CT SCANNING CASTINGS FOR POROSITY EVALUATION

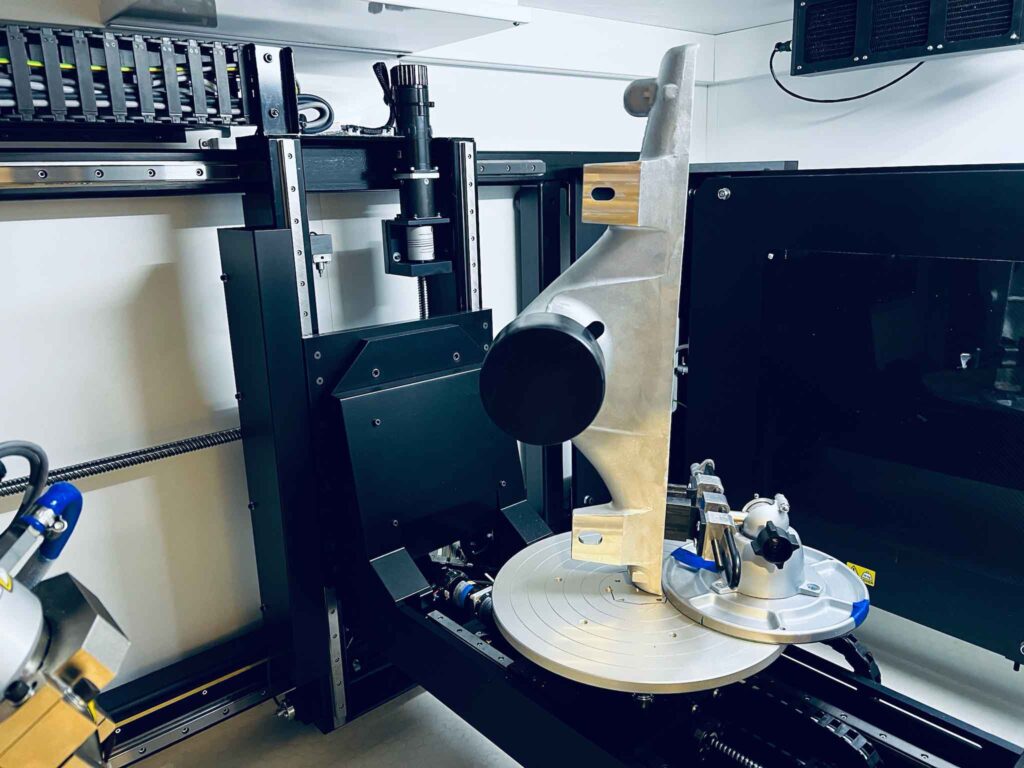

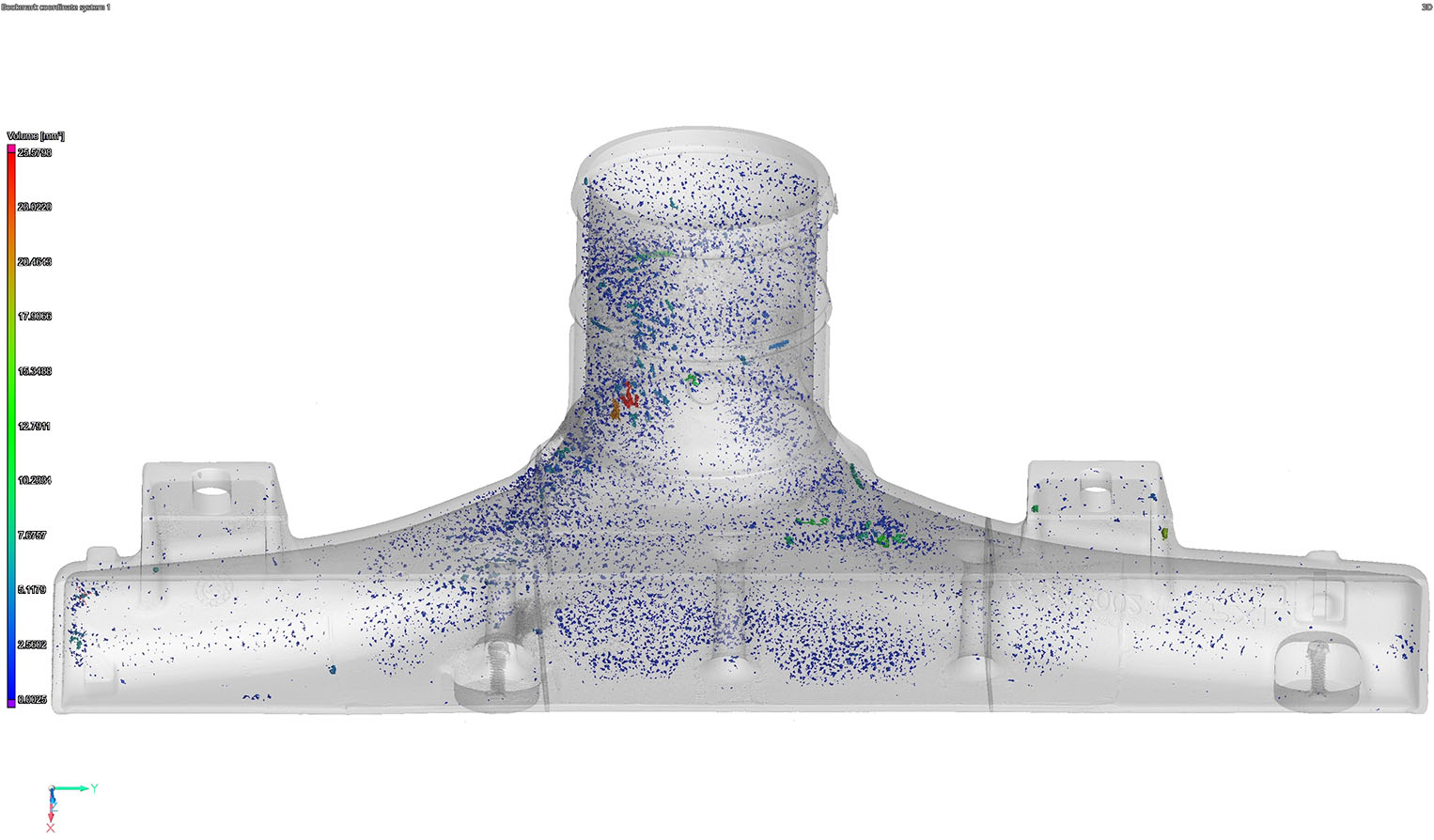

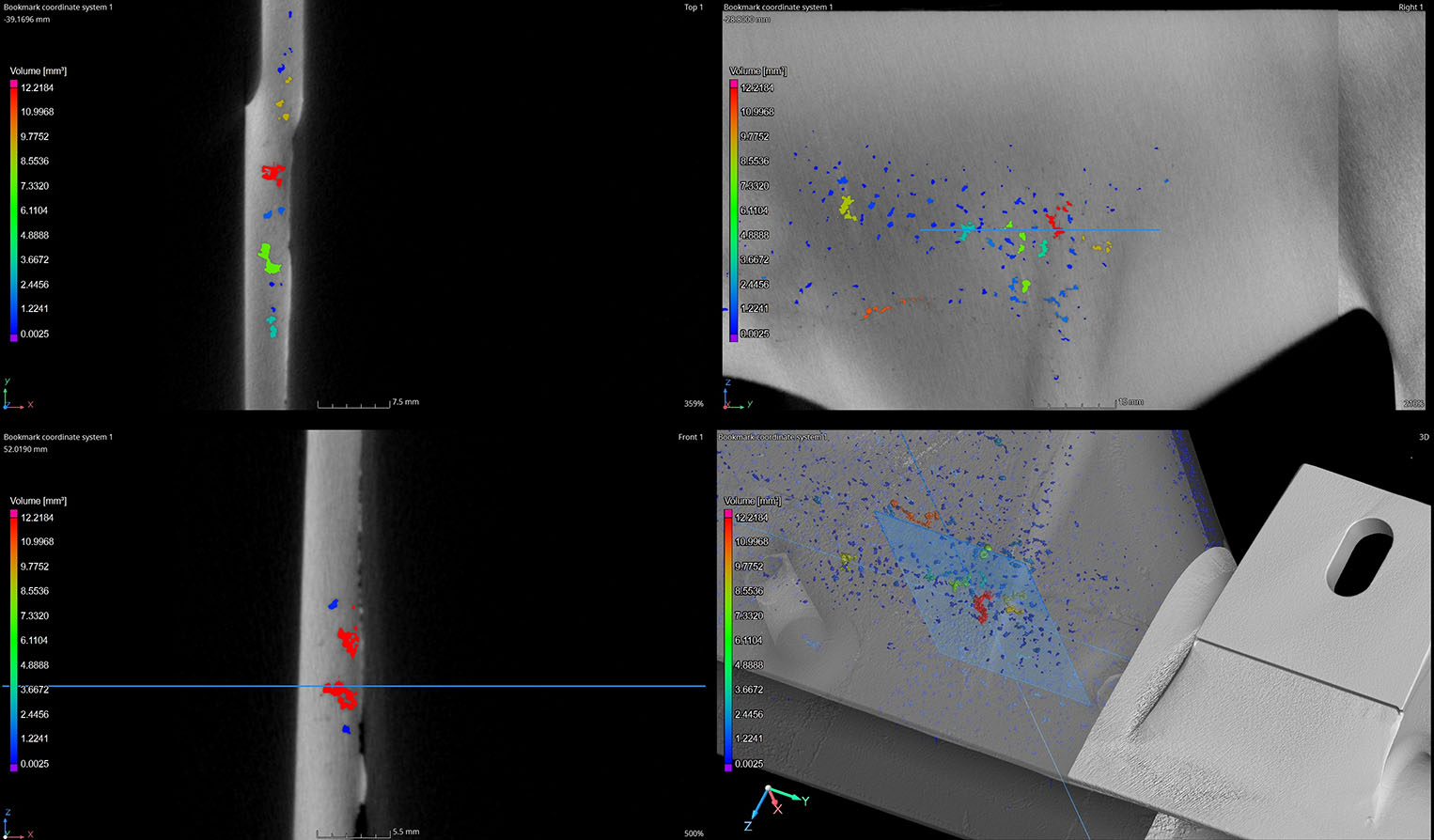

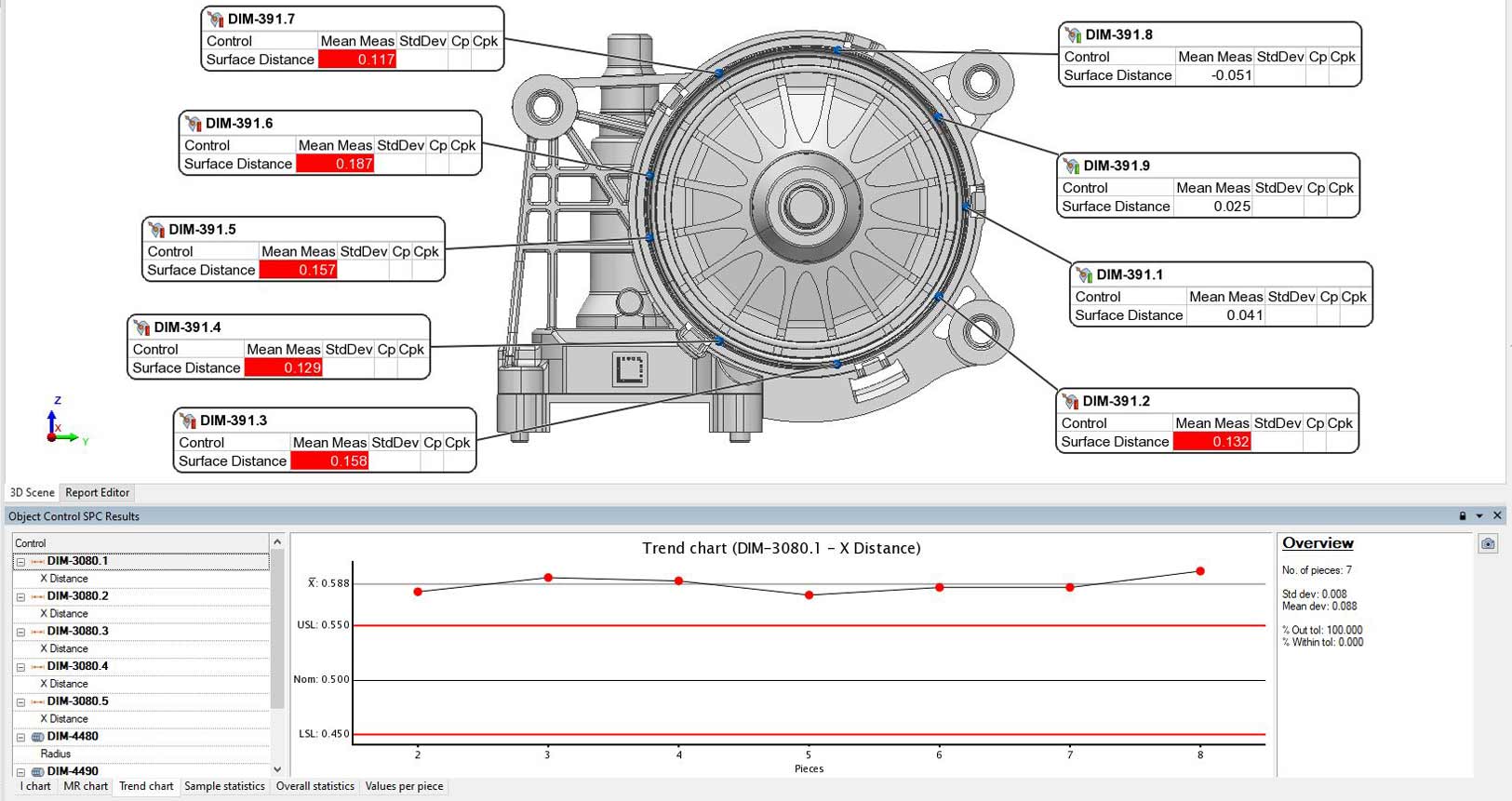

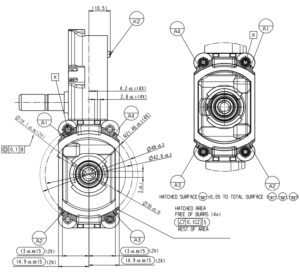

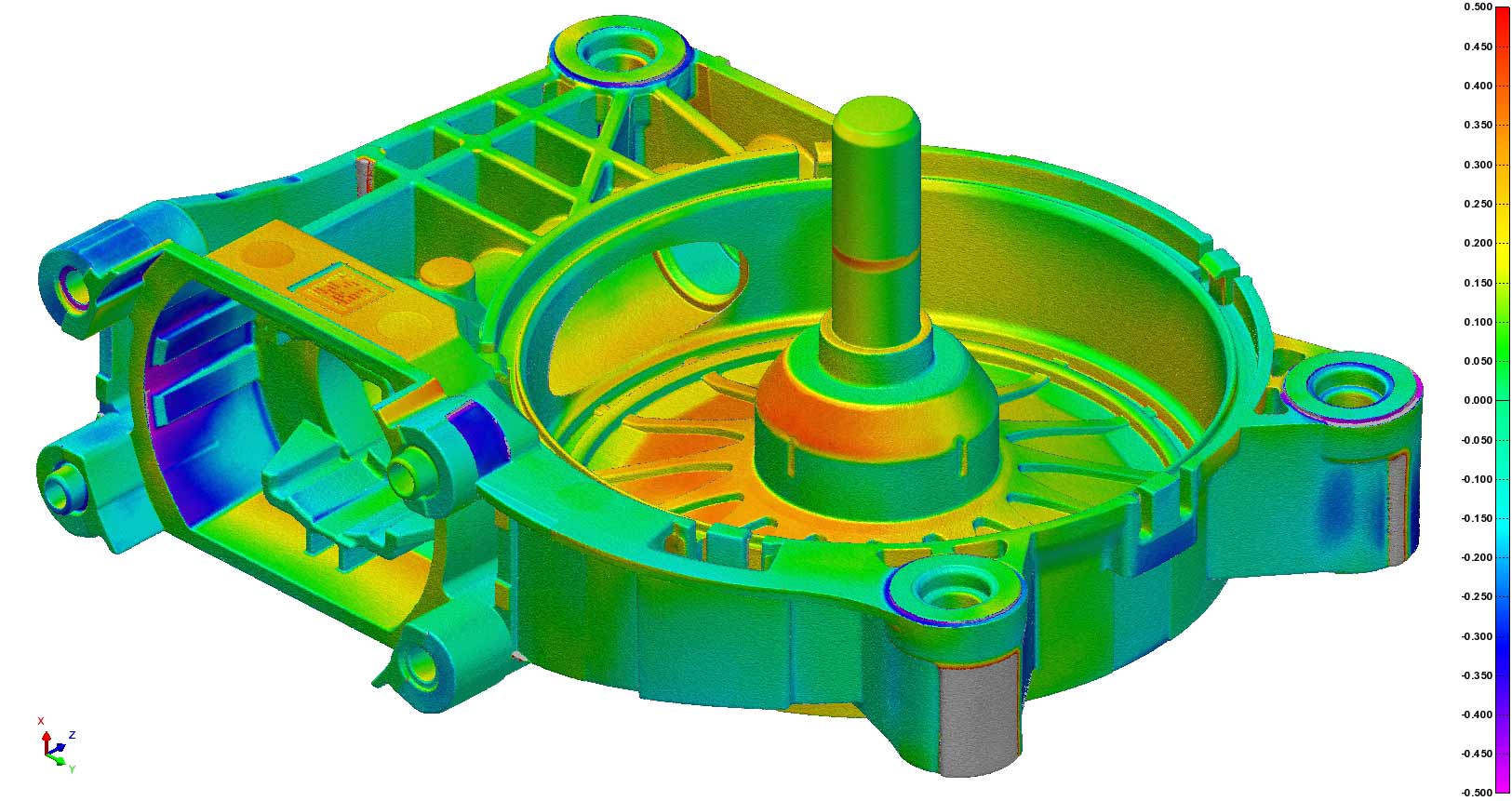

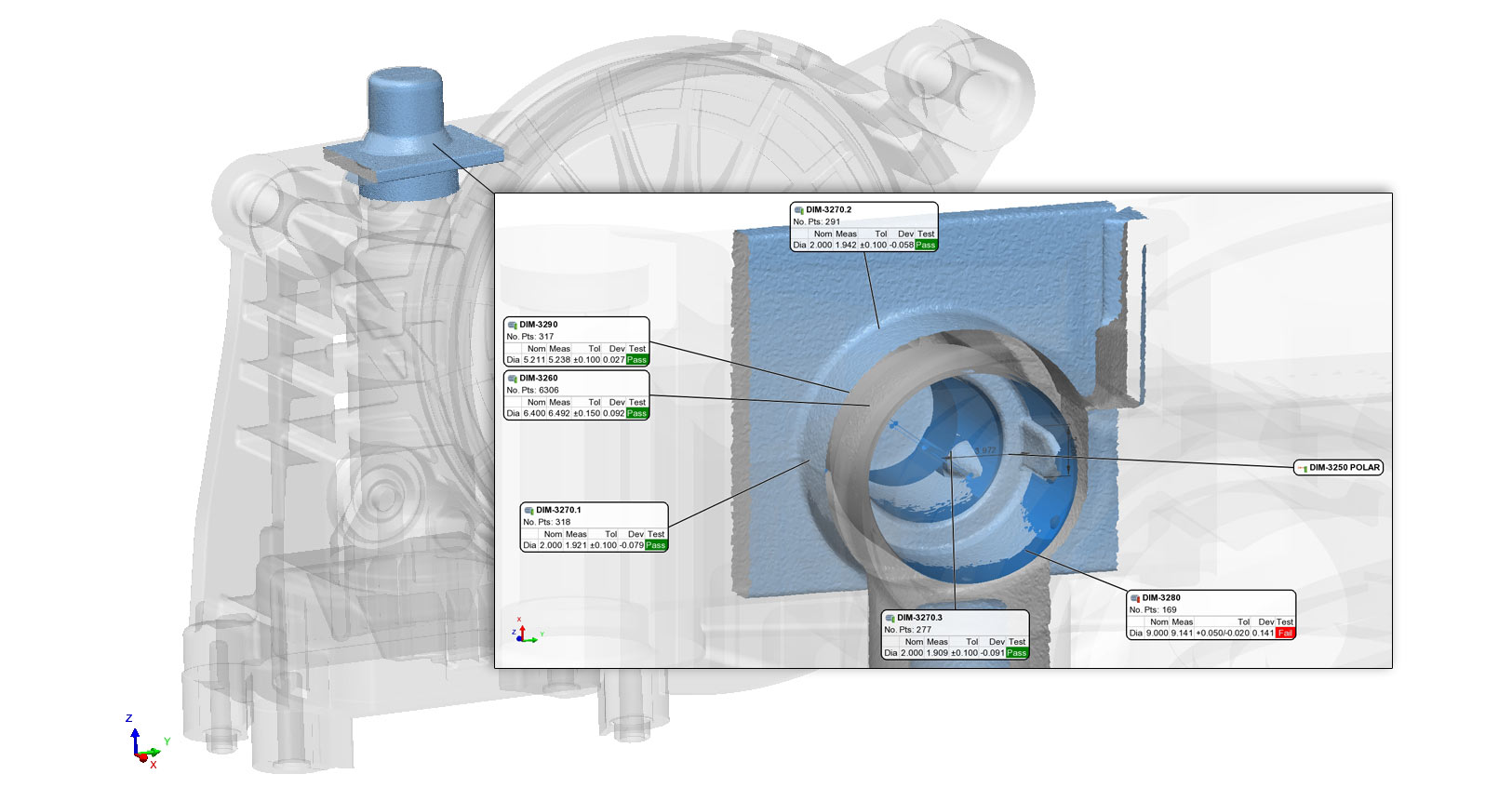

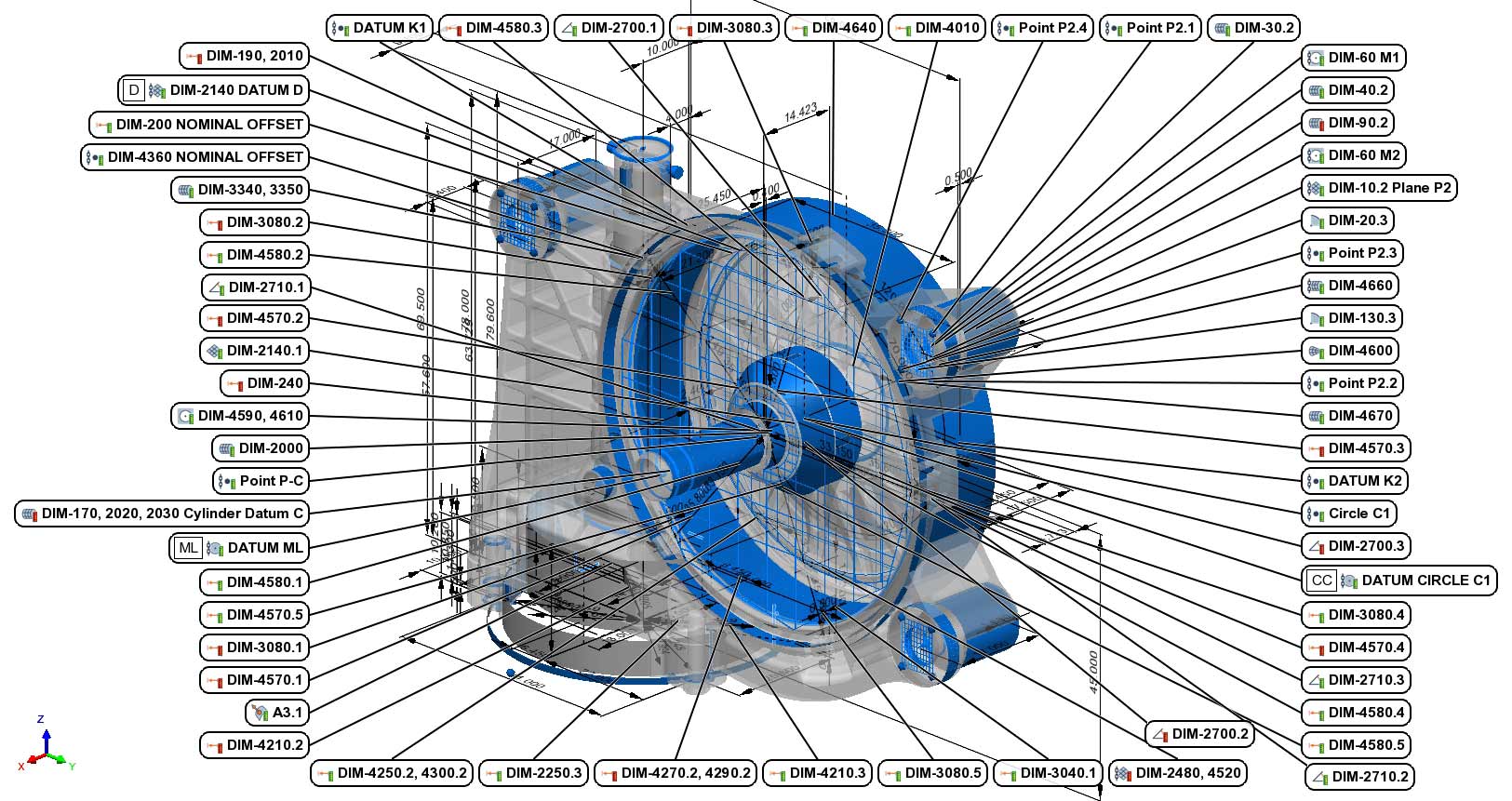

