First Article Inspections

First Article Inspection (FAI) is a comprehensive verification process used in manufacturing to ensure that a newly produced part or component meets all specified requirements. It involves inspecting and testing the first production item against the engineering drawings, specifications, and other applicable standards.

FAI typically involves detailed inspections, measurements, and testing to verify critical dimensions, material properties, functionality, and performance characteristics of the part.

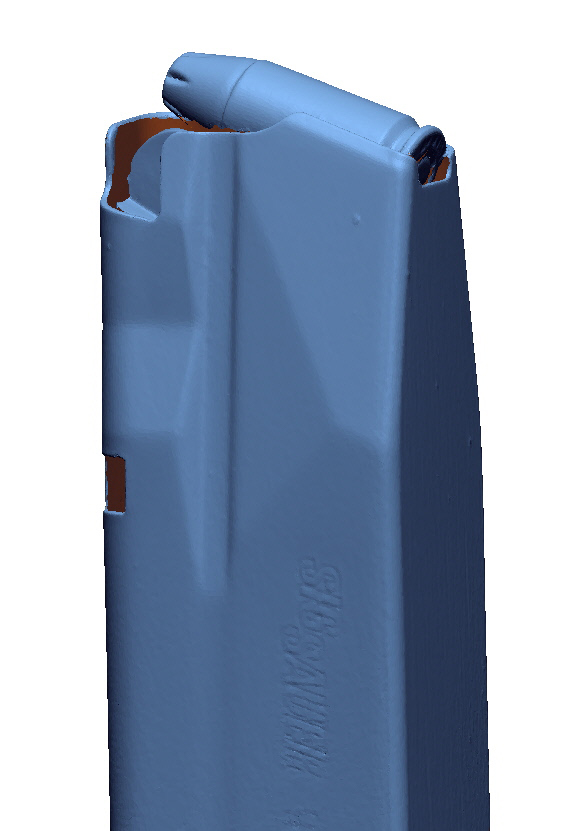

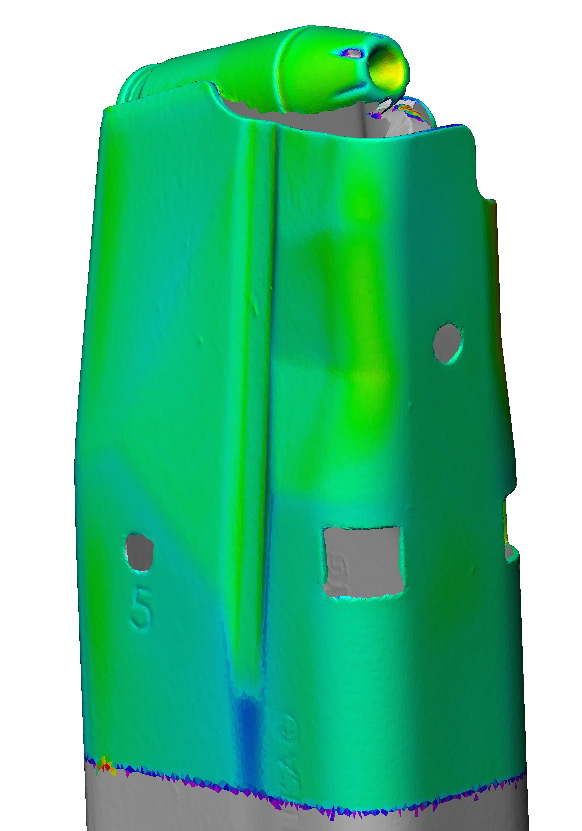

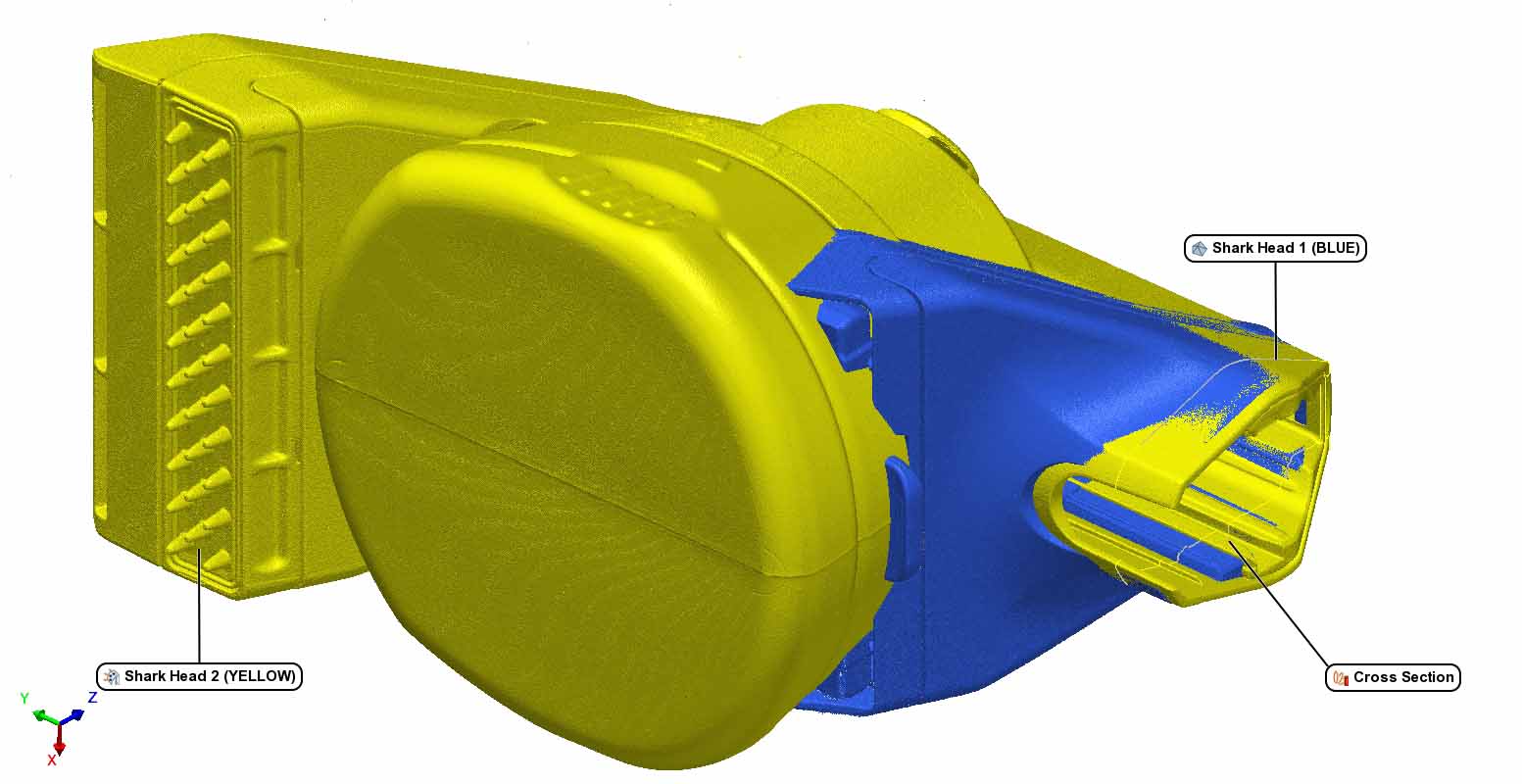

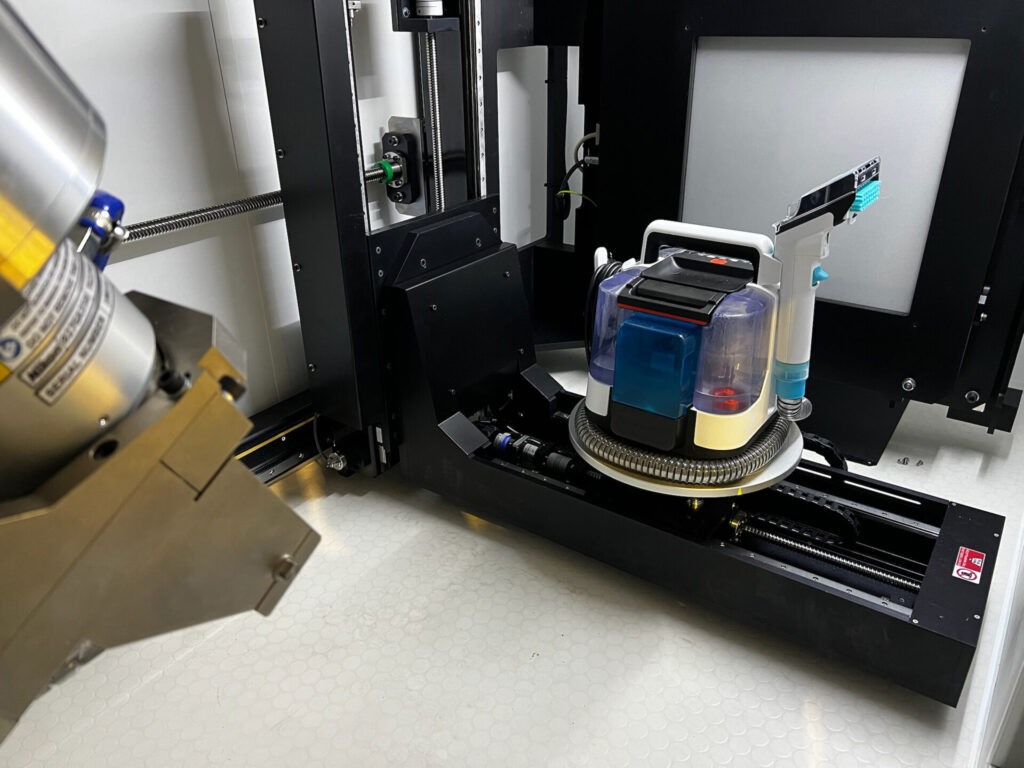

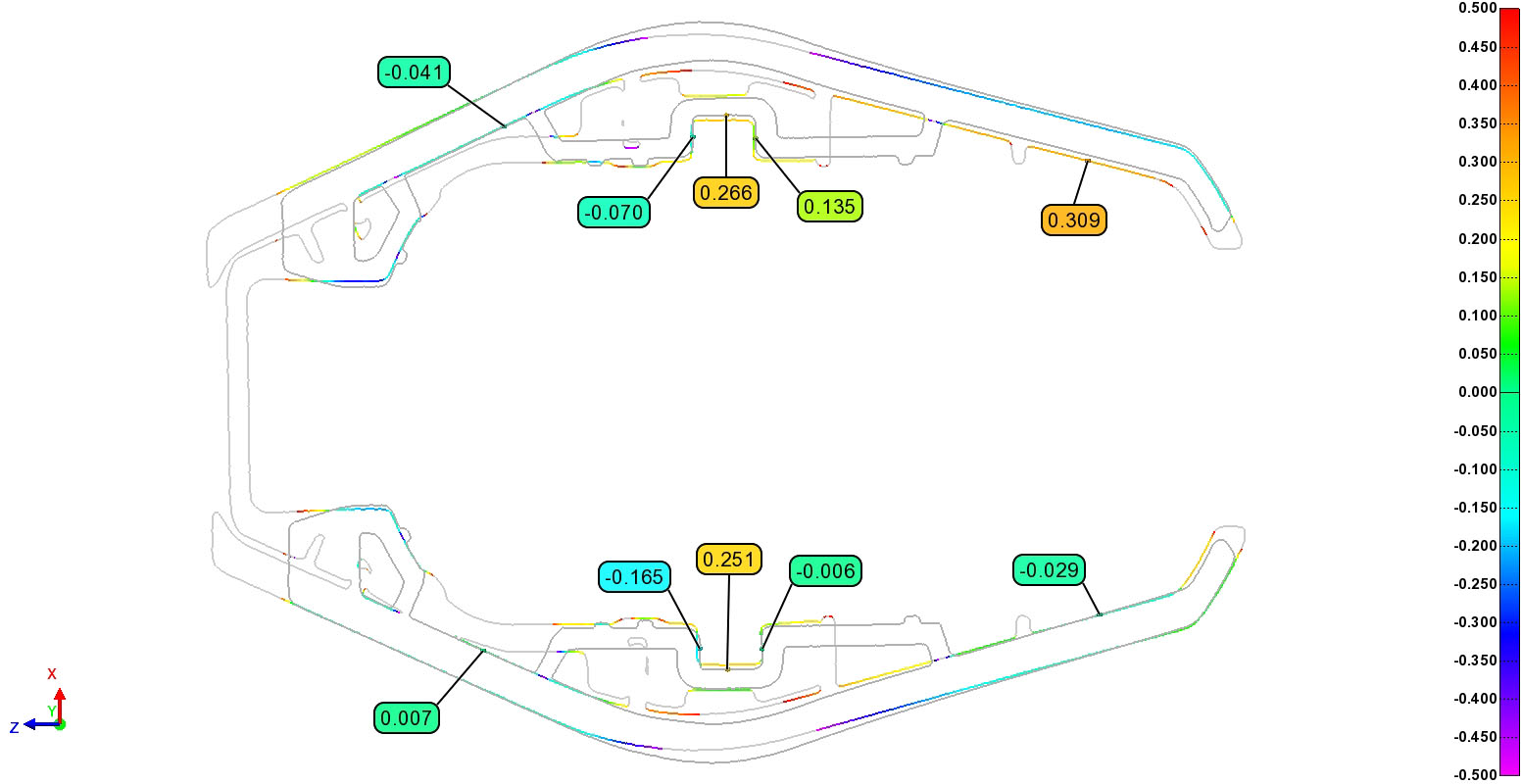

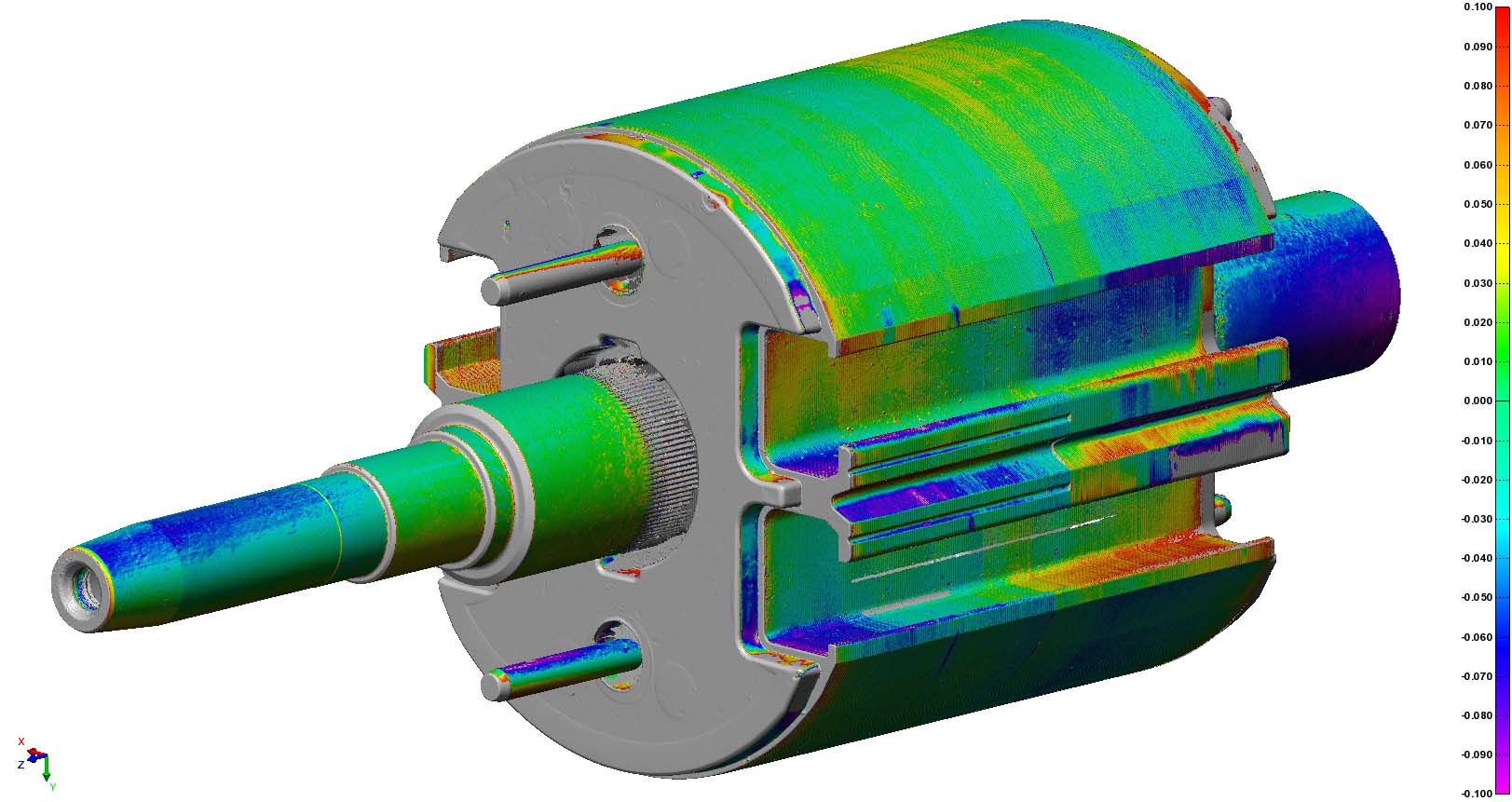

