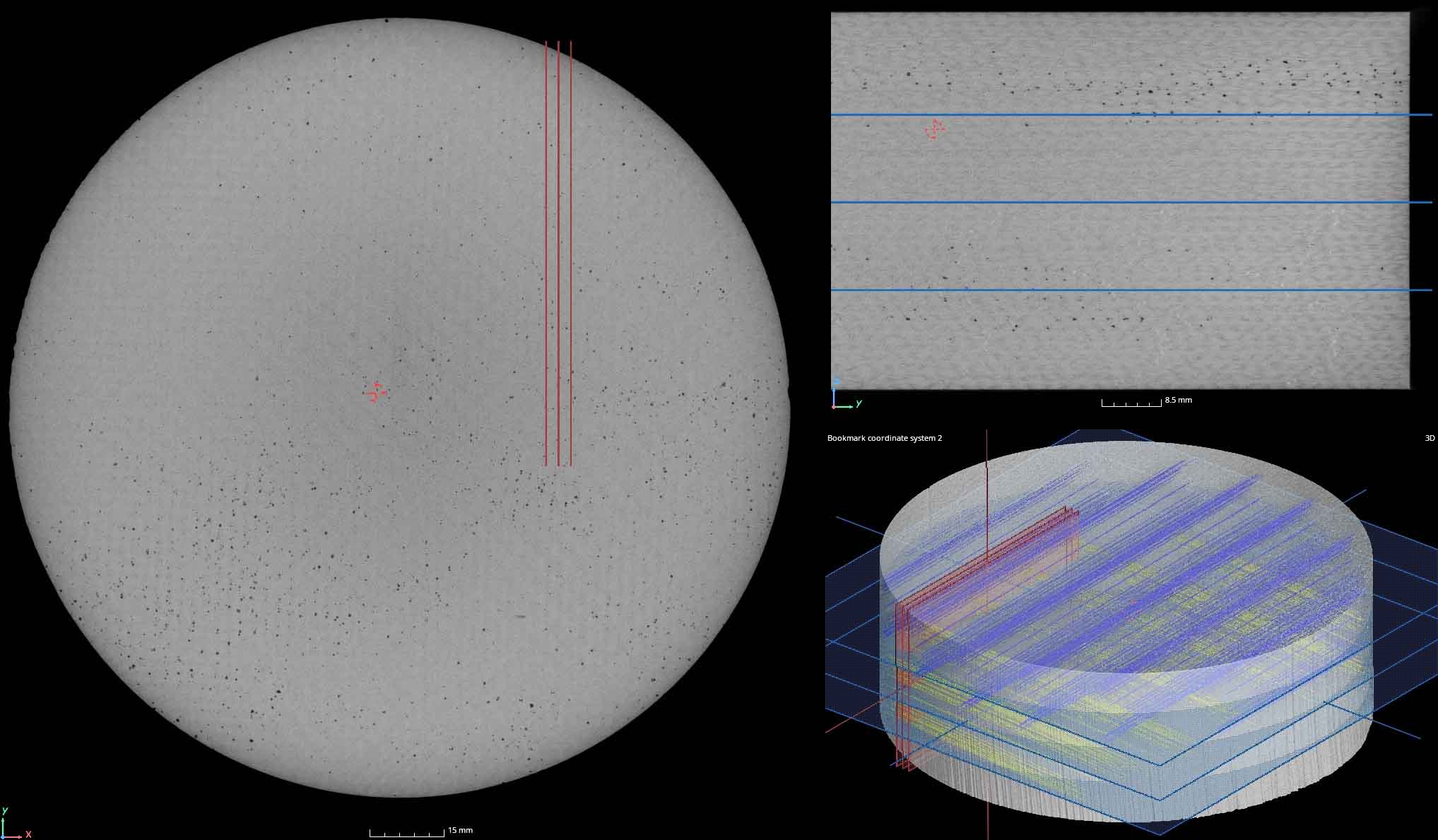

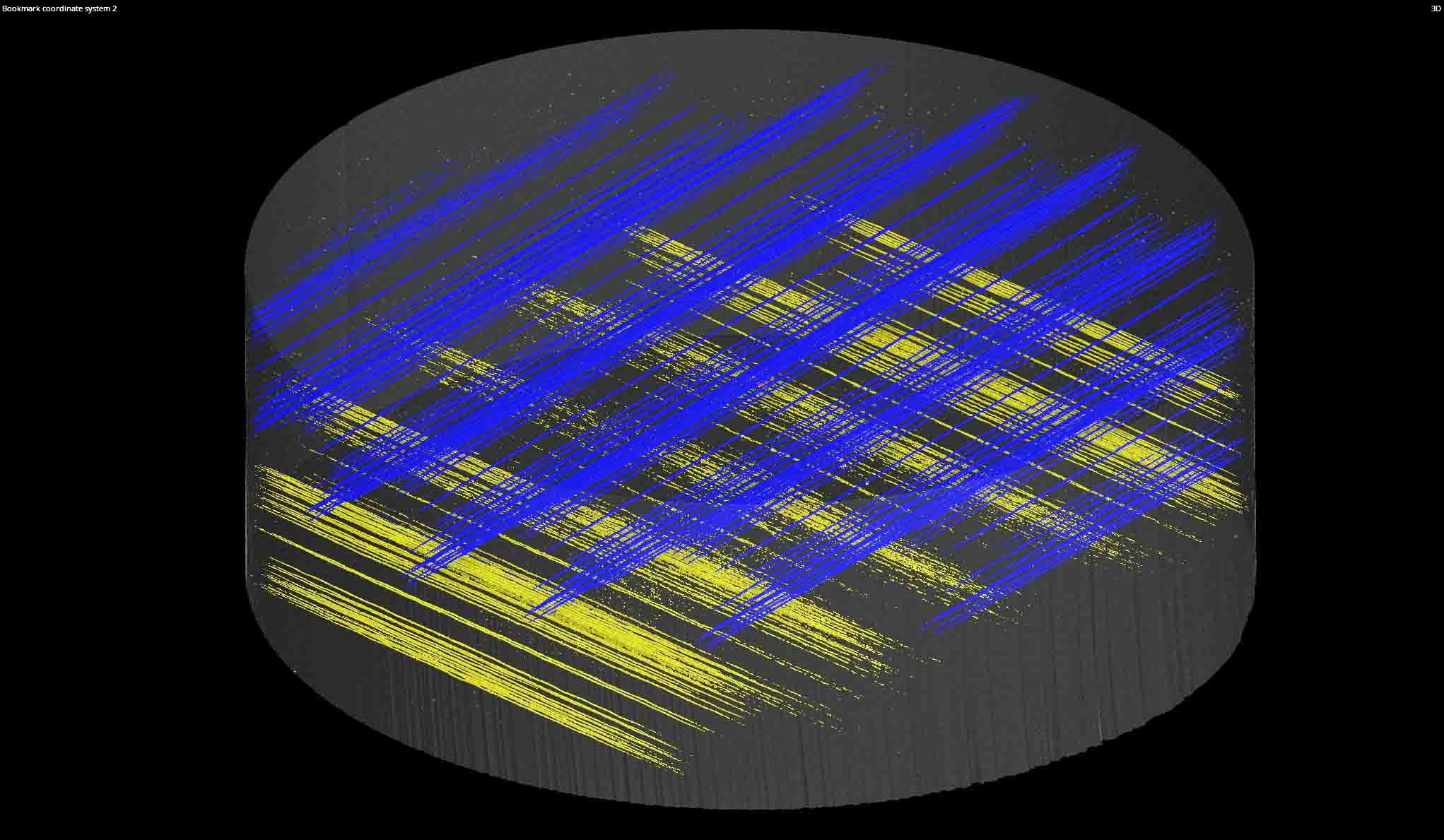

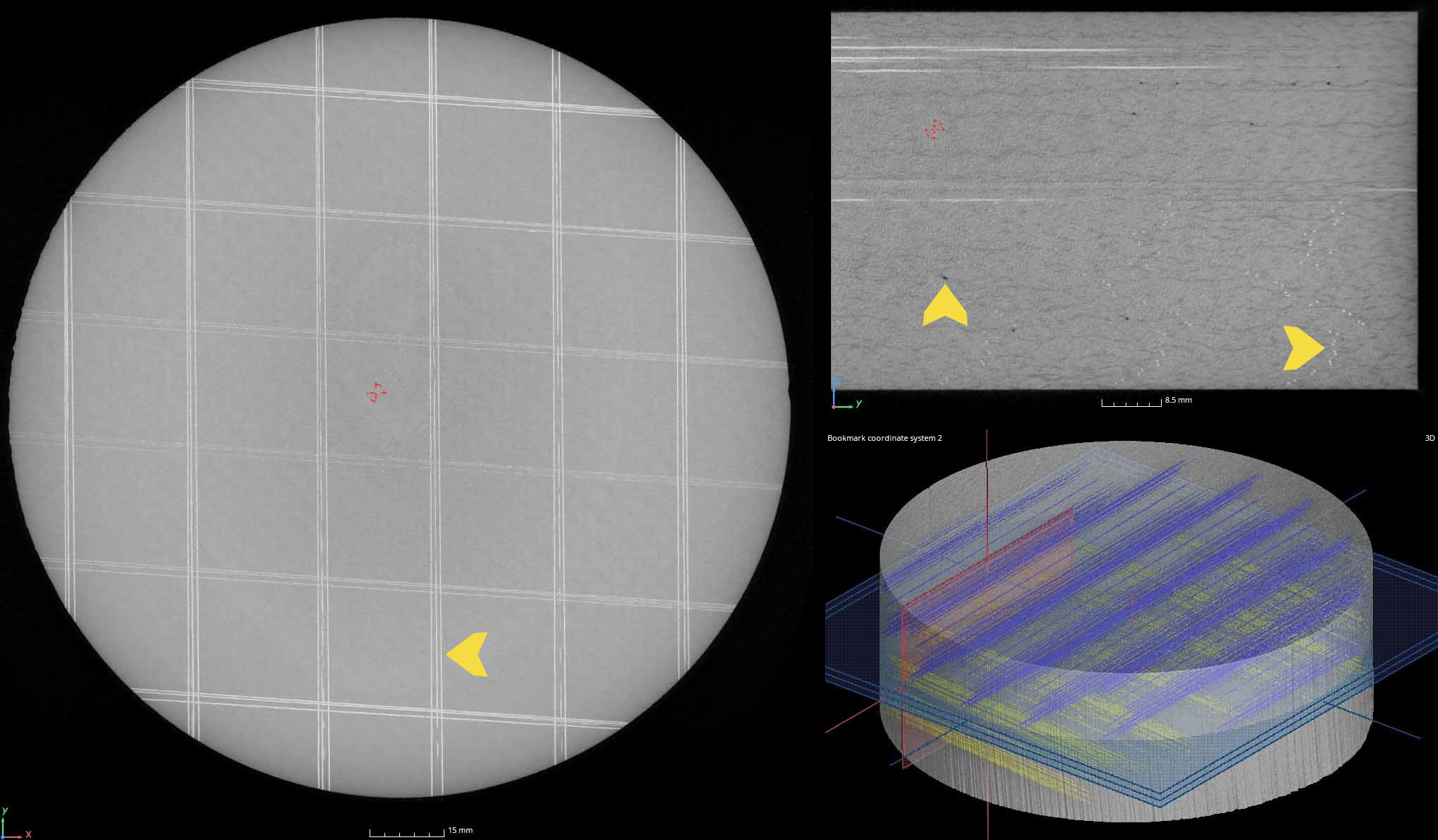

