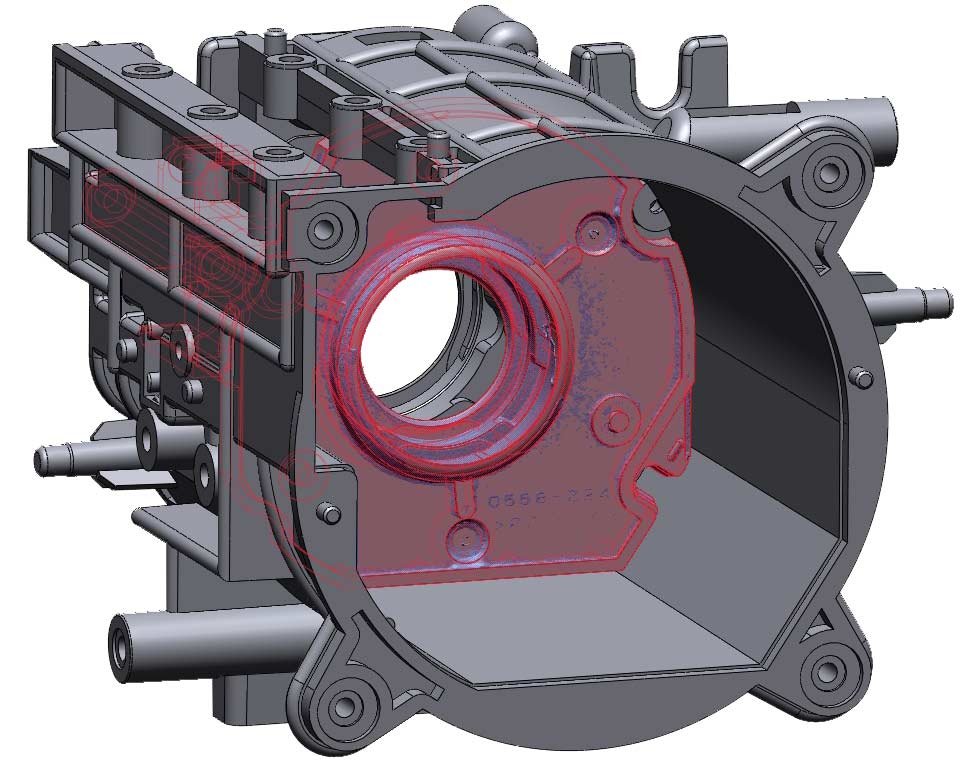

Dimensional Repeatability using CT Scanning

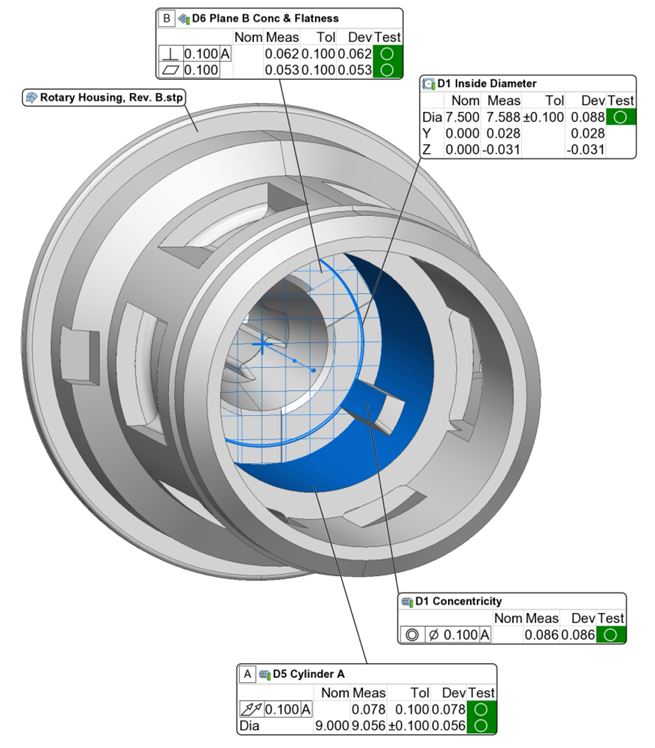

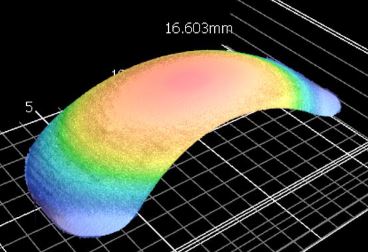