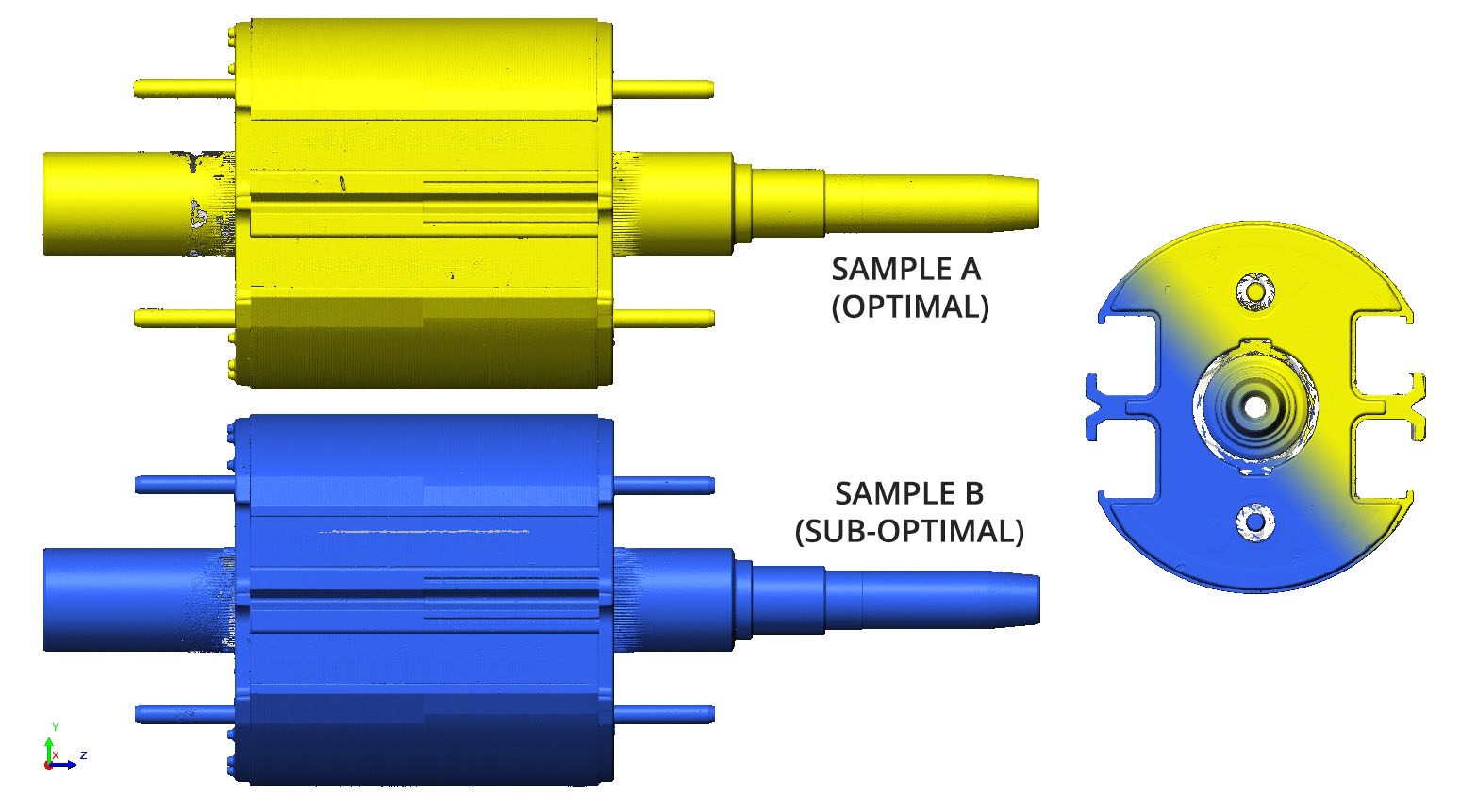

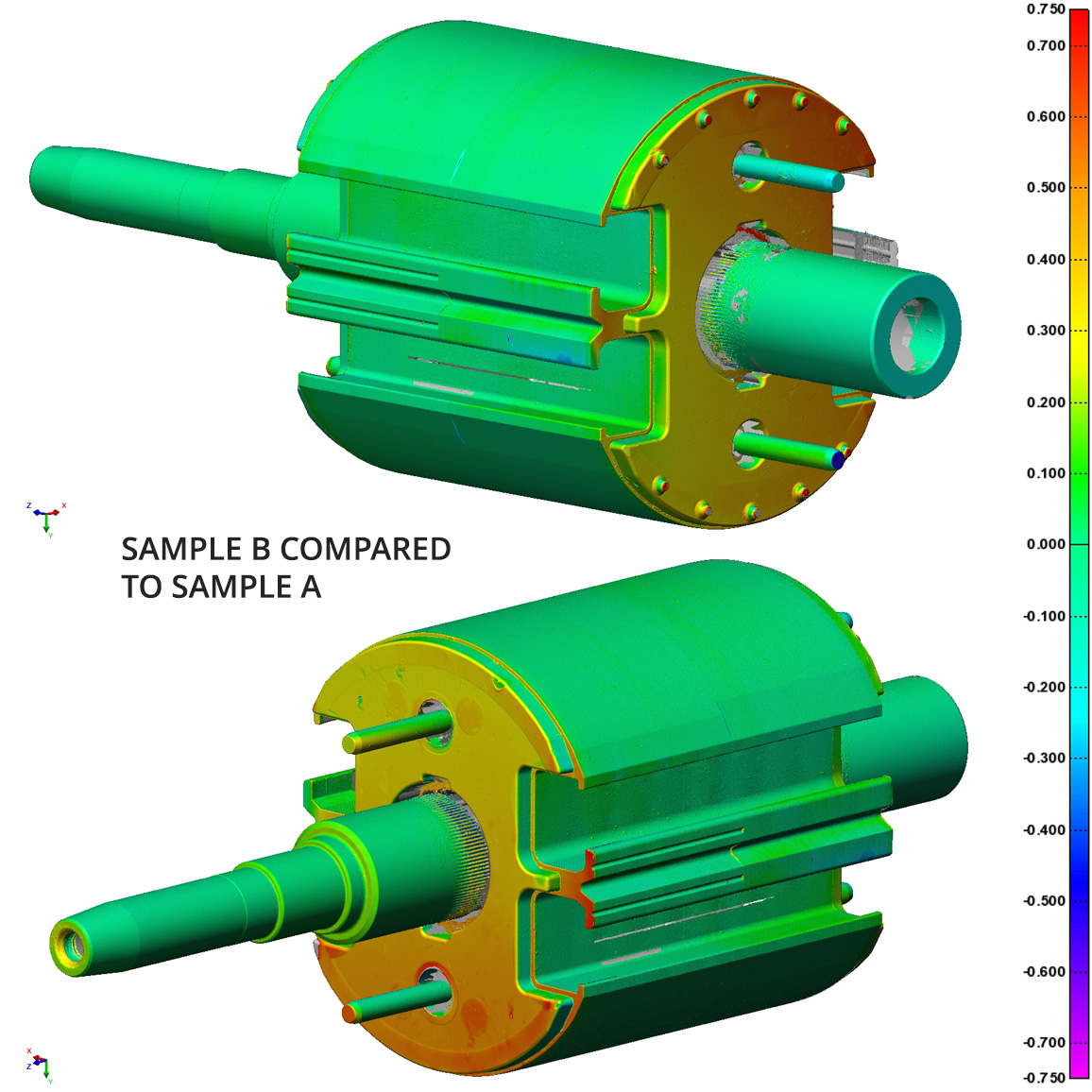

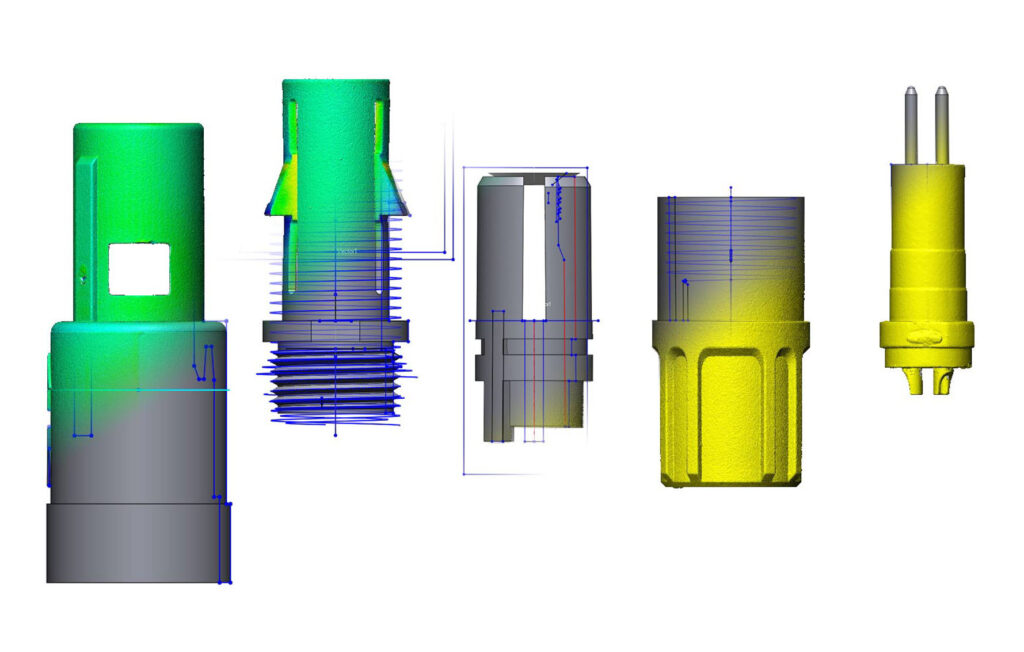

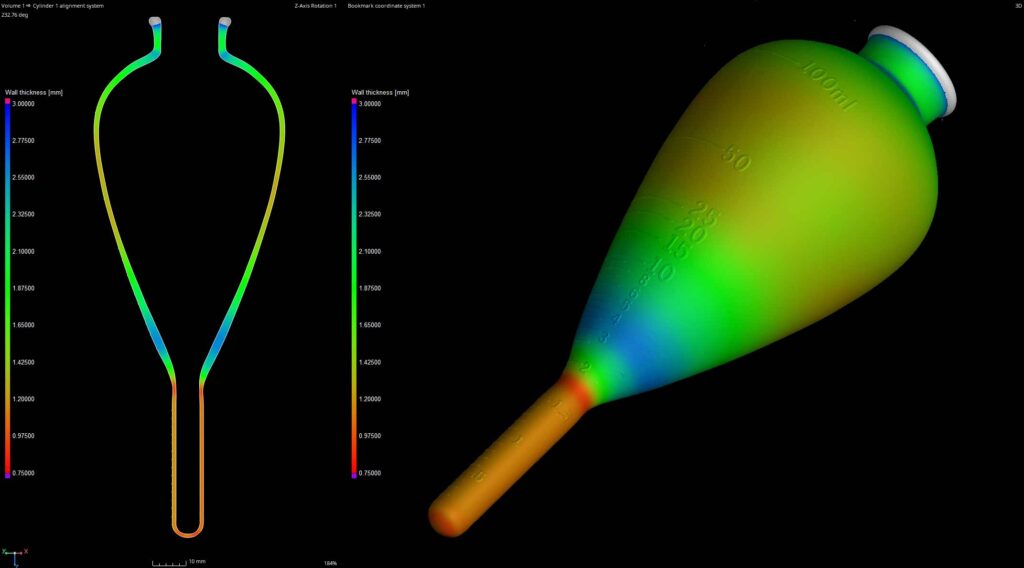

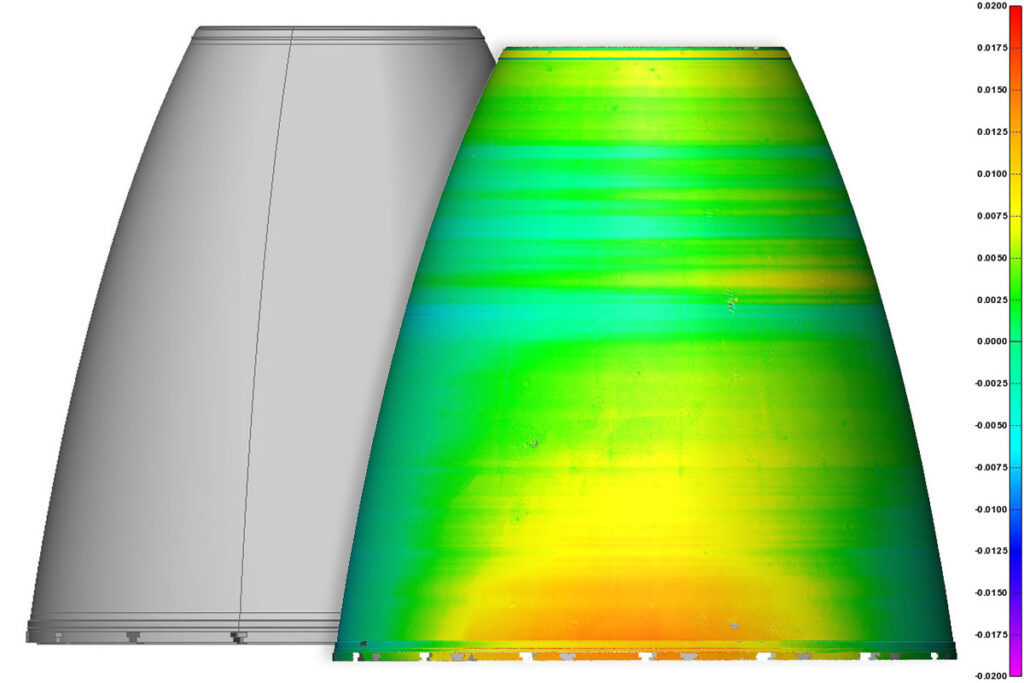

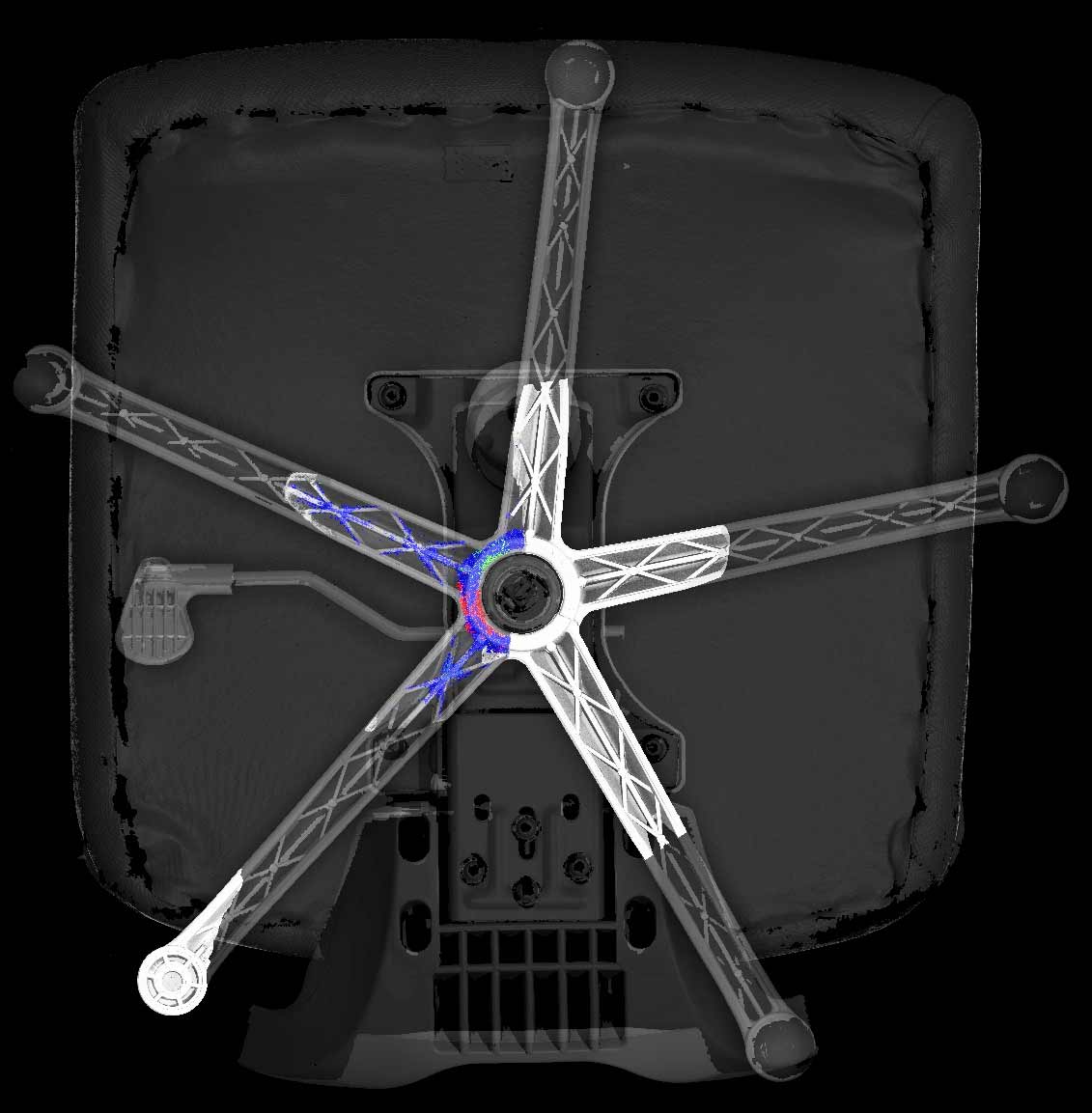

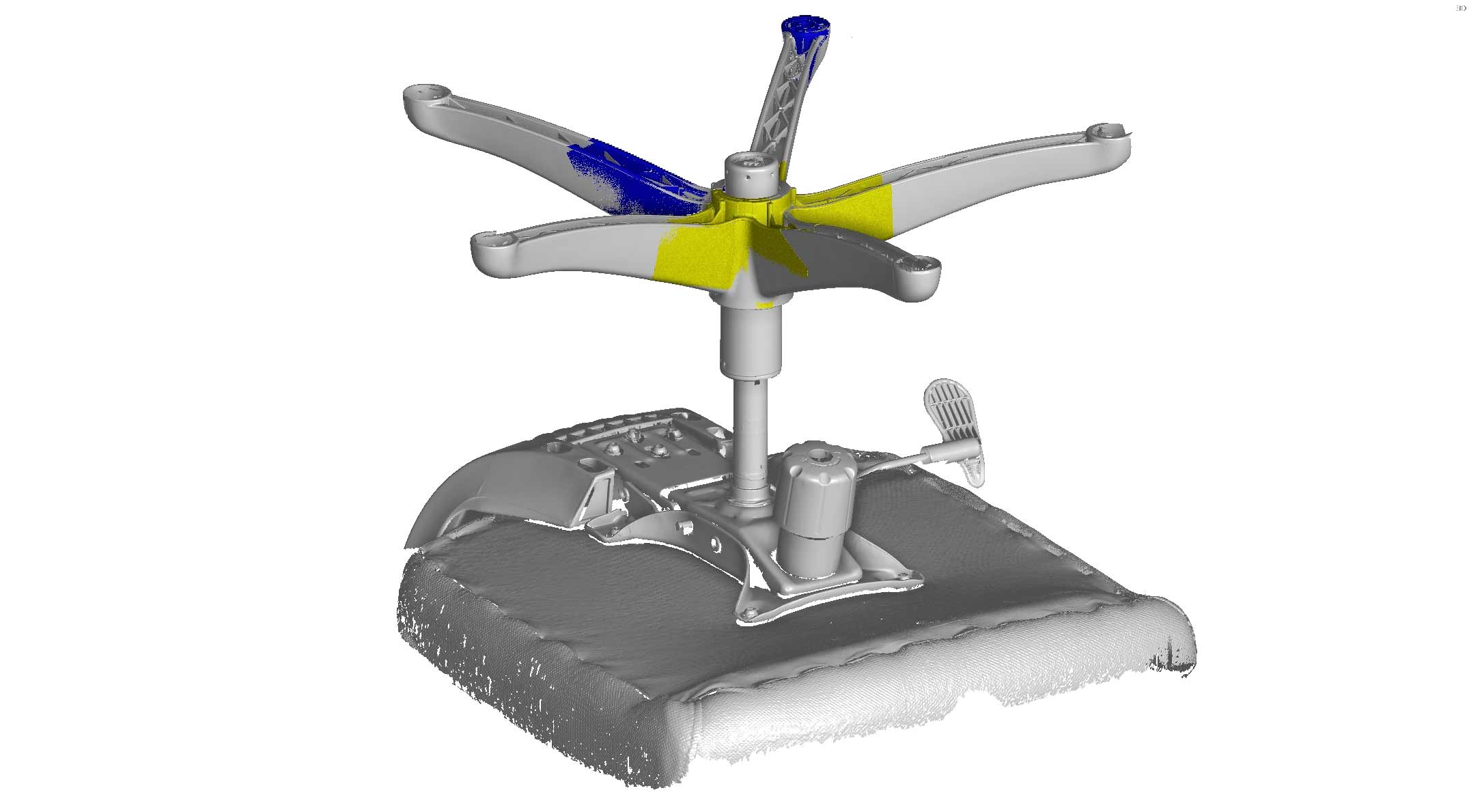

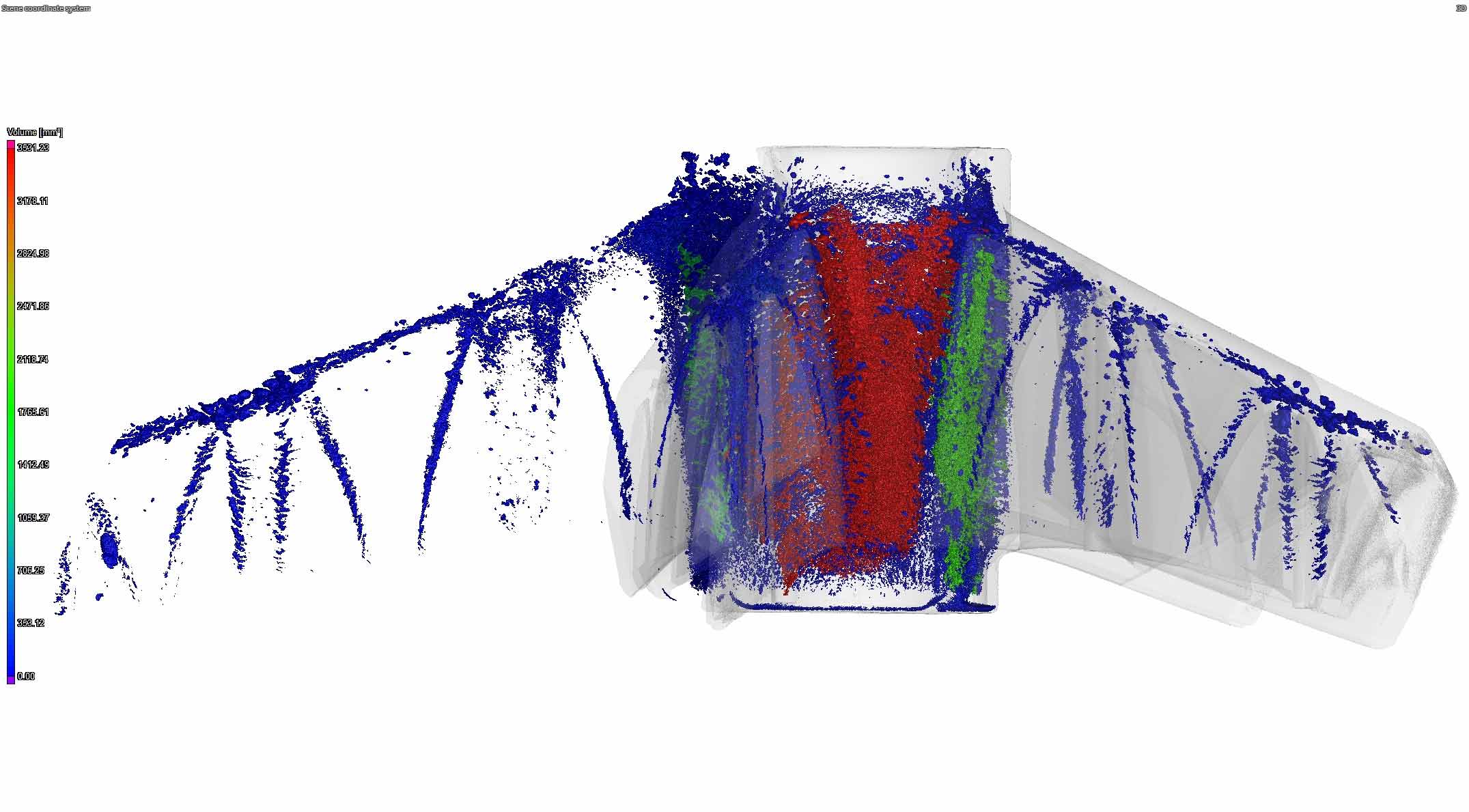

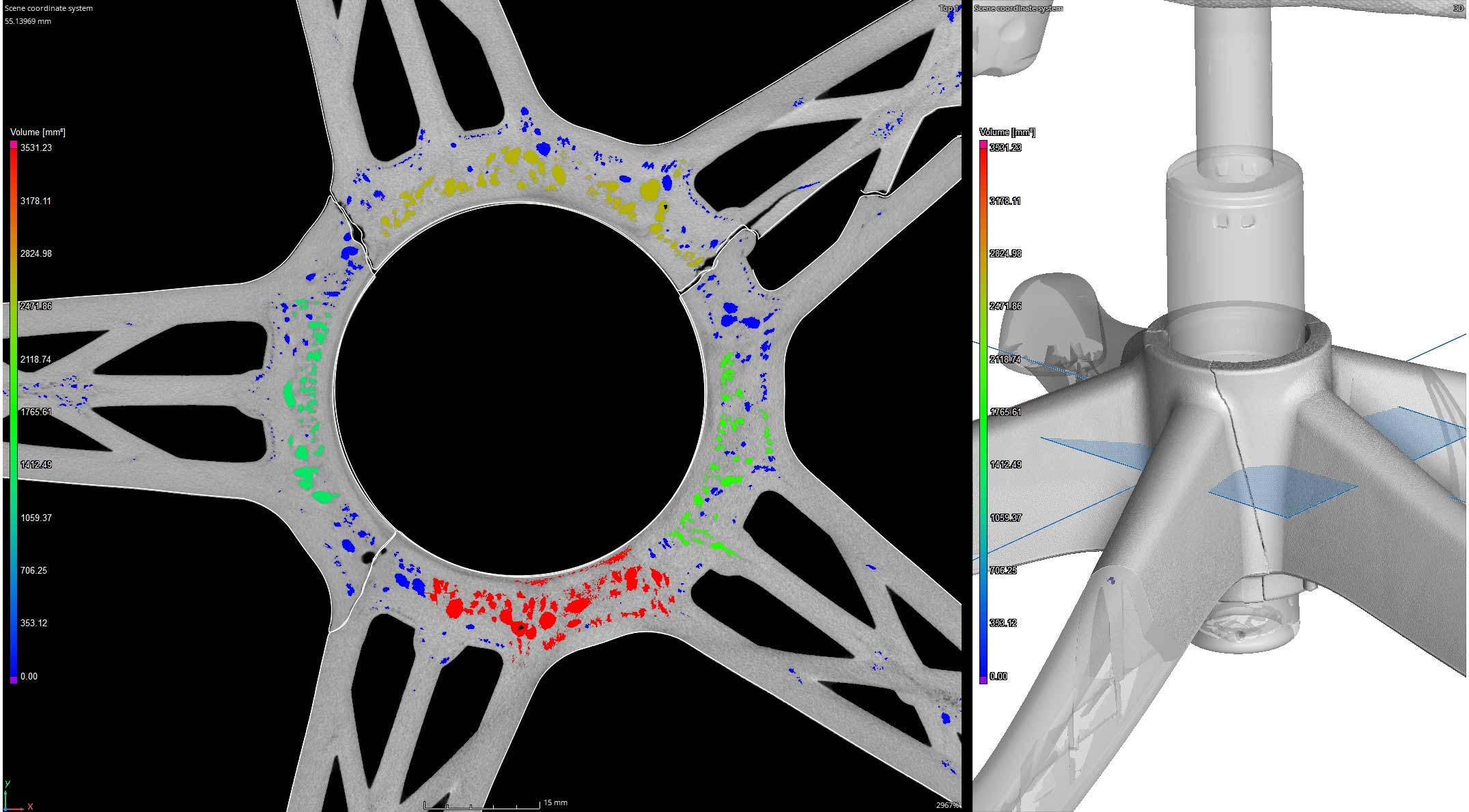

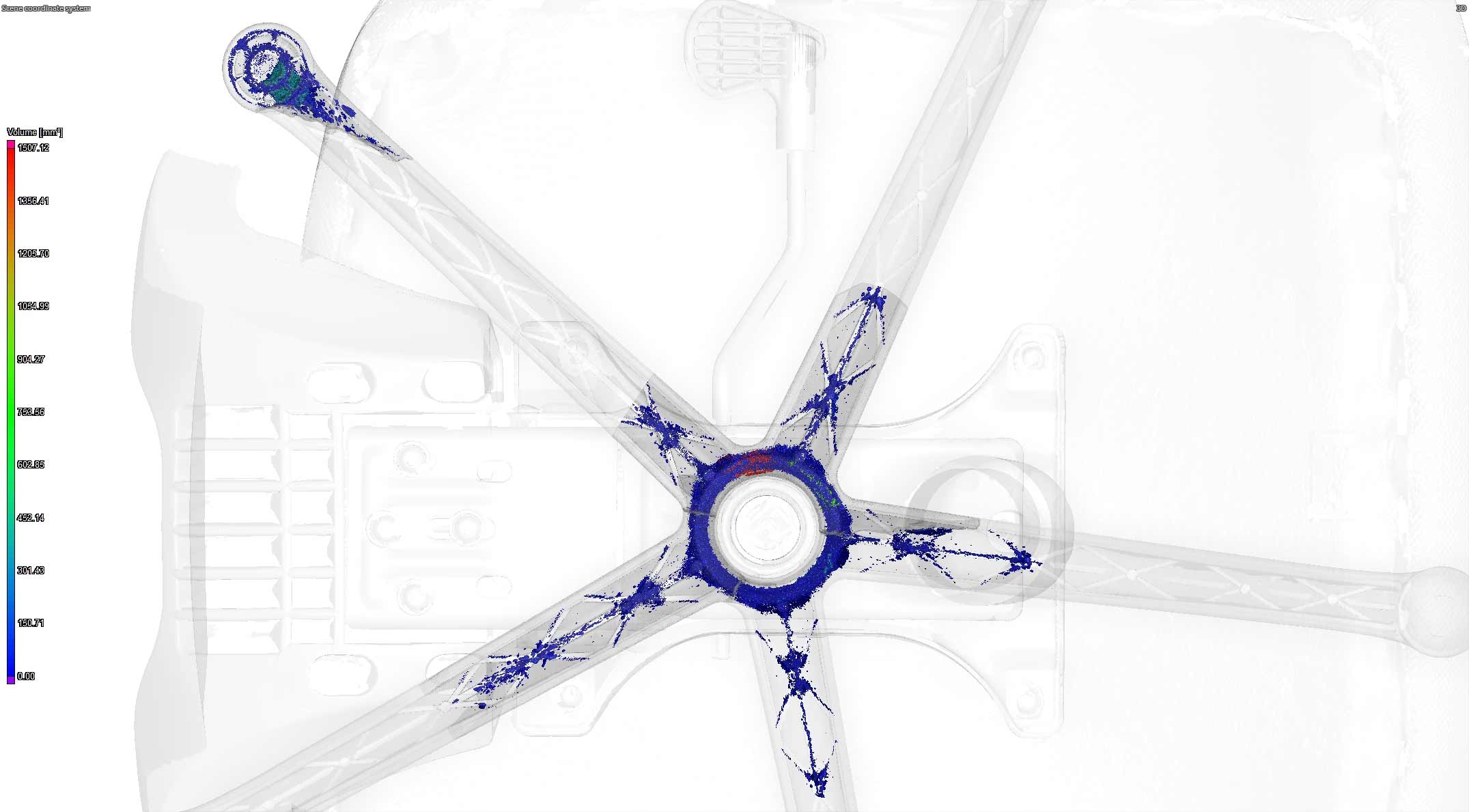