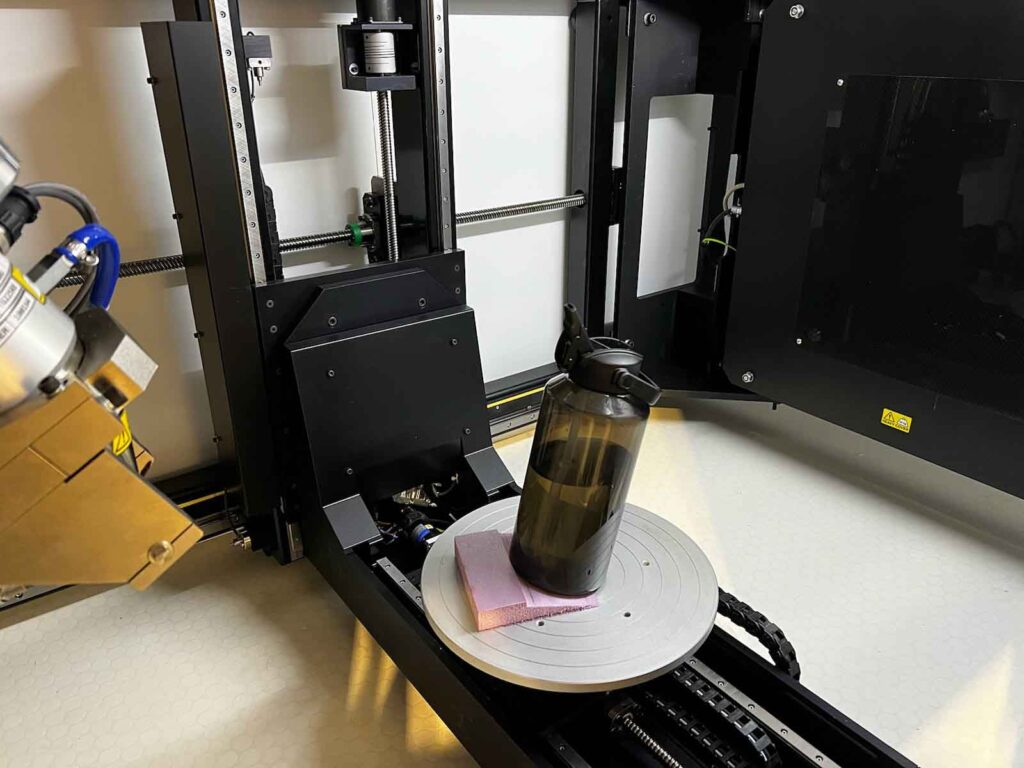

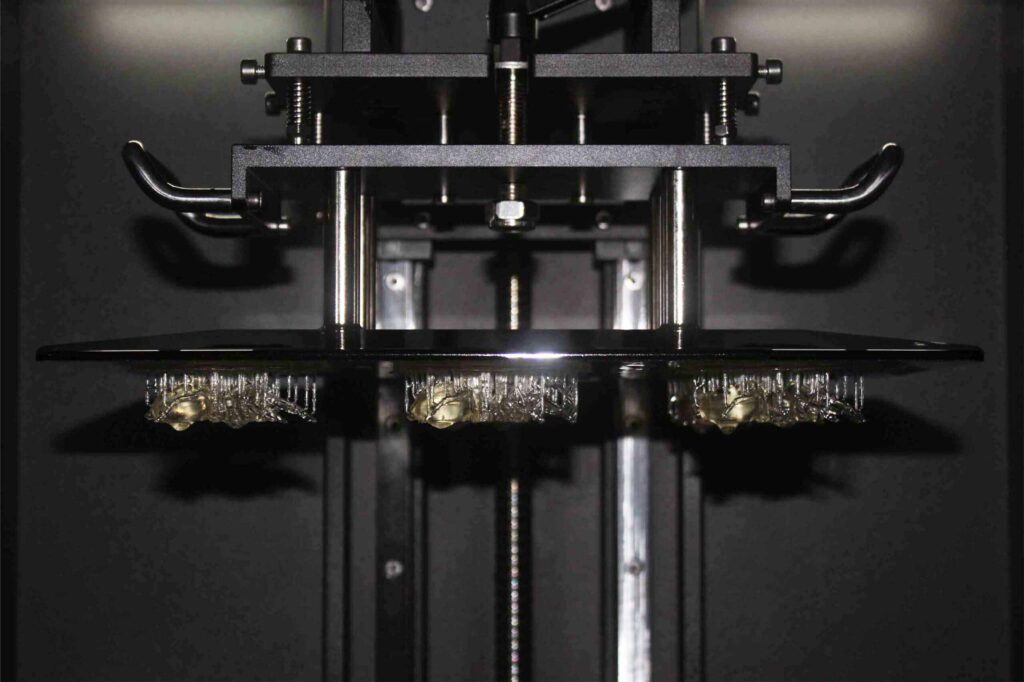

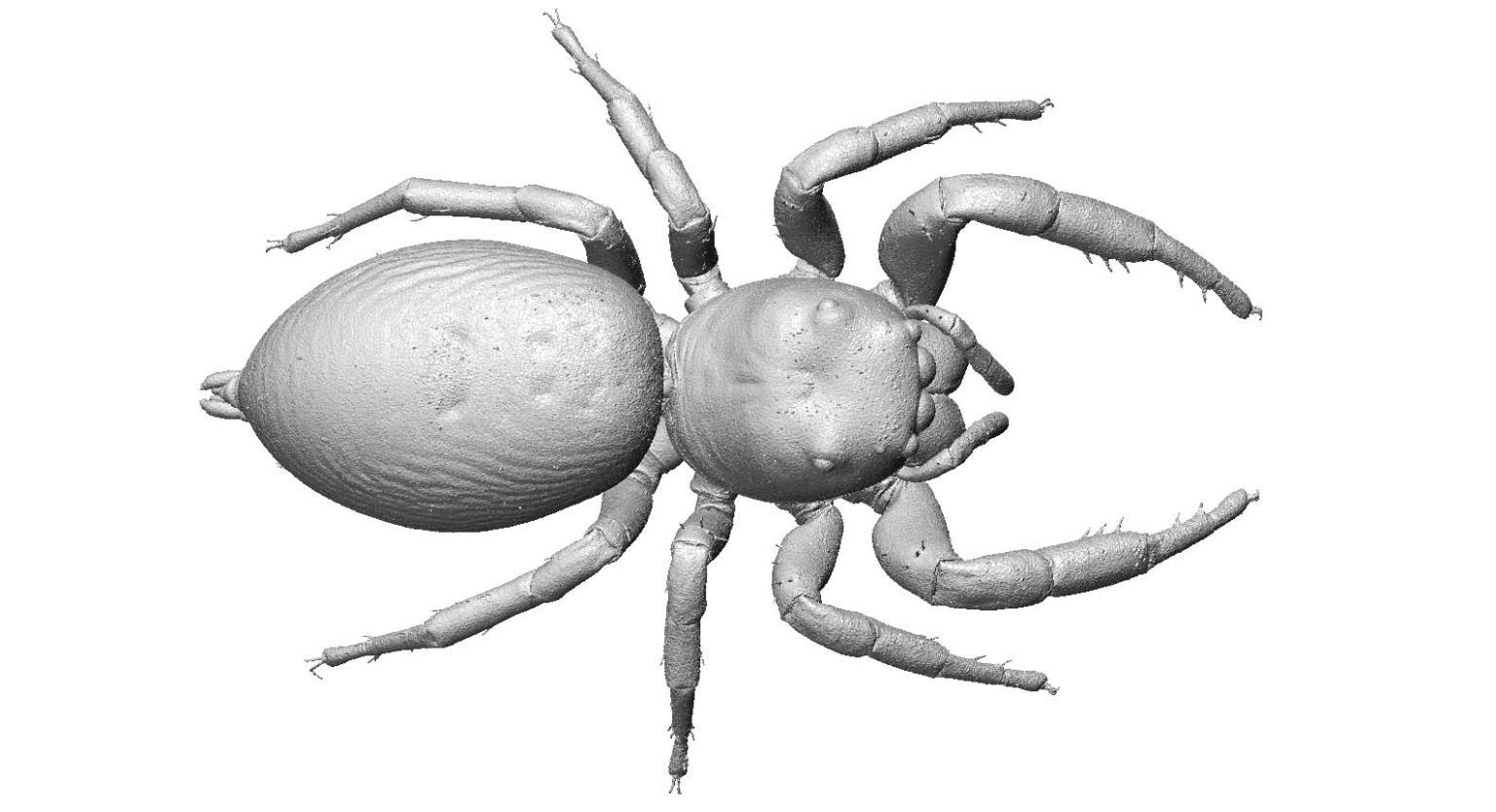

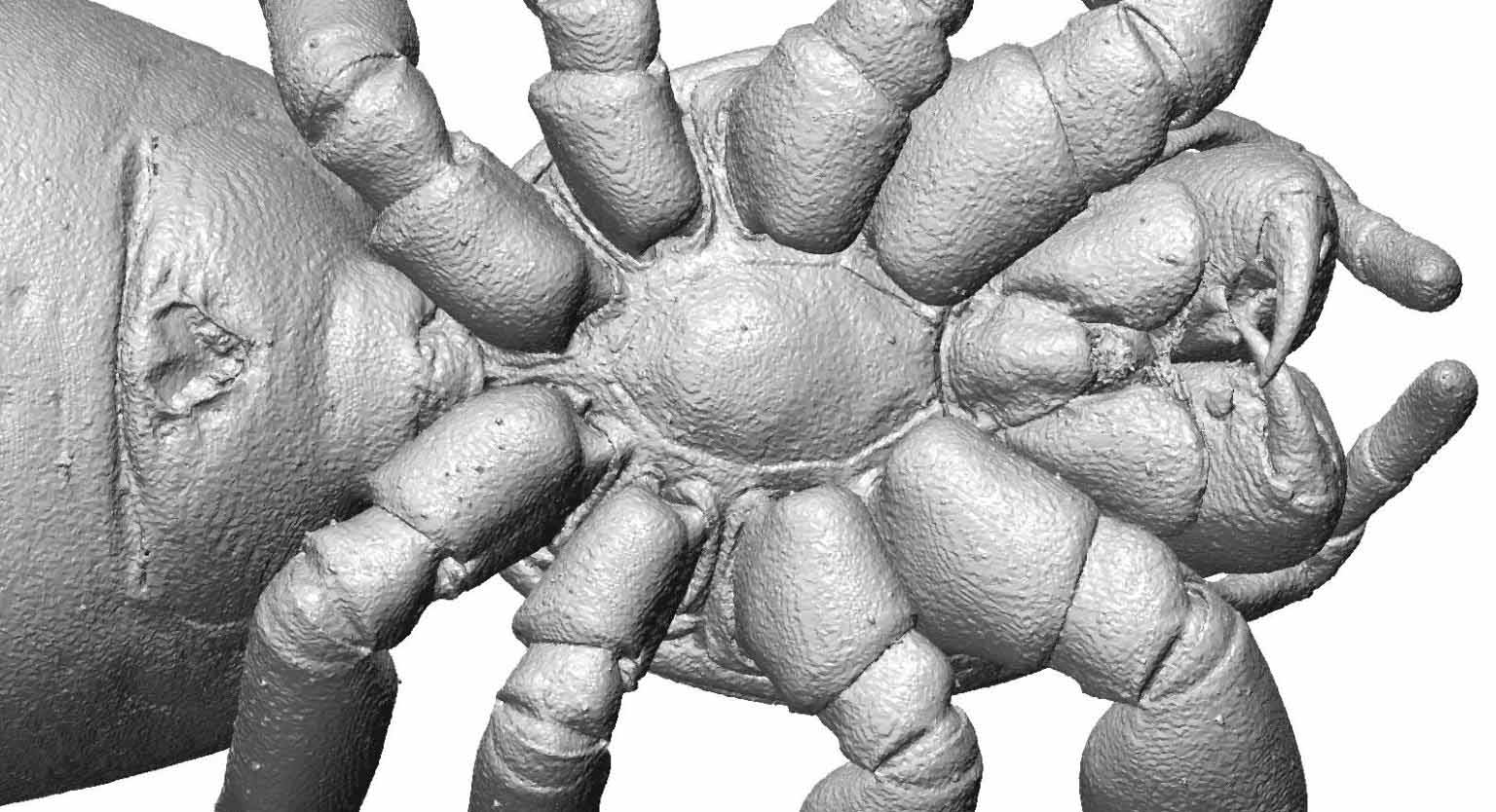

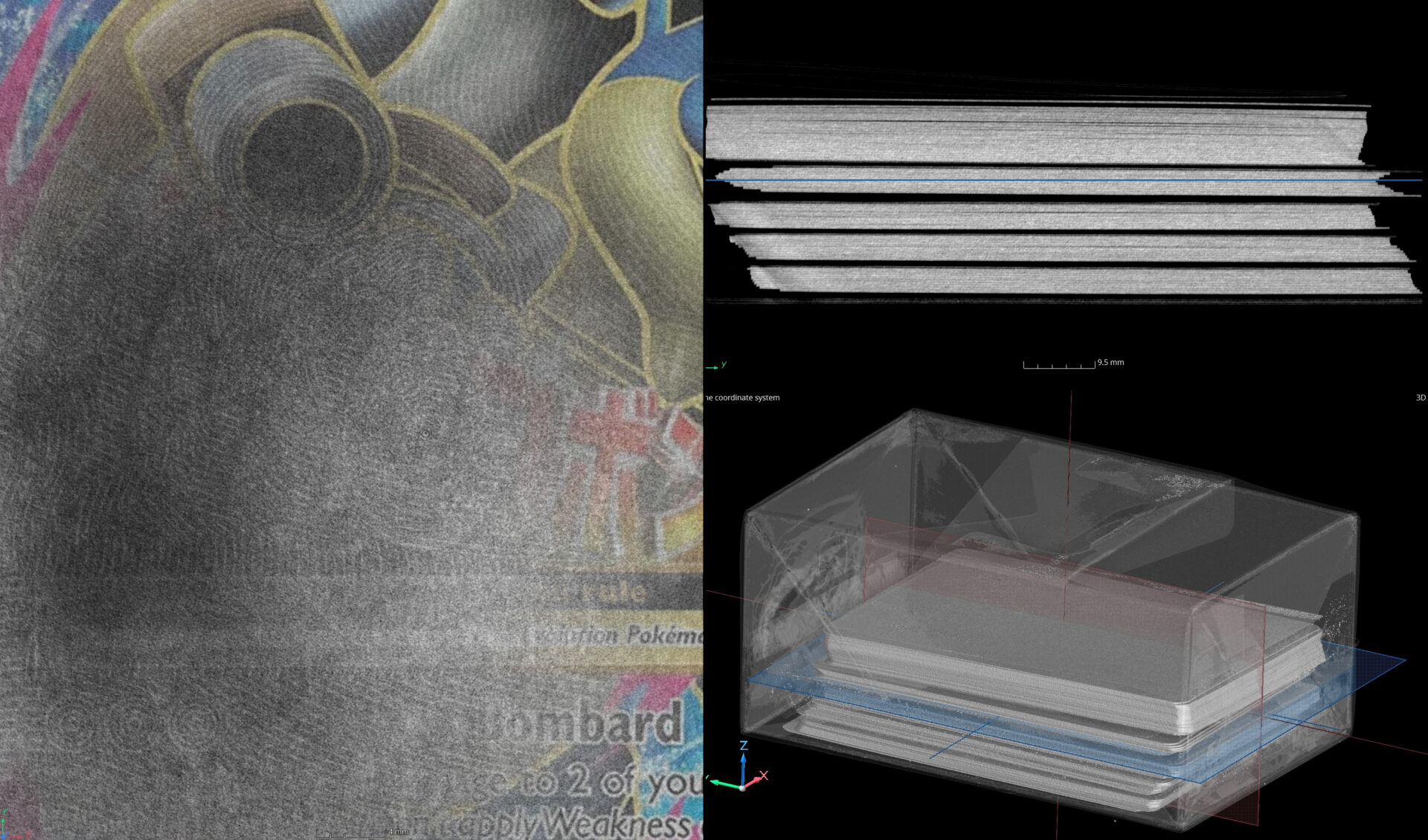

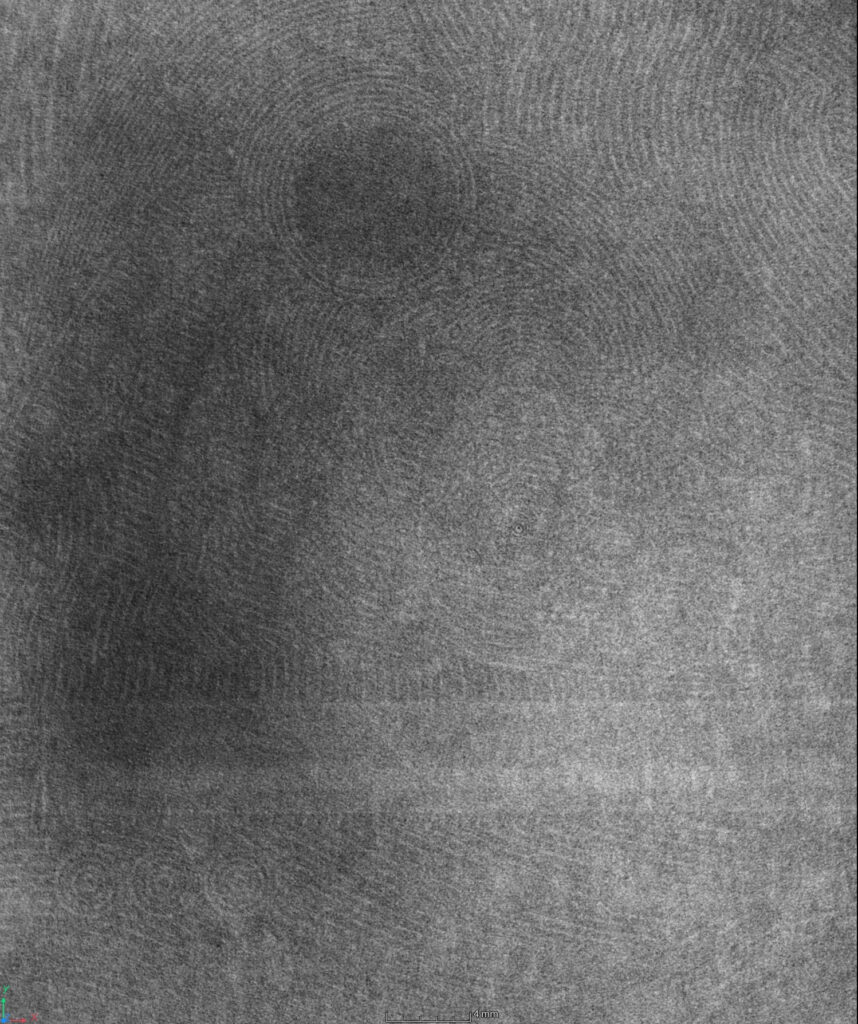

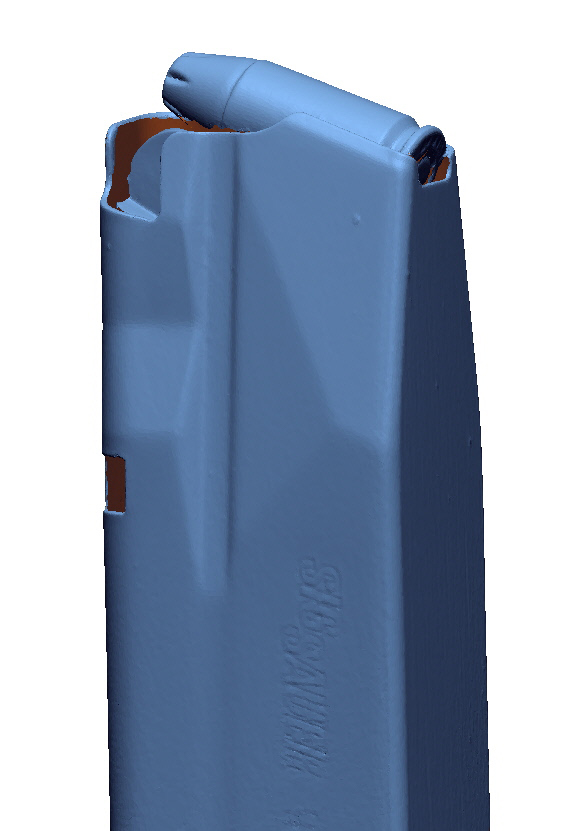

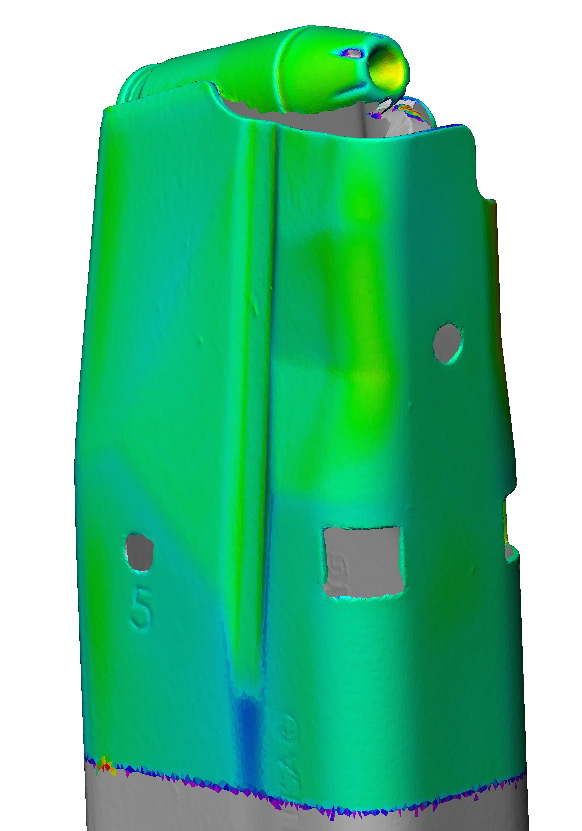

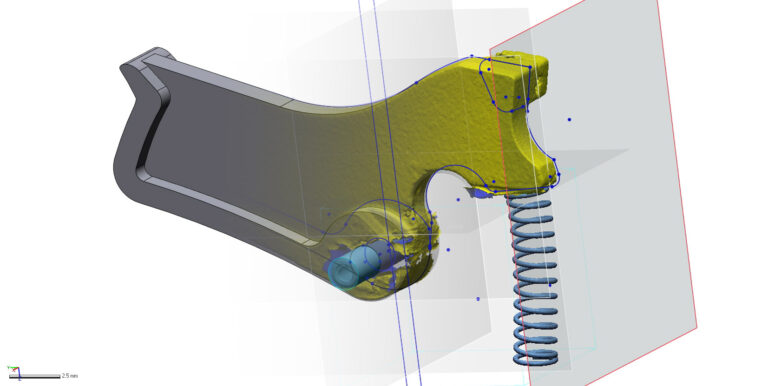

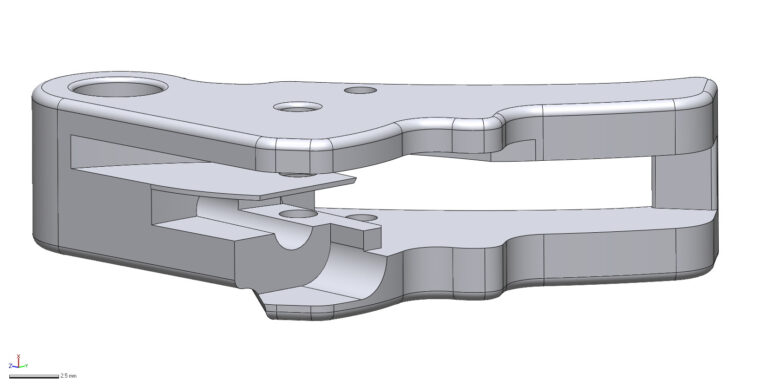

