BREAKING: Spam Moisturizer Ads Weren’t Lying

Metrology Lab Confirms “Visibly Smoother” claims are true, sending shockwaves through law enforcement agencies.

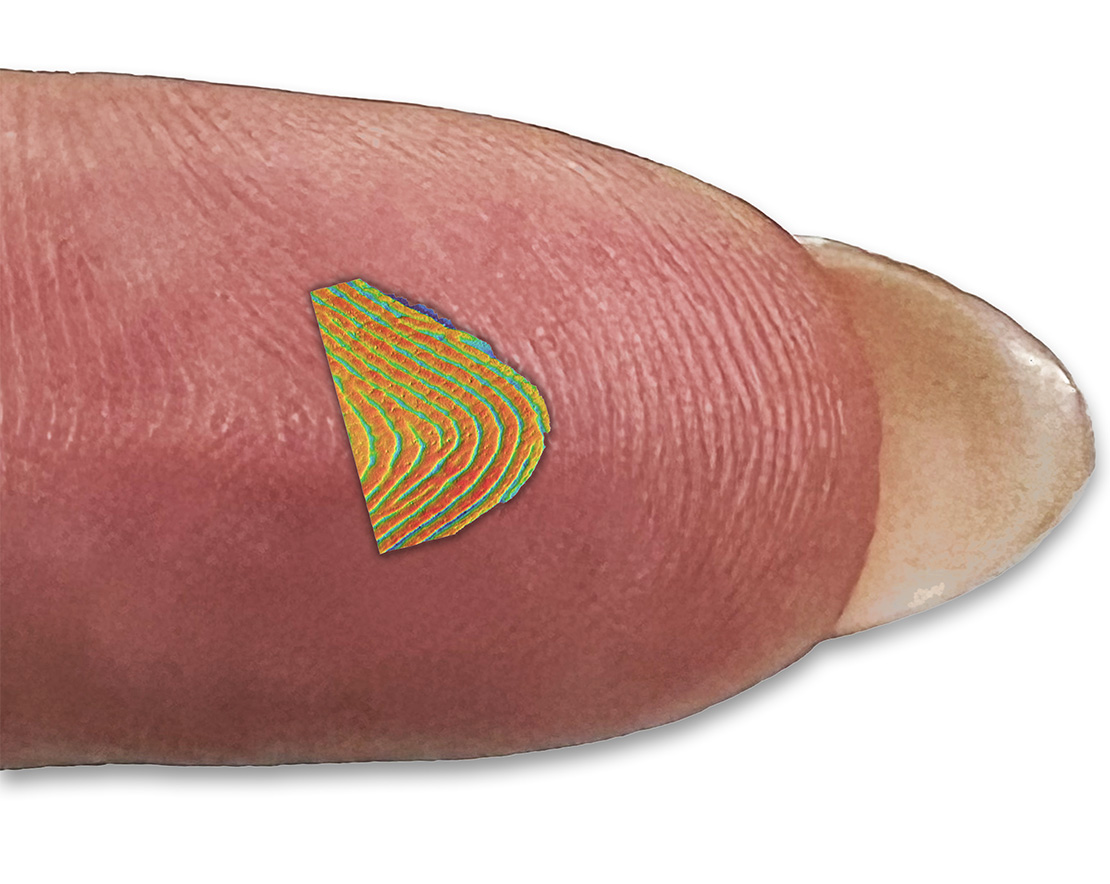

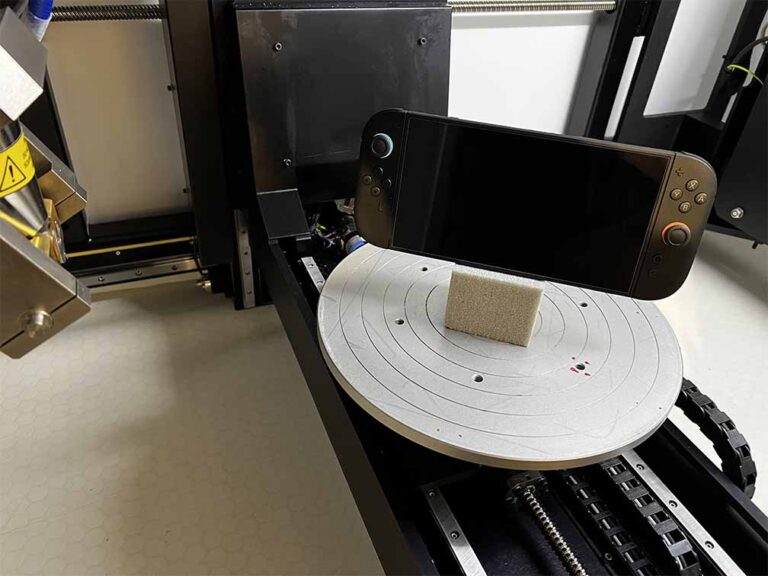

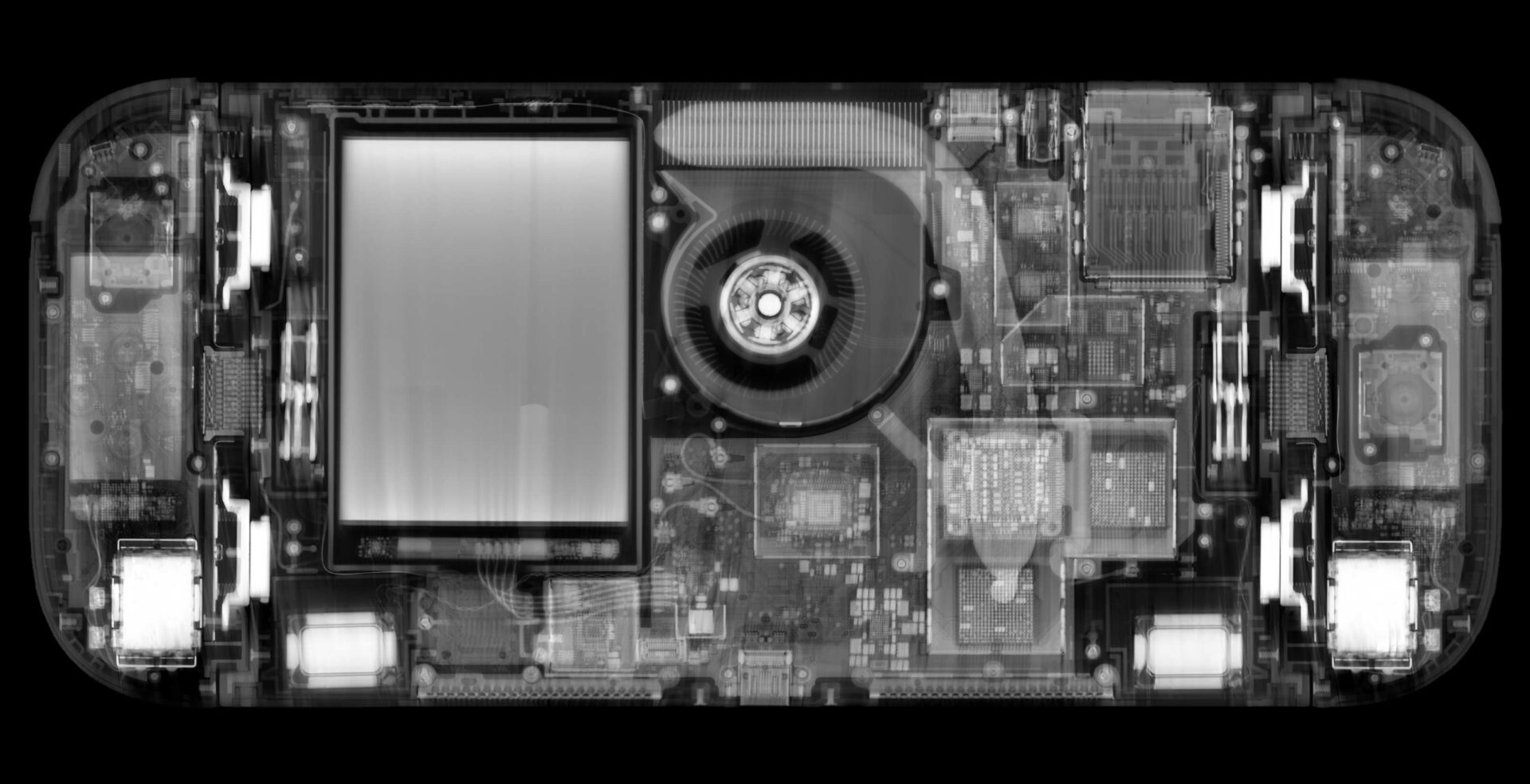