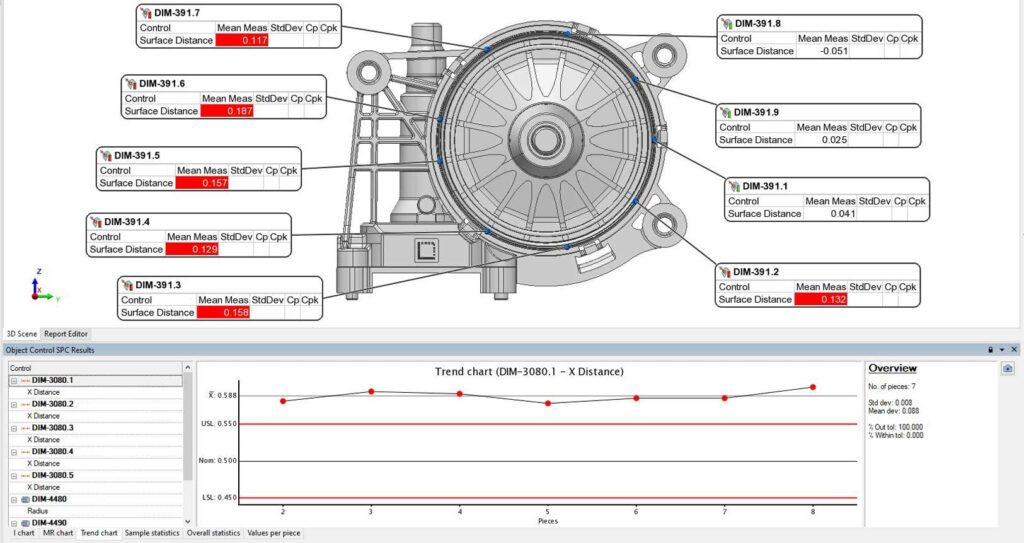

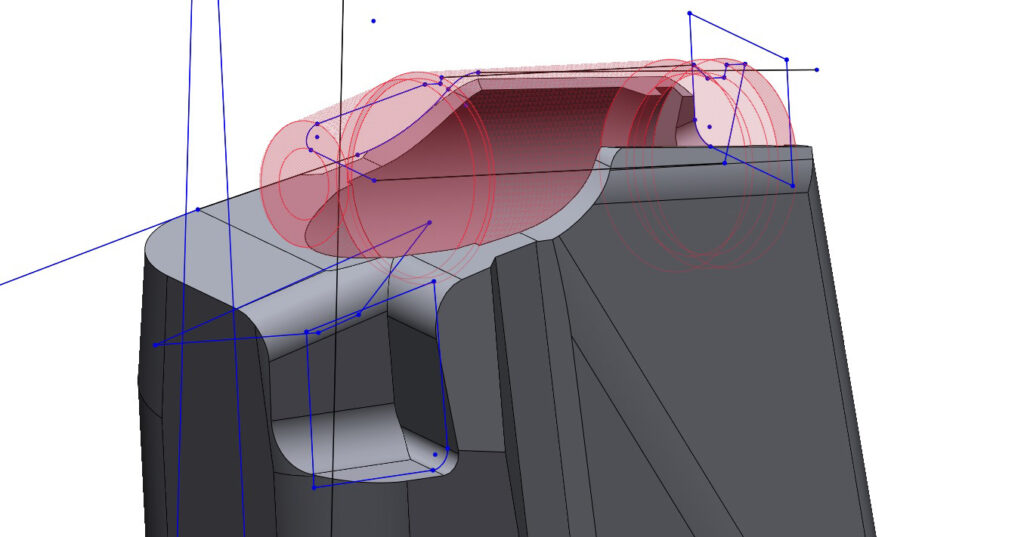

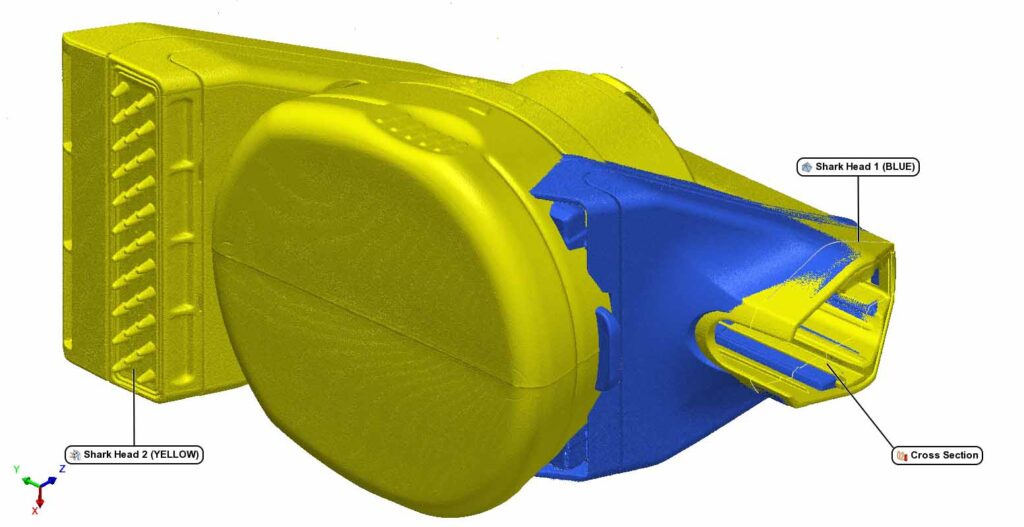