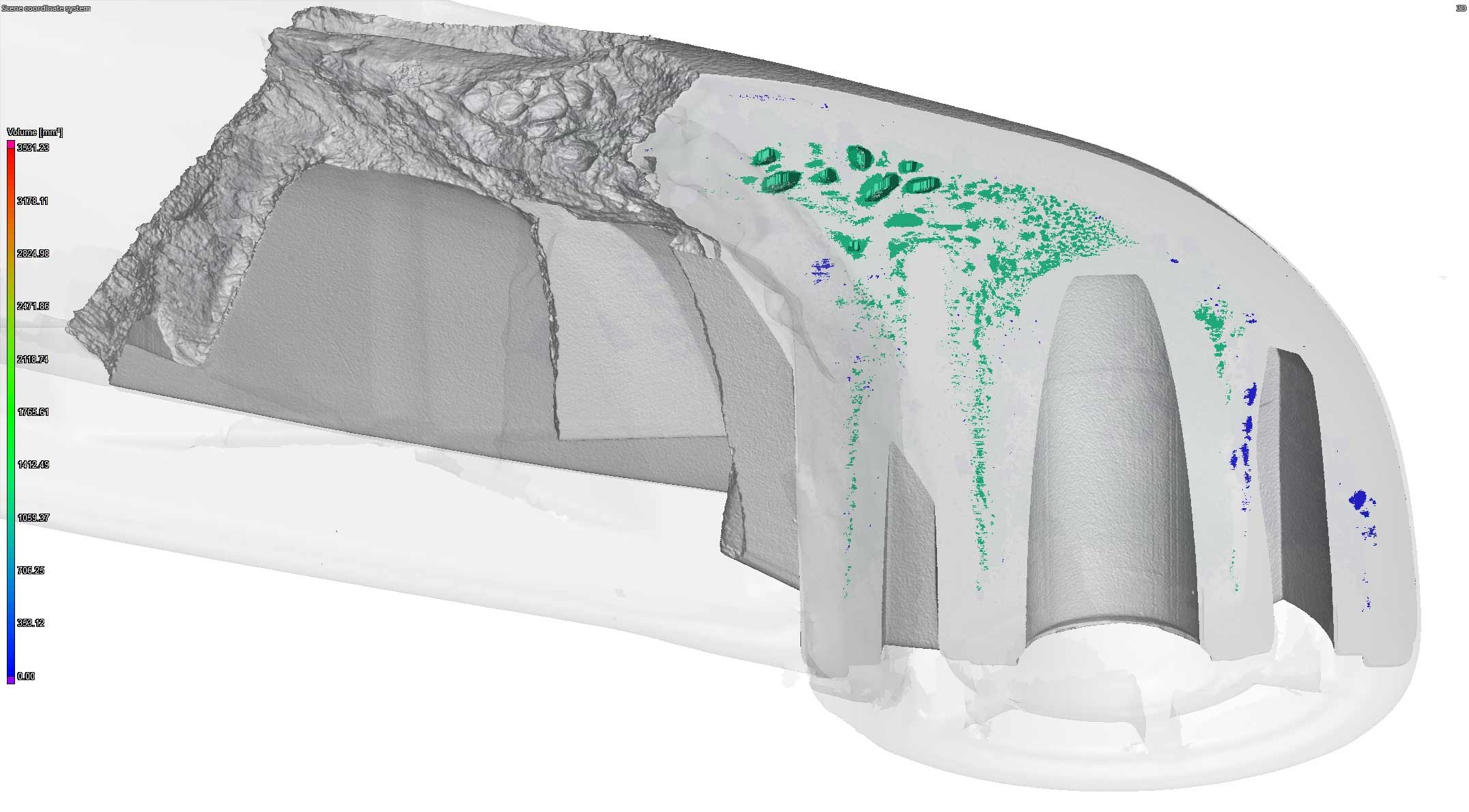

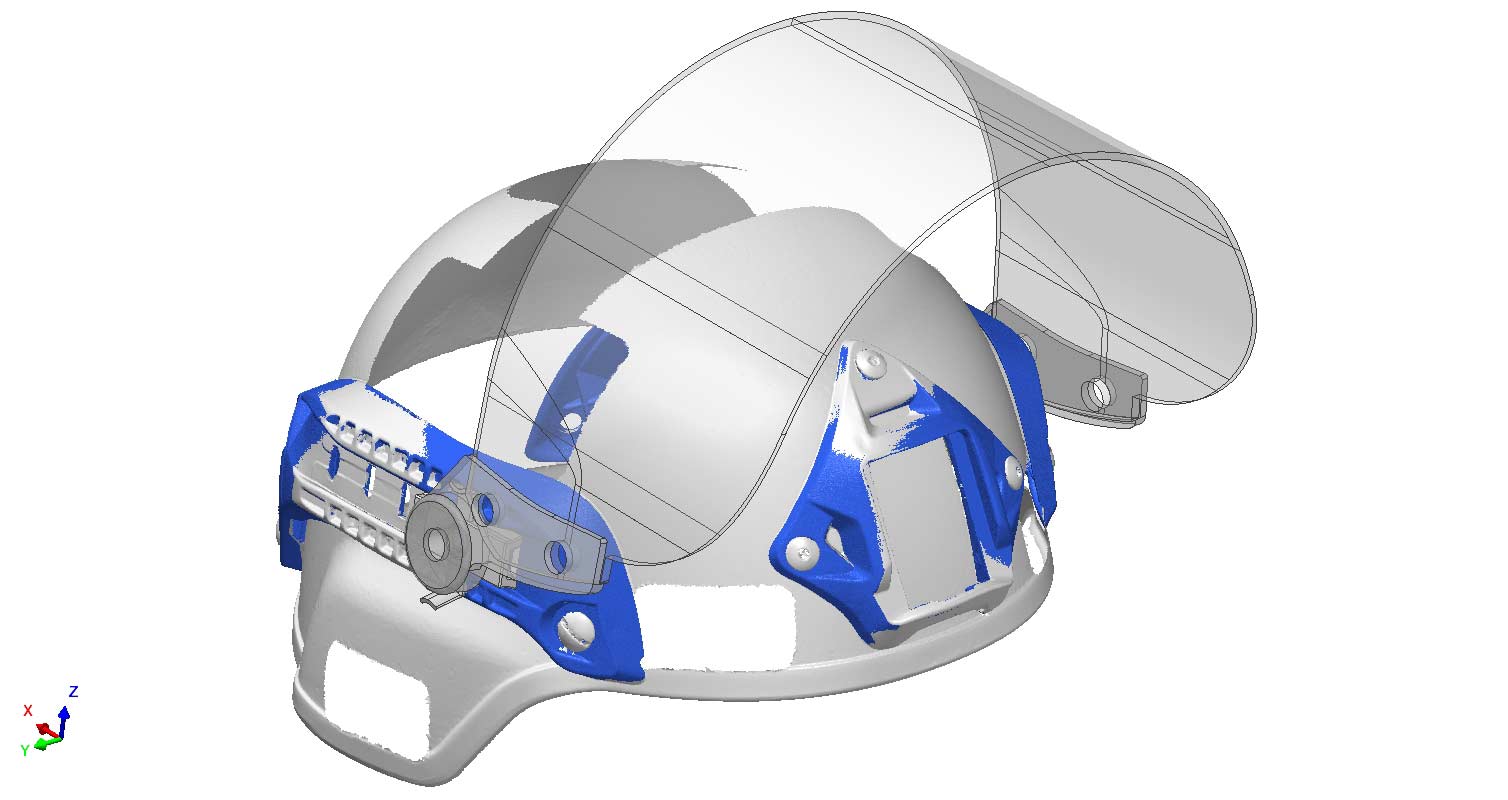

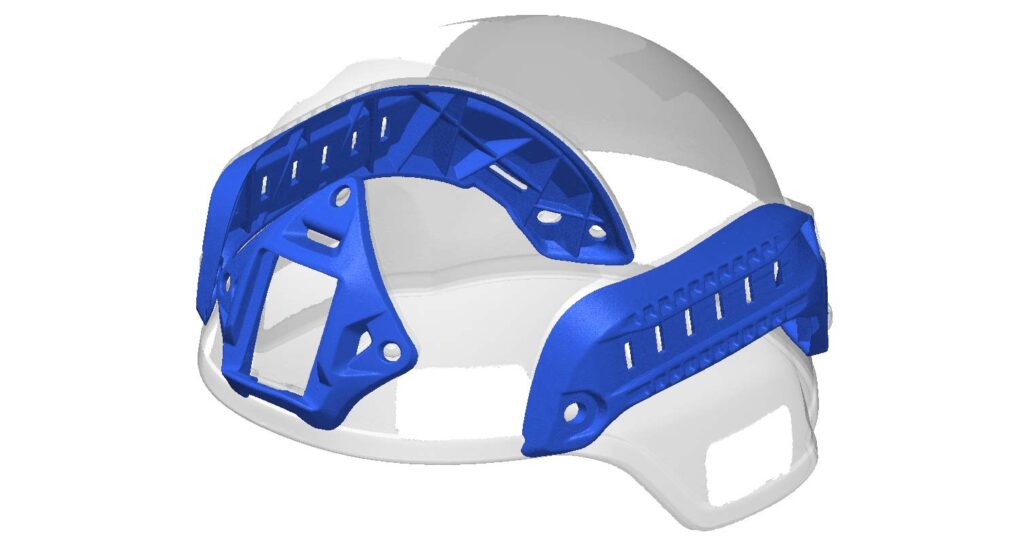

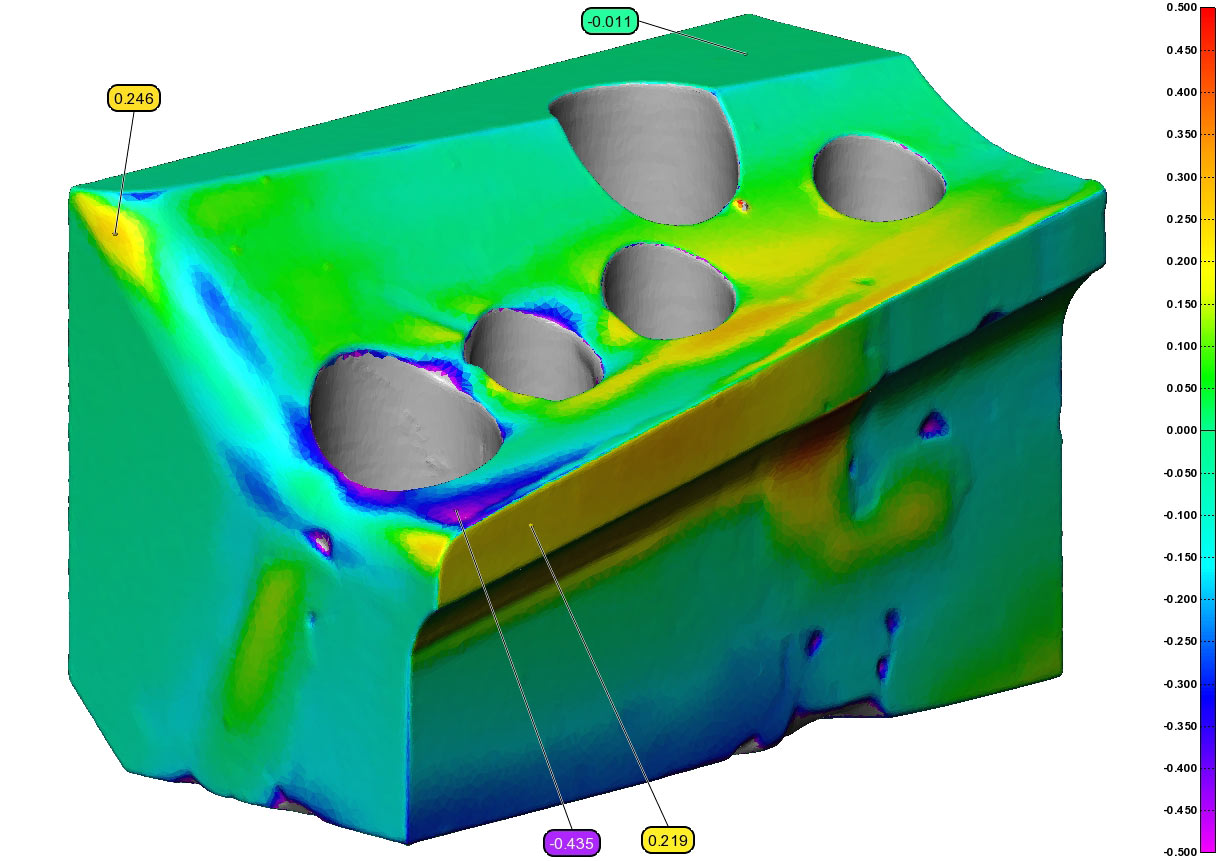

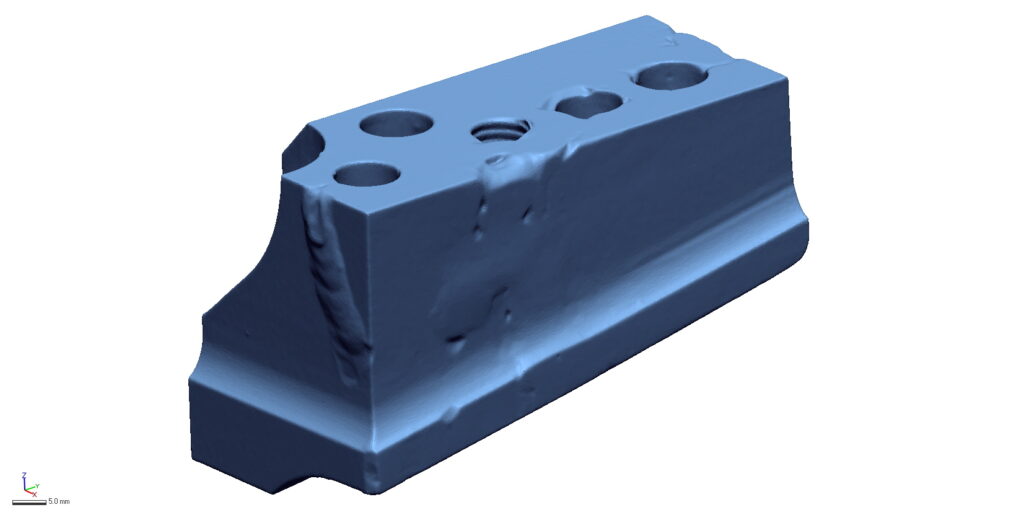

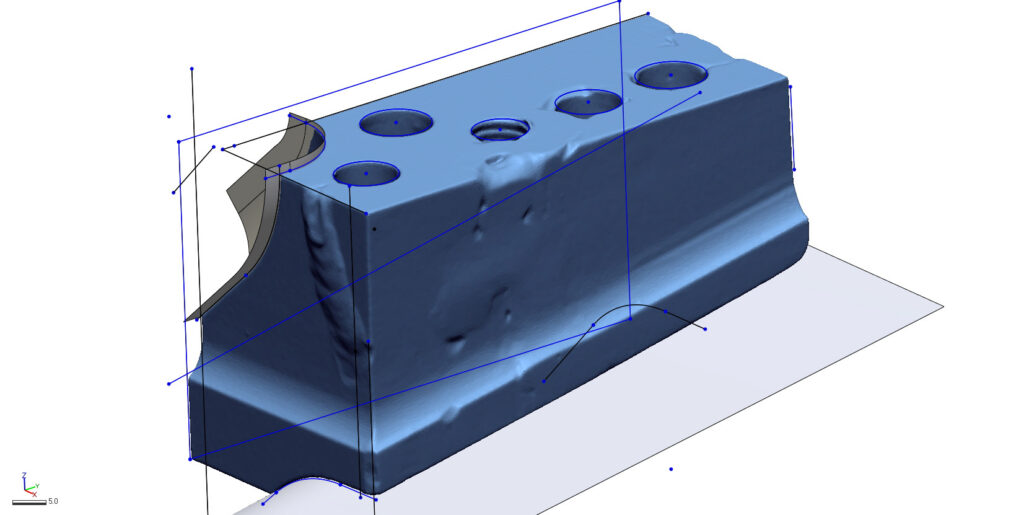

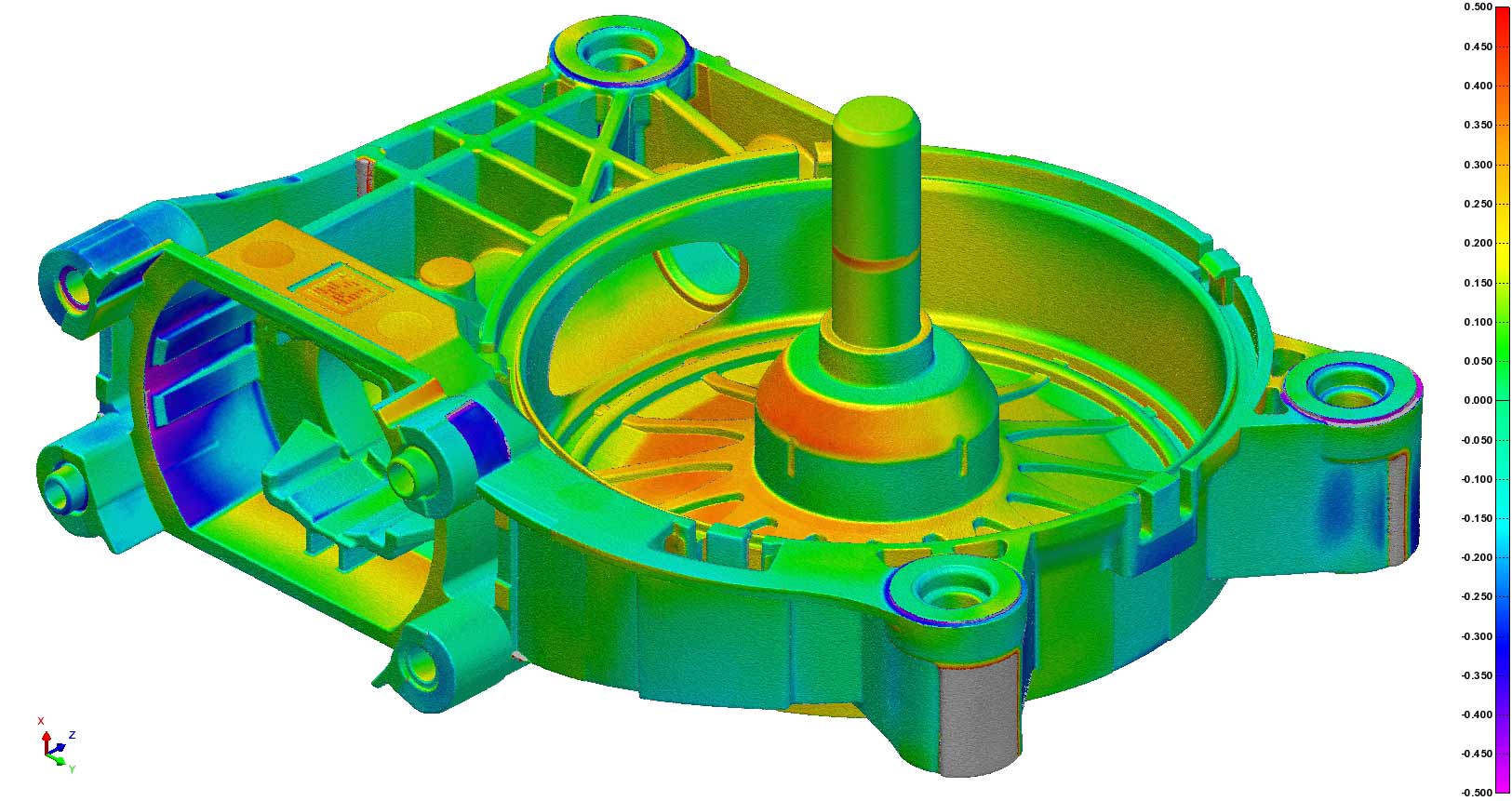

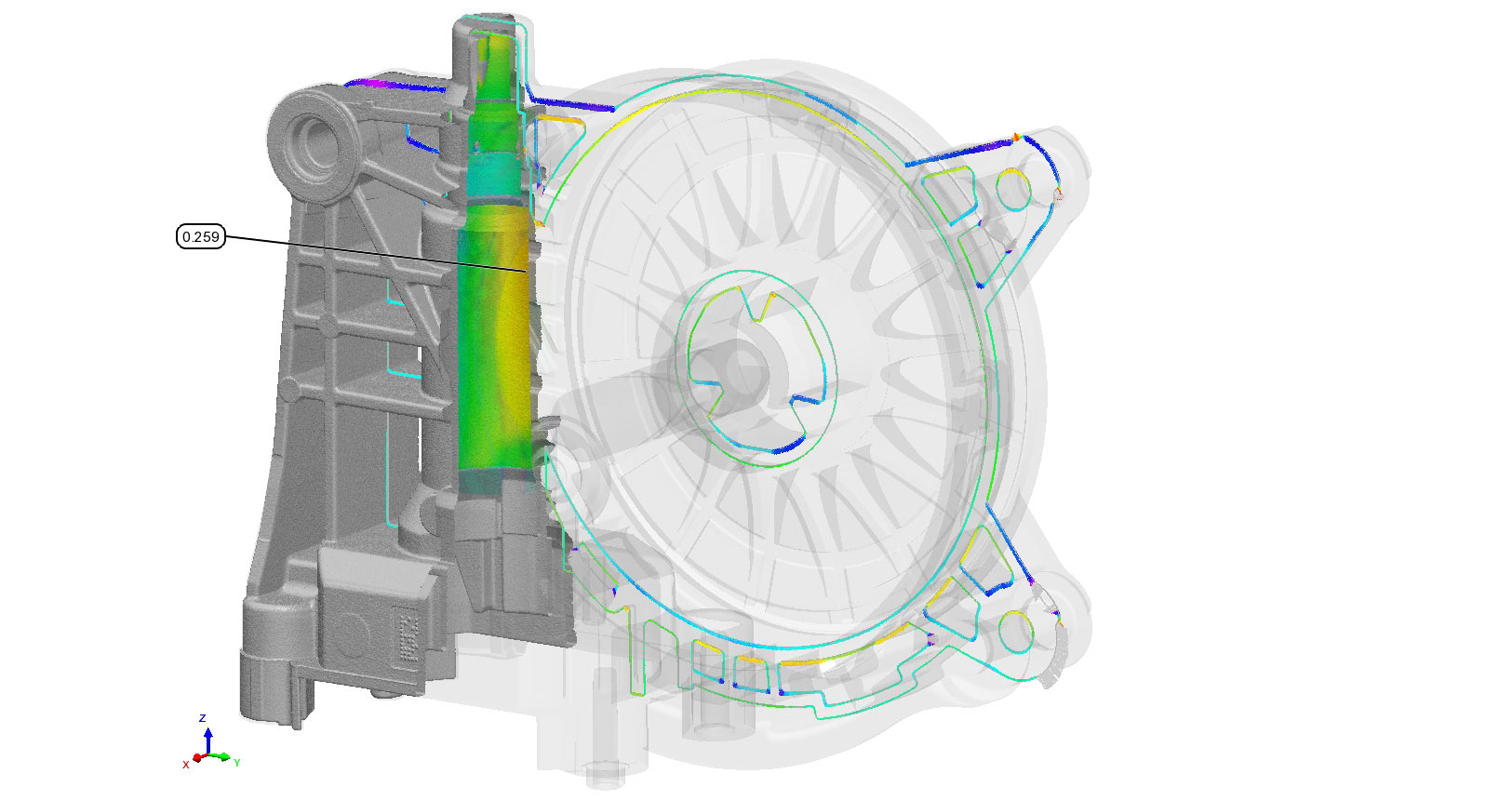

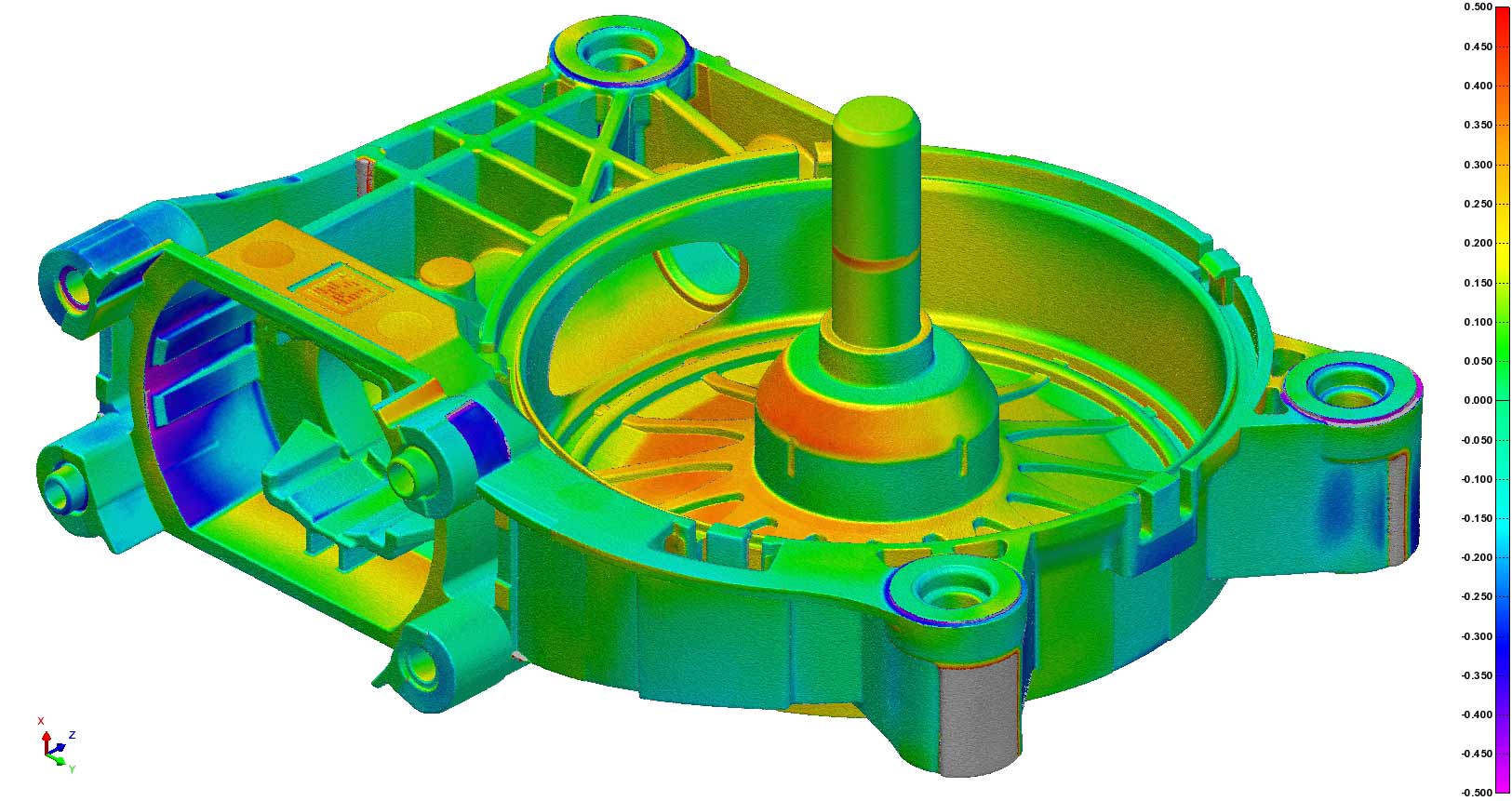