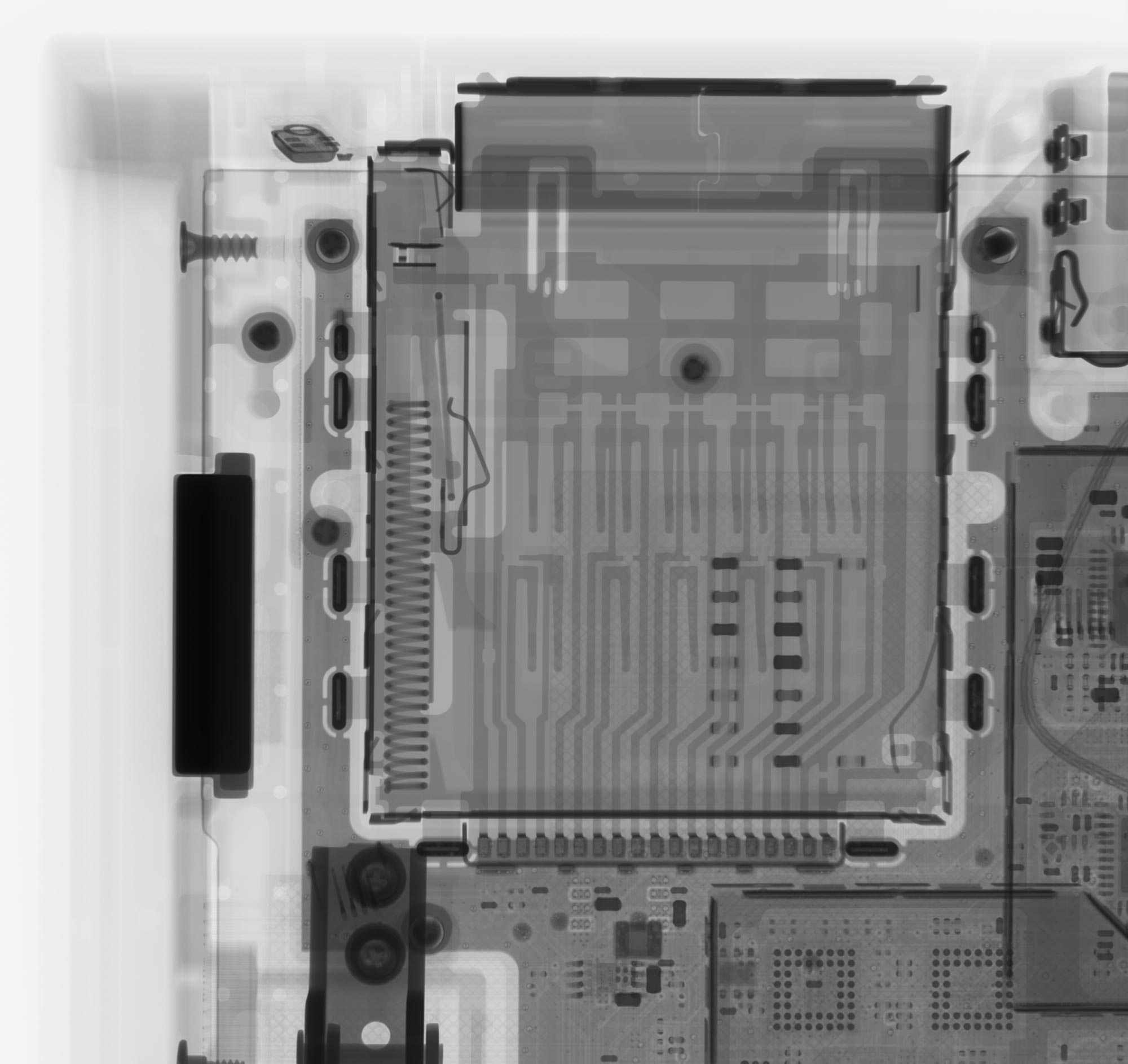

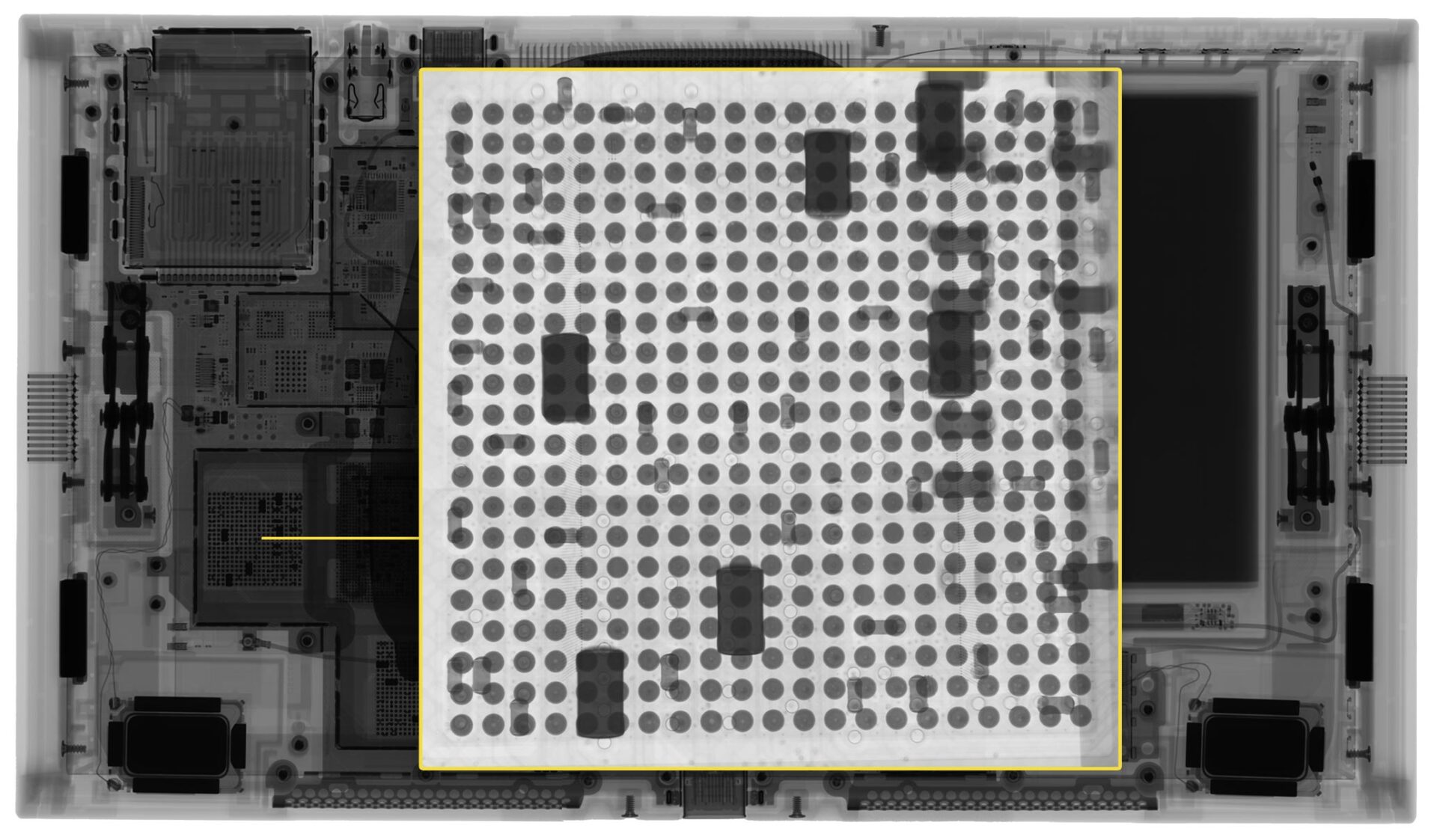

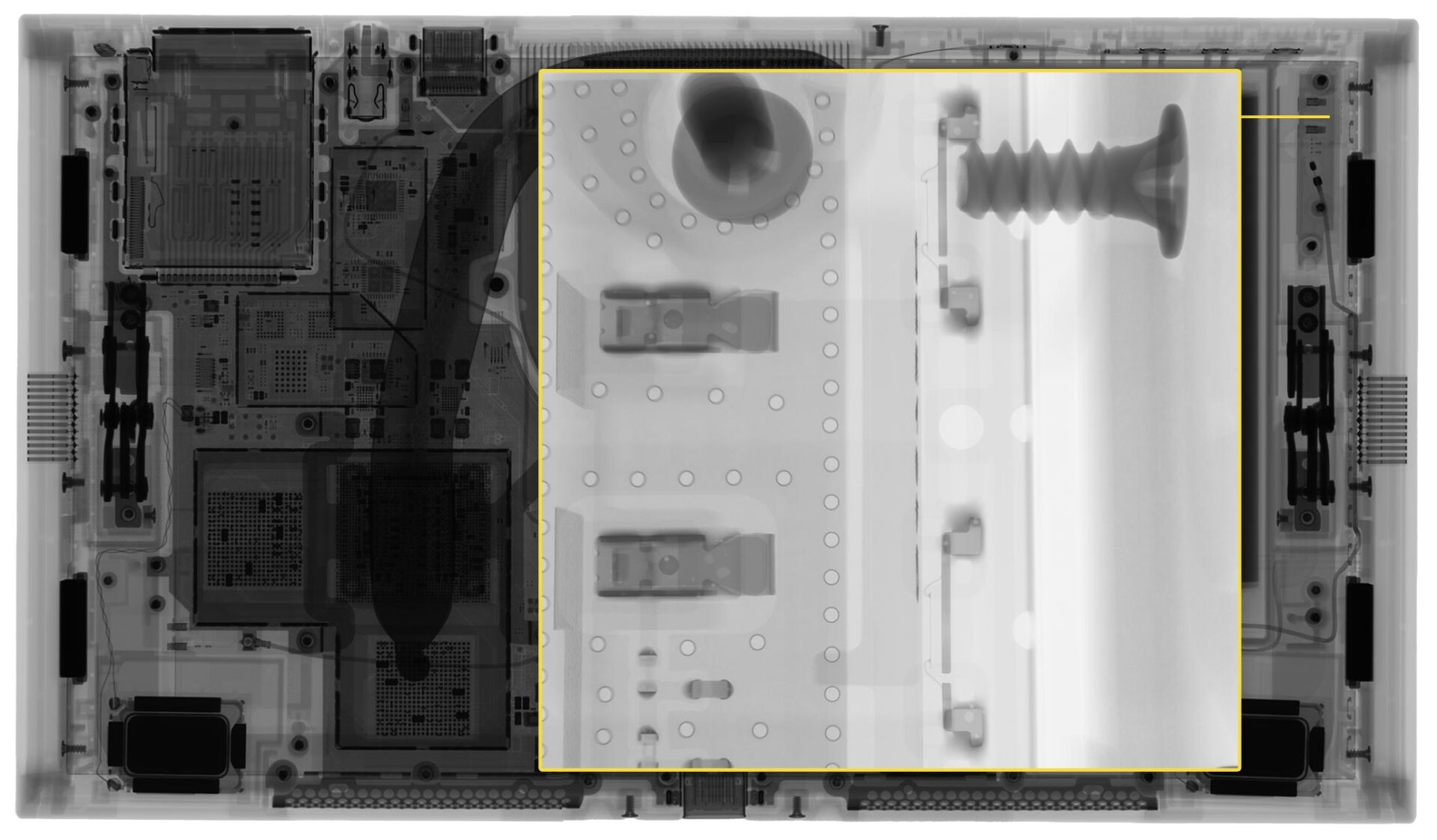

