CT Scanning Aluminum Charged Air Cooler for Leaks

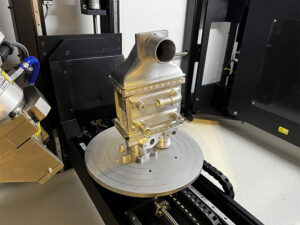

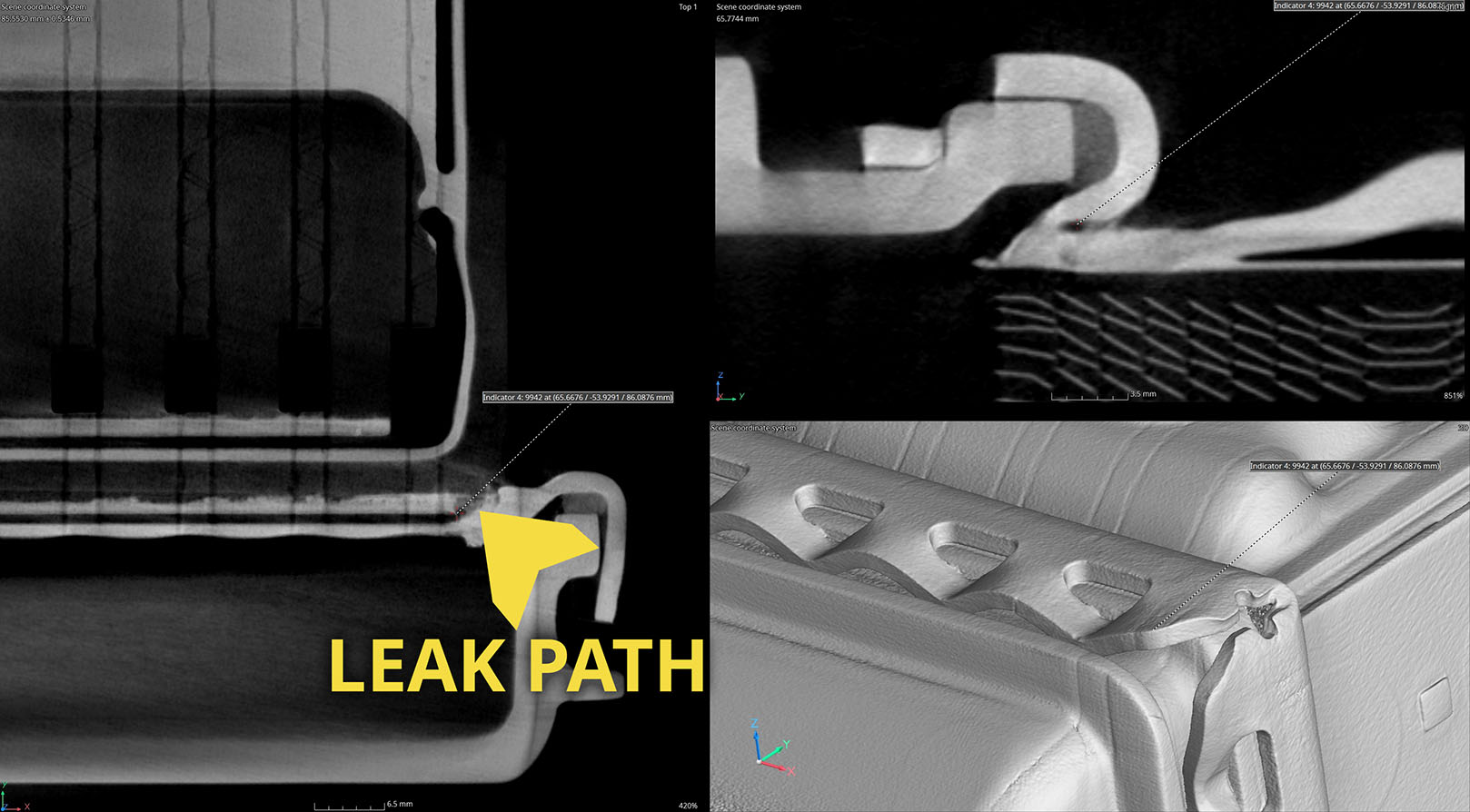

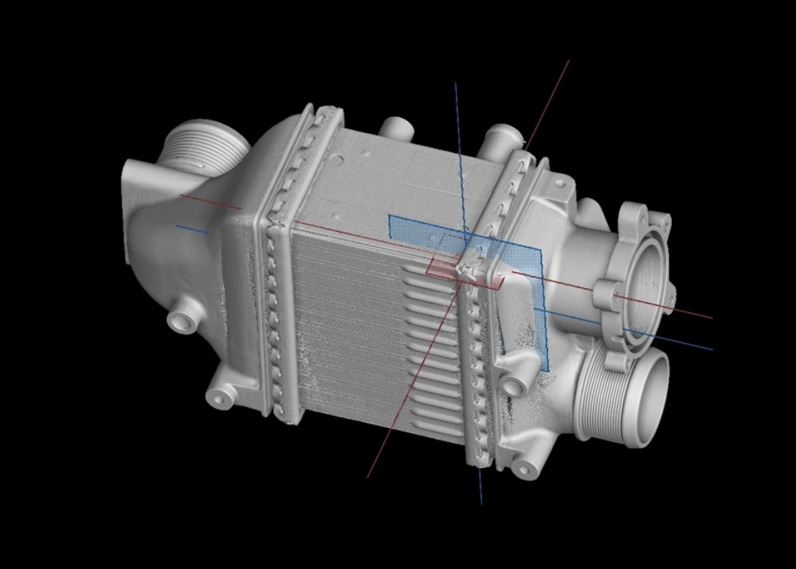