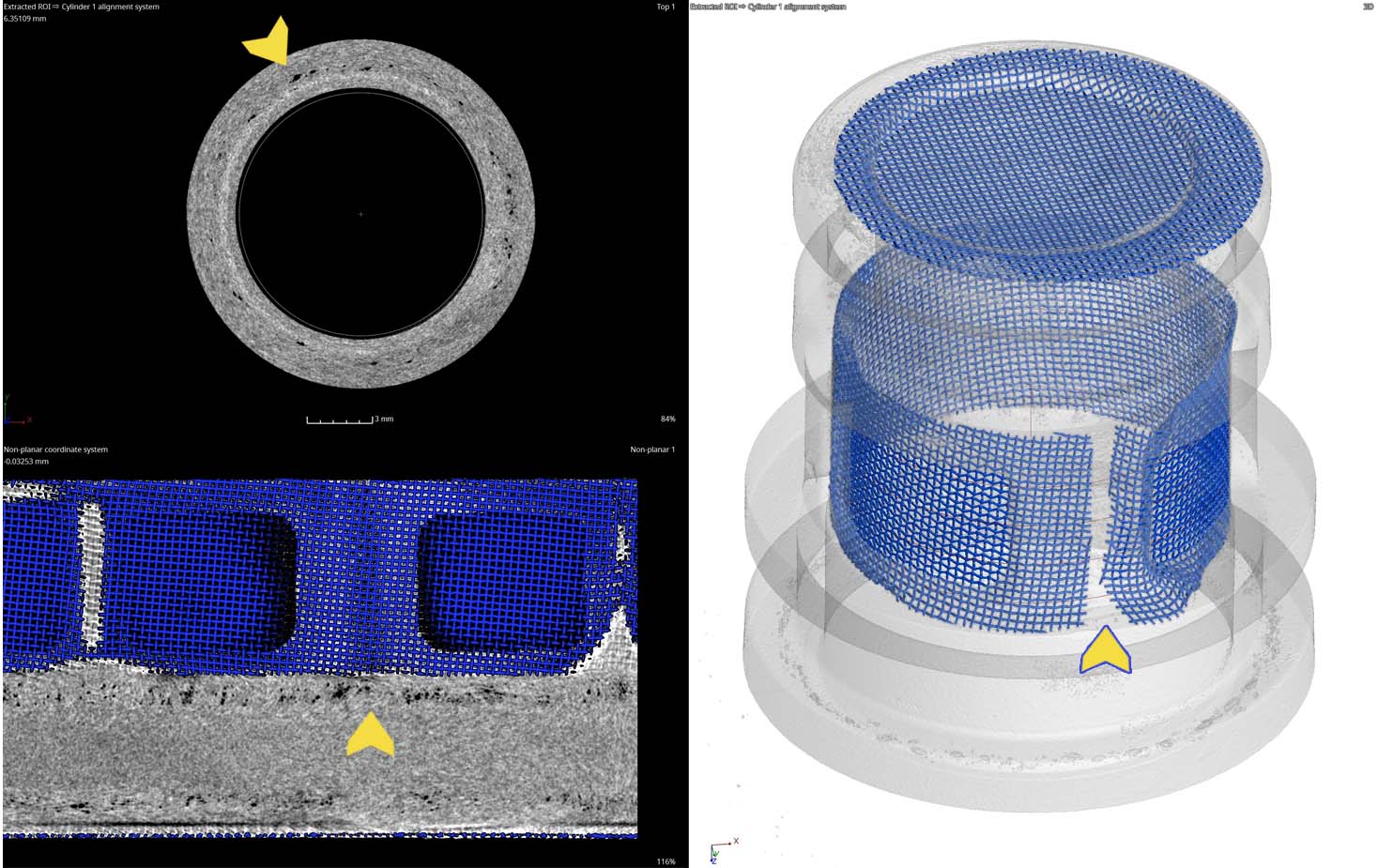

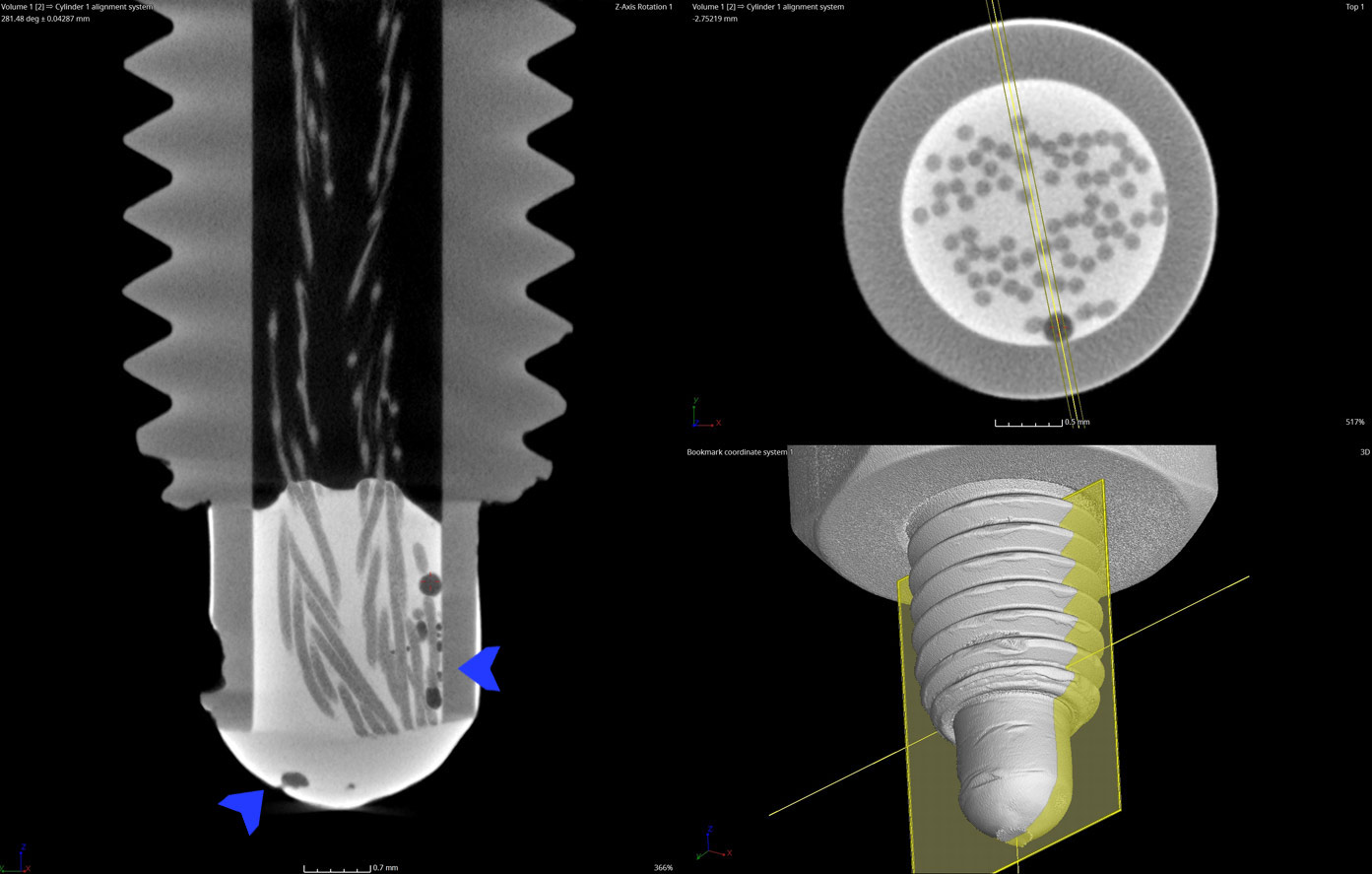