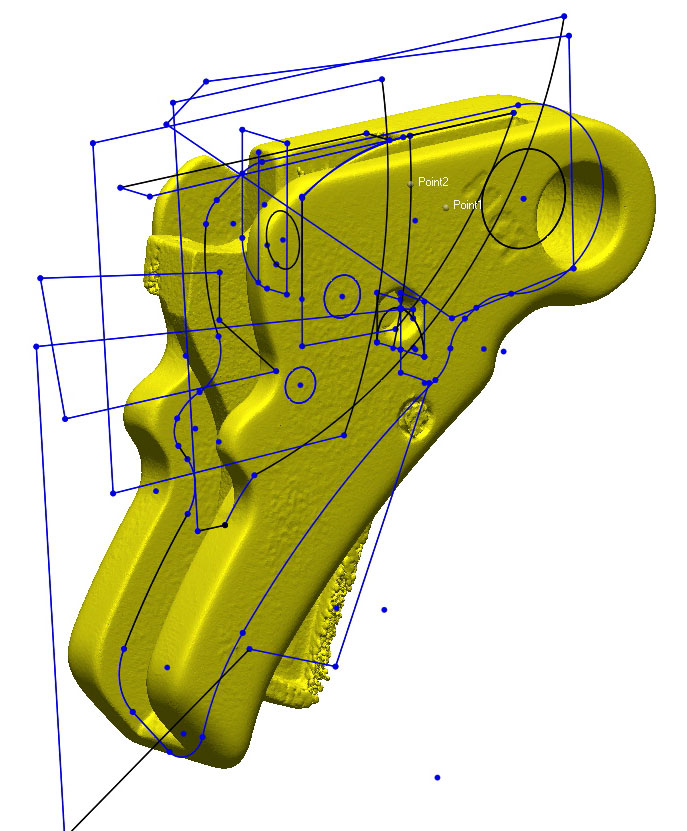

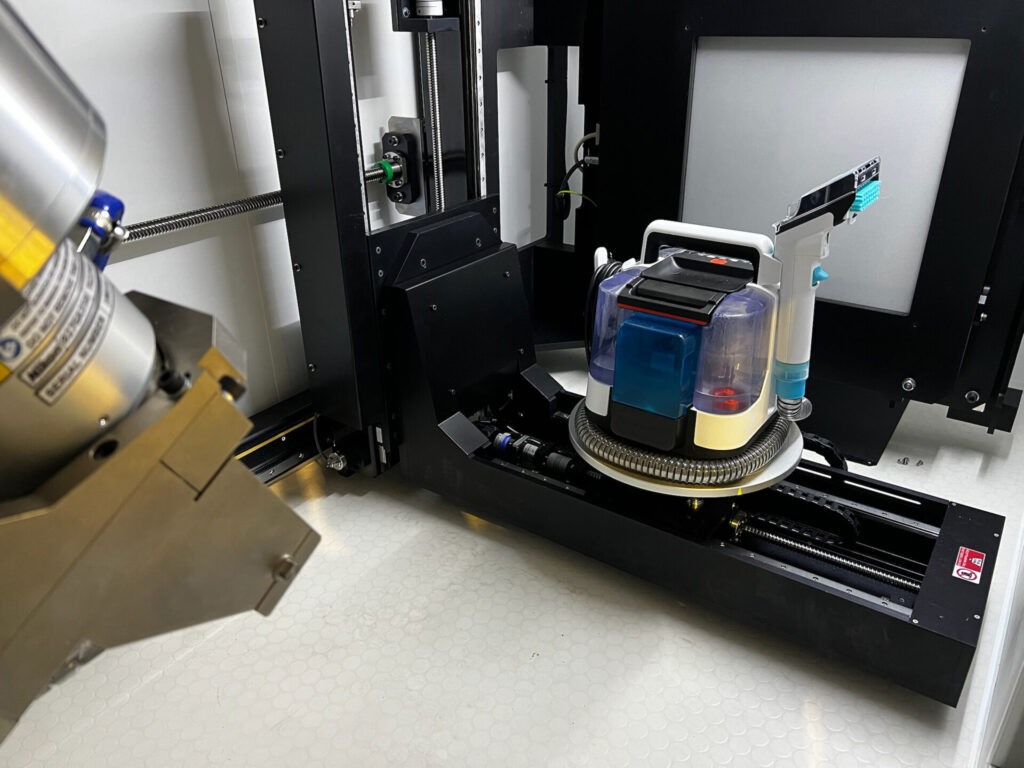

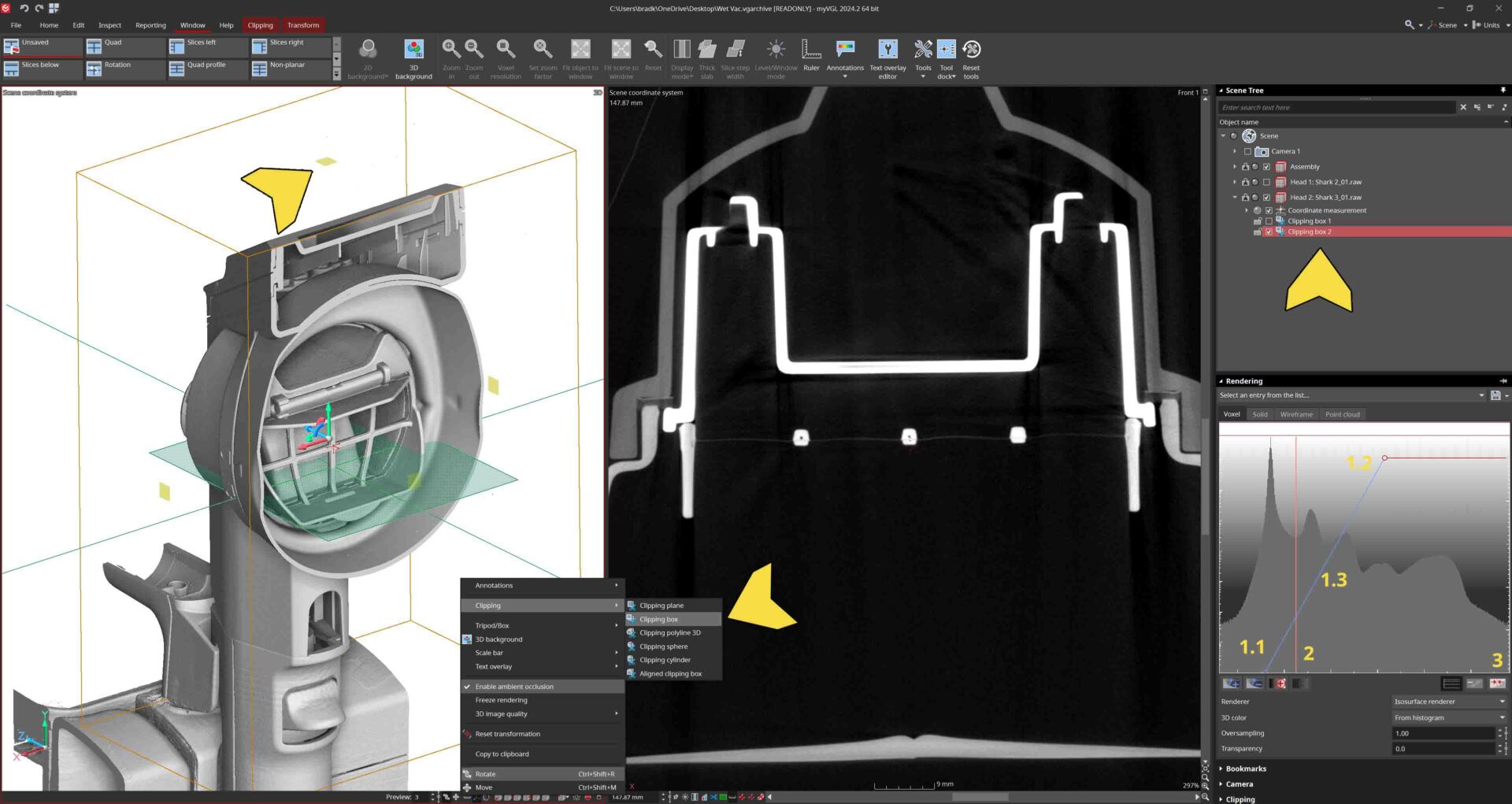

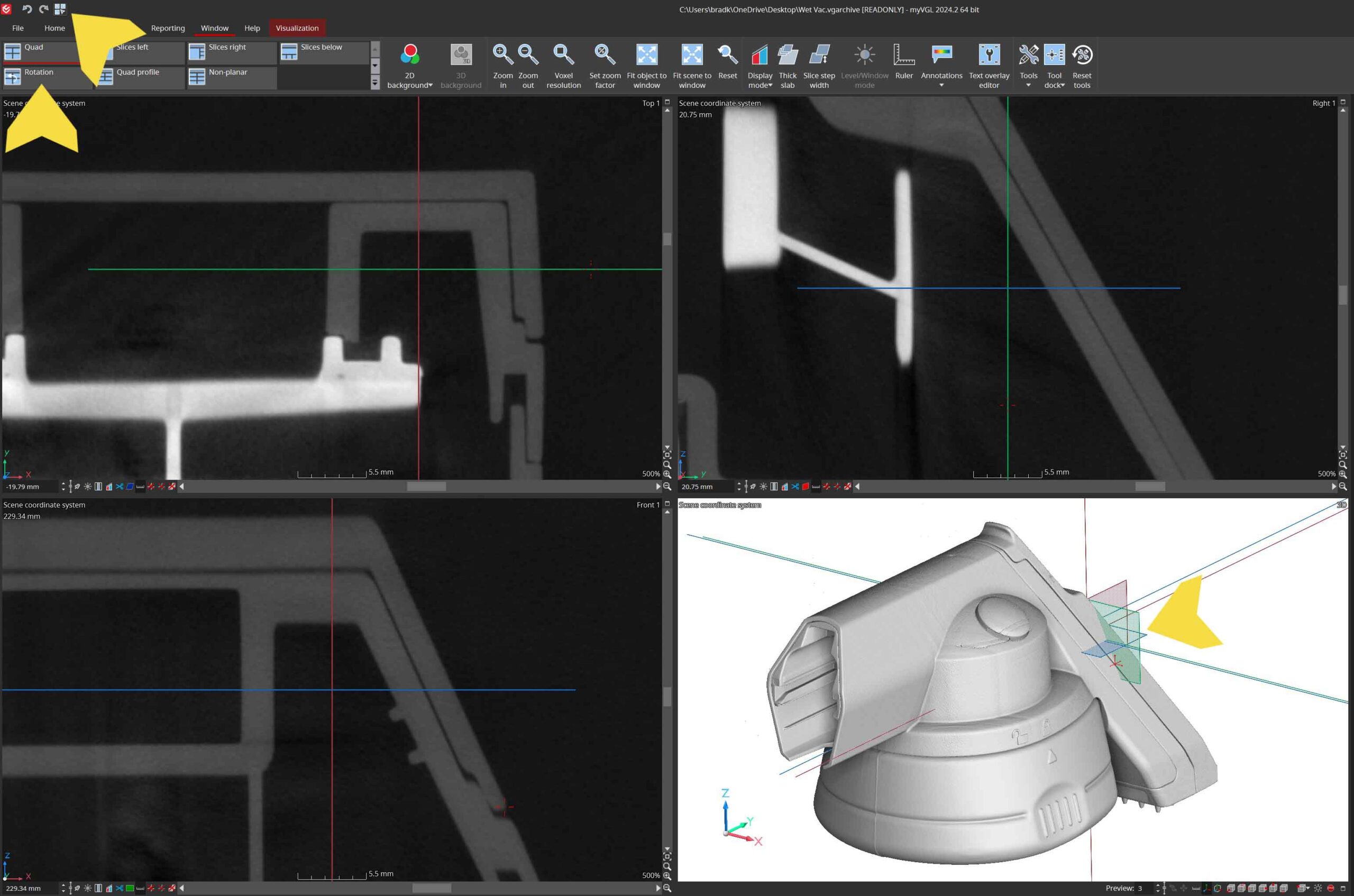

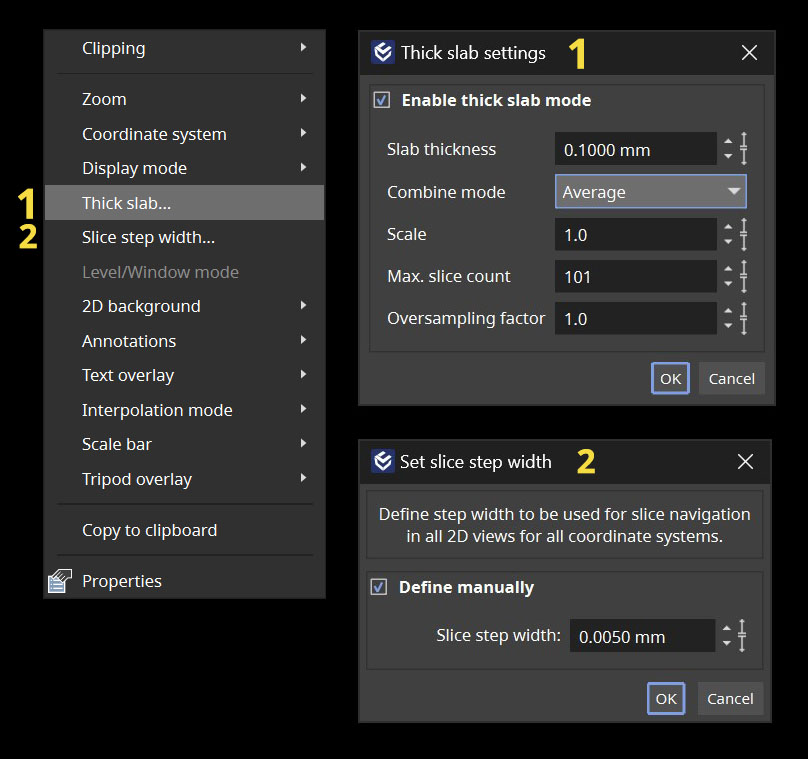

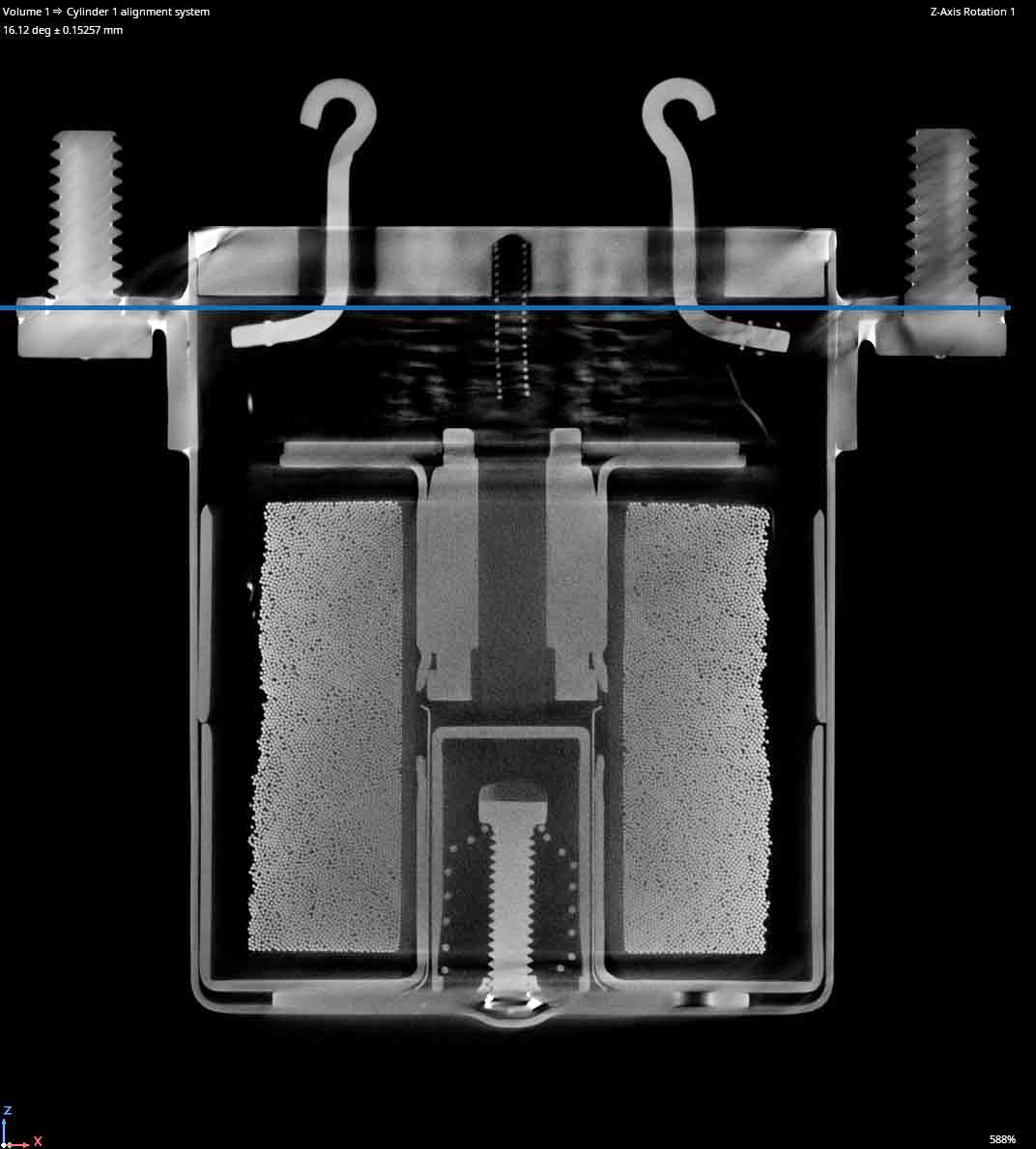

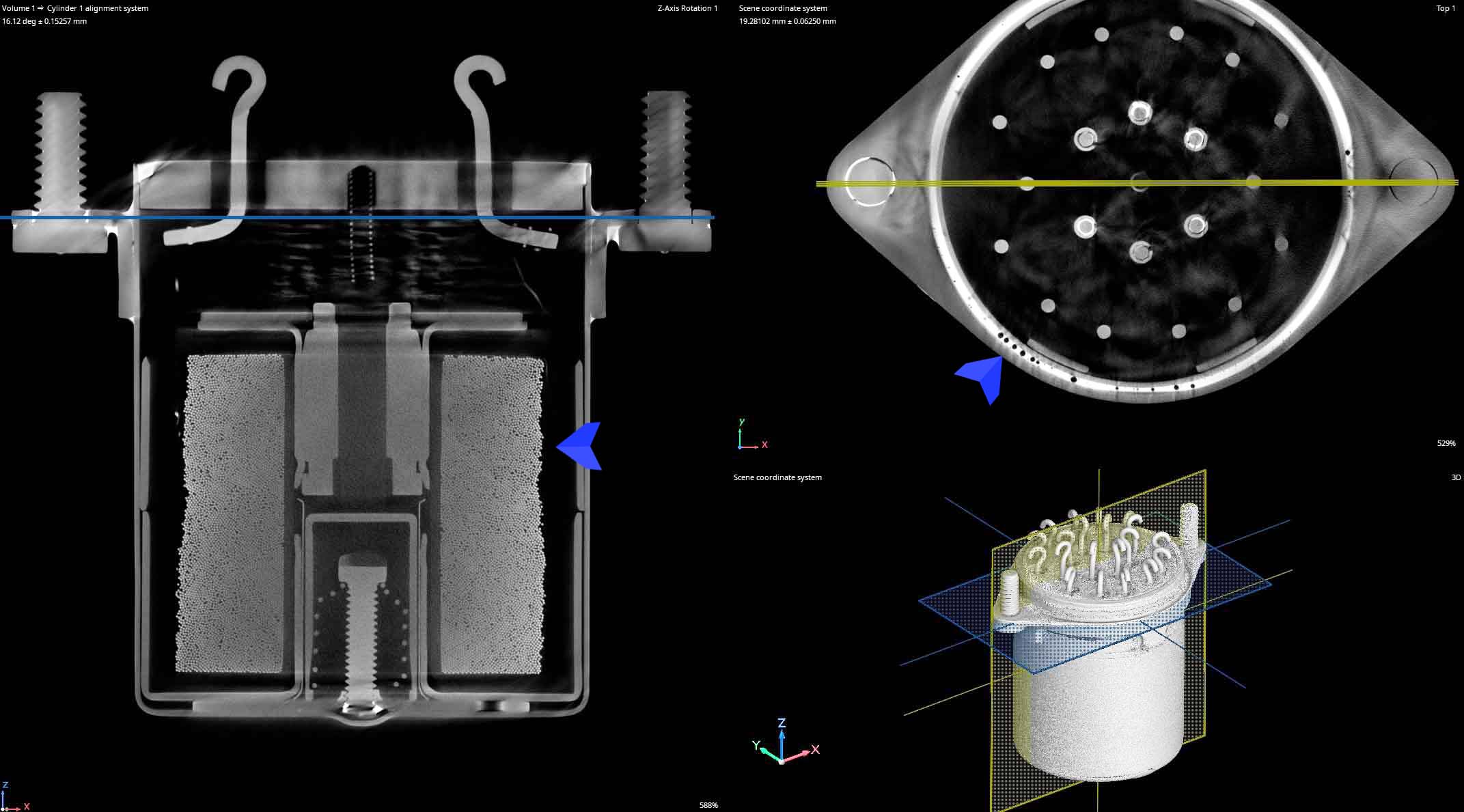

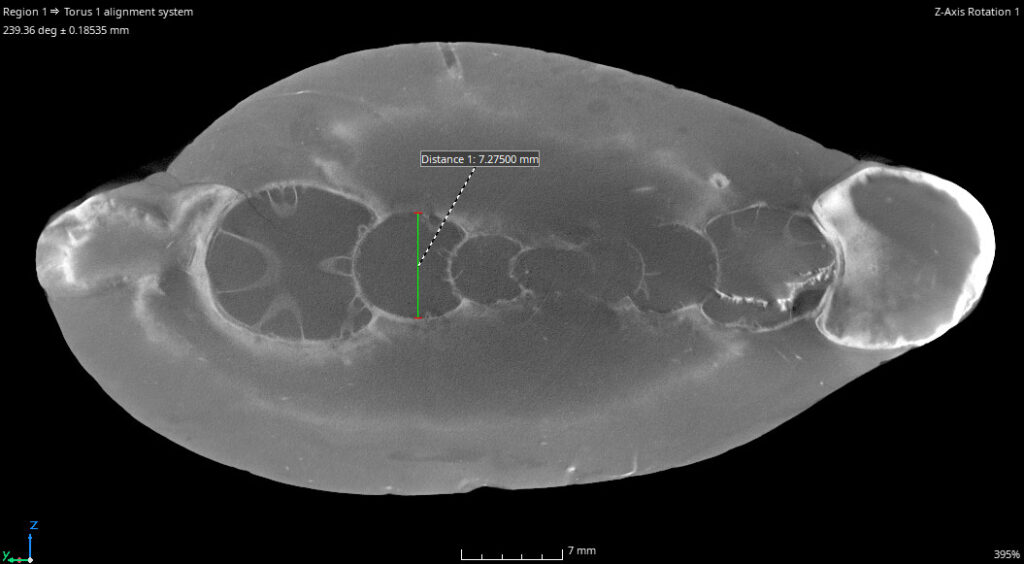

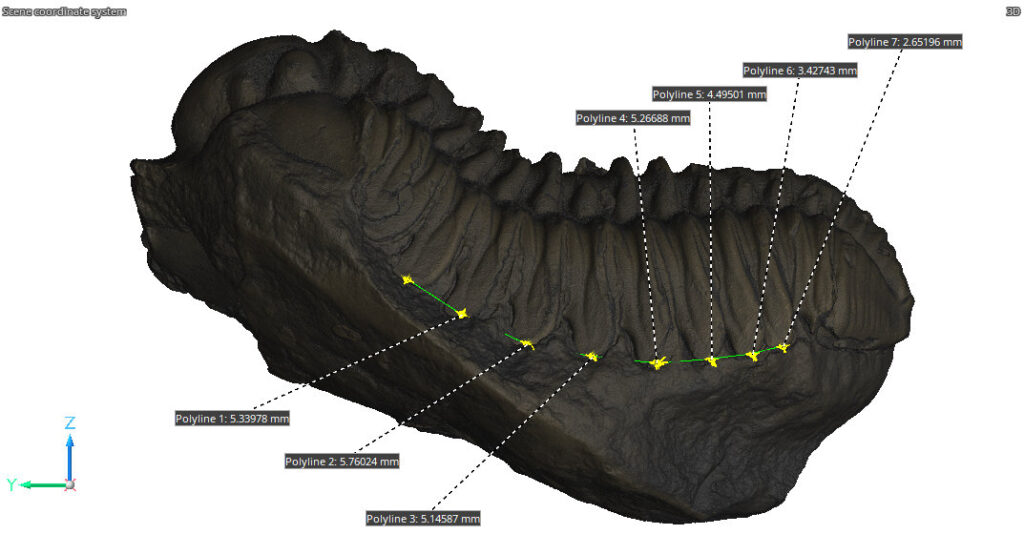

CT Scanning is used to quantify porosity within a part – whether it be plastics or metals. This information is useful for applications like process changes to reduce machining fallout or investigating failures like through wall leaks. As technology rapidly changes, large format, high energy CT systems paired with software packages like Volume Graphics can accommodate large and high density products.