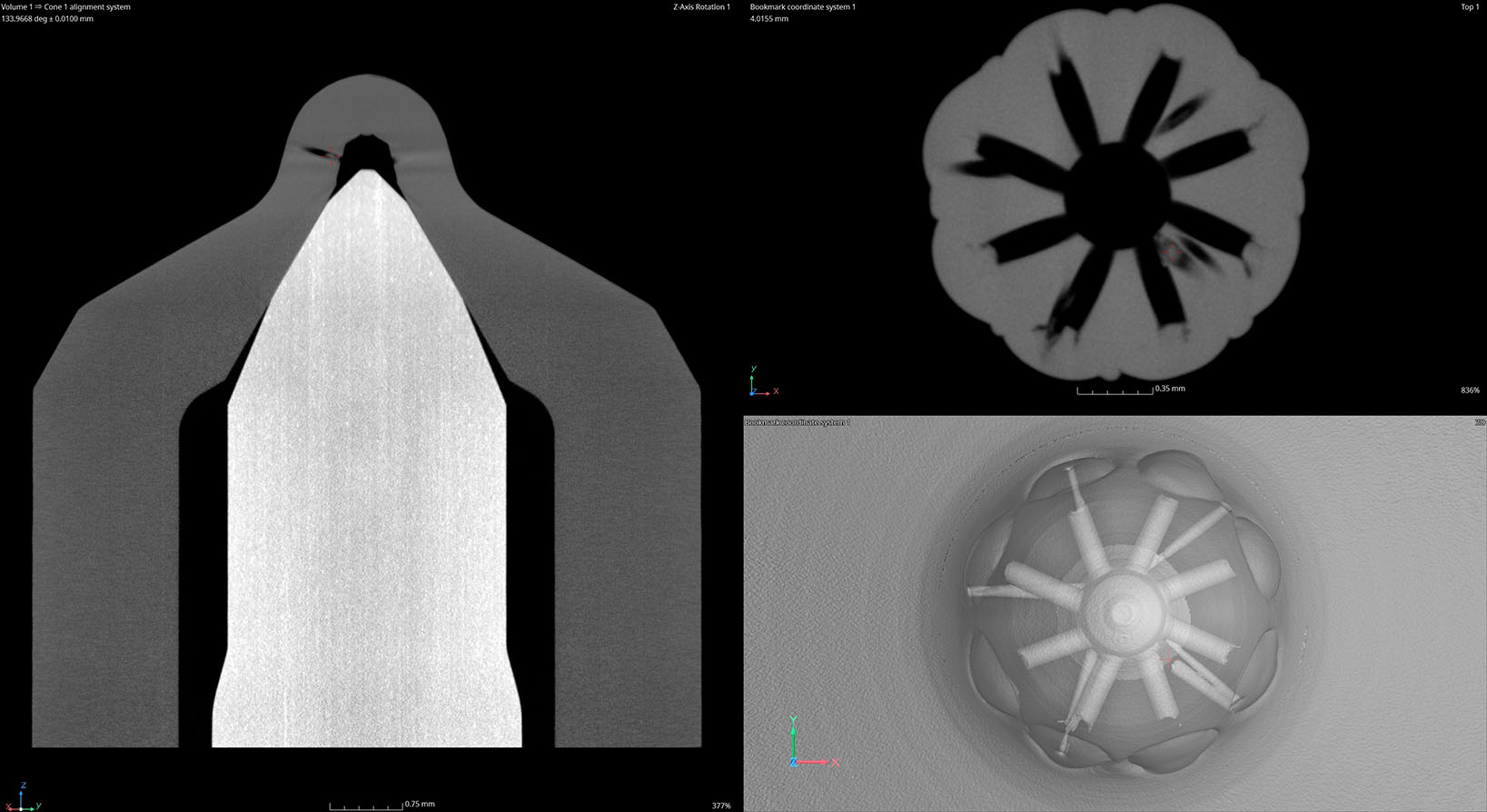

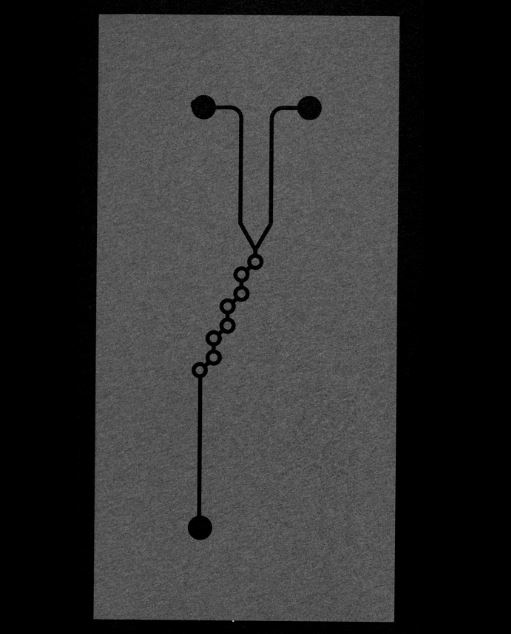

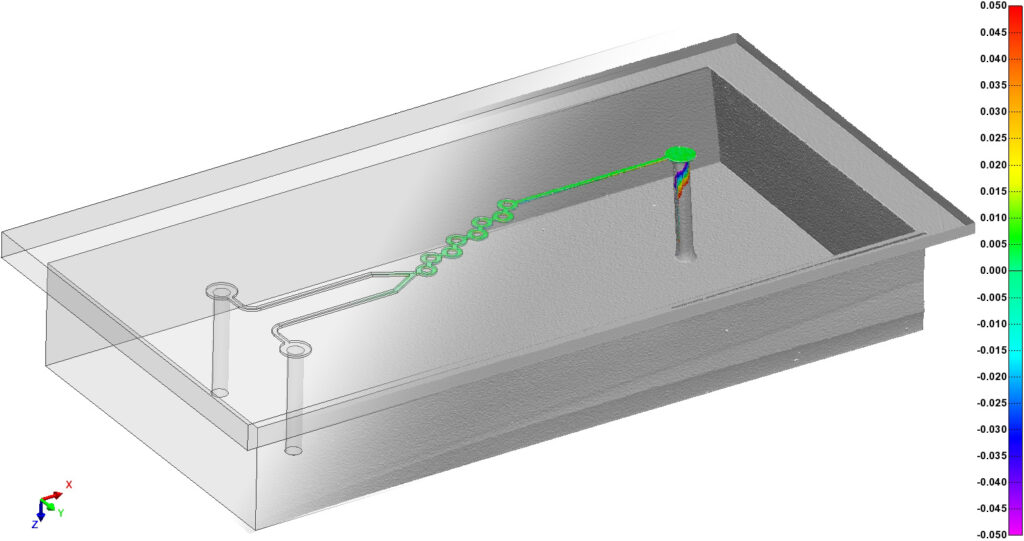

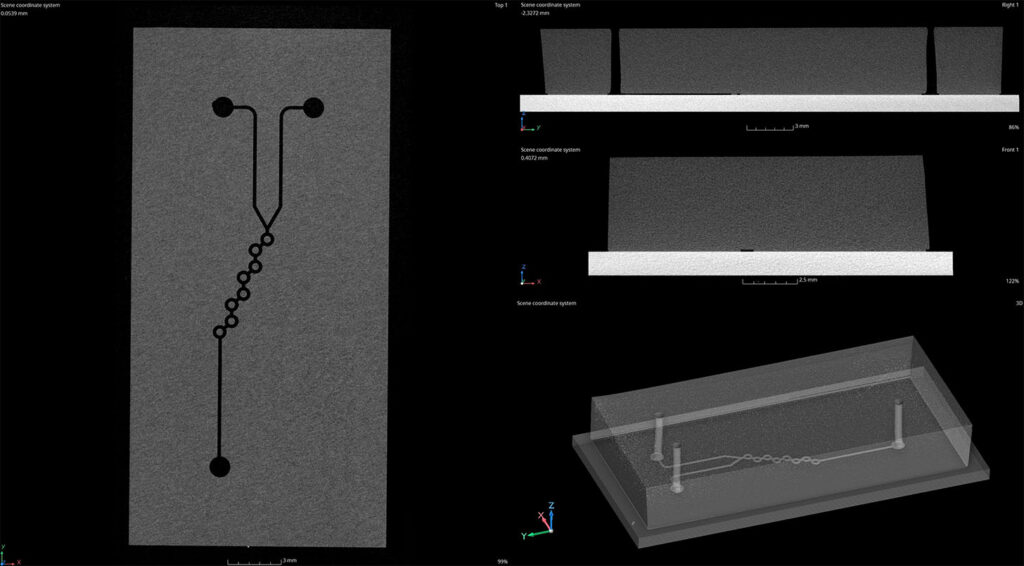