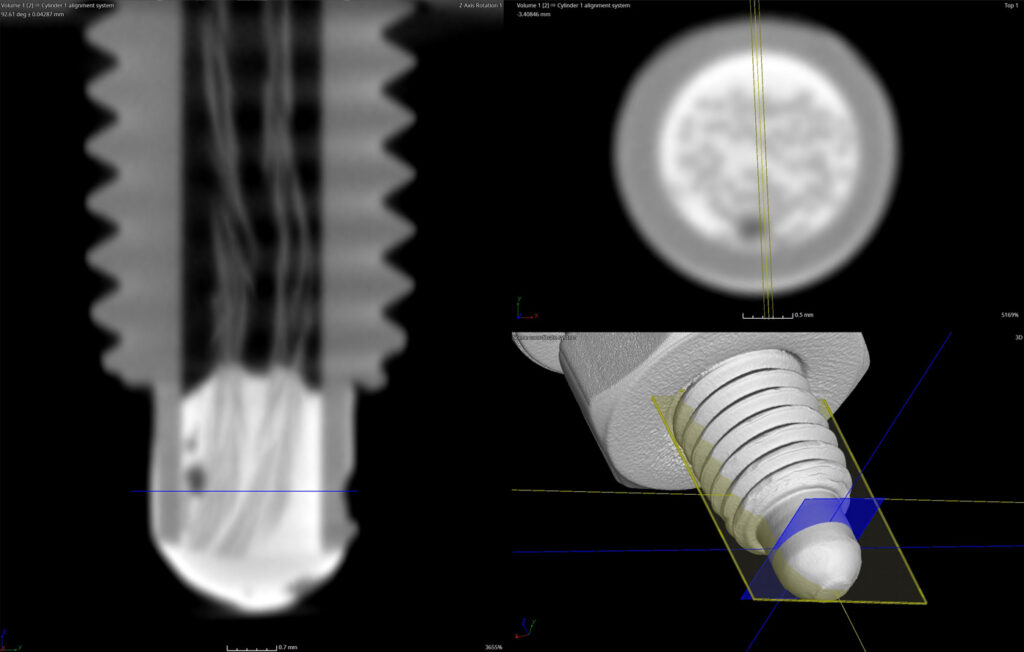

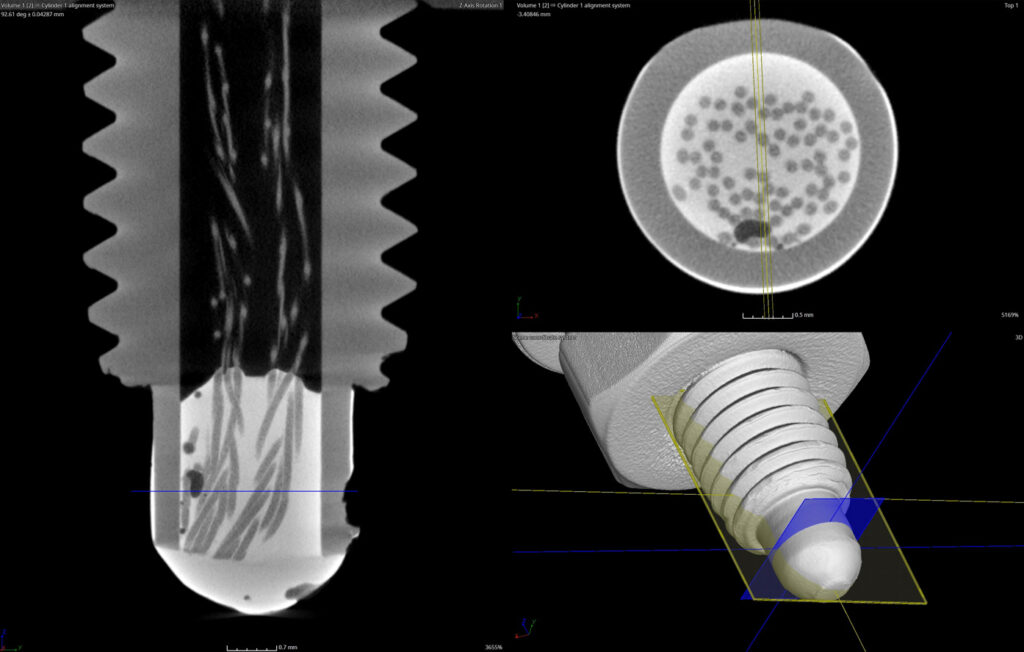

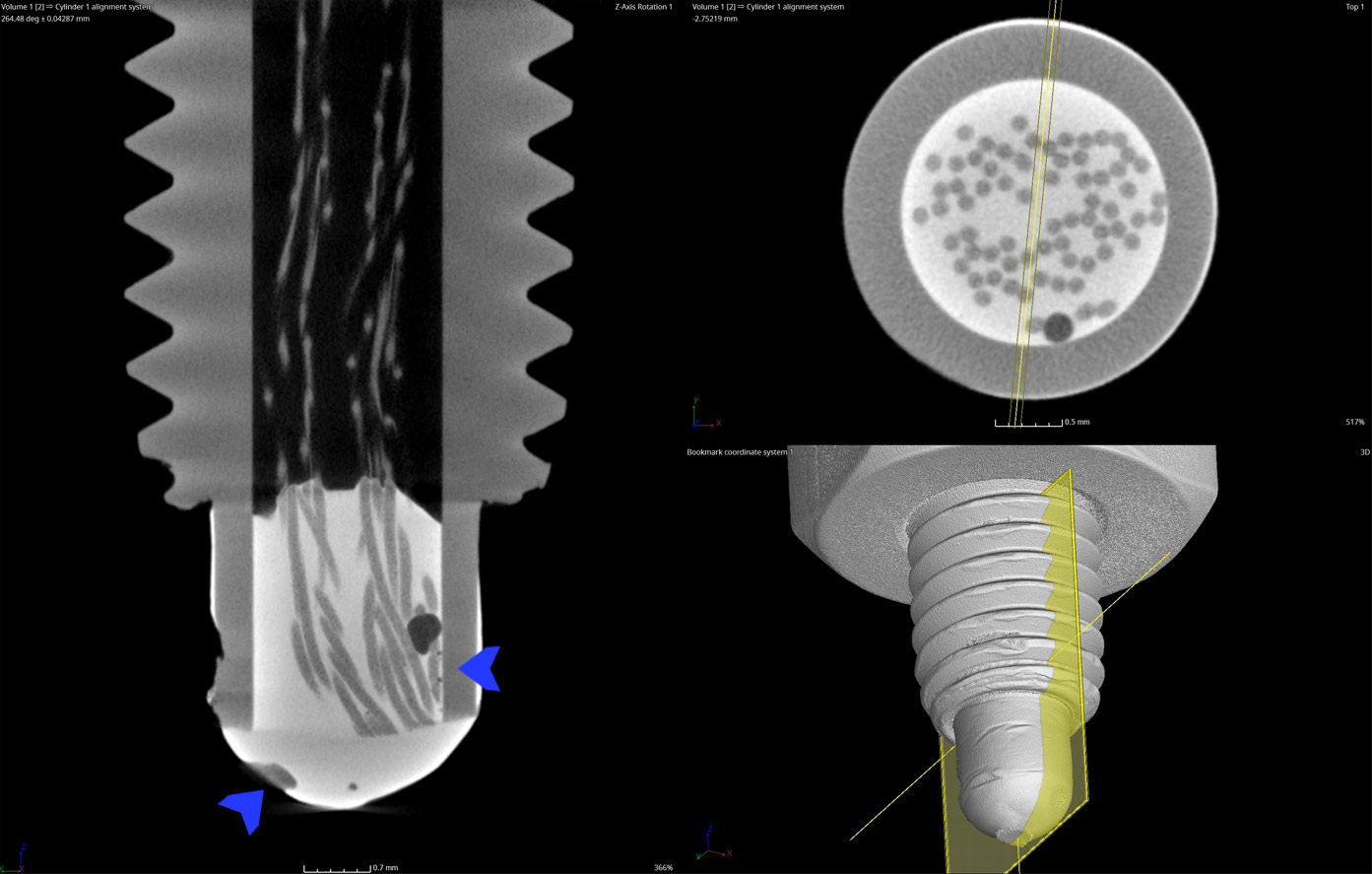