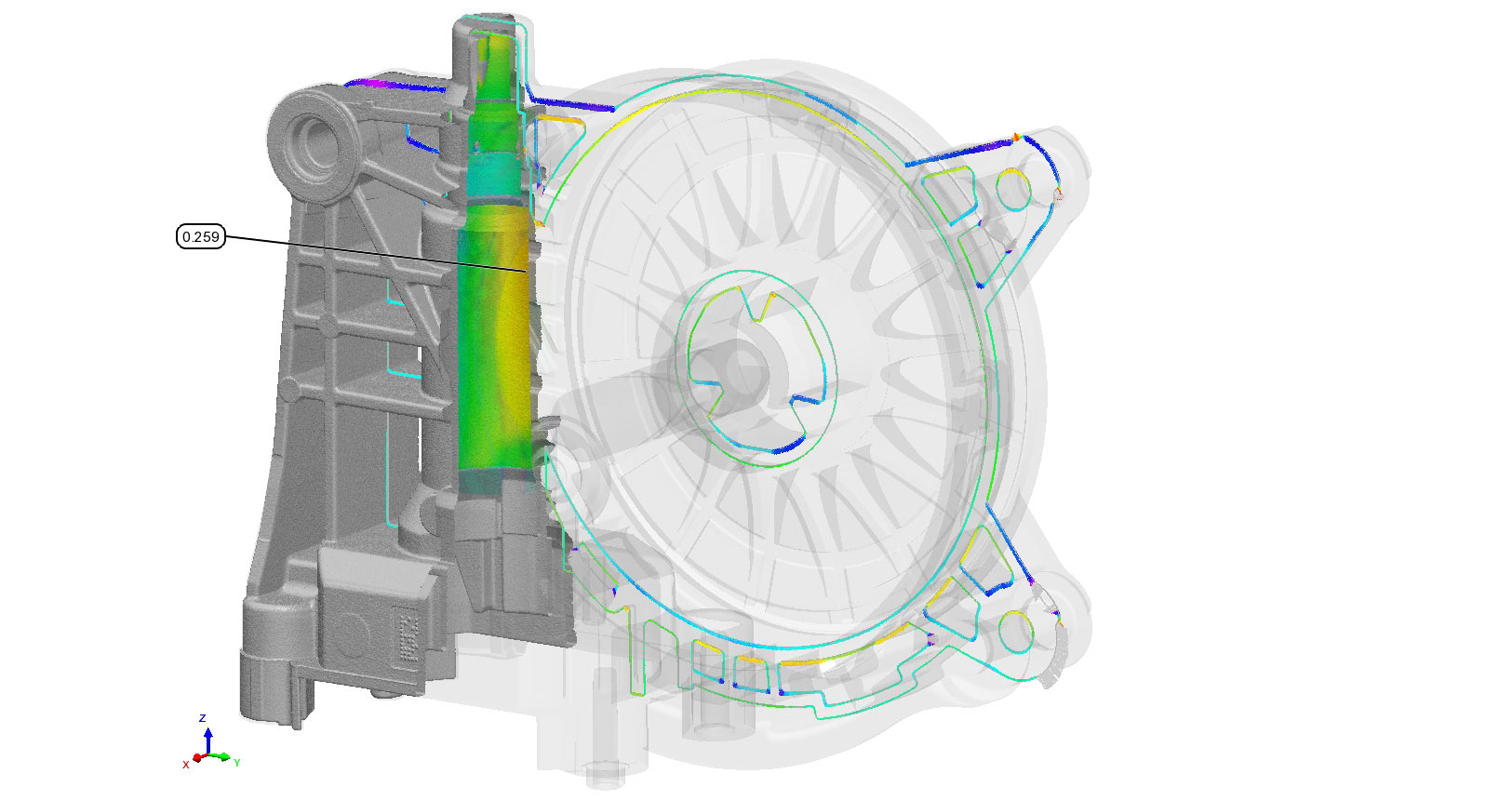

3D PROFILING

3D scanning is the process of creating a three-dimensional representation of an object. This representation is in the form of a scan file which can be compared to the perfect design model. The profile comparison heat map allows inspectors and manufacturers to identify defects, deviations, or areas of concern. The scale can be set to any tolerance:

Green to Red represents material “above” CAD surfaces

Green to Blue represents material “below” CAD surfaces

Gray represents geometry outside of the tolerance band

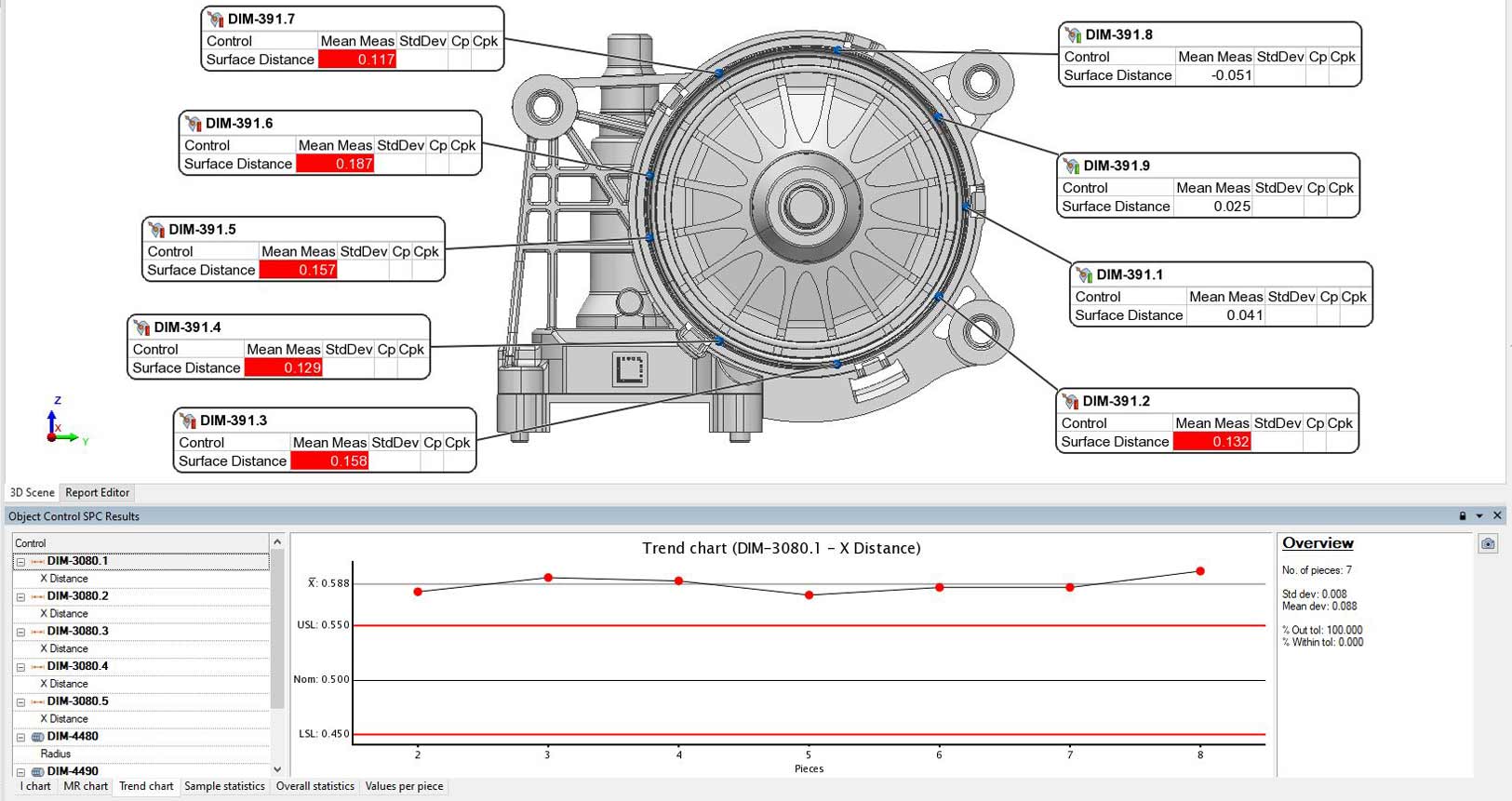

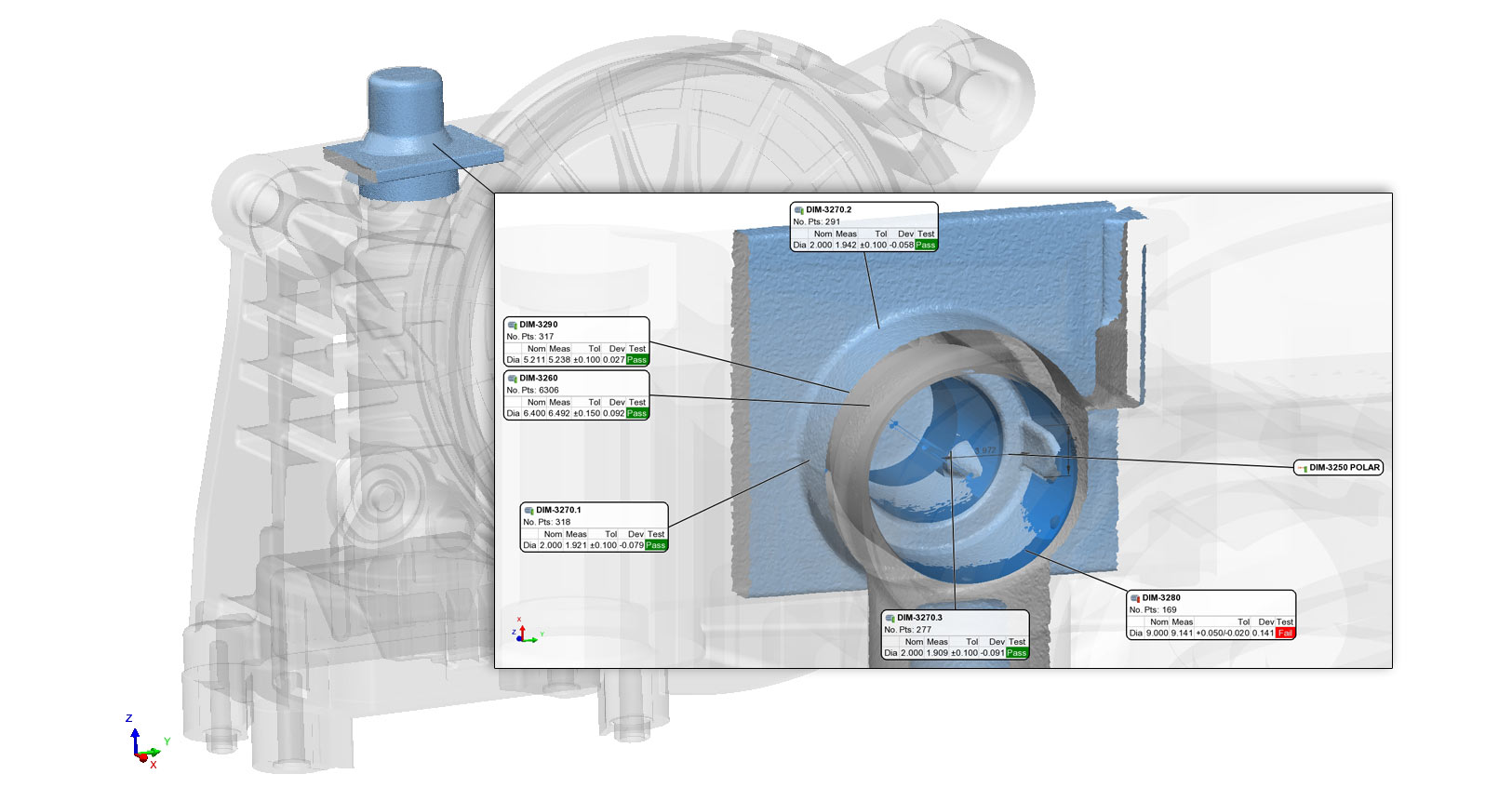

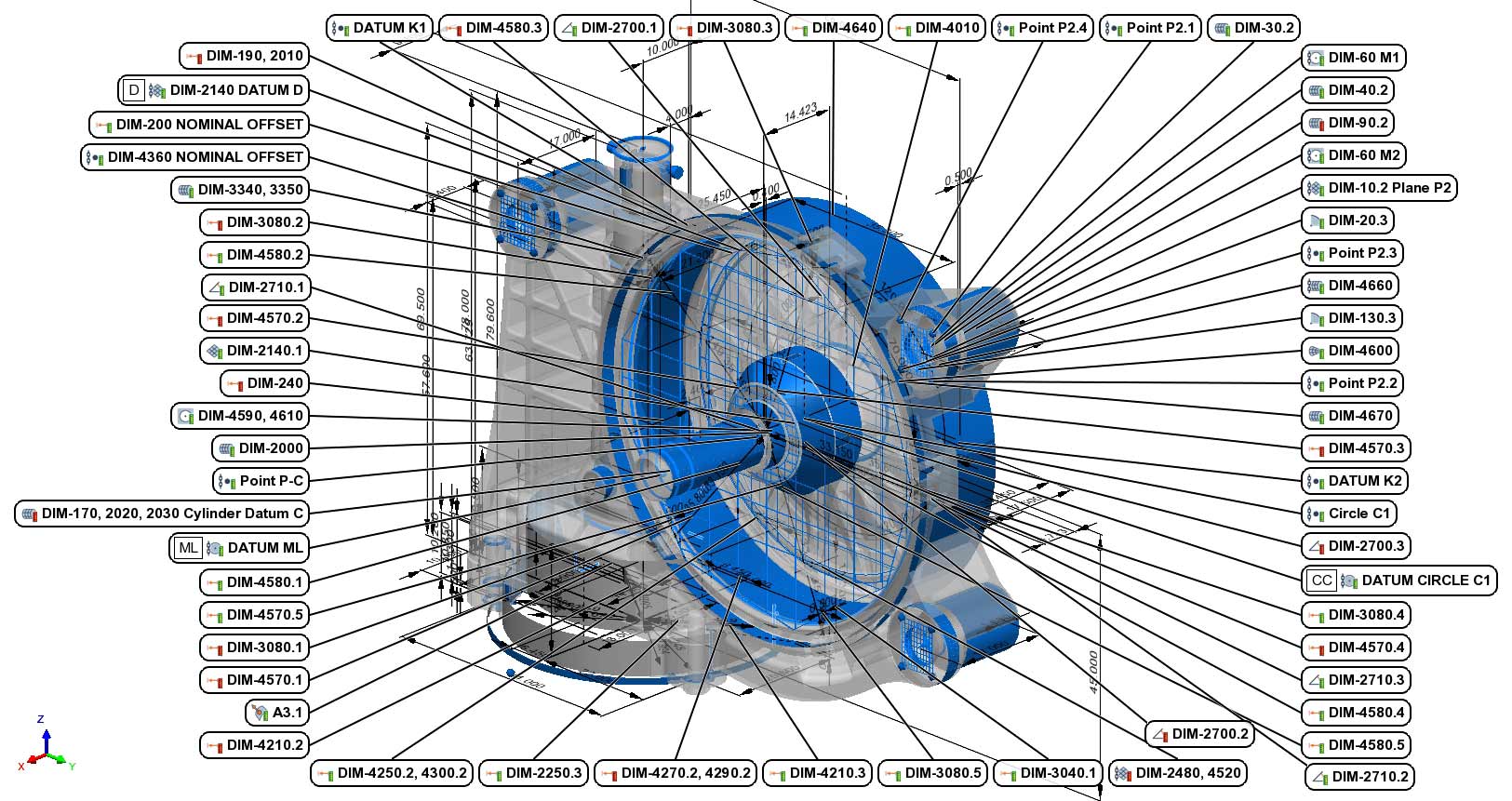

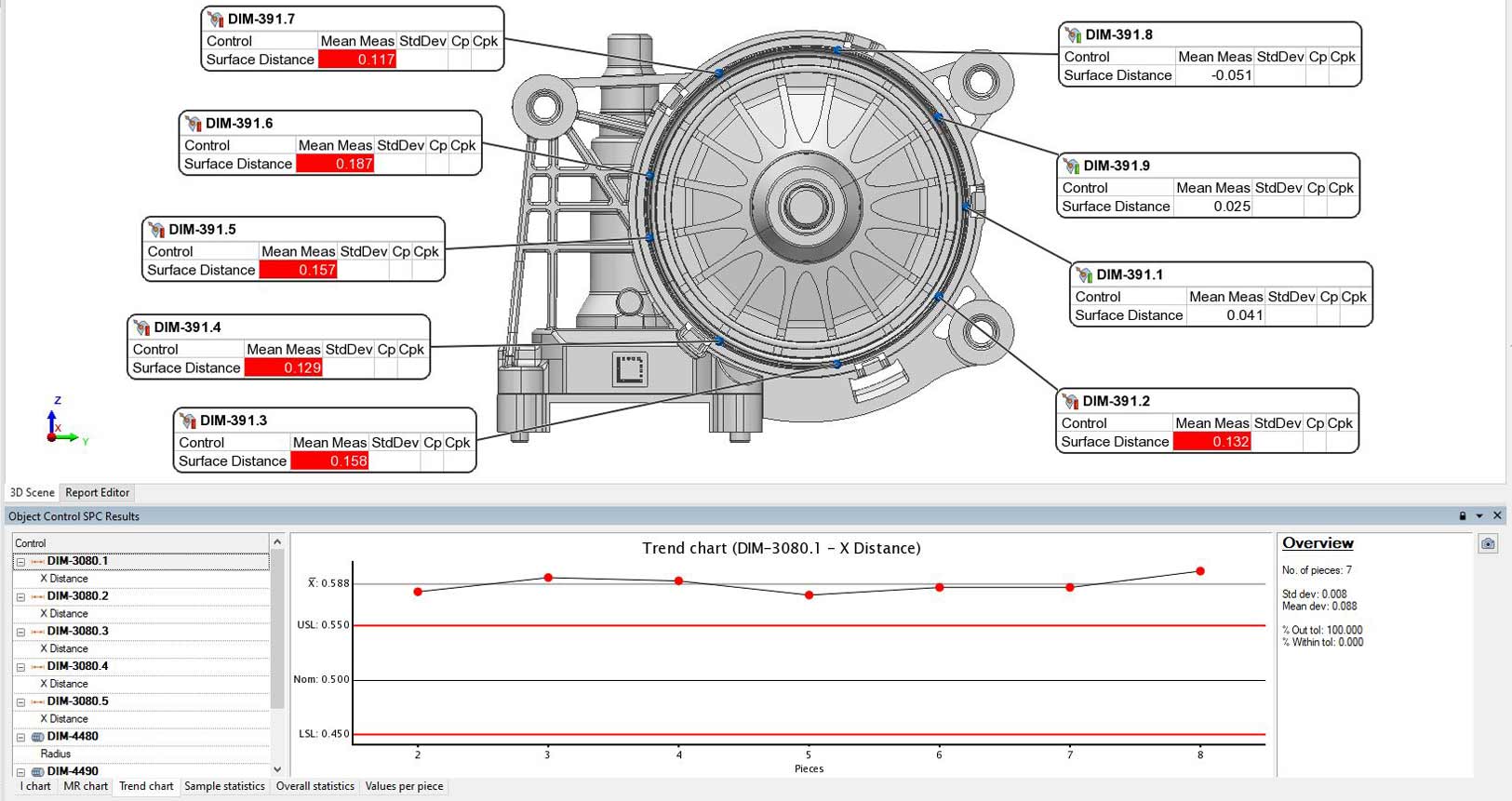

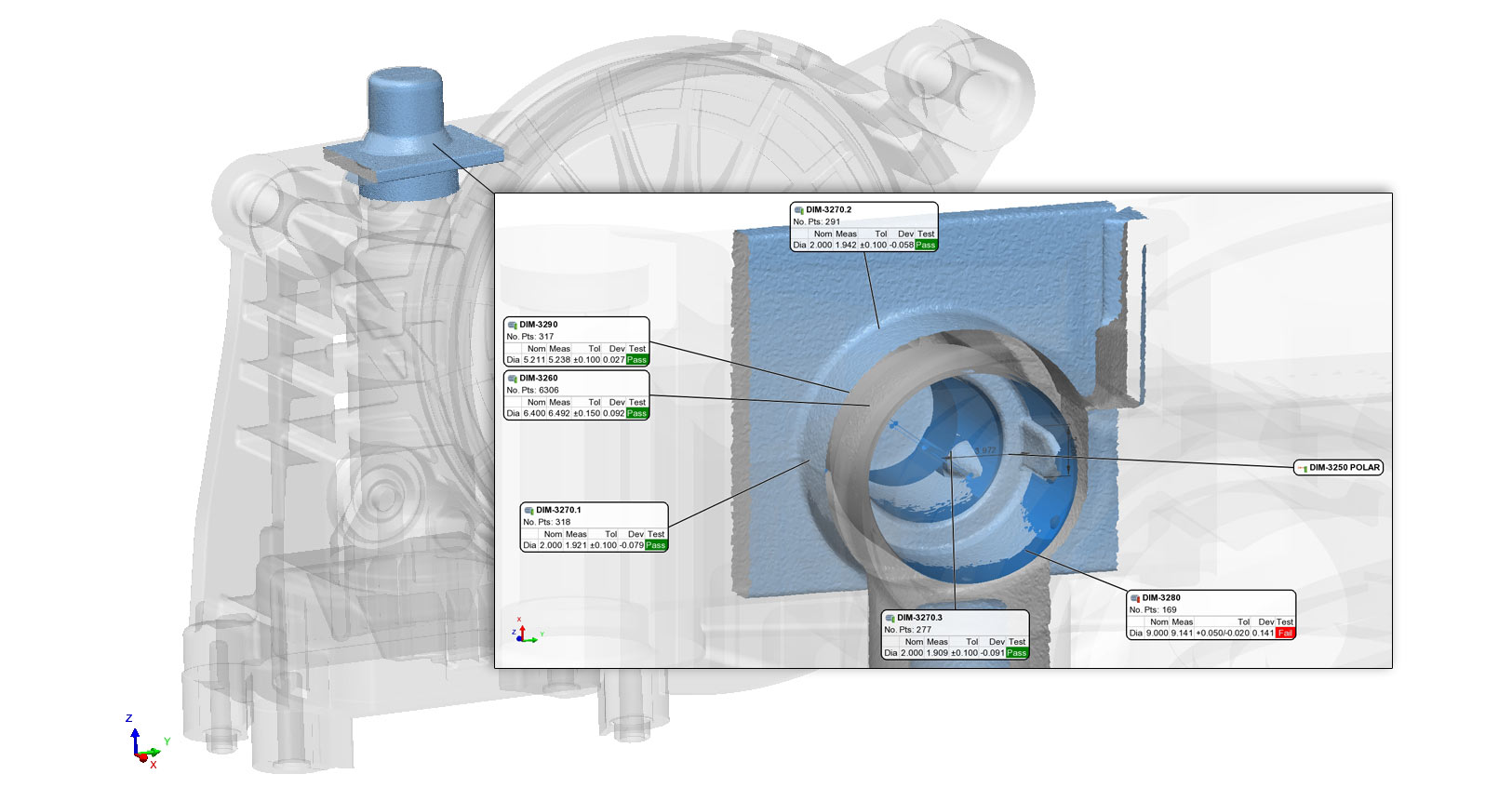

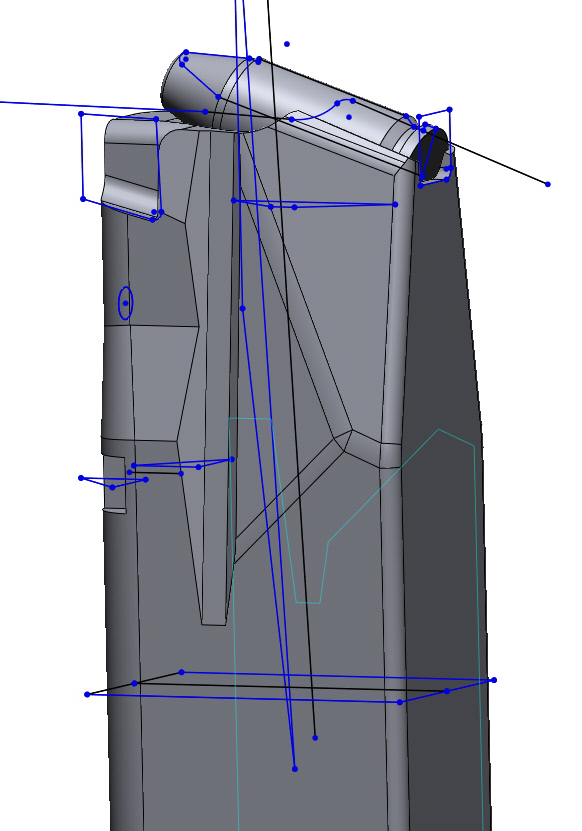

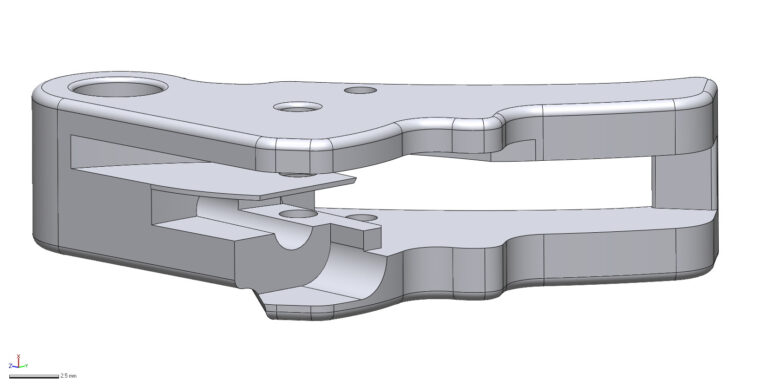

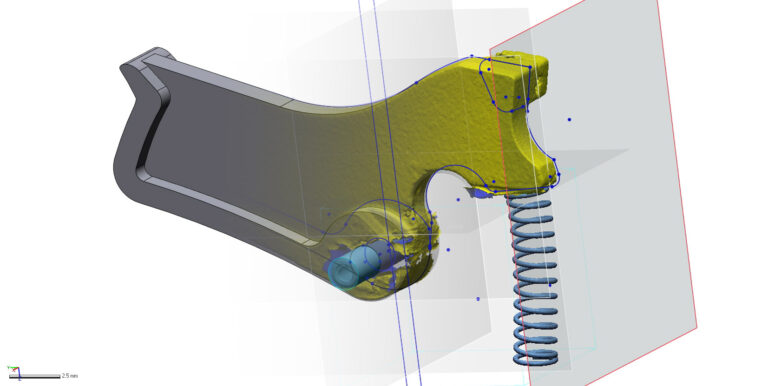