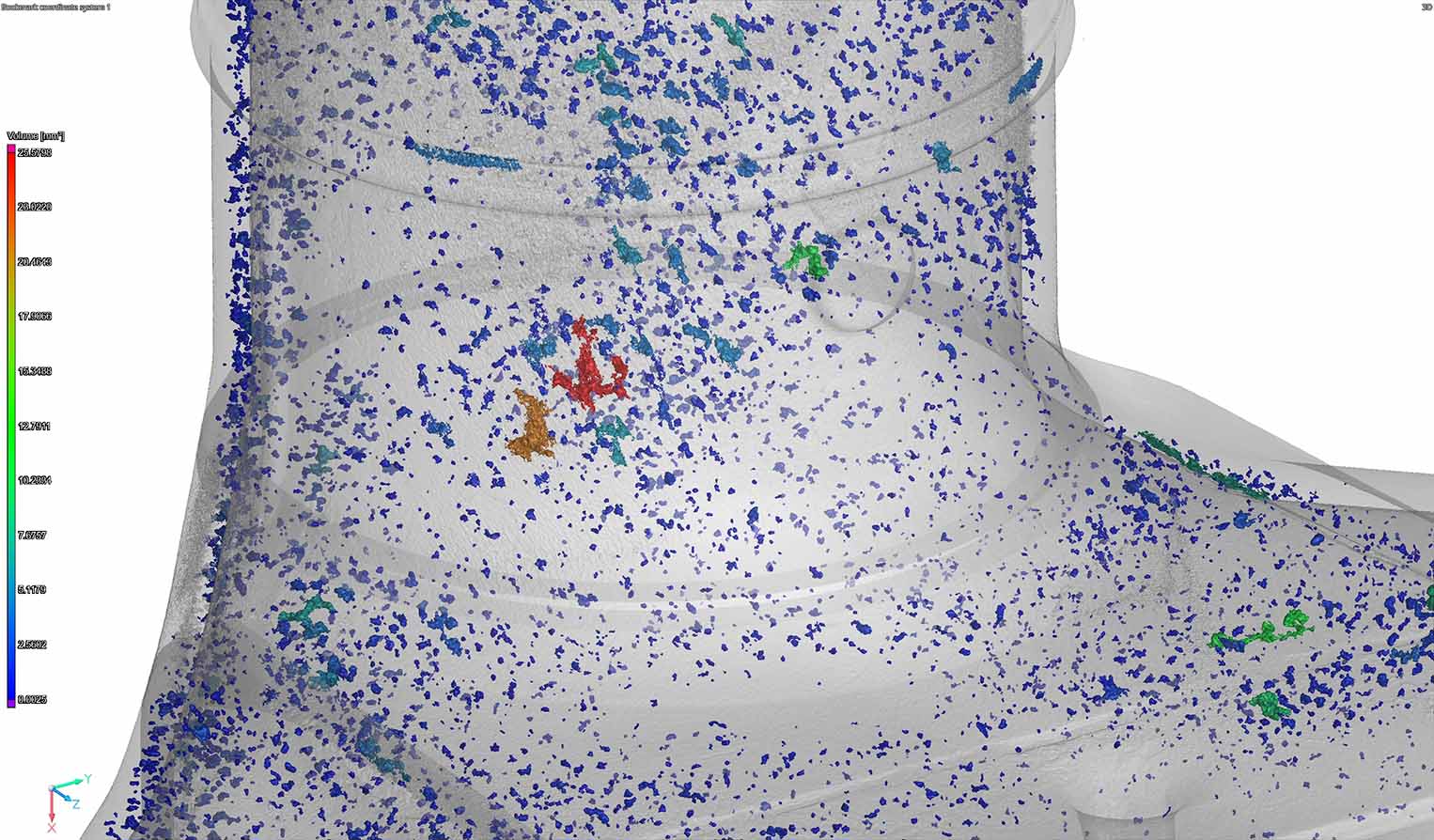

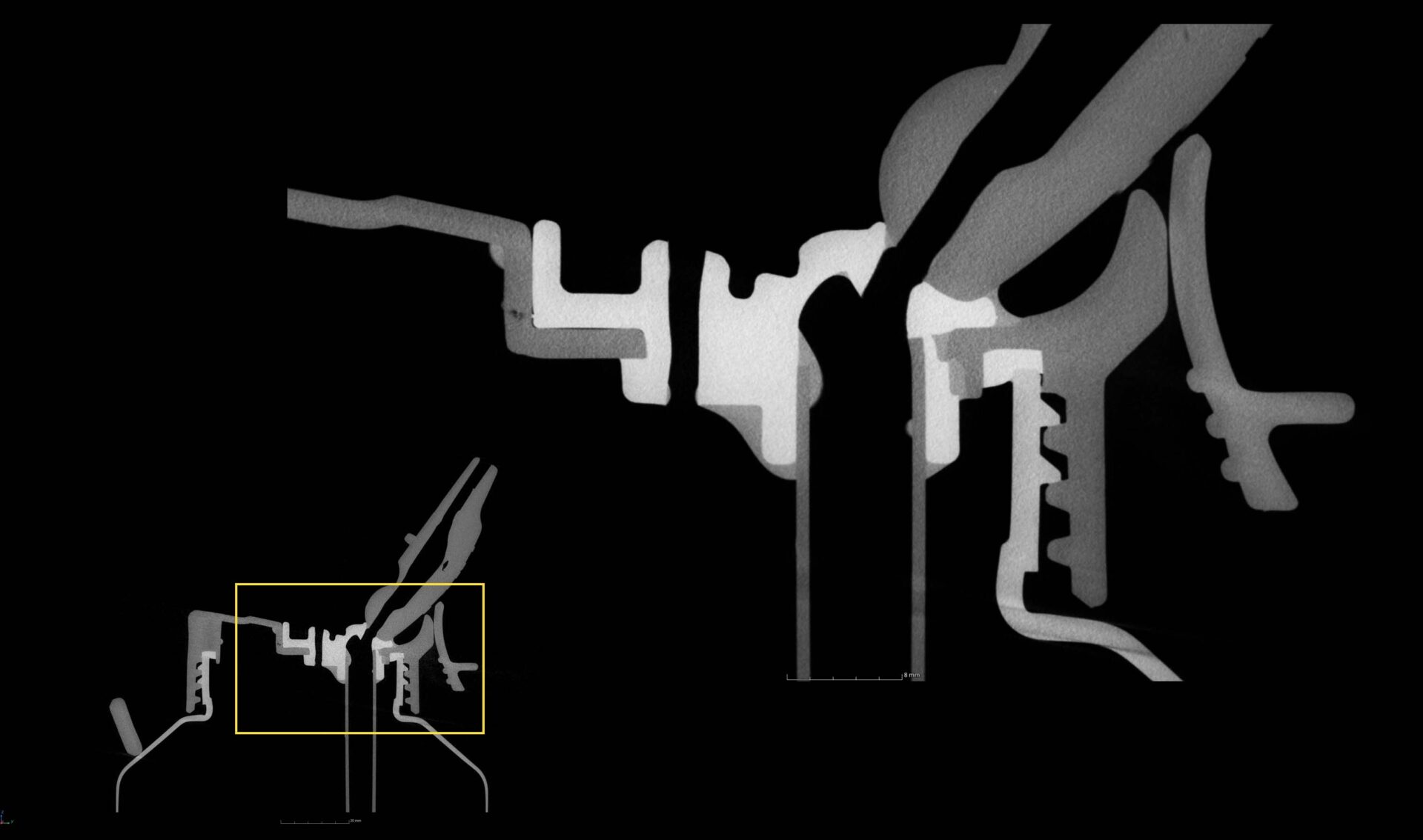

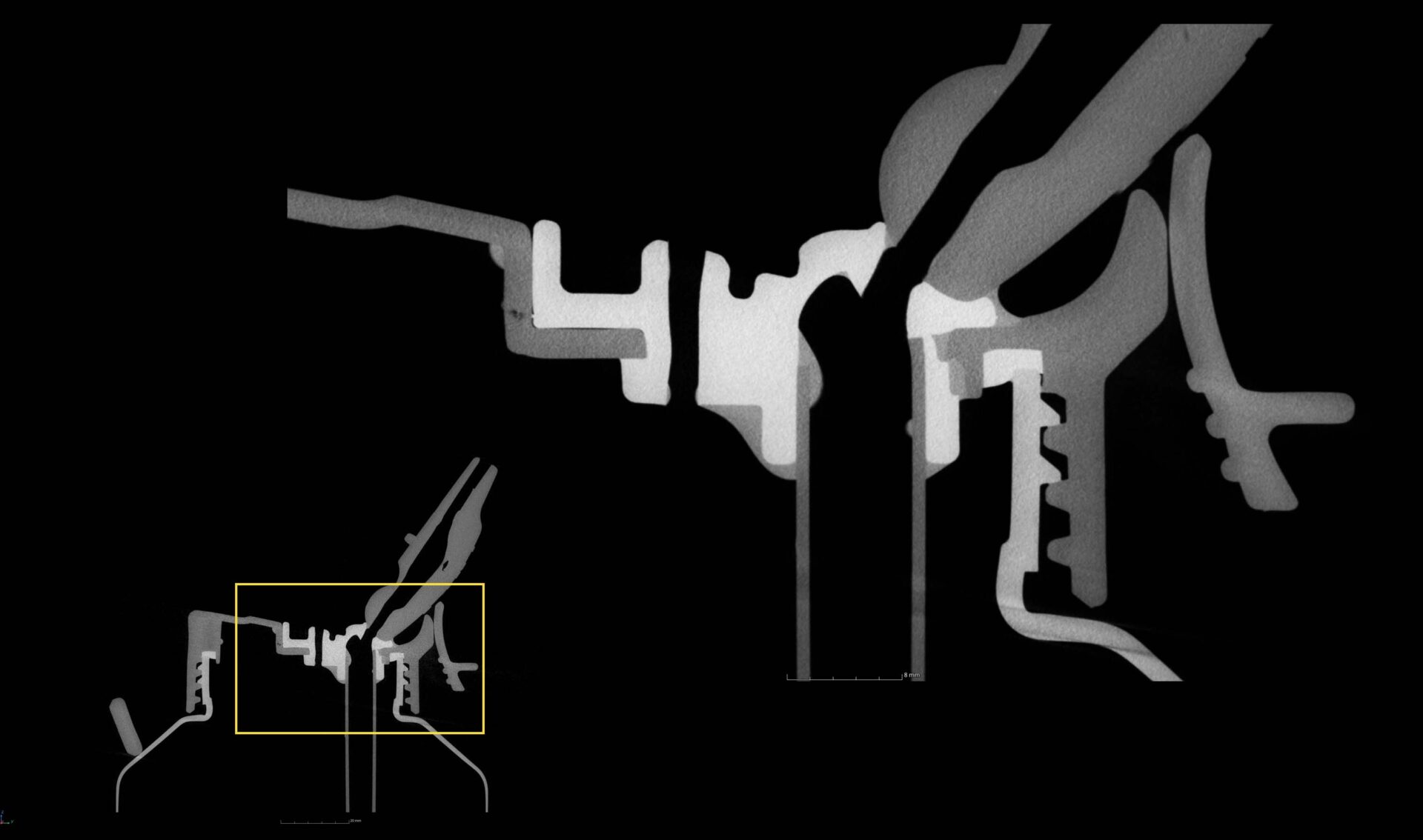

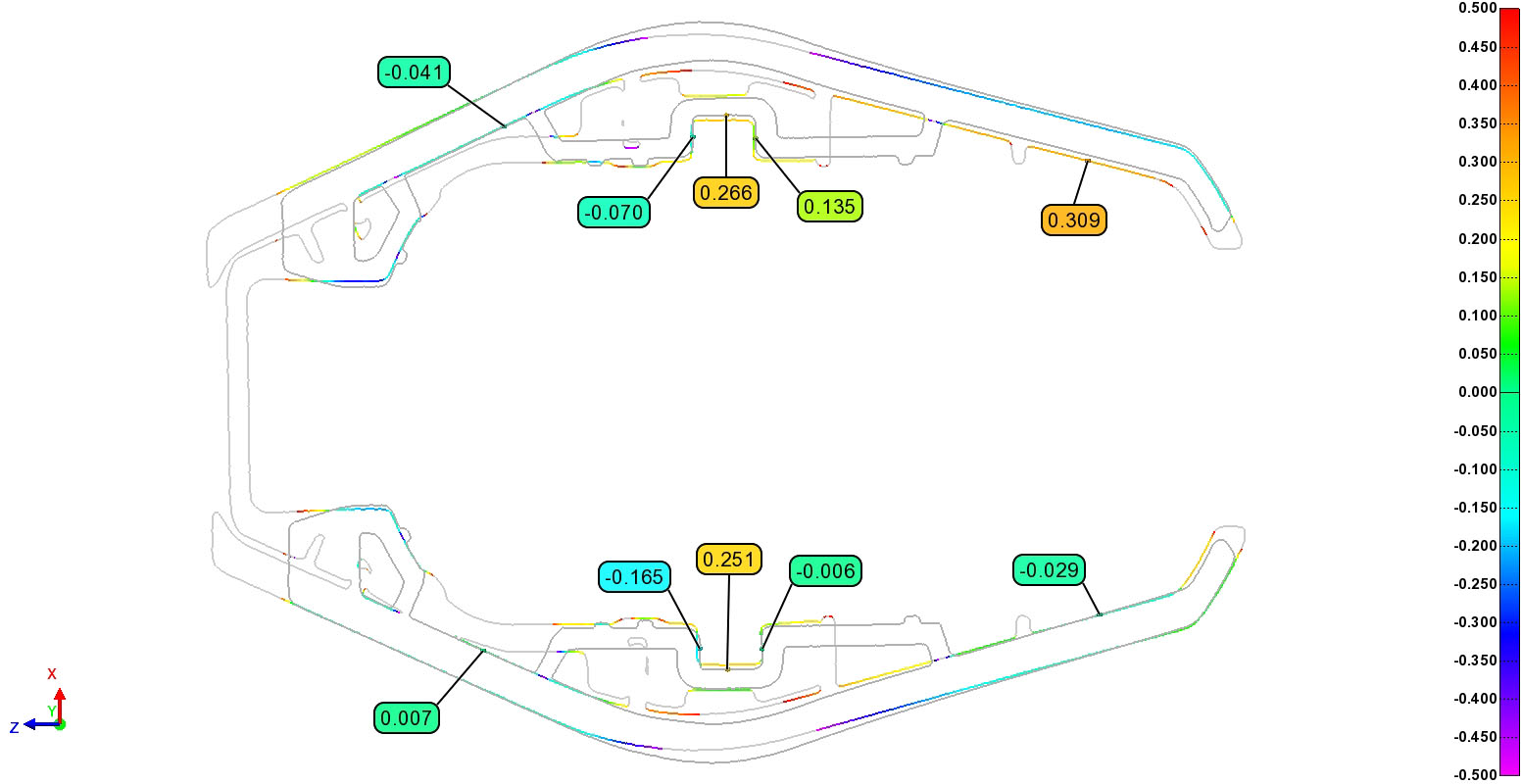

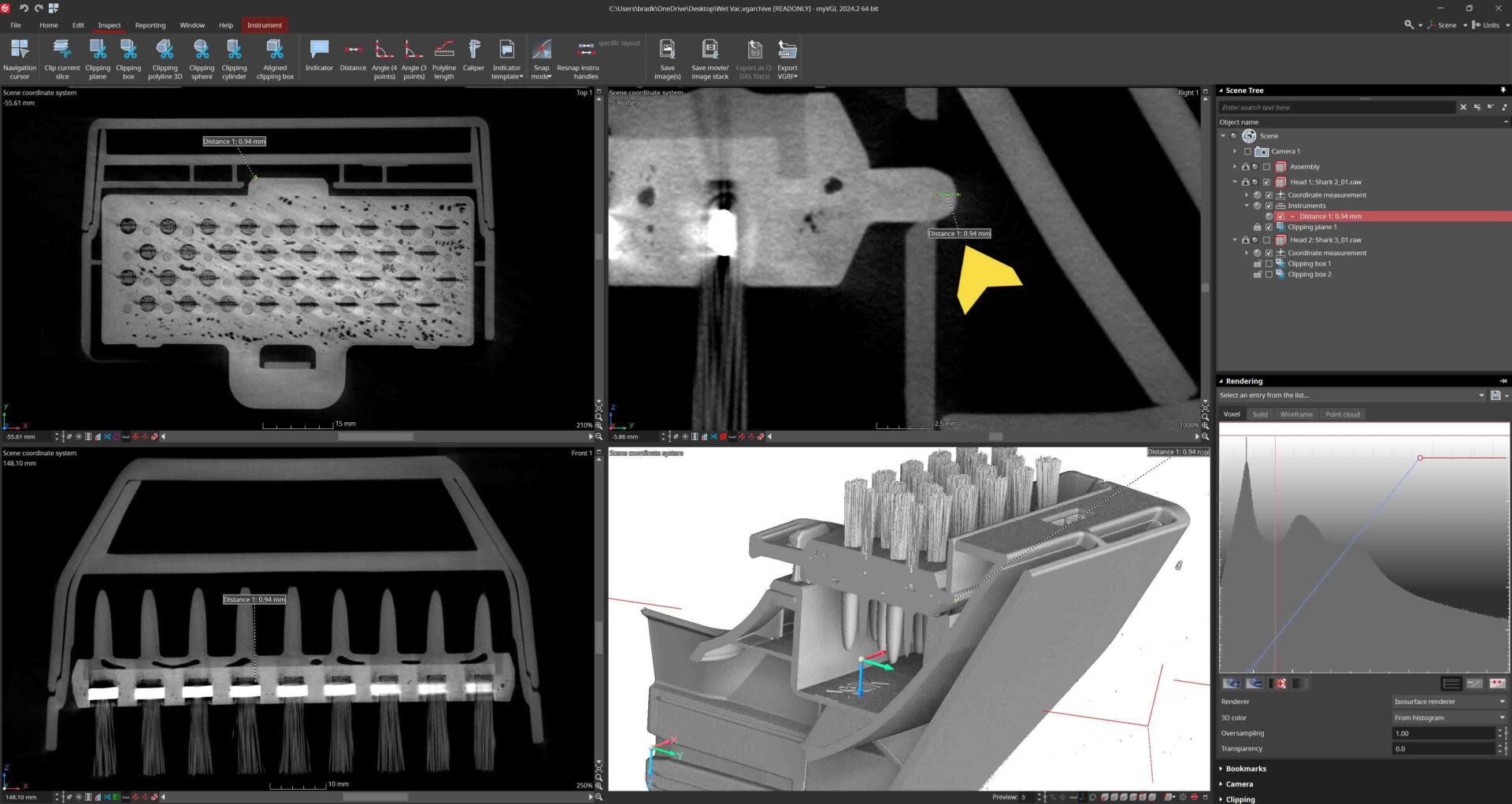

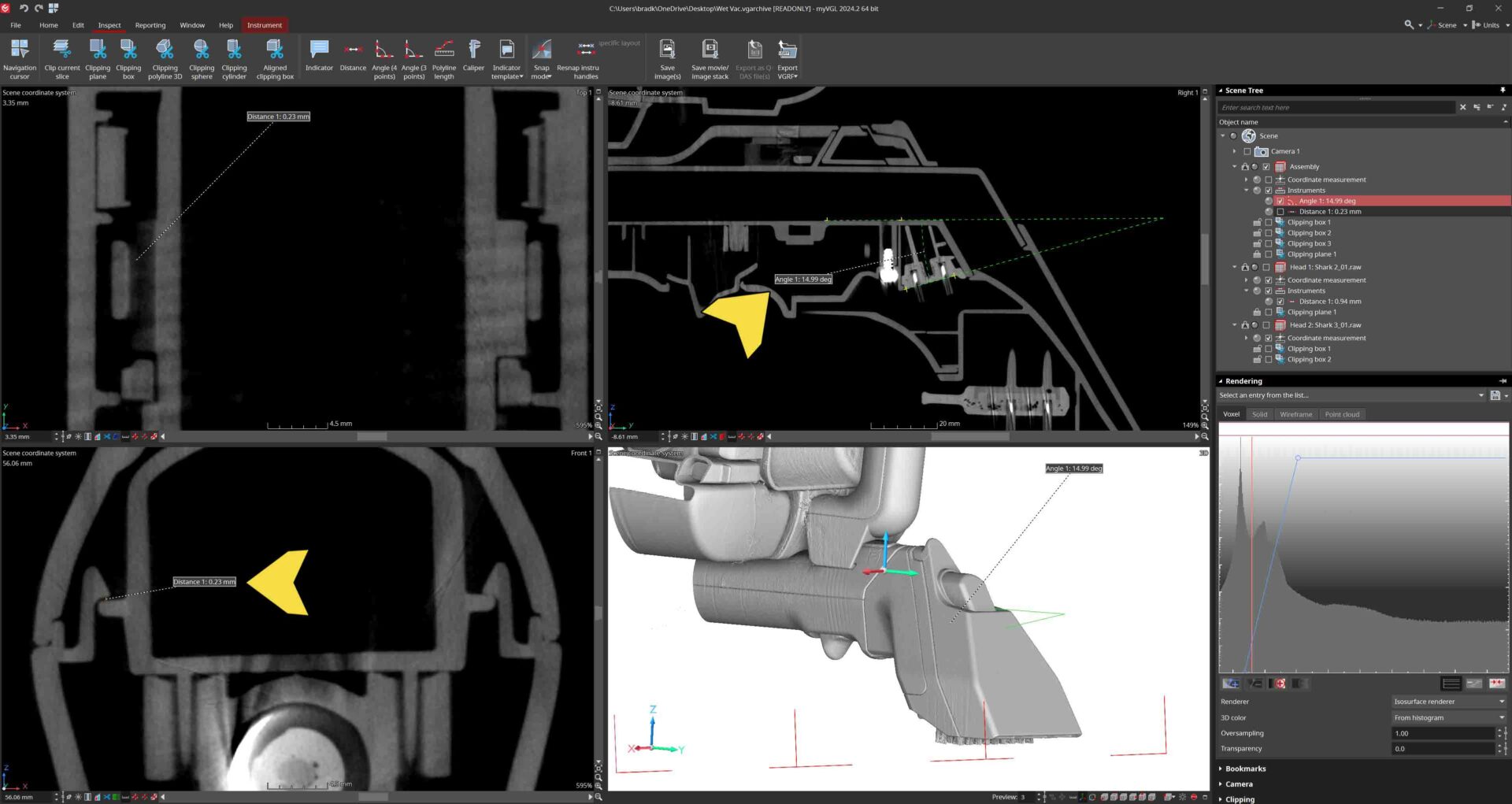

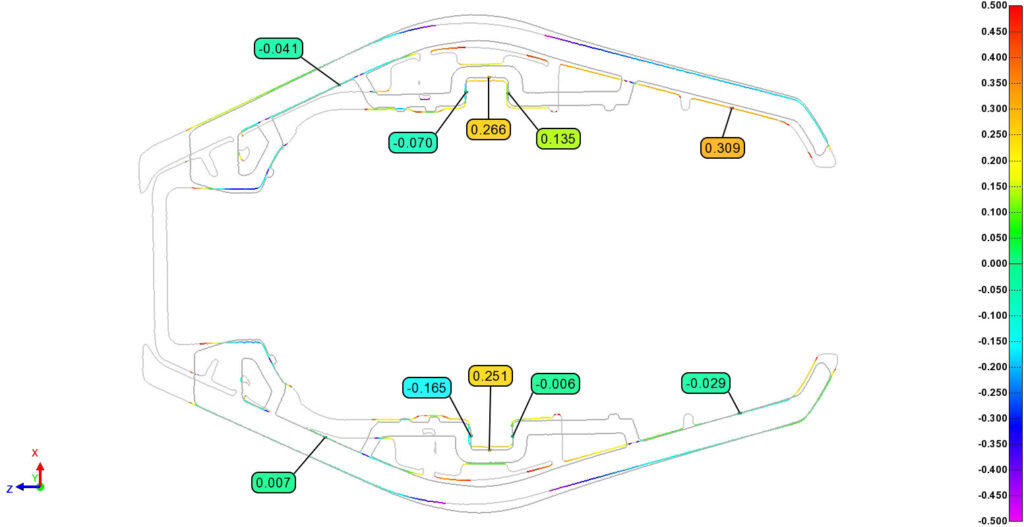