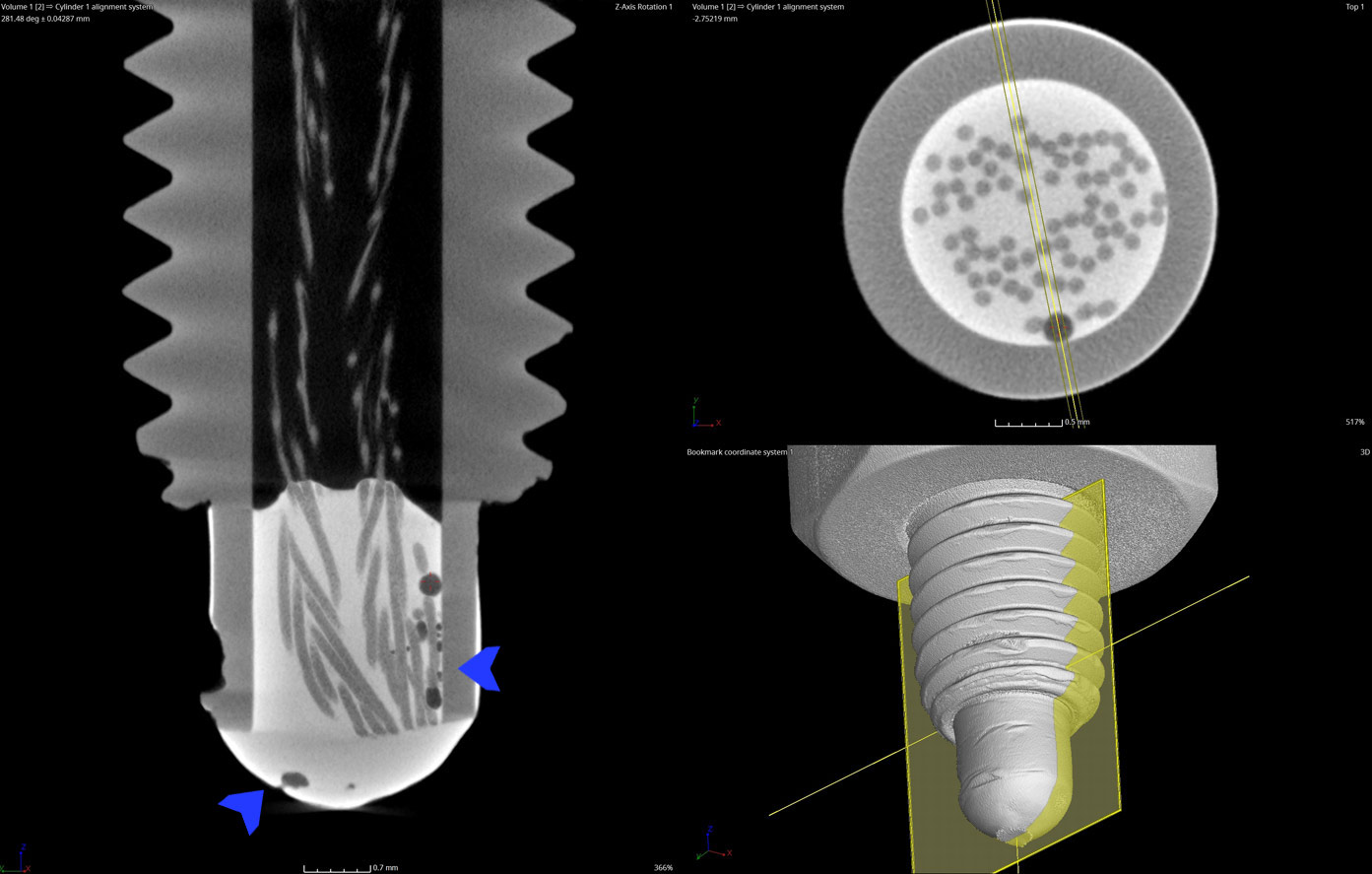

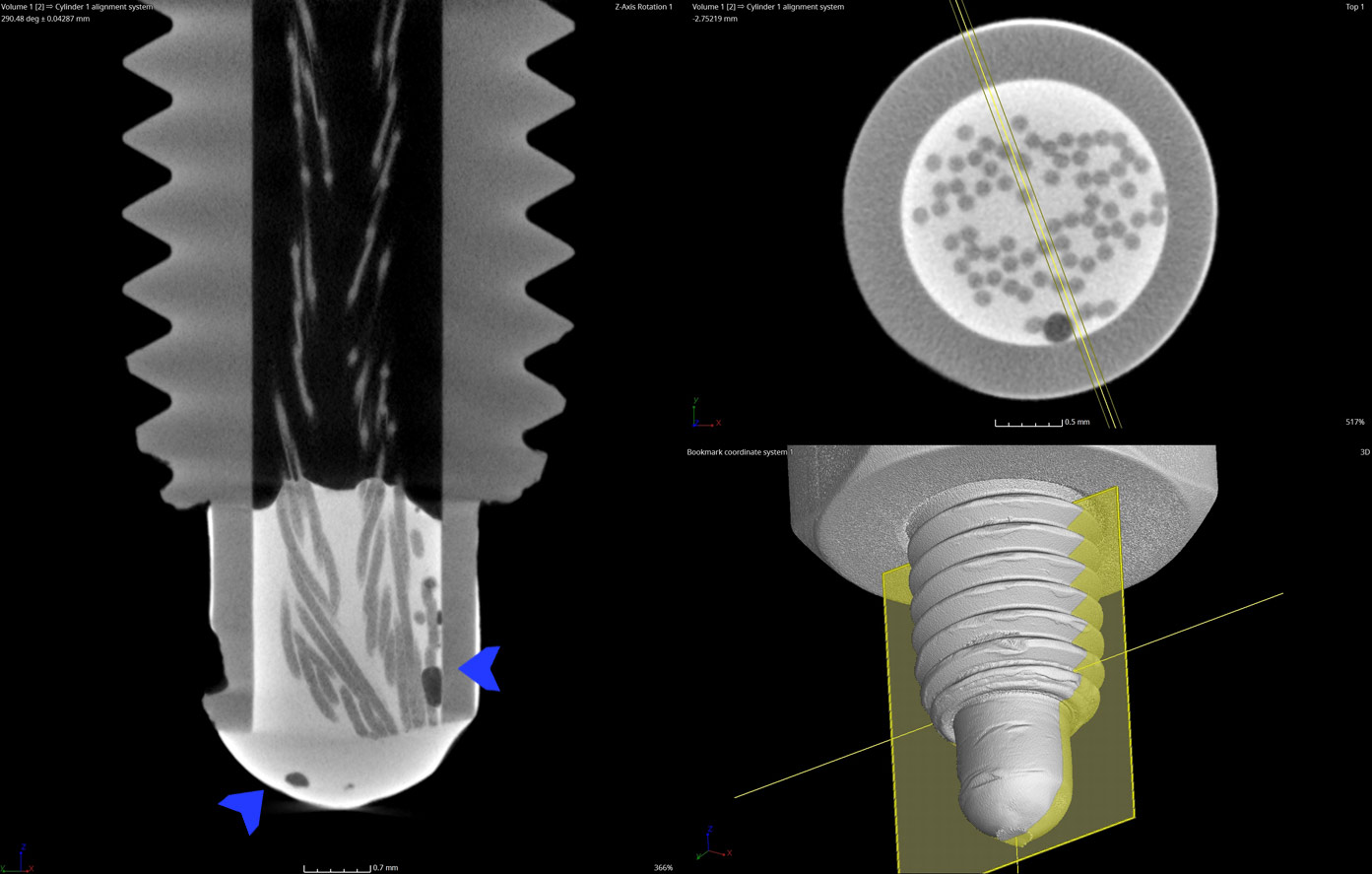