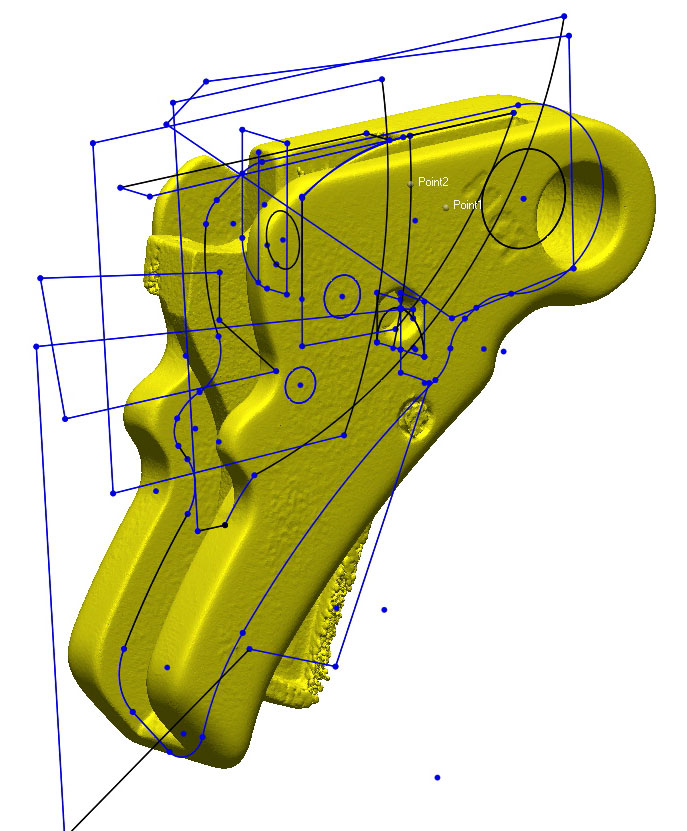

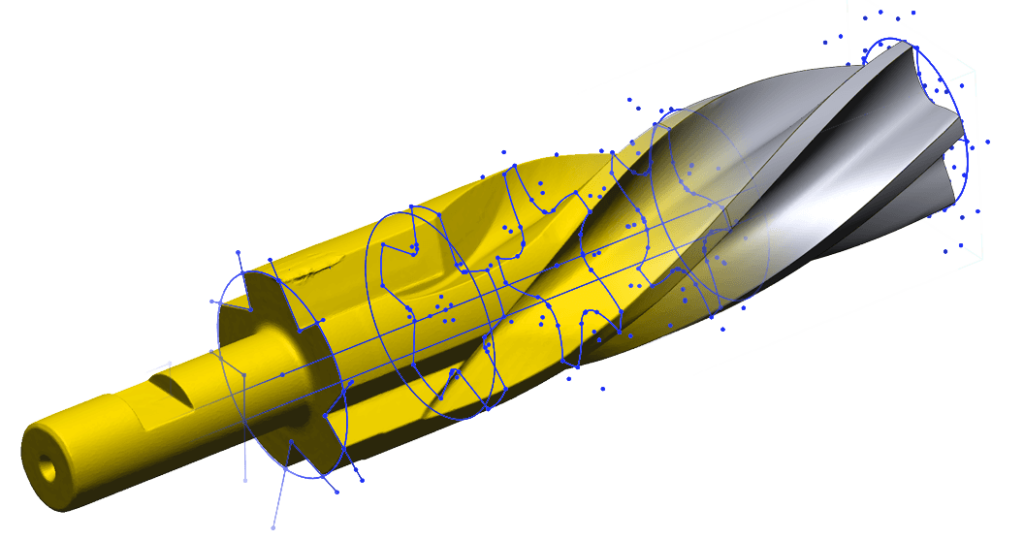

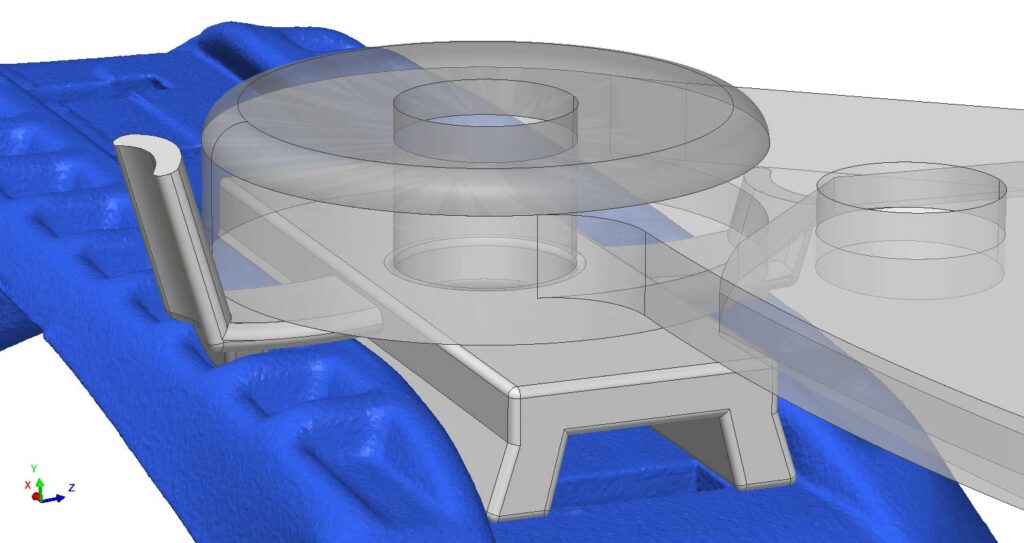

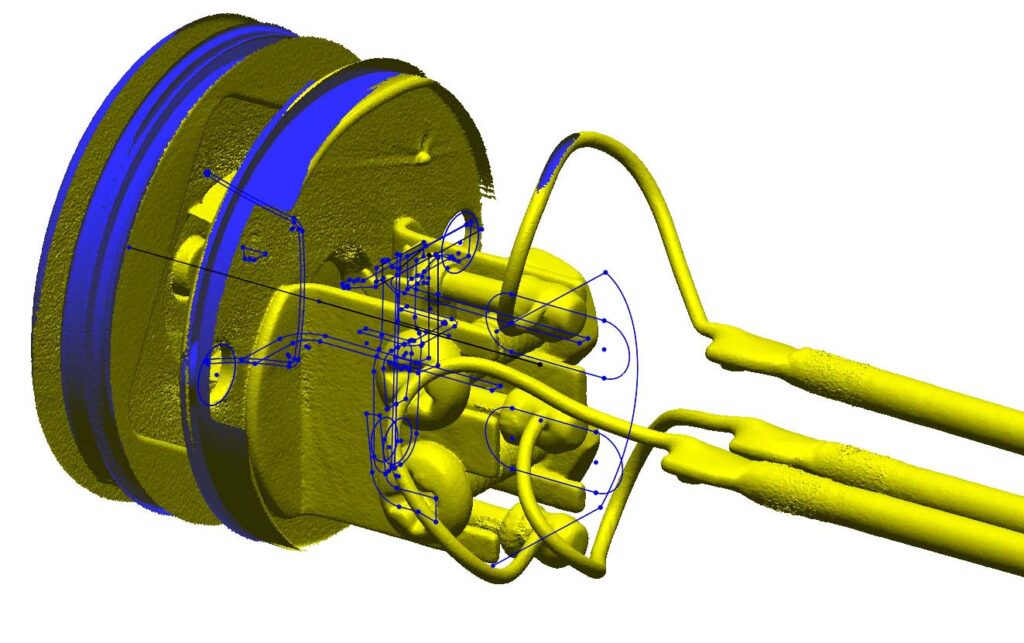

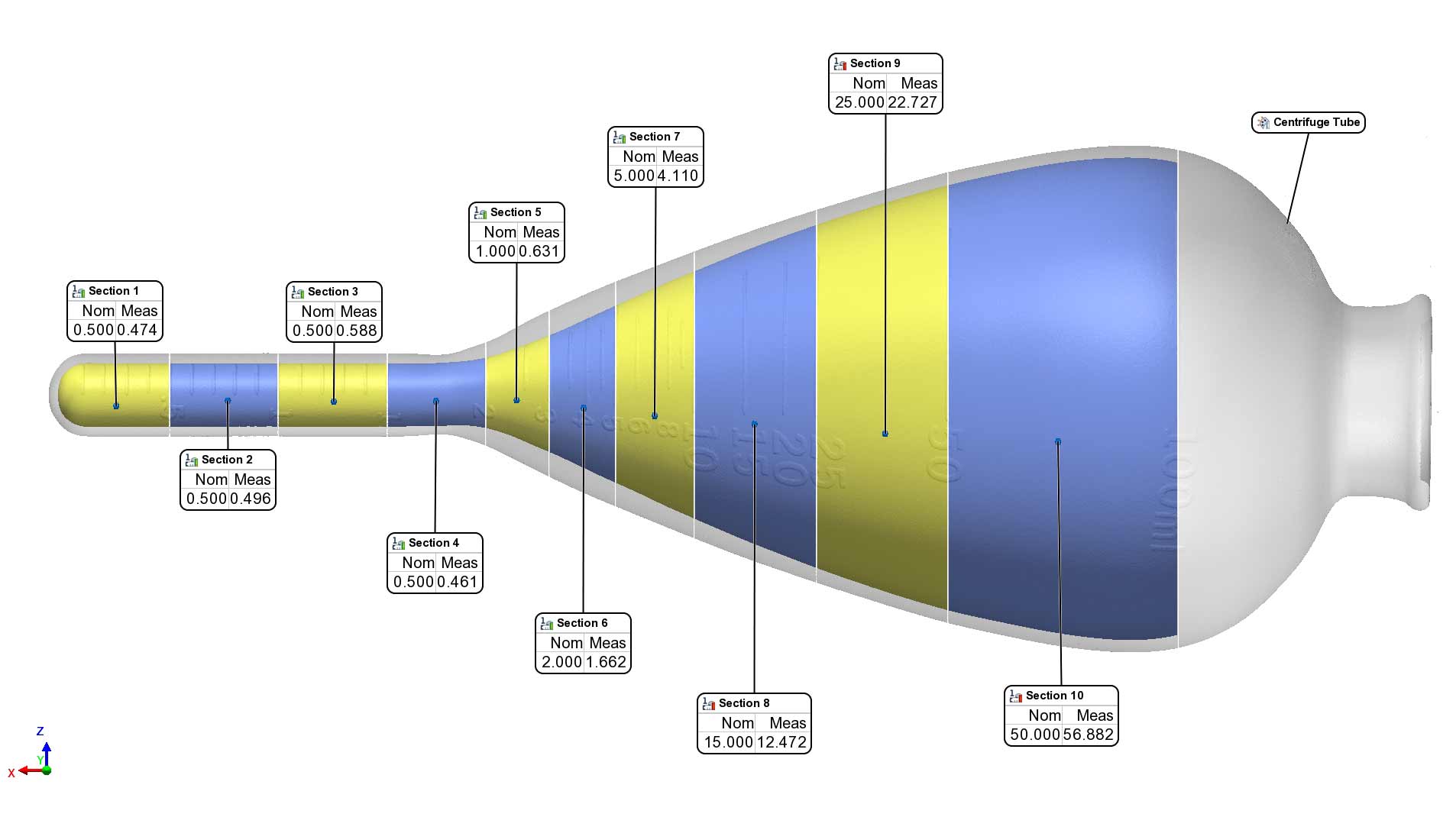

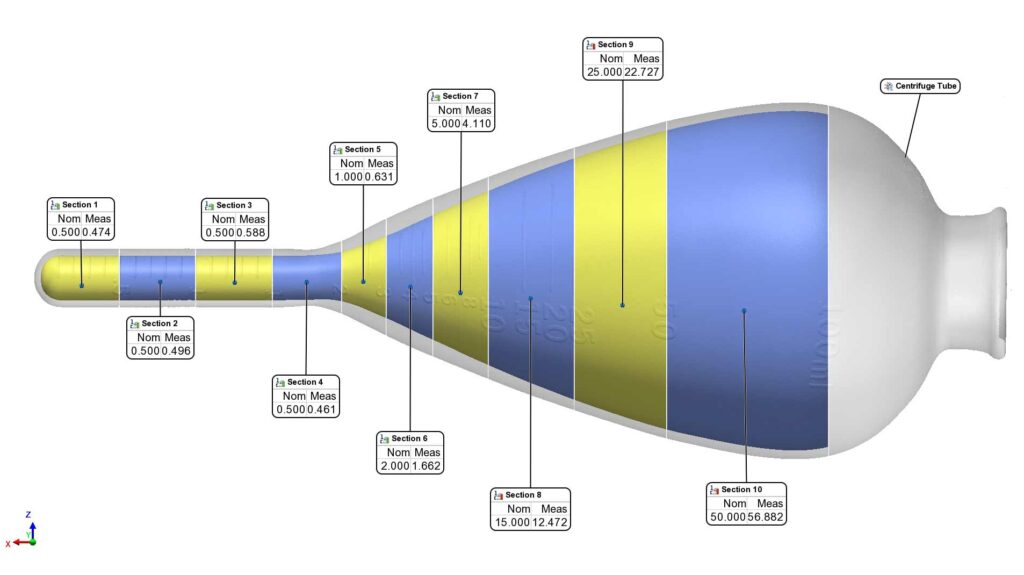

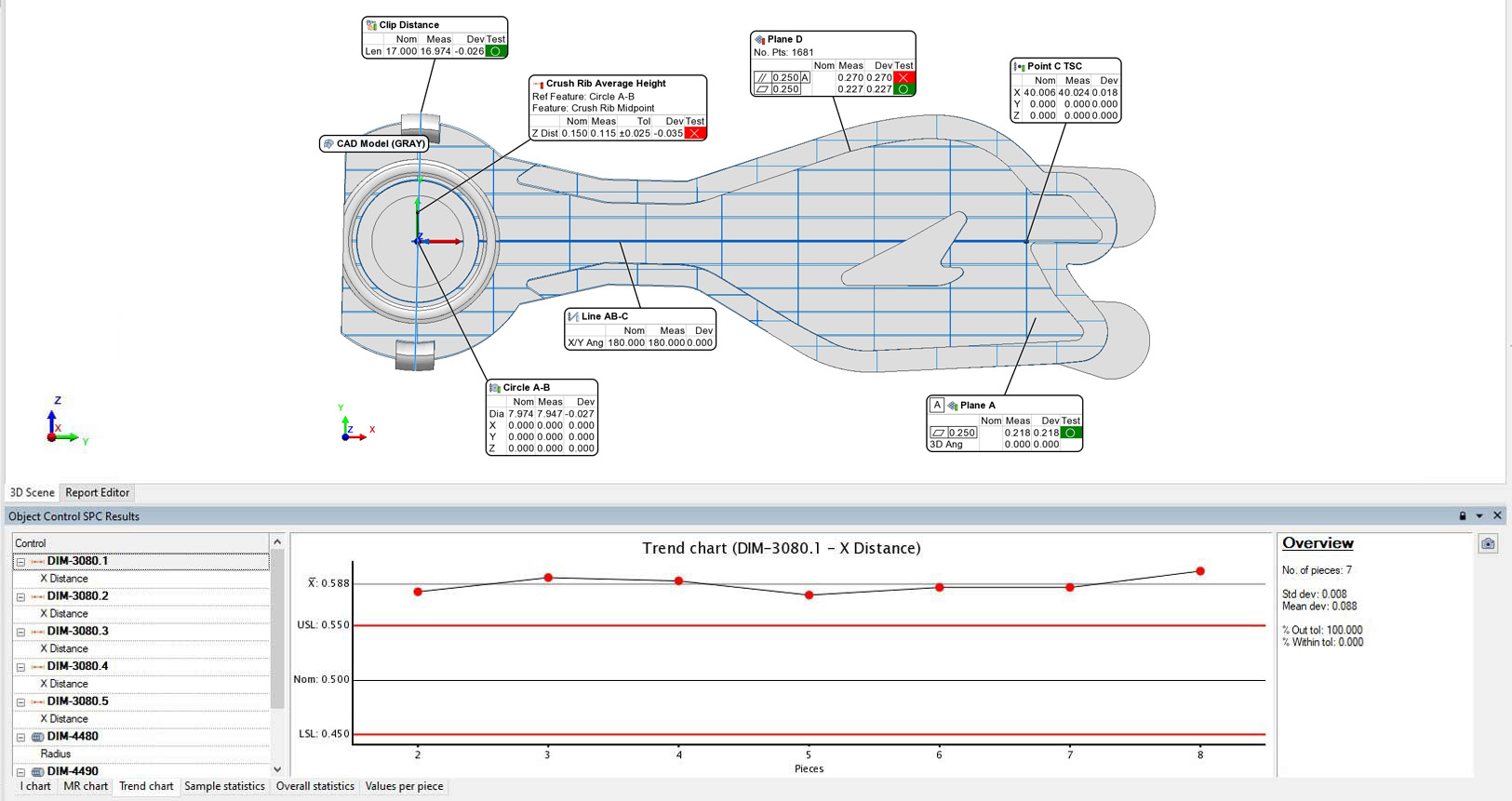

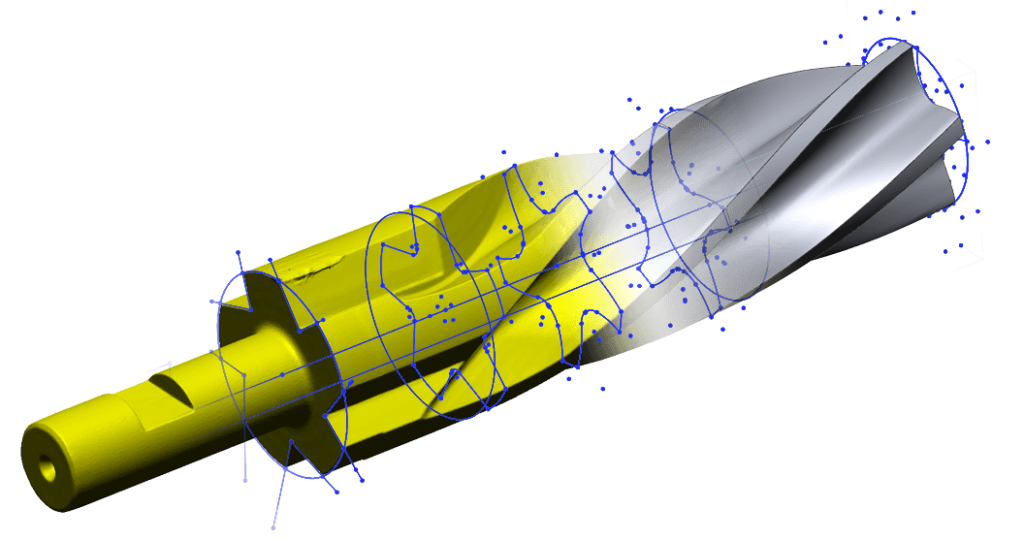

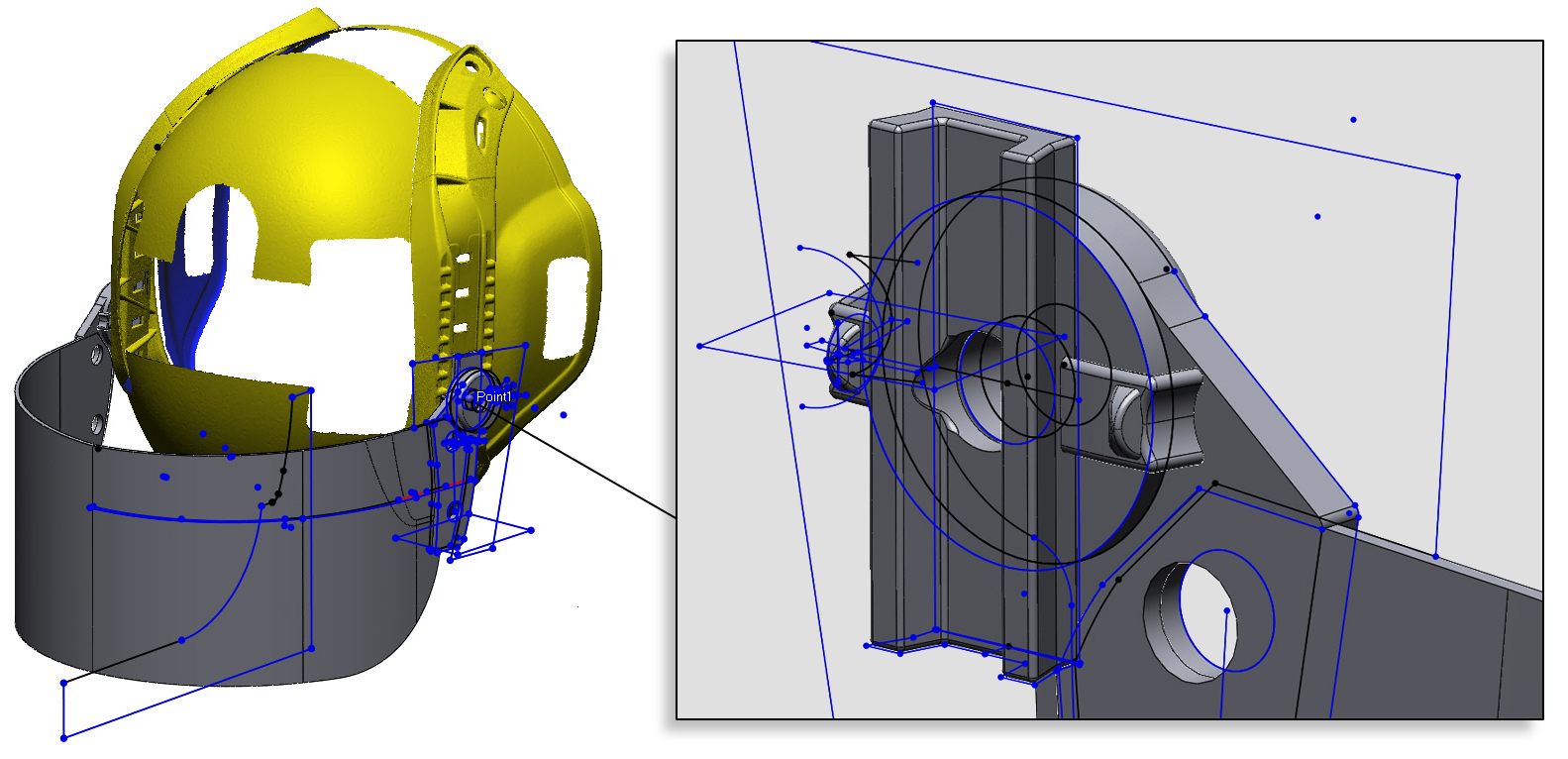

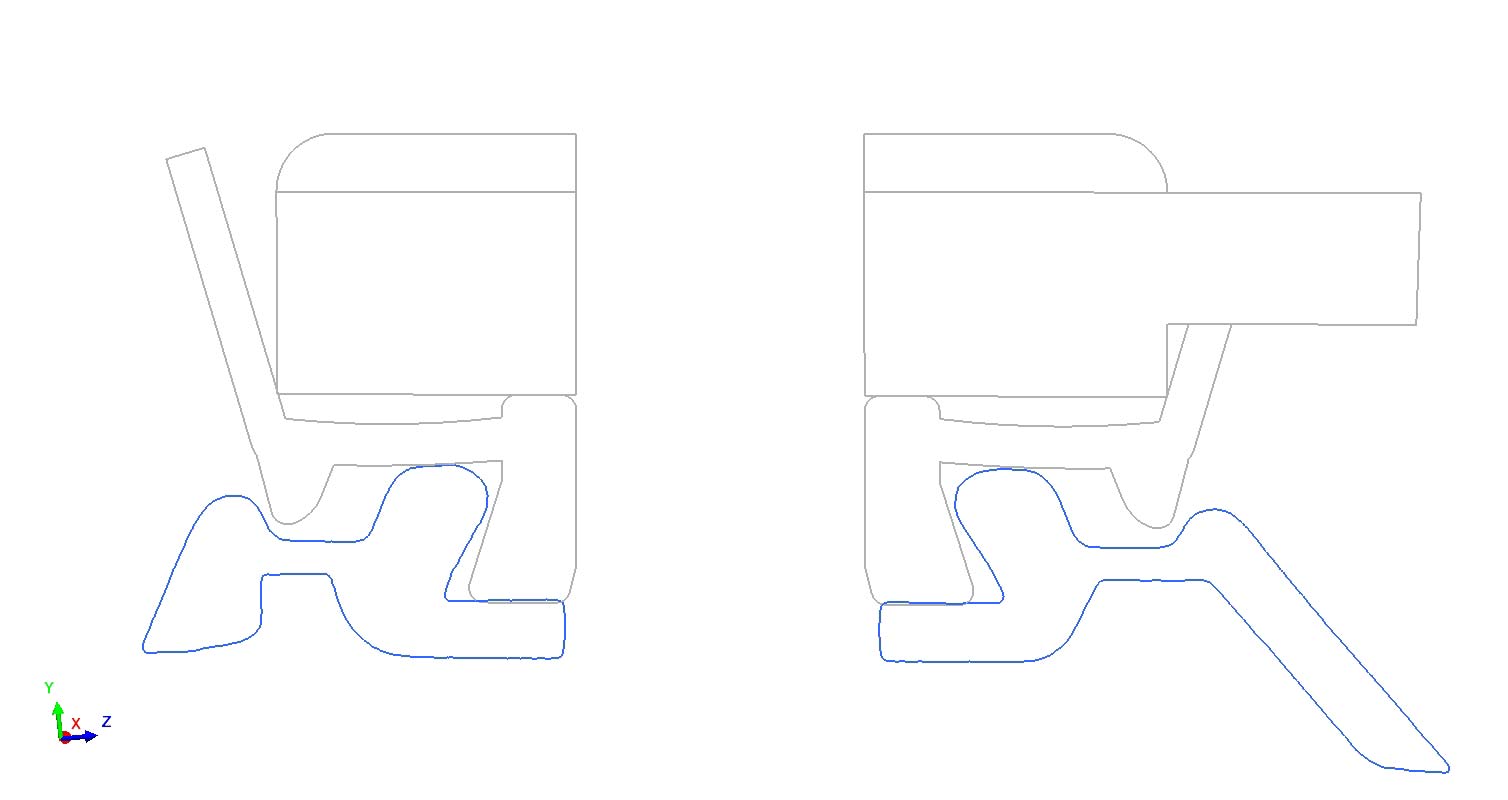

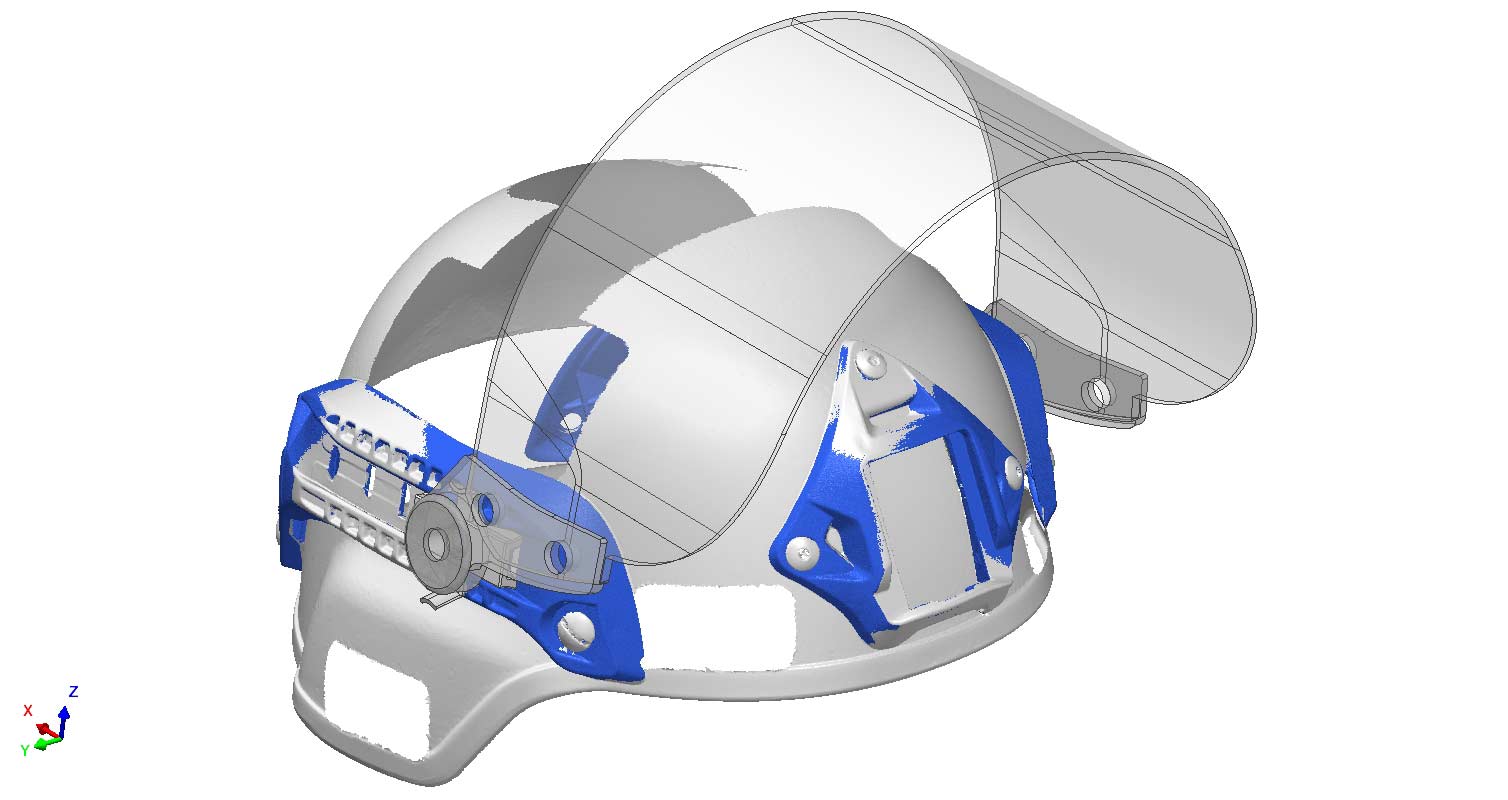