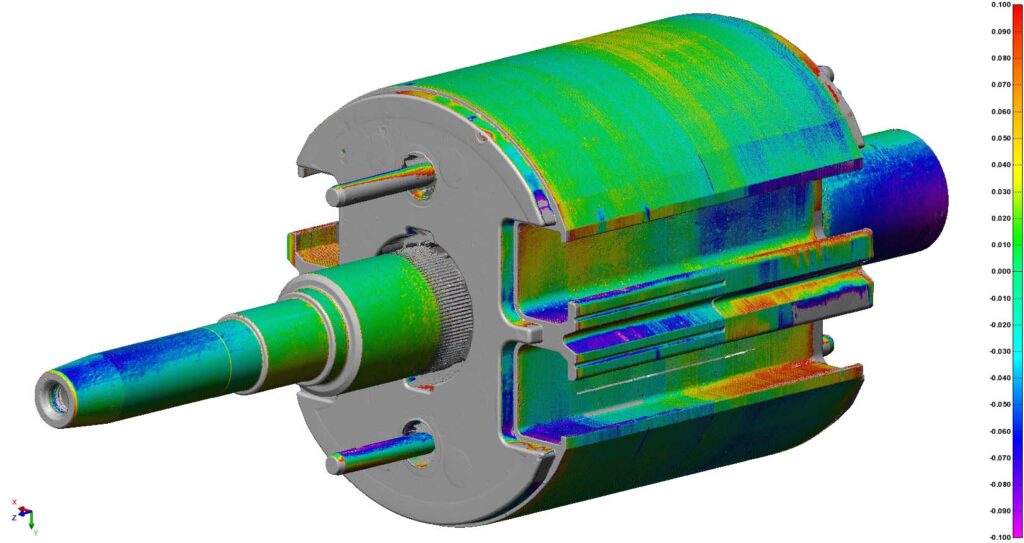

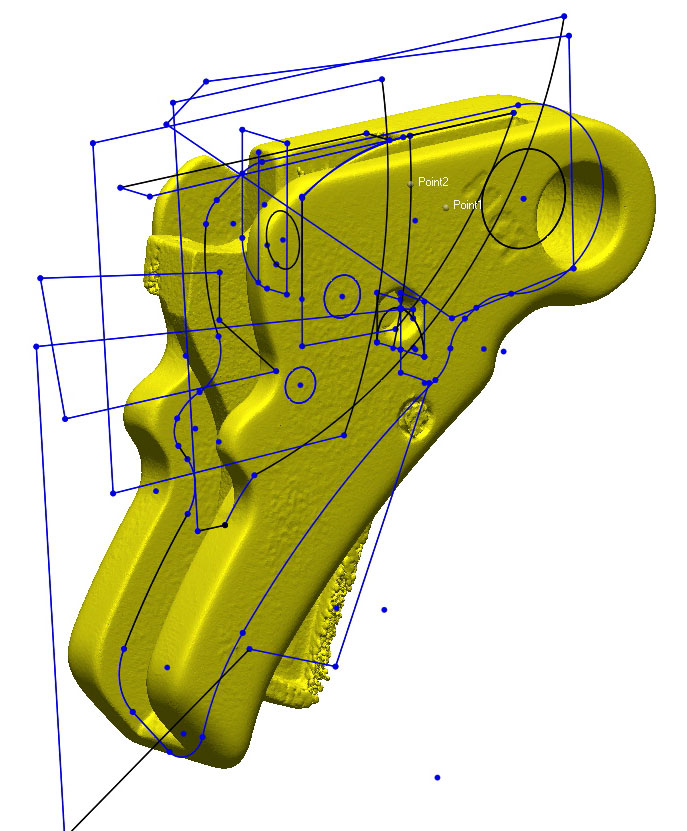

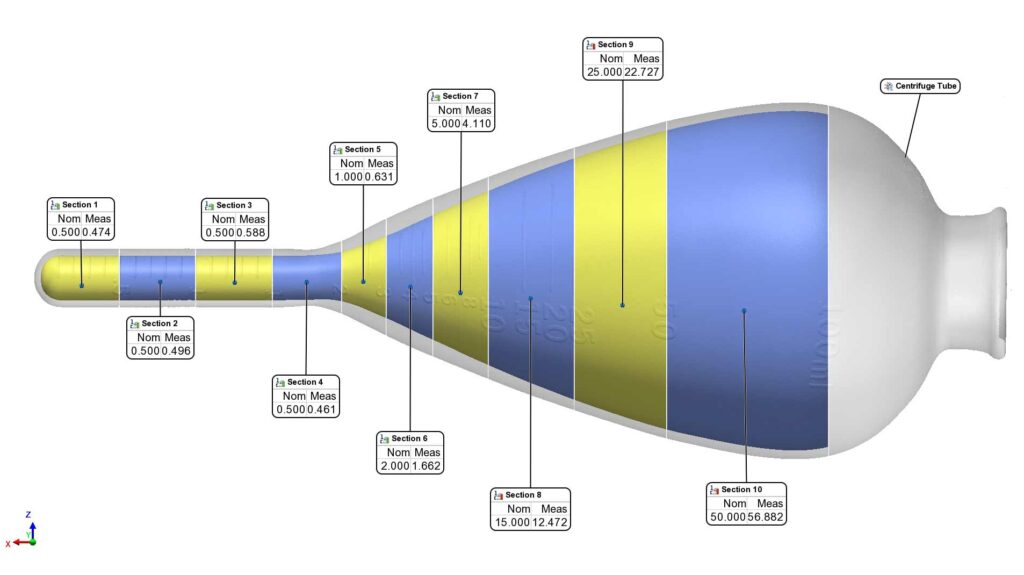

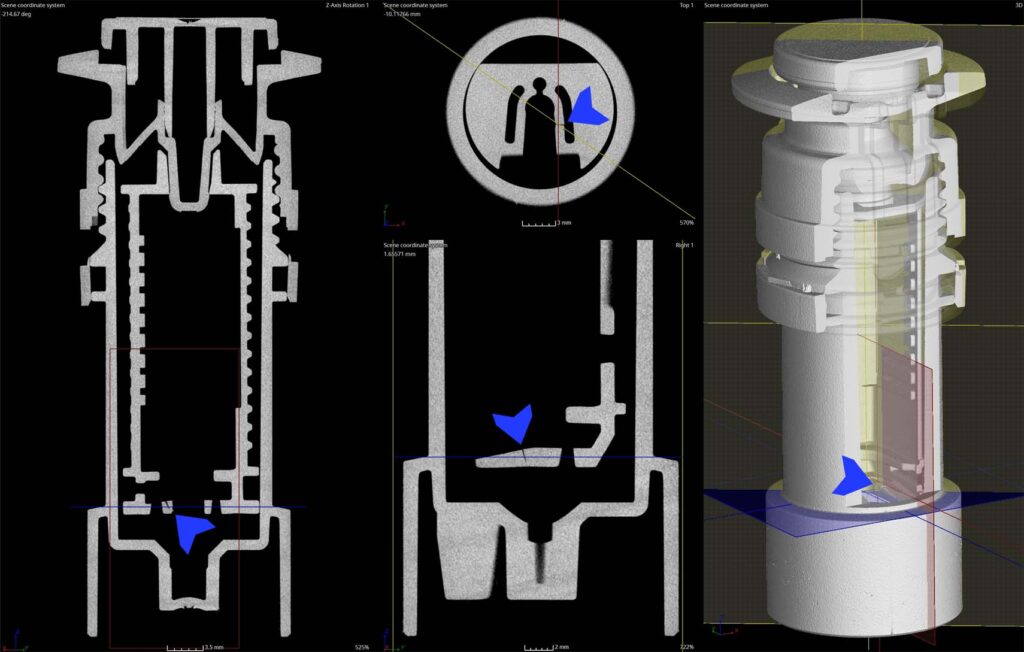