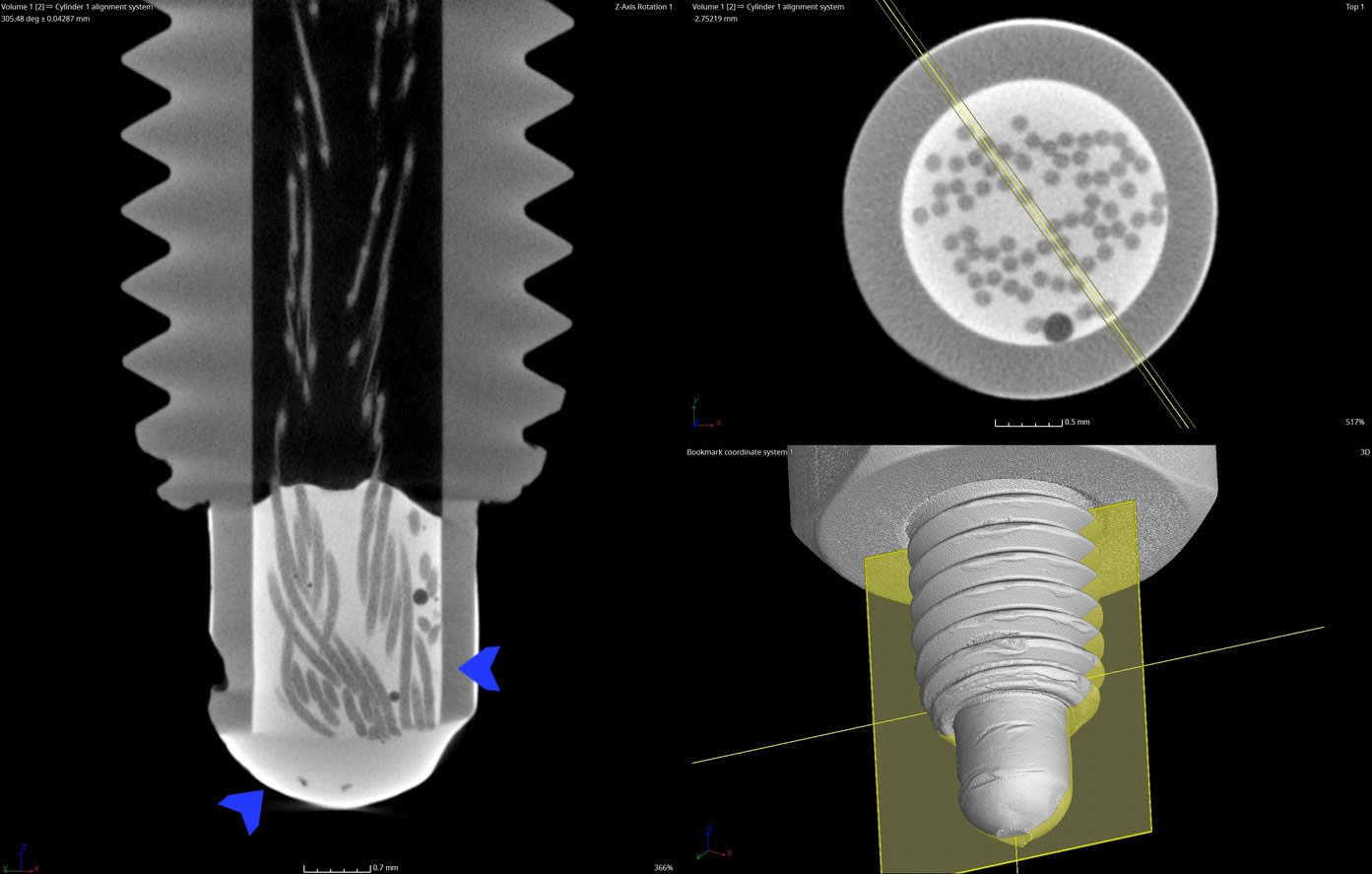

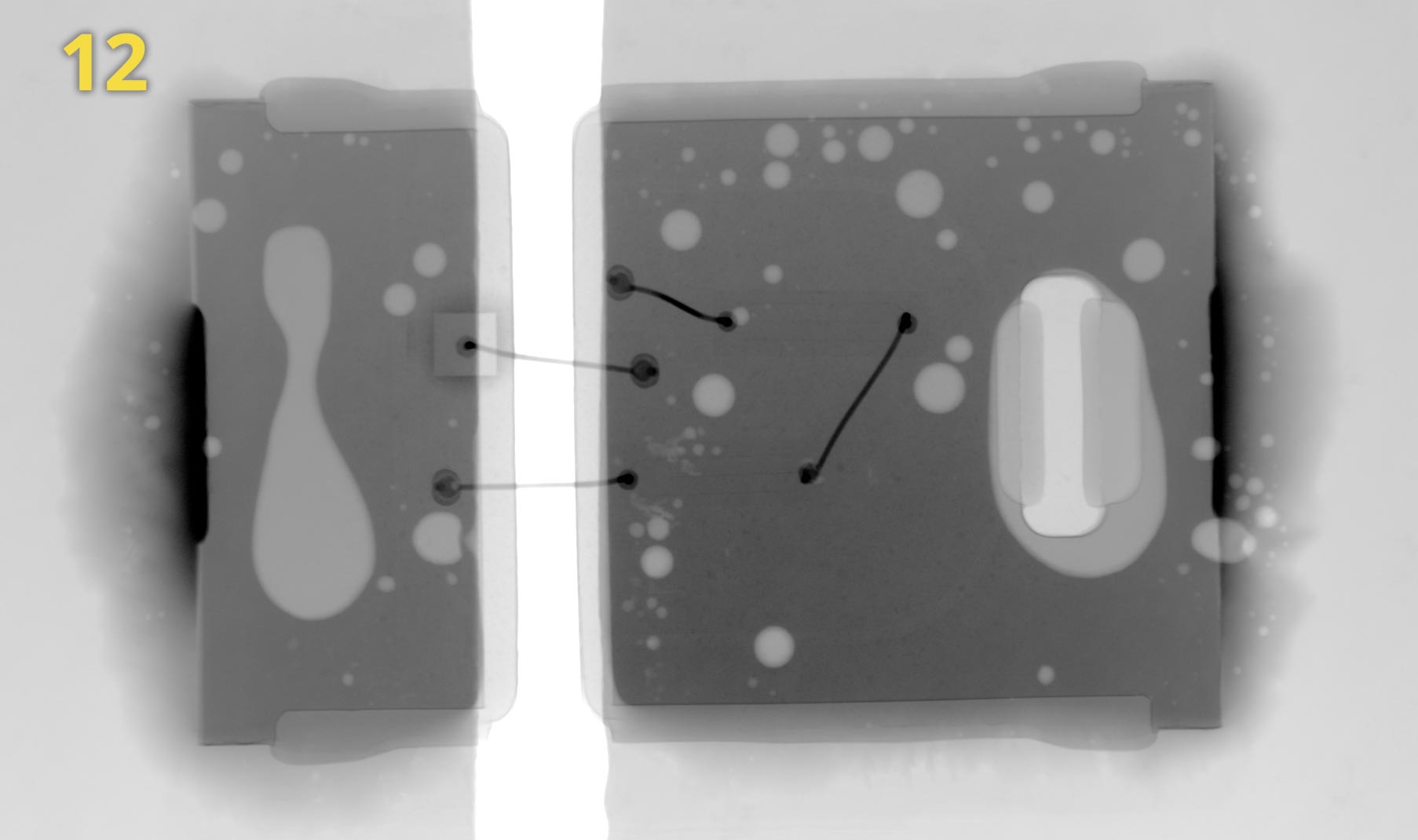

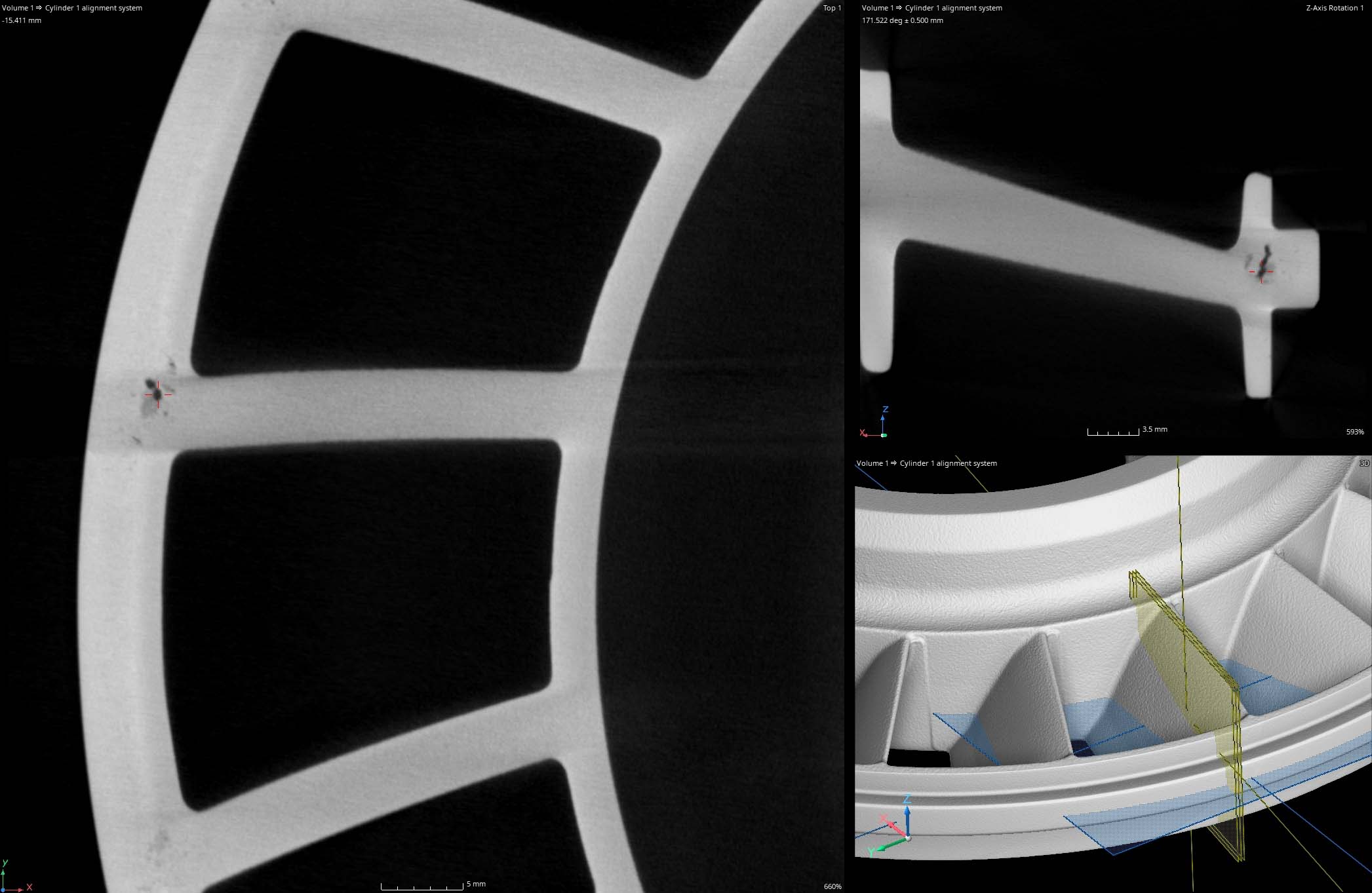