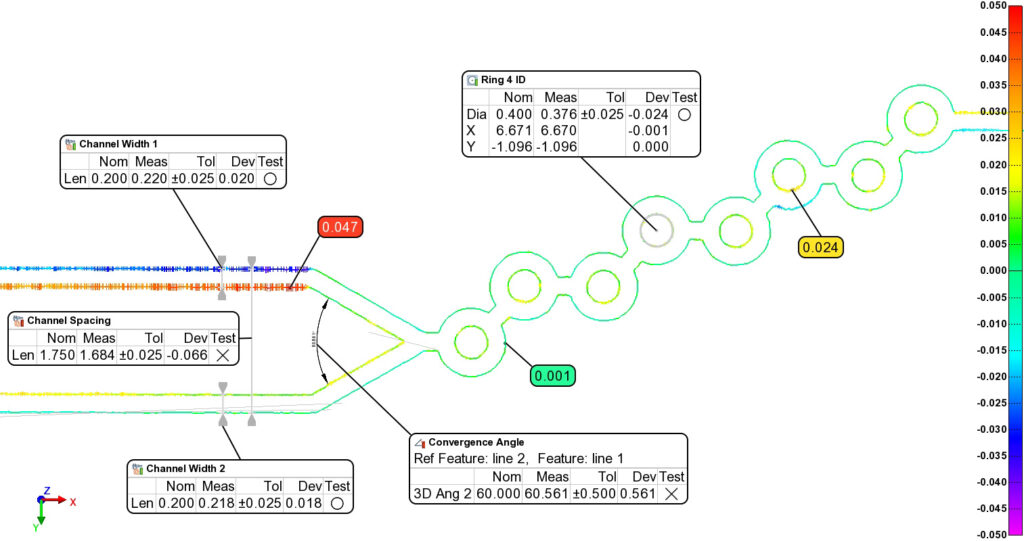

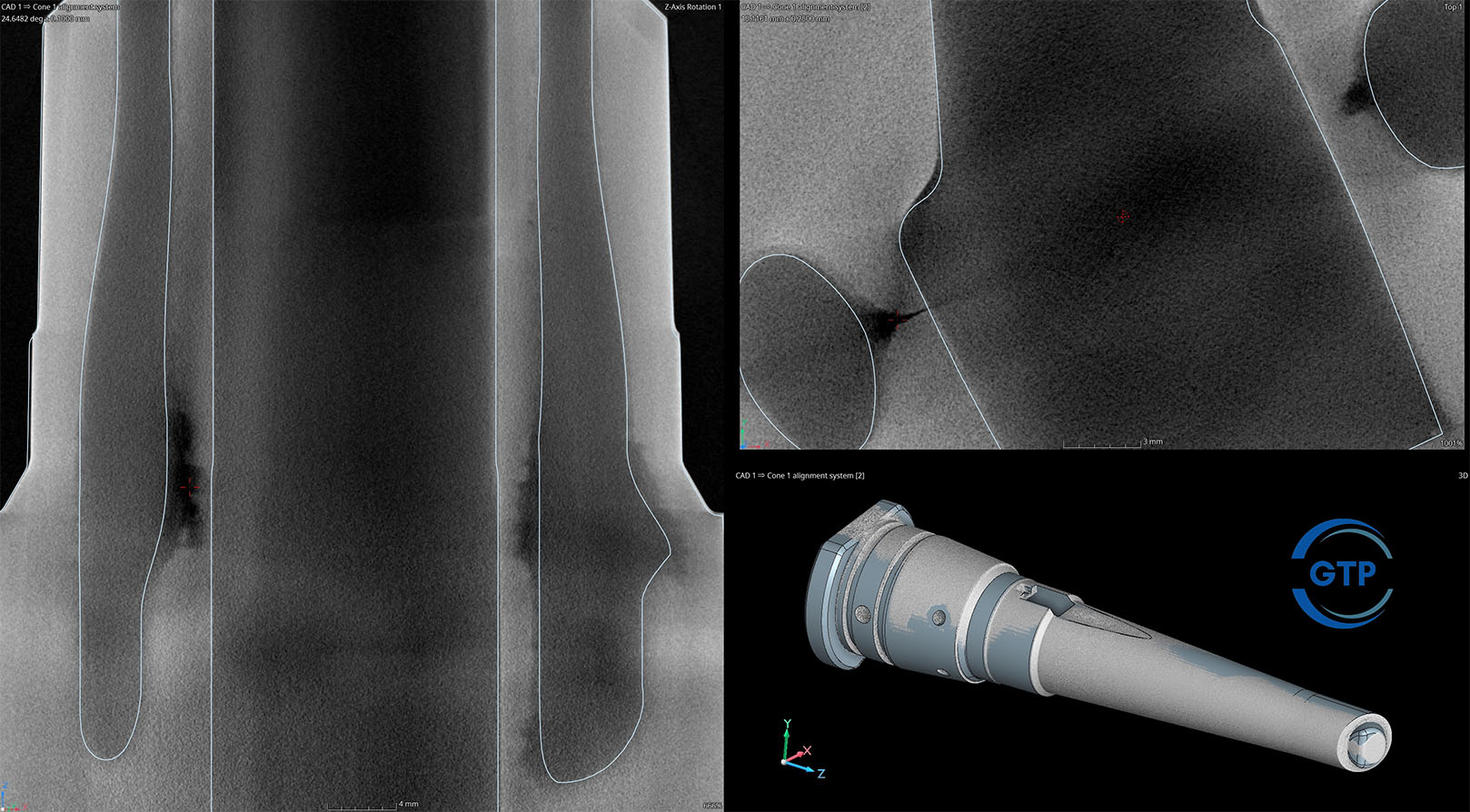

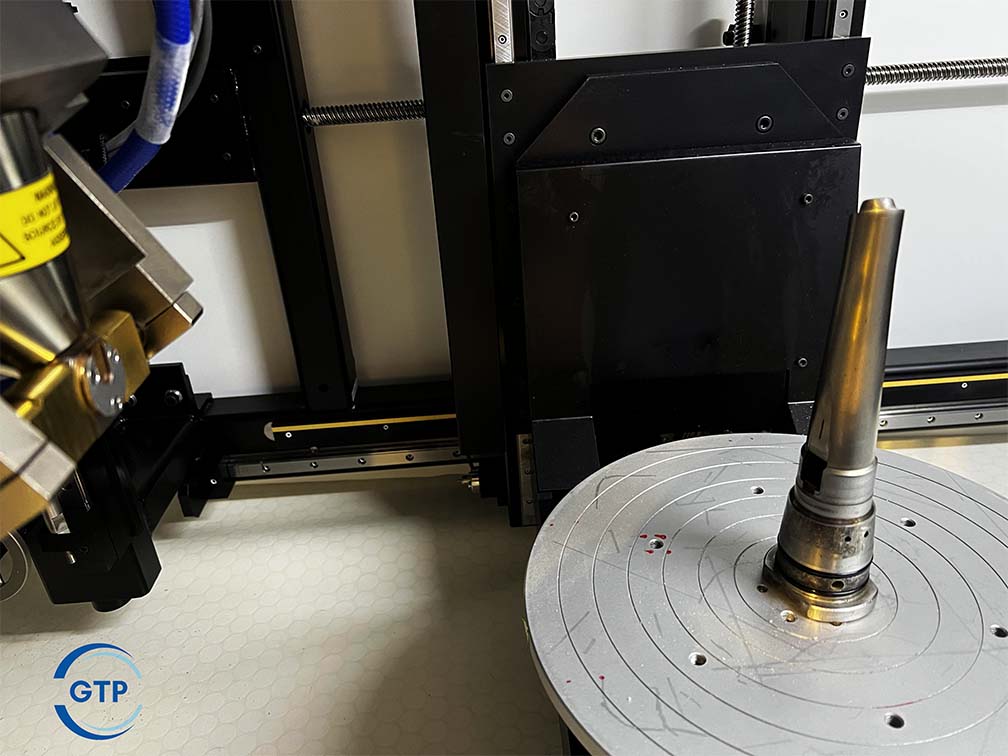

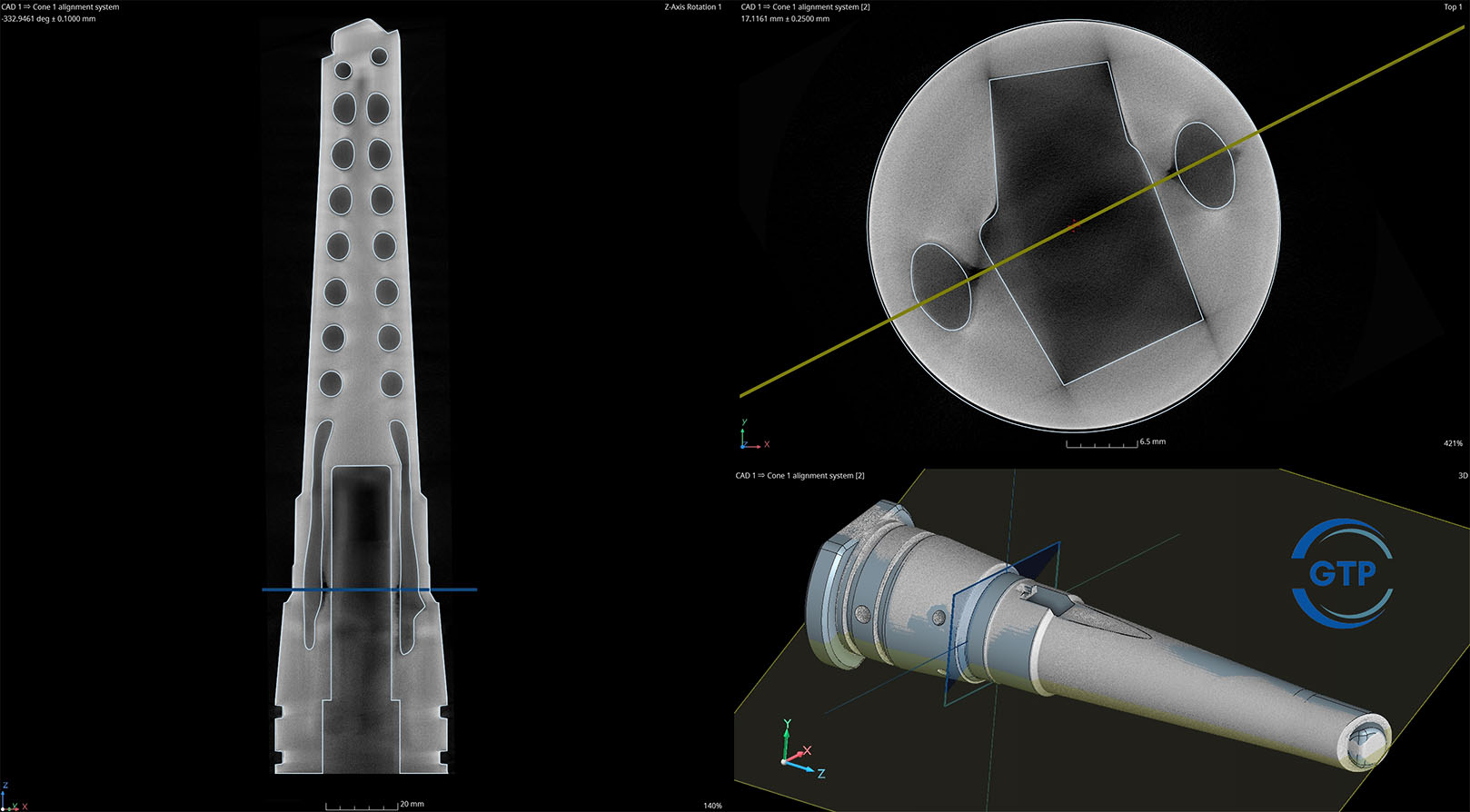

CT scanning was used to nondestructively identify leaks in the seal area of this aluminum charged air cooler. A high exposure helical scan was used to capture a single, high resolution scan of the oblong assembly.

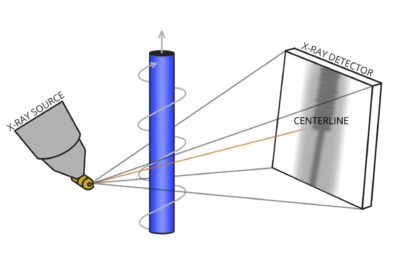

Helical scanning works by continuously rotating and raising the object with the part manipulator, creating a spiral dataset. The benefit of helix scans is that resolution is limited to the object’s greatest width, rather than it’s length. Additionally, CT artifacts like beam hardening are dissipated throughout the sample rather than concentrated in a localized, circular zone. Some drawbacks to helical scans are exceptionally large files (this was around 70gb), and spiral artifacts.