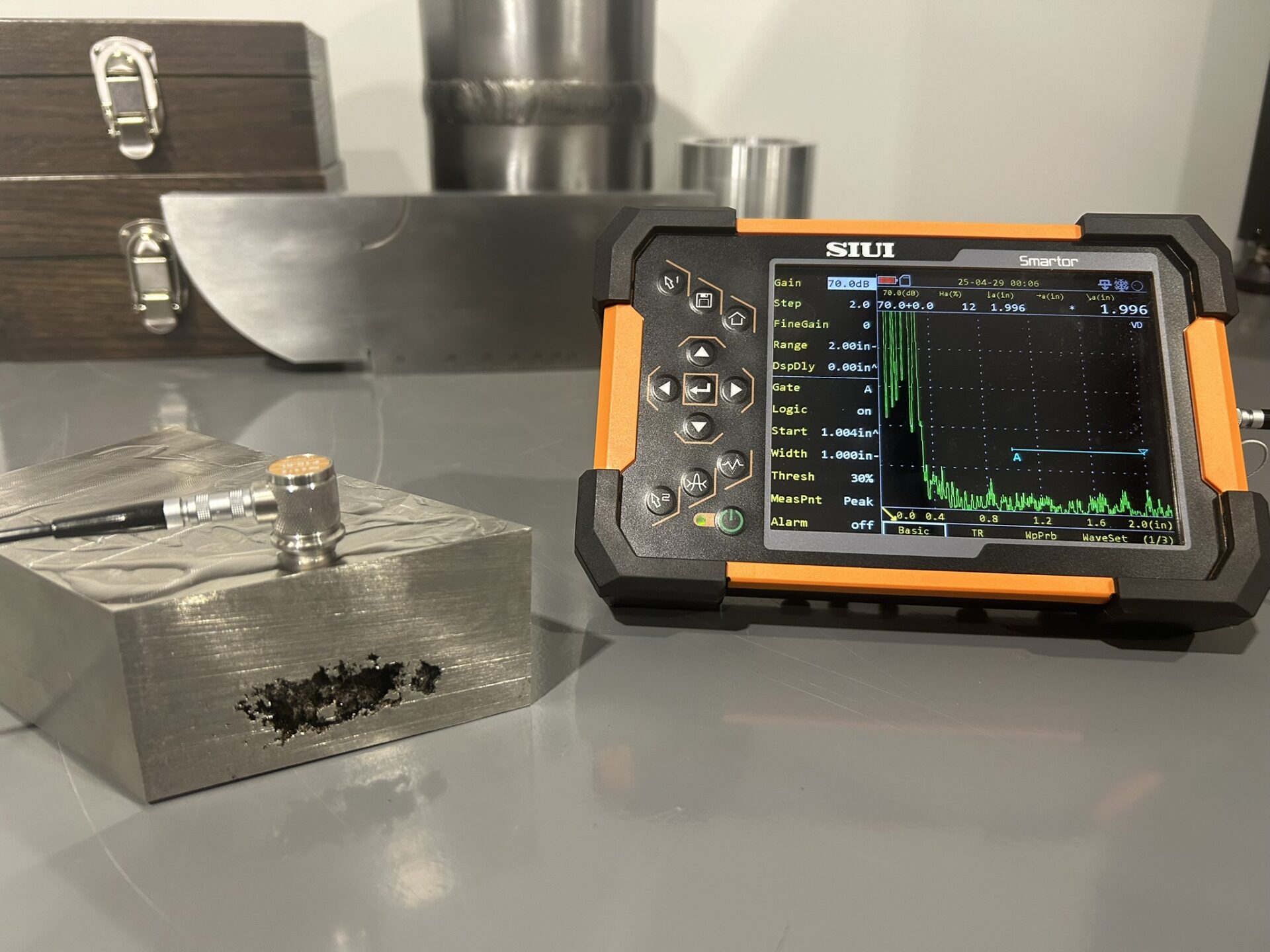

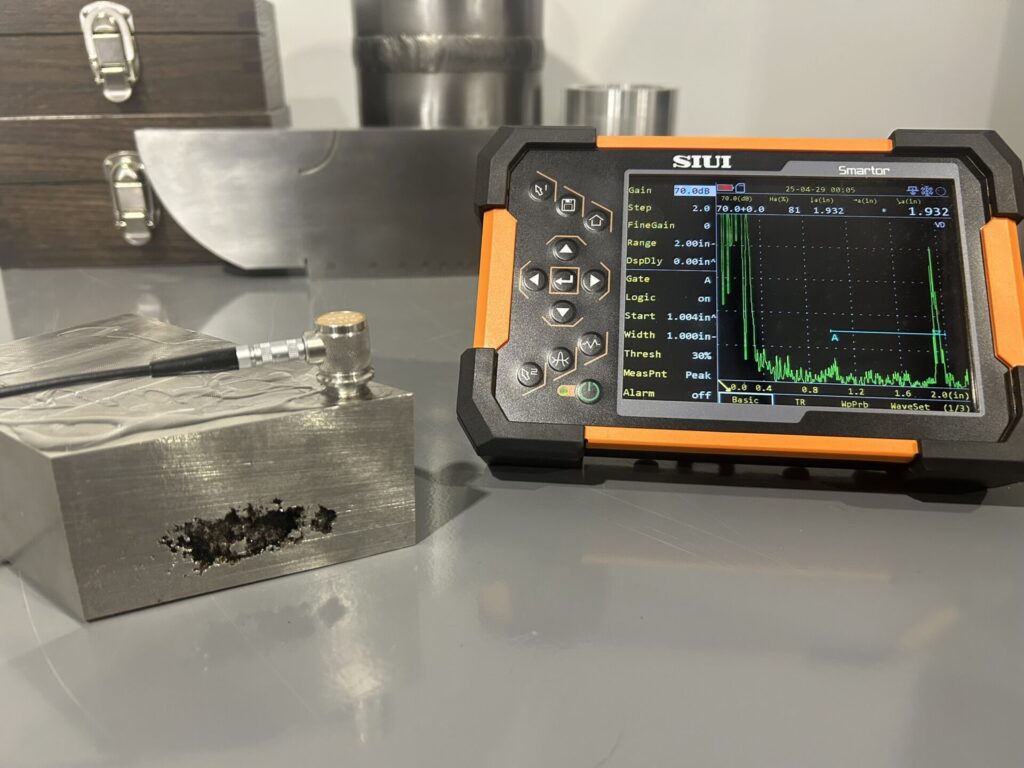

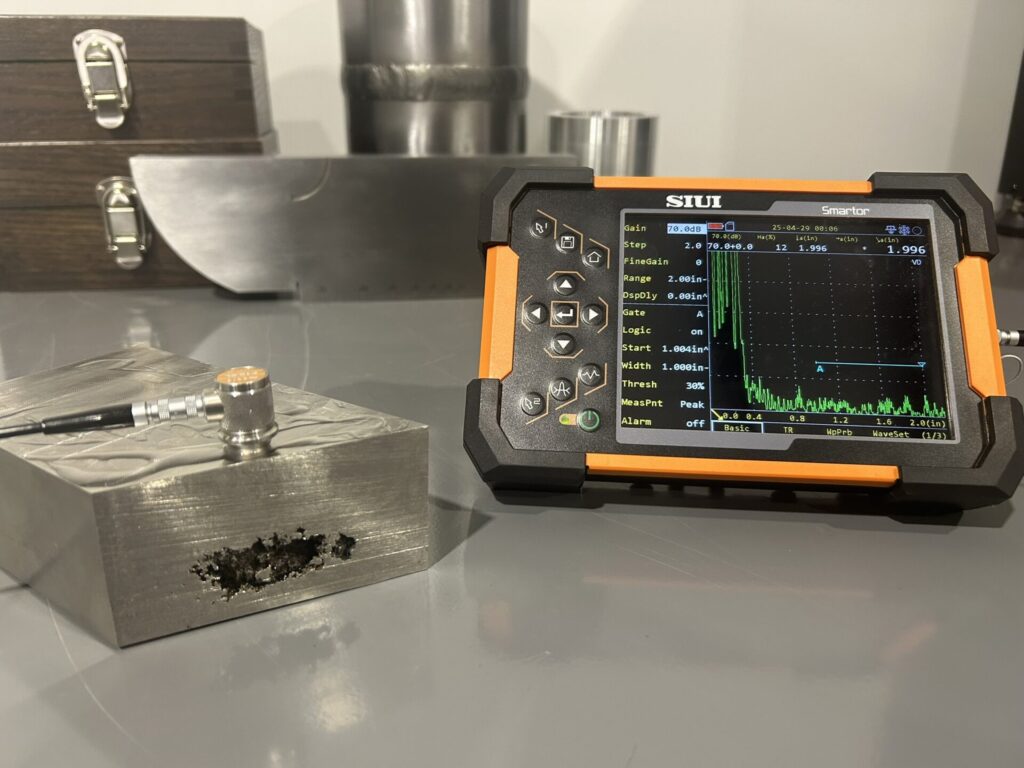

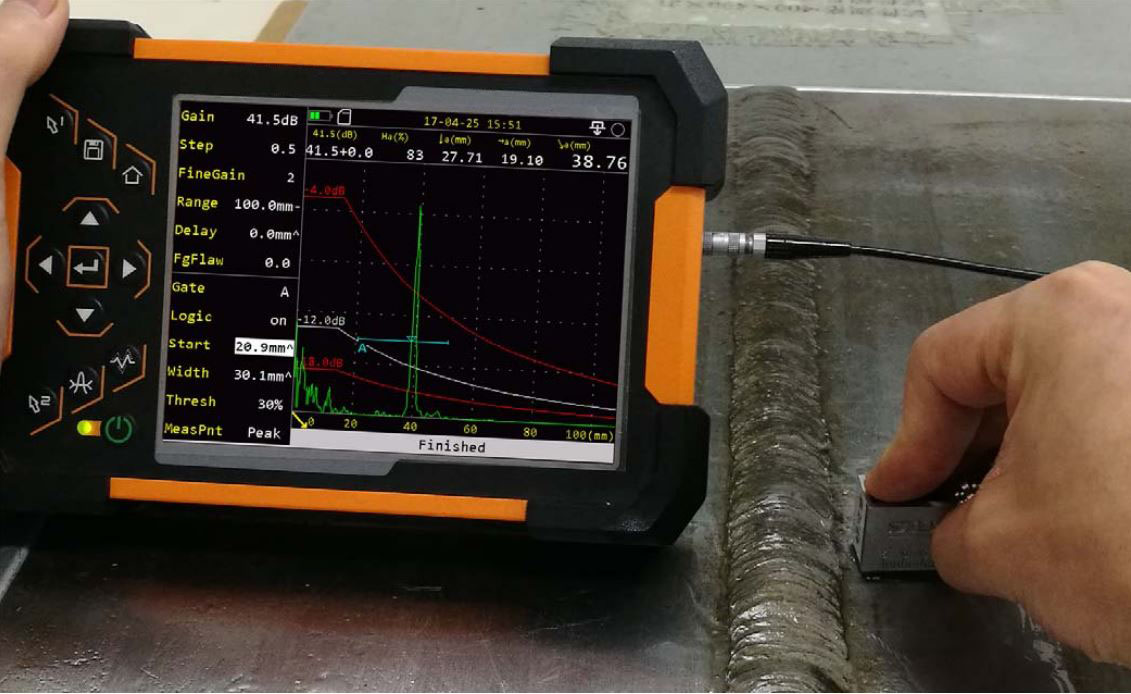

Ultrasonic Testing (UT) is a nondestructive testing method used to inspect and evaluate material properties and internal structures. It’s particularly useful for detecting flaws, measuring thickness, and assessing material integrity. UT is most effective on materials that efficiently transmit high-frequency sound waves.

Ultrasonic testing is used to evaluate raw materials and bar stock for internal defects before machining, helping save time and reduce waste.

Material Type | UT Suitability | Notes |

|---|---|---|

Metals | Excellent | Most common use |

Composites | Good–Moderate | Depends on type and layup |

Ceramics | Moderate | Best for dense, engineered types |

Plastics/Polymers | Moderate | Limited by attenuation |

Concrete | Moderate | Specialized methods used |

Porous/Natural/Foams | Poor | High attenuation/scattering |