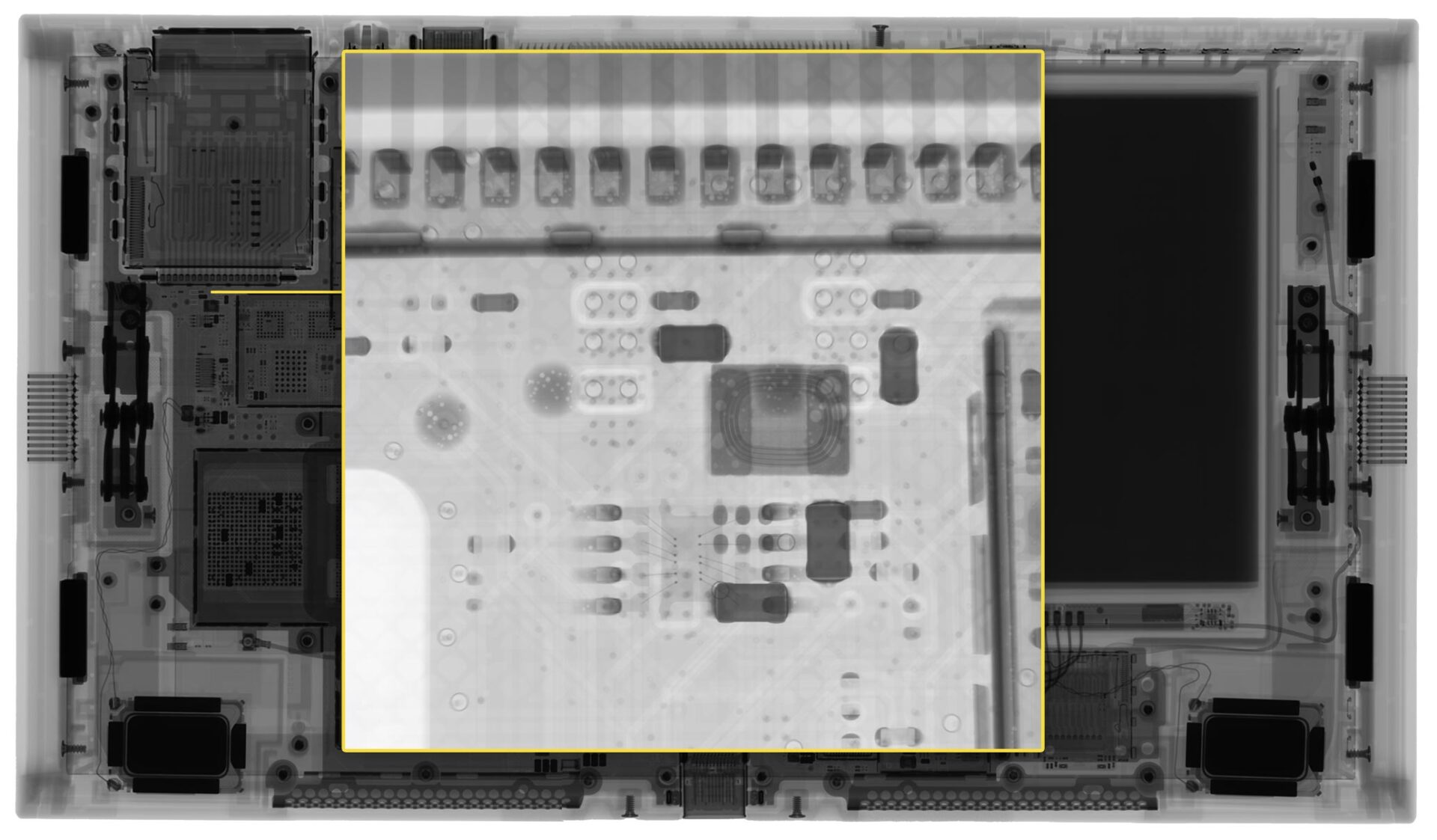

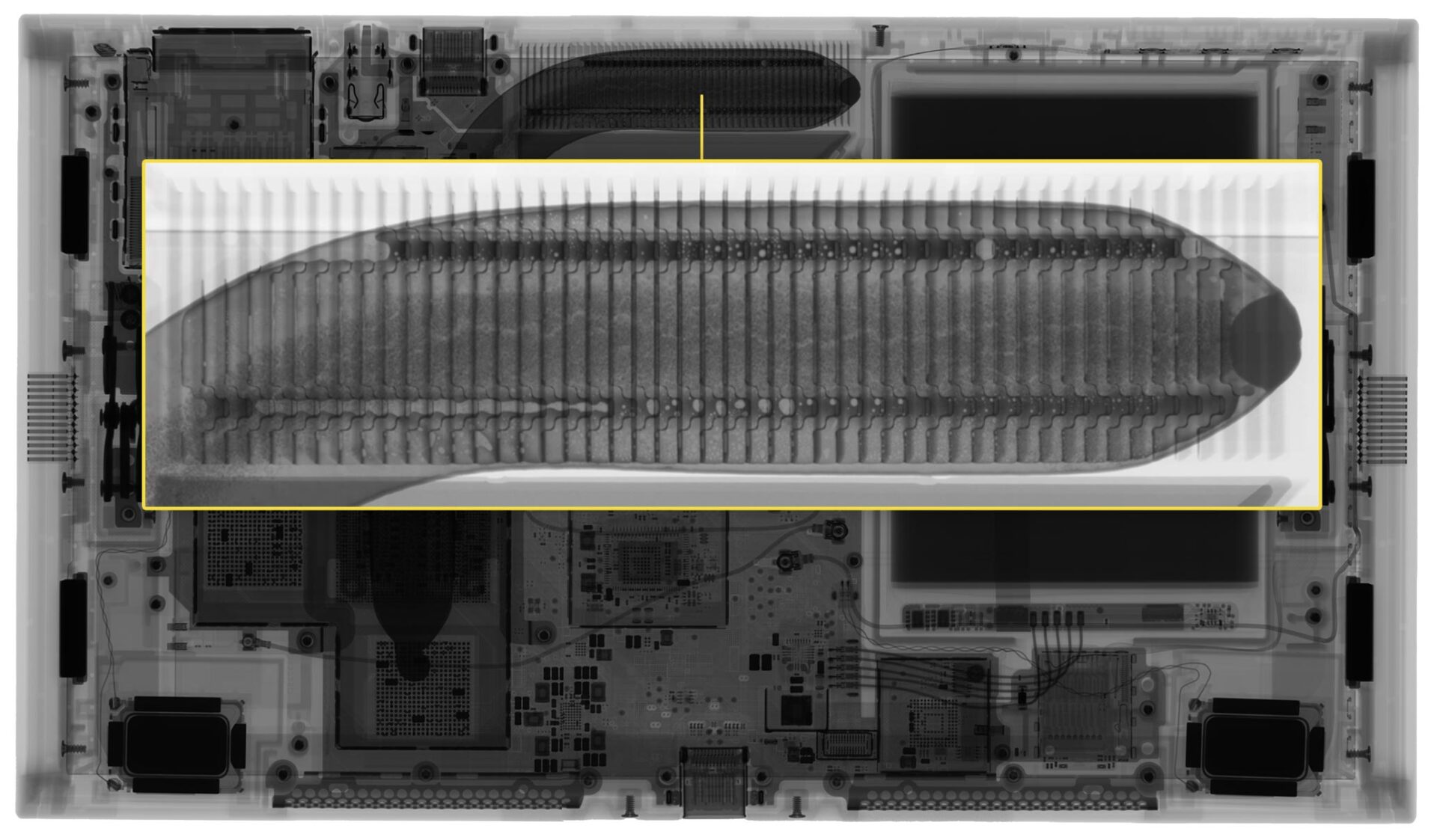

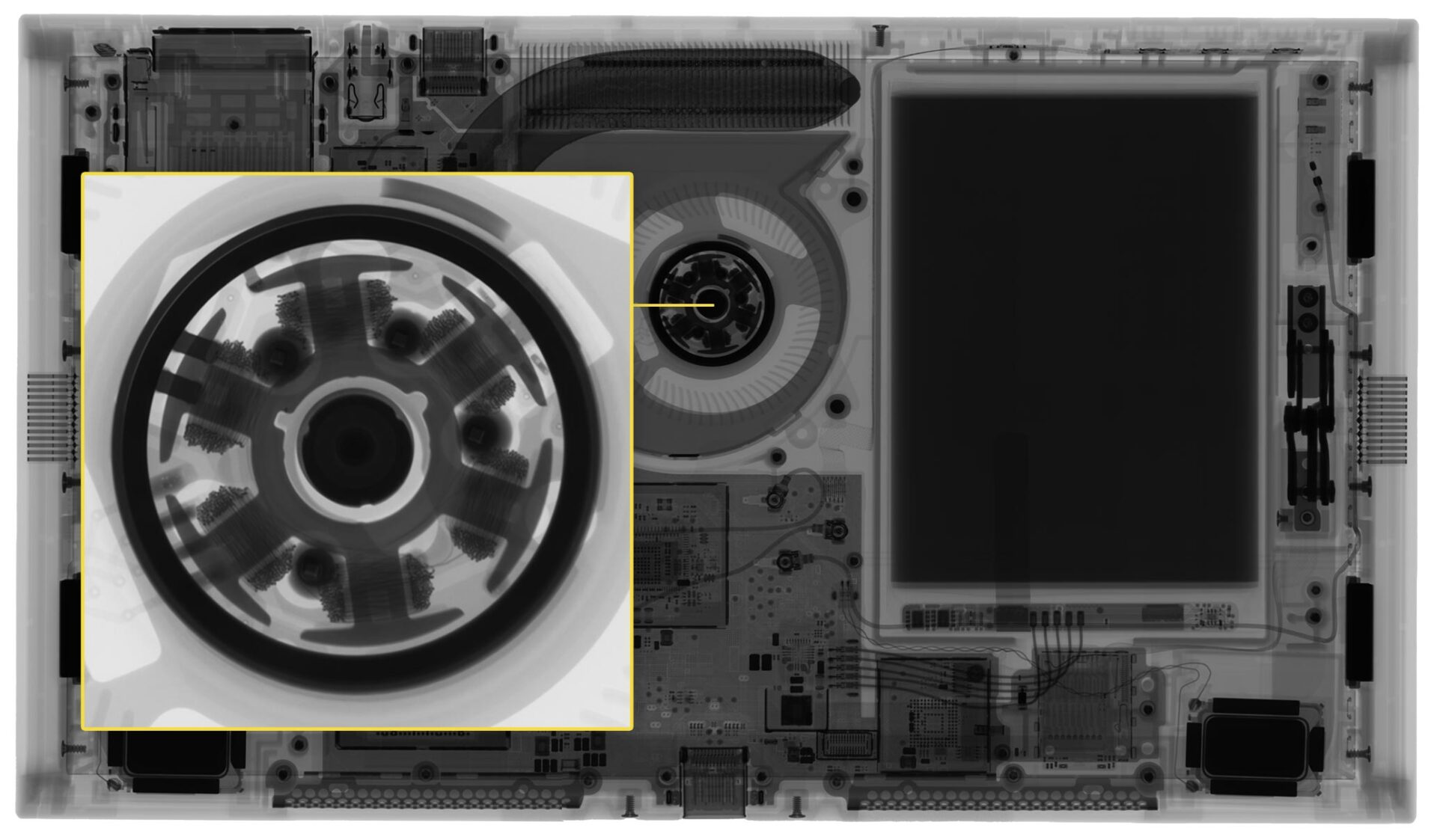

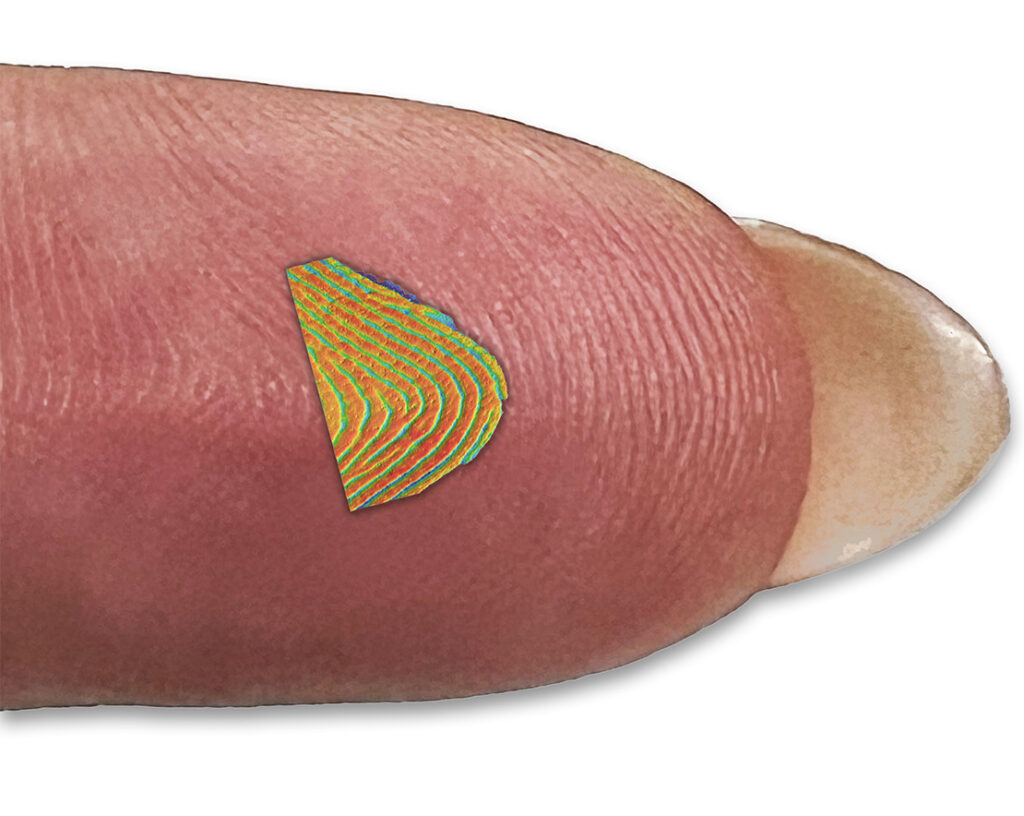

In a discovery that has shaken both the skincare and law enforcement communities, Industrial Inspection & Consulting unleashed the full fury of their Keyence VR6000 optical profilometer on a single, well-moisturized index finger, and the results were criminally smooth.