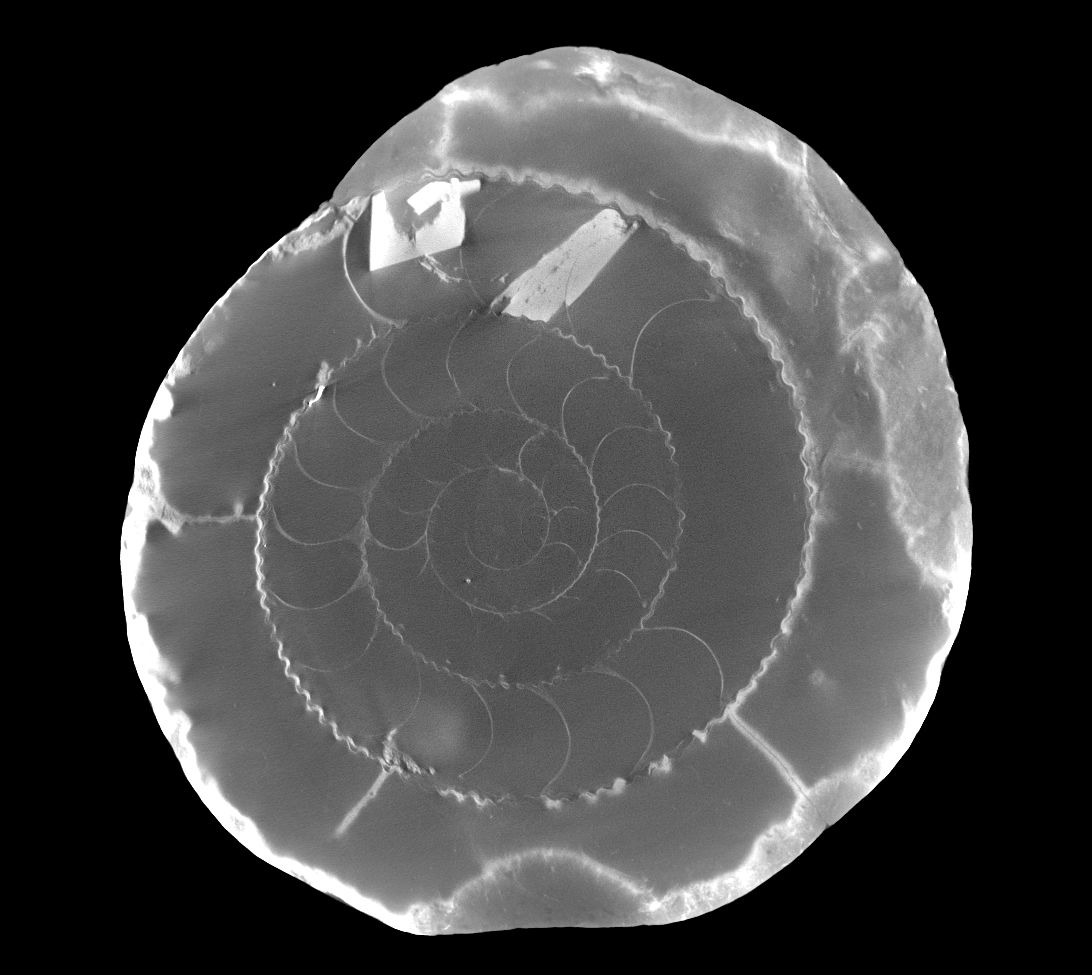

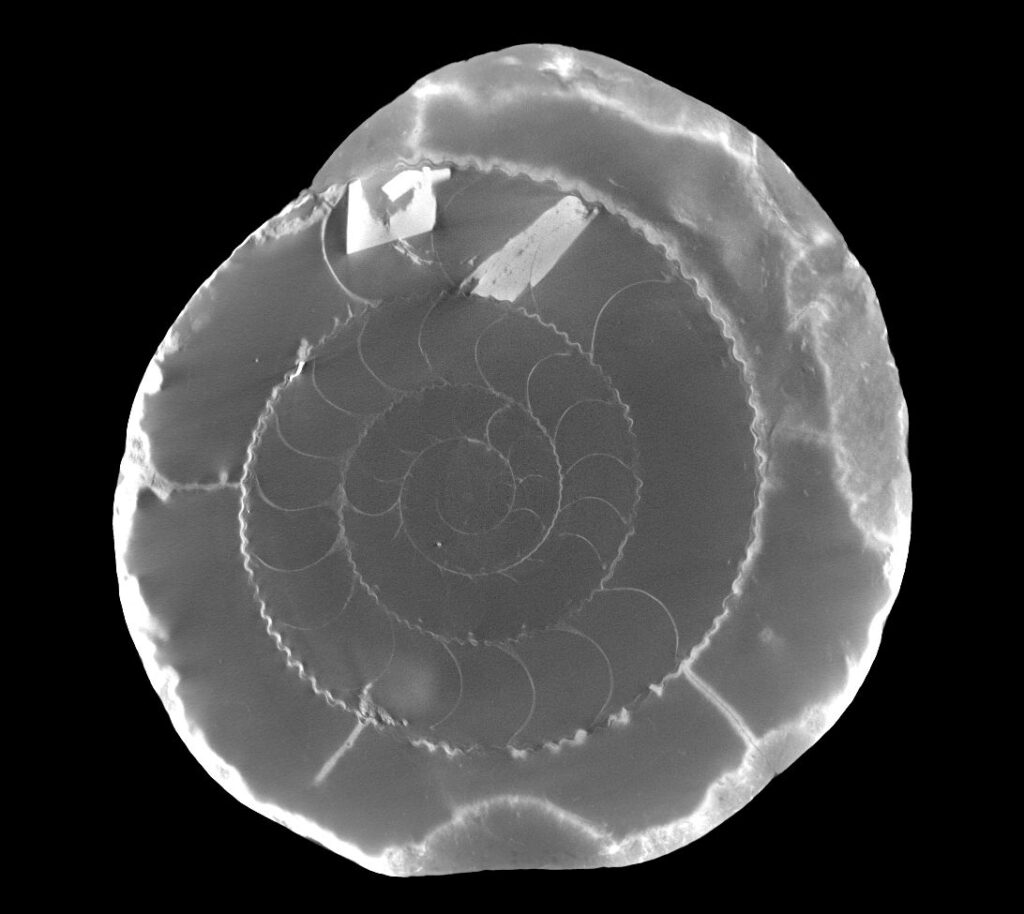

Unlike 2D X-Ray imaging, 3D CT Scanning can volumetrically quantify porosity. This quantification can be exported to Excel for statistical analysis to comare between manufacturing changes.