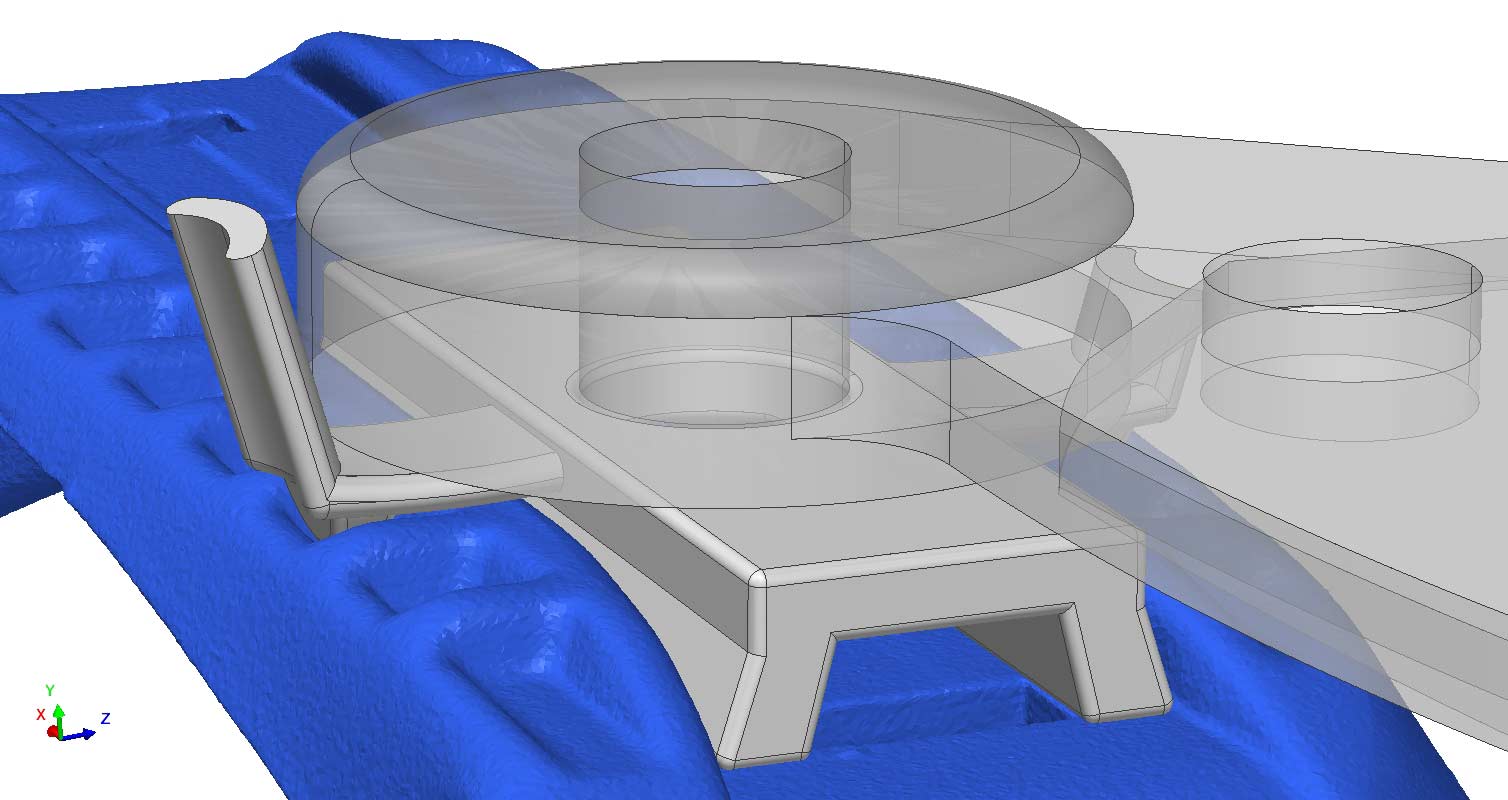

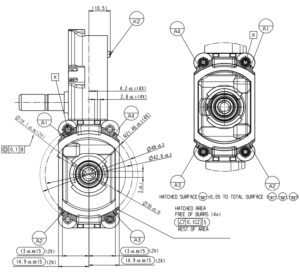

DIMENSIONAL INSPECTION

Dimensional inspection involves measuring various dimensions, such as distances, diameters, angles, complex GD&T like true positions, concentricity, and runout. These controls are used to ensure products conform to the design specifications and tolerances provided by engineering drawings.

We use PolyWorks Metrology Suite for programming, automated inspection, SPC evaluation, and imaging.