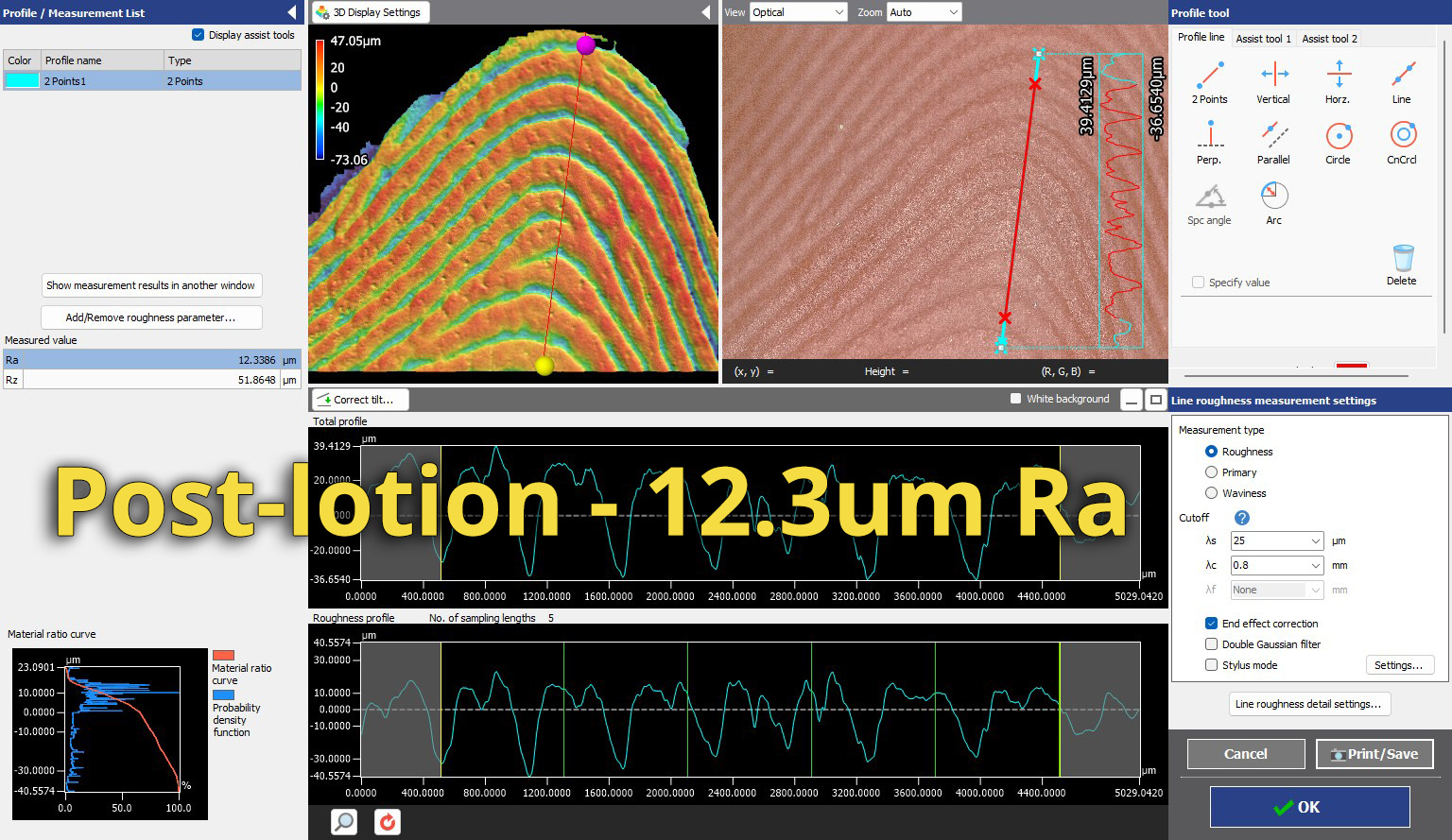

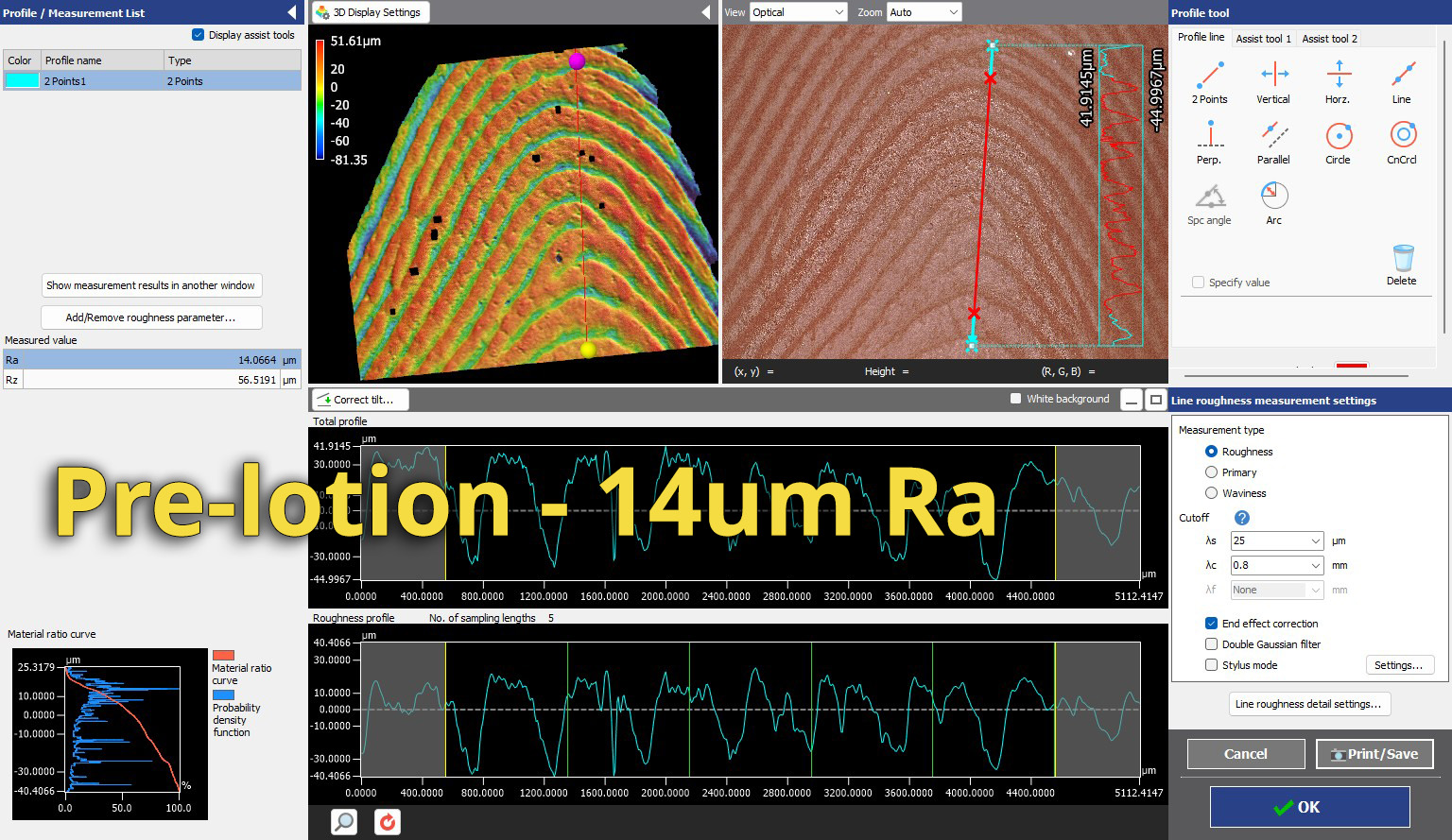

The device, typically reserved for aerospace alloys and semiconductor surfaces, revealed a 2-micron decrease in surface roughness post-lotion application. “At first, we thought the sample was polished titanium,” said one bewildered analyst. The implications were immediate and devastating: fingerprint databases were thrown into chaos, biometric scanners began malfunctioning, and multiple agencies reportedly initiated emergency meetings under the codename Operation: Slippery Grip. As one FBI official put it, “We were prepared for deepfakes, not deep hydration.”

This story is still developing — check back for updates as more fingers (and moisturizers) come under scrutiny.

This post is satire, but we will gladly scan your fingers.