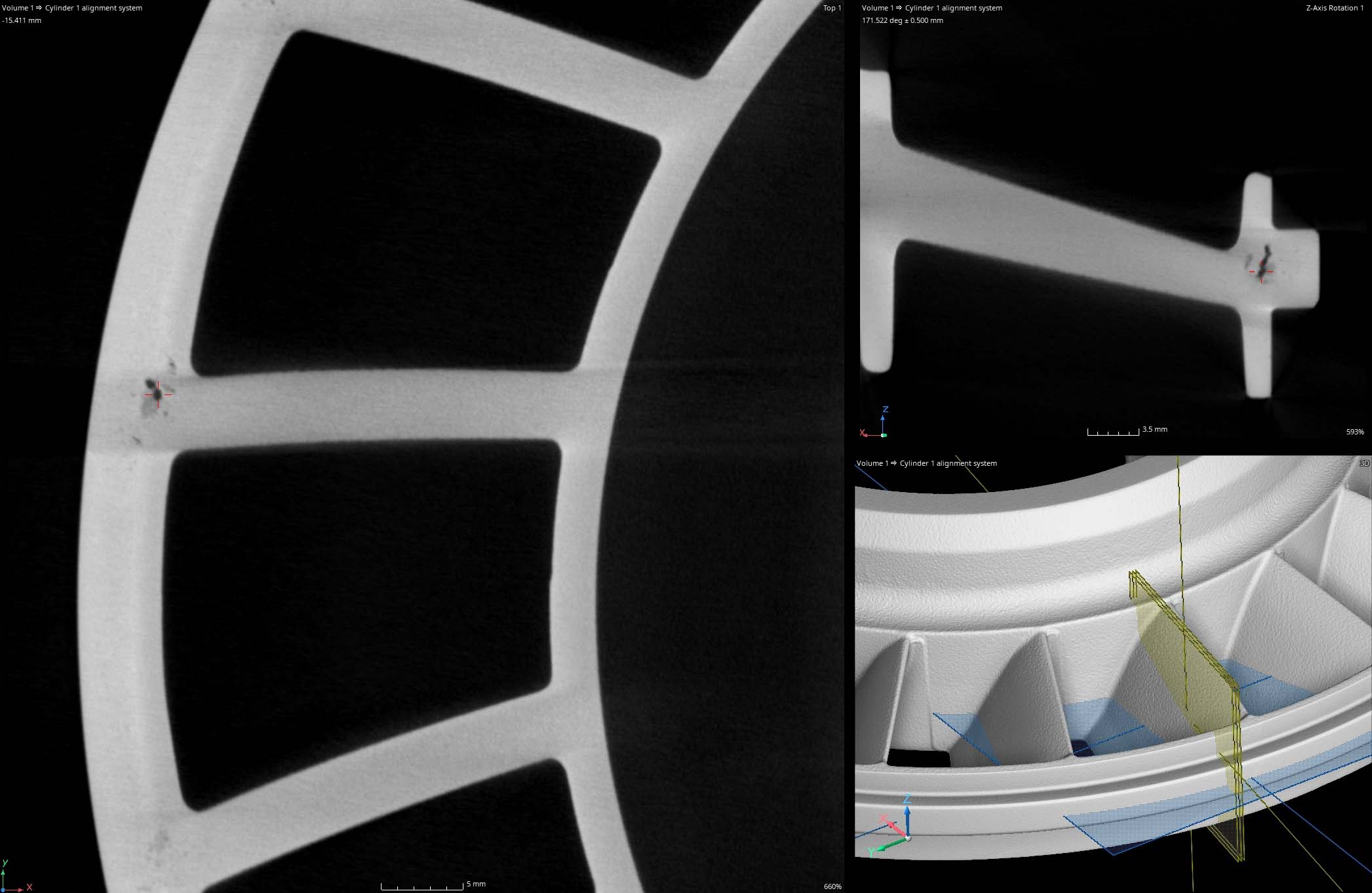

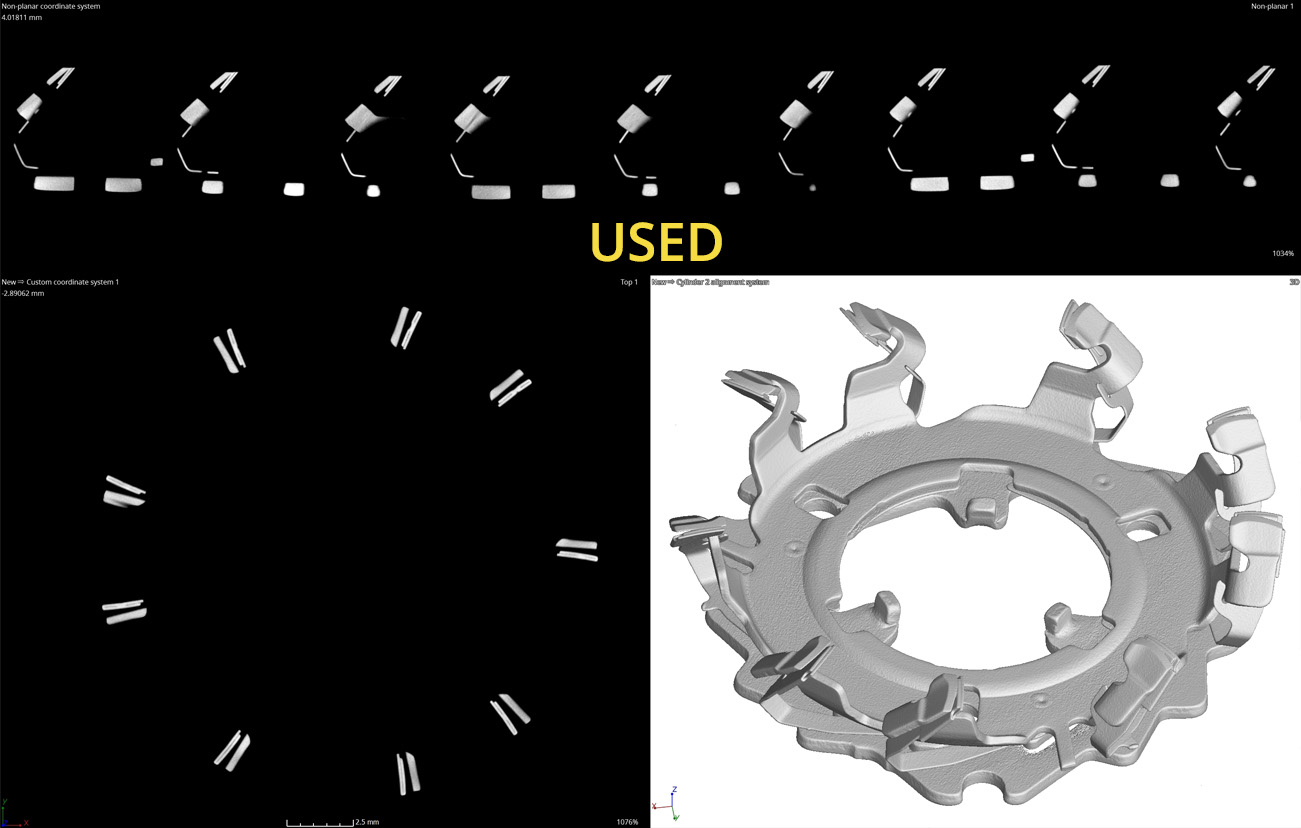