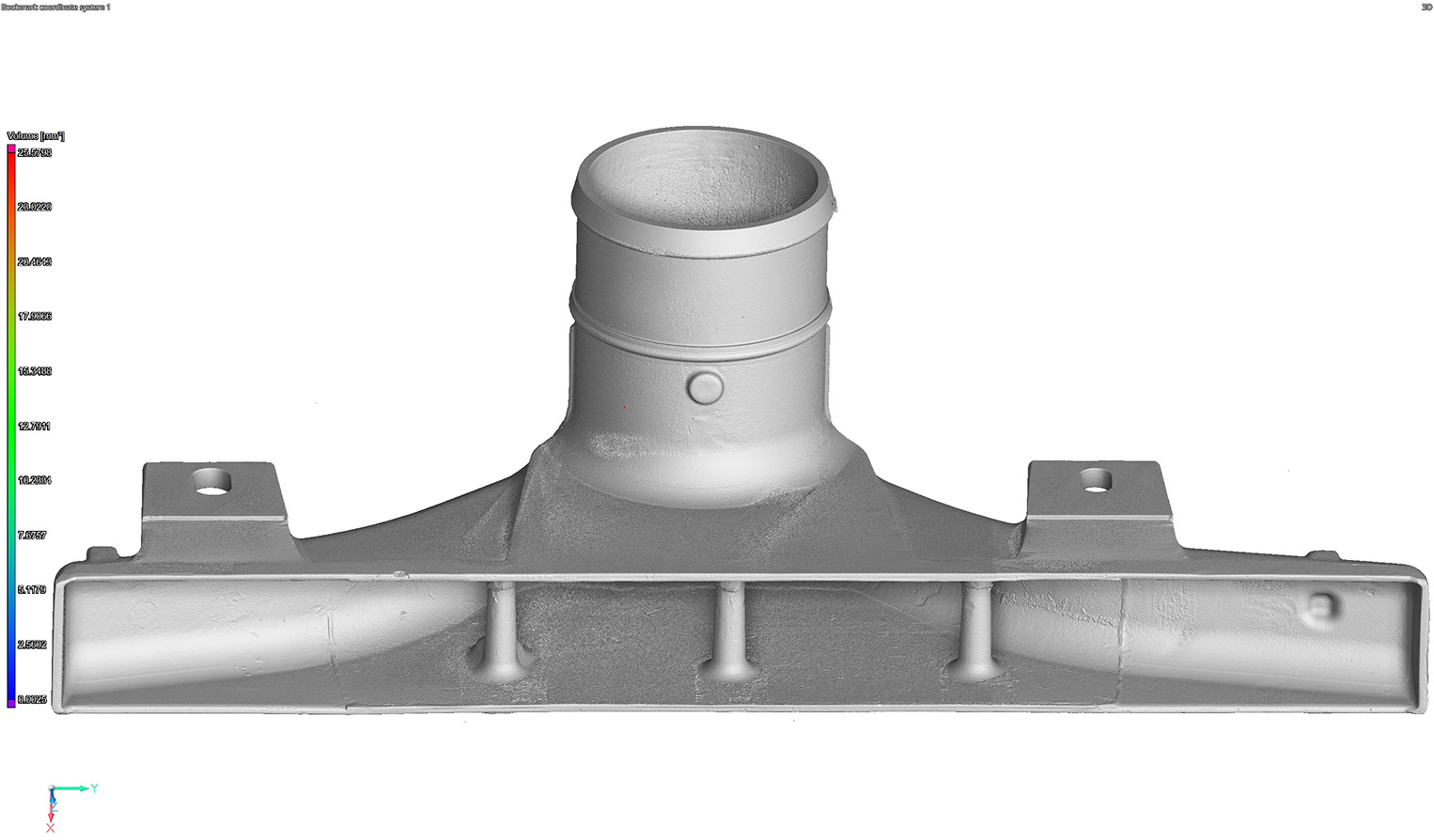

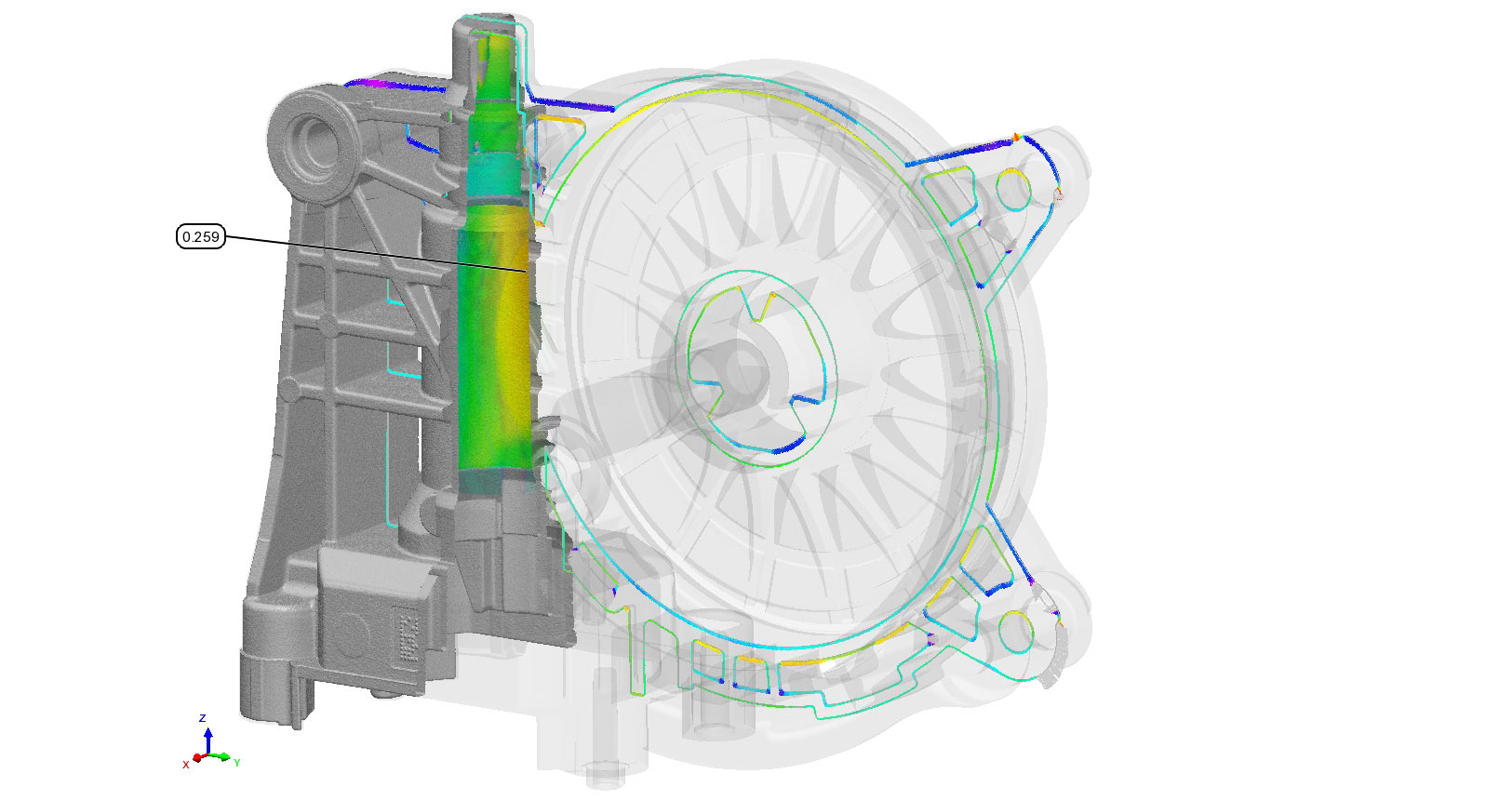

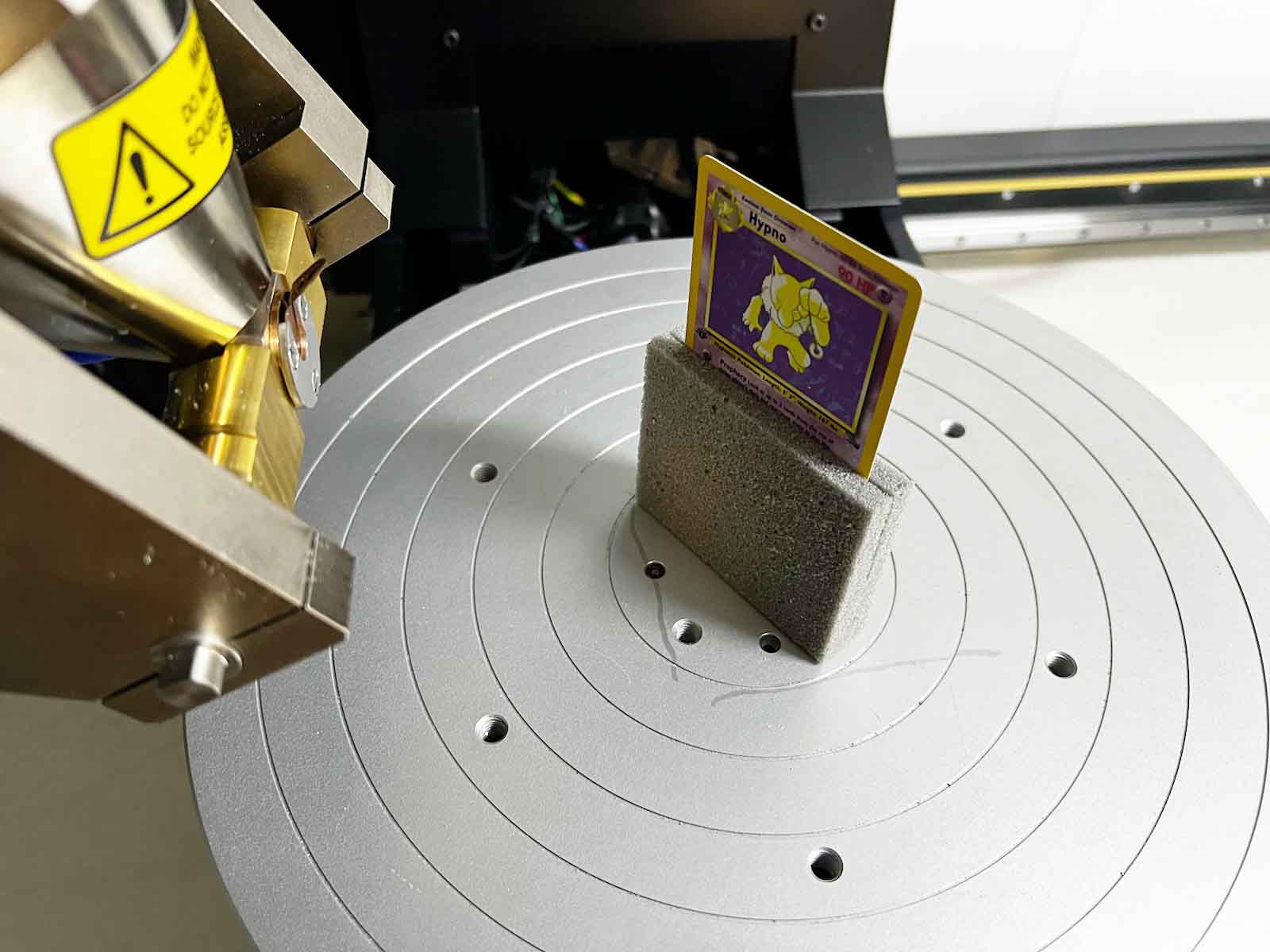

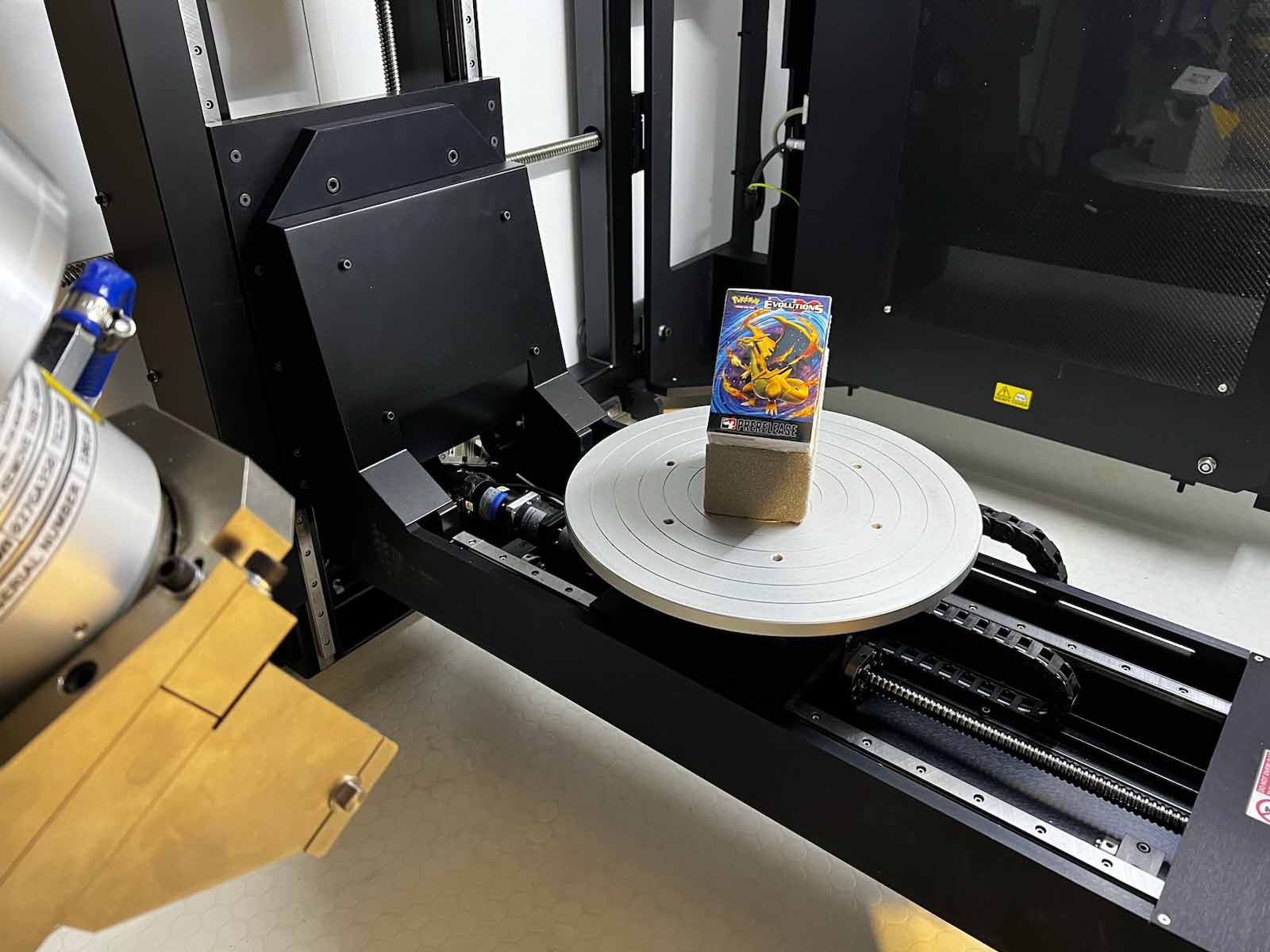

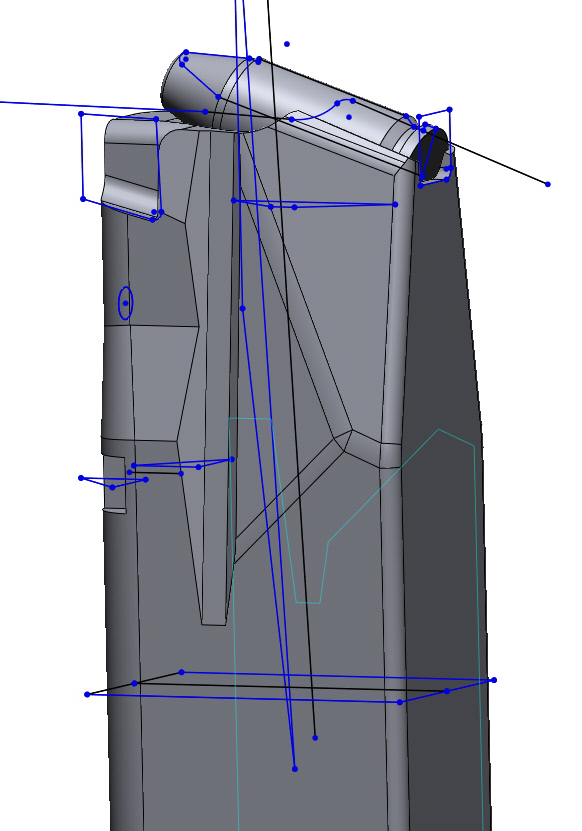

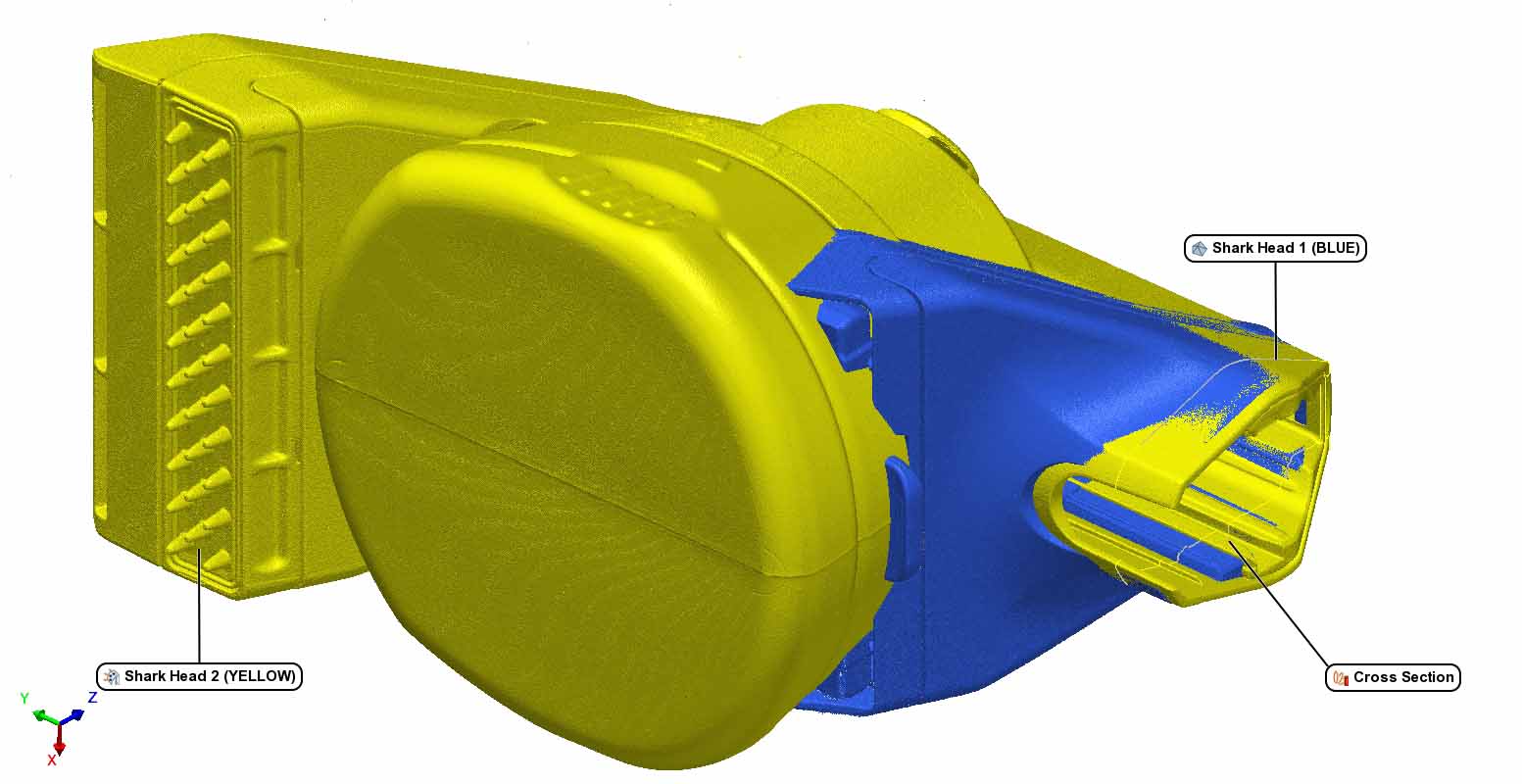