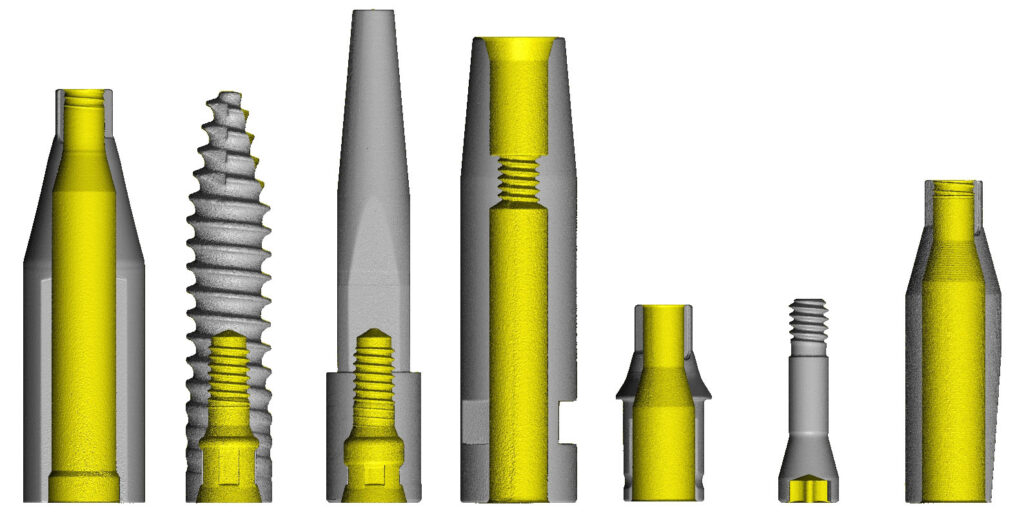

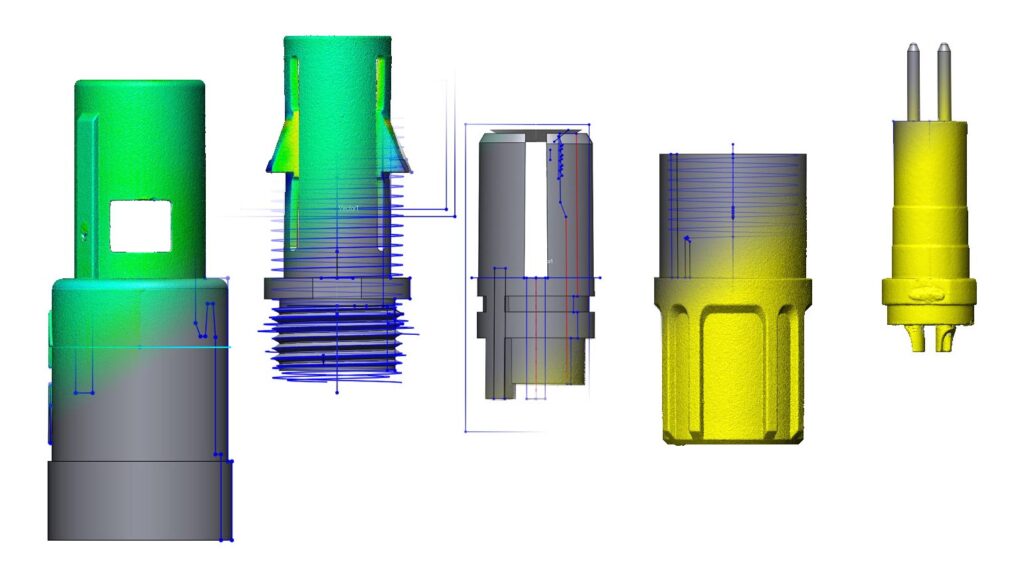

Dimensional Repeatability, Fitment Evaluations, and Internal Defect Detection using CT Scanning In this validation study we performed five independent CT scans of a small injection-molded rotary housing to assess process