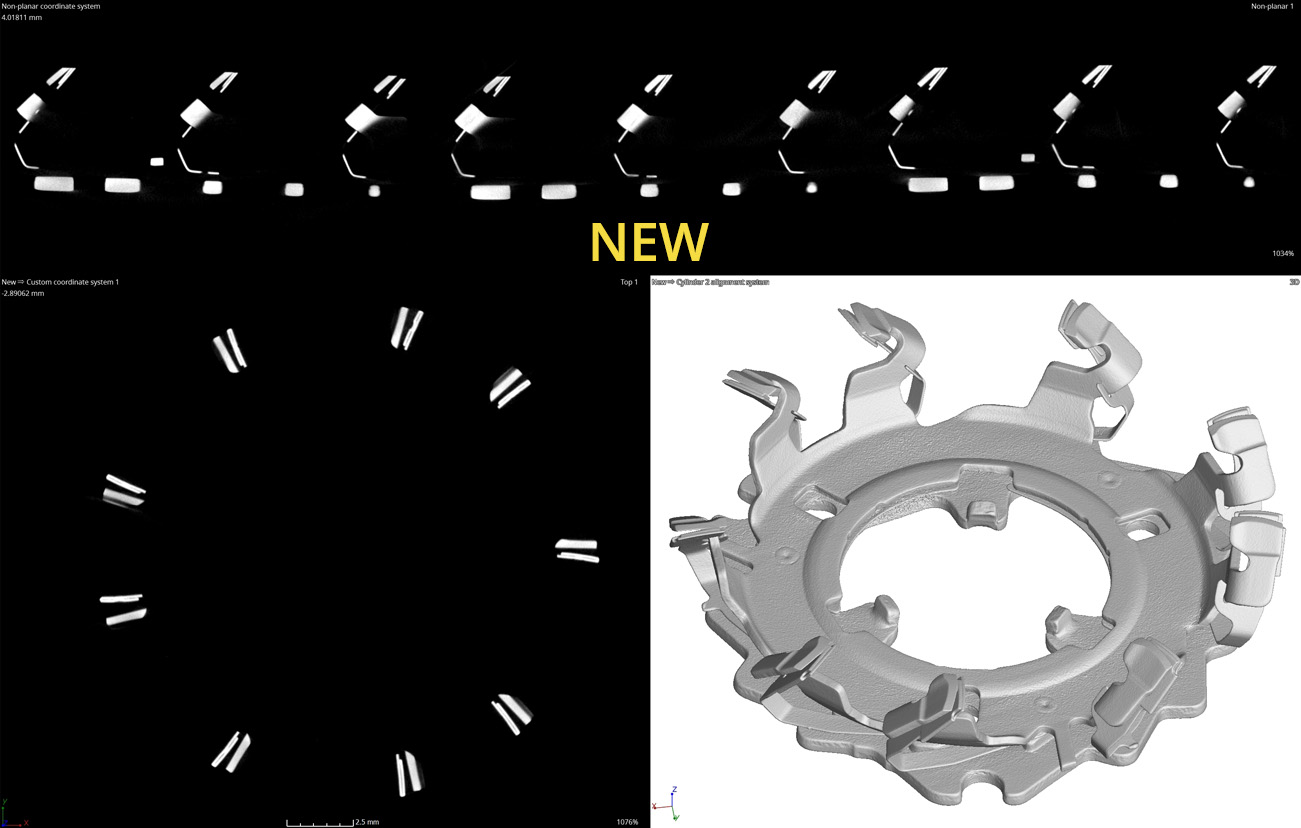

Industrial CT Scanning Micro Filters

Micro-CT scanning allows us to inspect small components like stainless mesh filters for porosity, gaps, and overmold conditions.

Continue reading