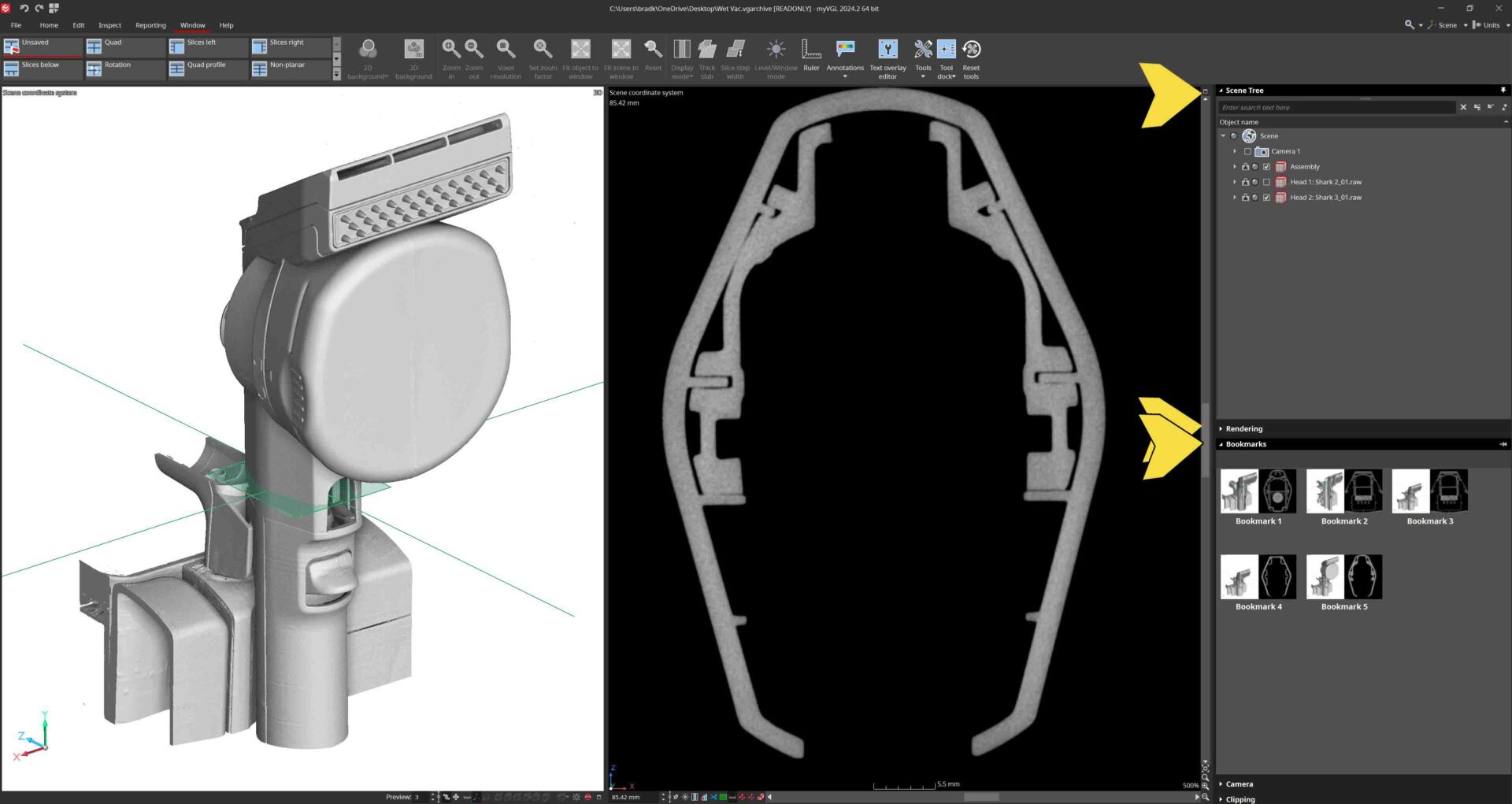

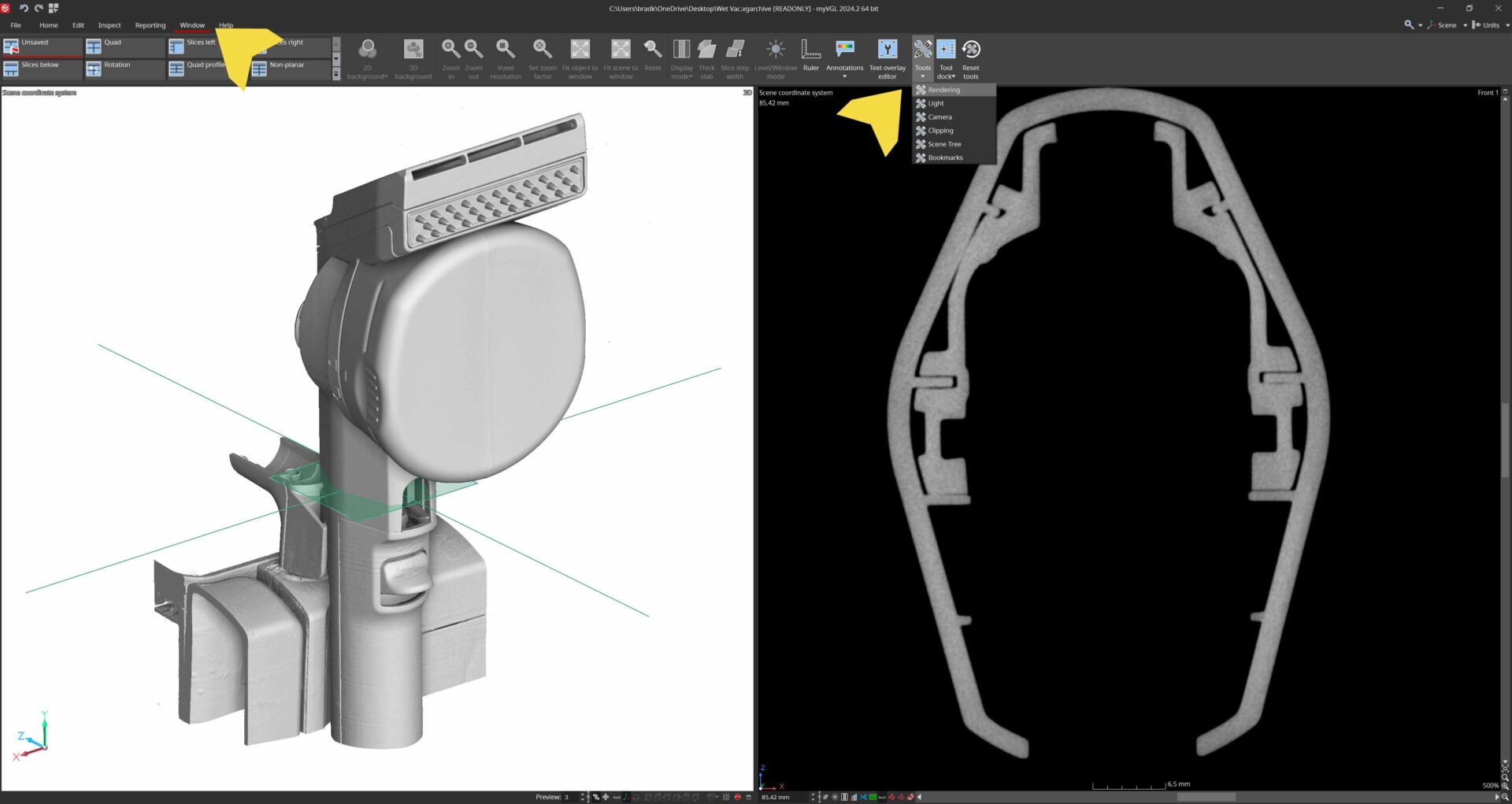

This large air cooler required four scans for total data acquisition. We then aligned and contrast adjusted the CT scans for a seamless review of the casting.