UPDATE 8/3/2024:

We are aware of and working through the moral dilemma of CT scanning sealed collectibles. Our objective position is one of scientific ability and data-driven results. It is not our responsibility to determine the ethical positions and choices of others and we do not accept responsibility for their actions.

1. We have brought awareness to the entire industry of the existence and capabilities of this technology; it is up to individuals to make informed decisions moving forward.

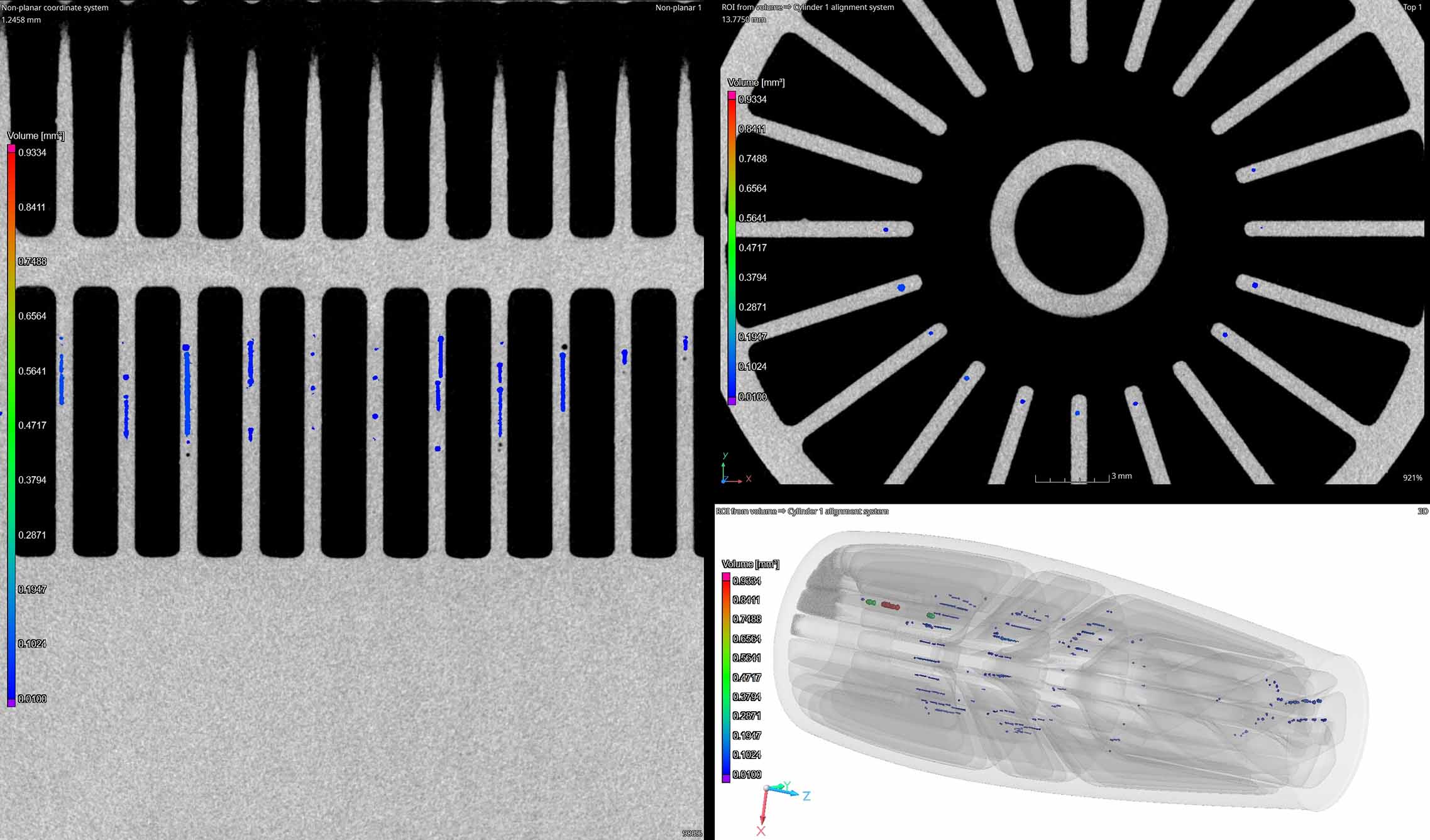

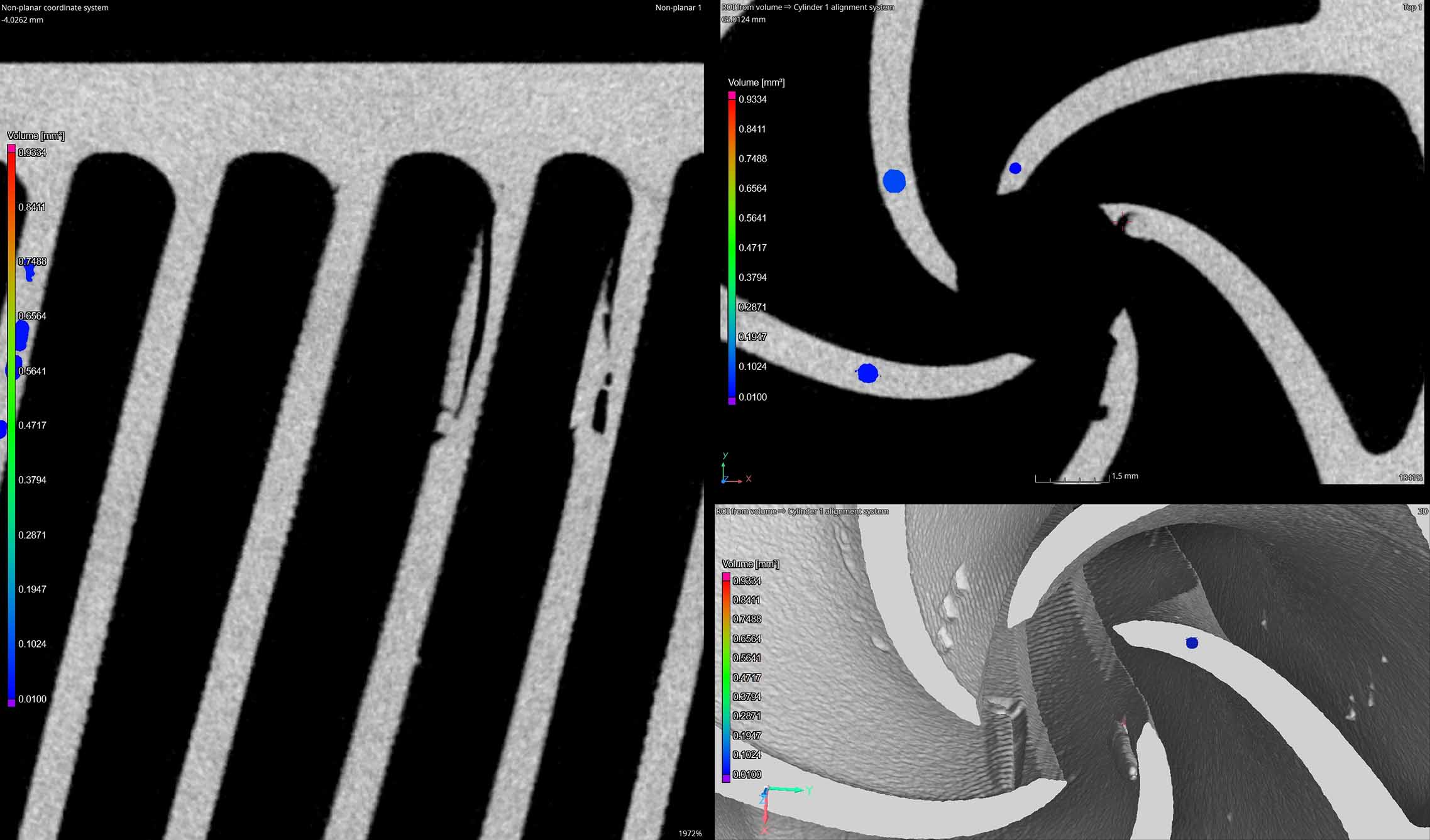

2. In light of information we have received from industry insiders, we believe companies are using this technology in secret to take advantage of the collectibles market.

3. We are making this technology accessible to everyone rather than to just a minority.

4. We are working on policies to combat deceptive practices.

5. We are working on partnering with manufacturers to develop packaging security solutions.

6. We will continue to consider every request we receive.

7. This technology is here to stay and there will probably be additional companies offering it as a service at some time in the future.

8. The majority of requests we have received have been from people curious about the value of their “30 year old collectible” and if this is their opportunity for a life changing moment.

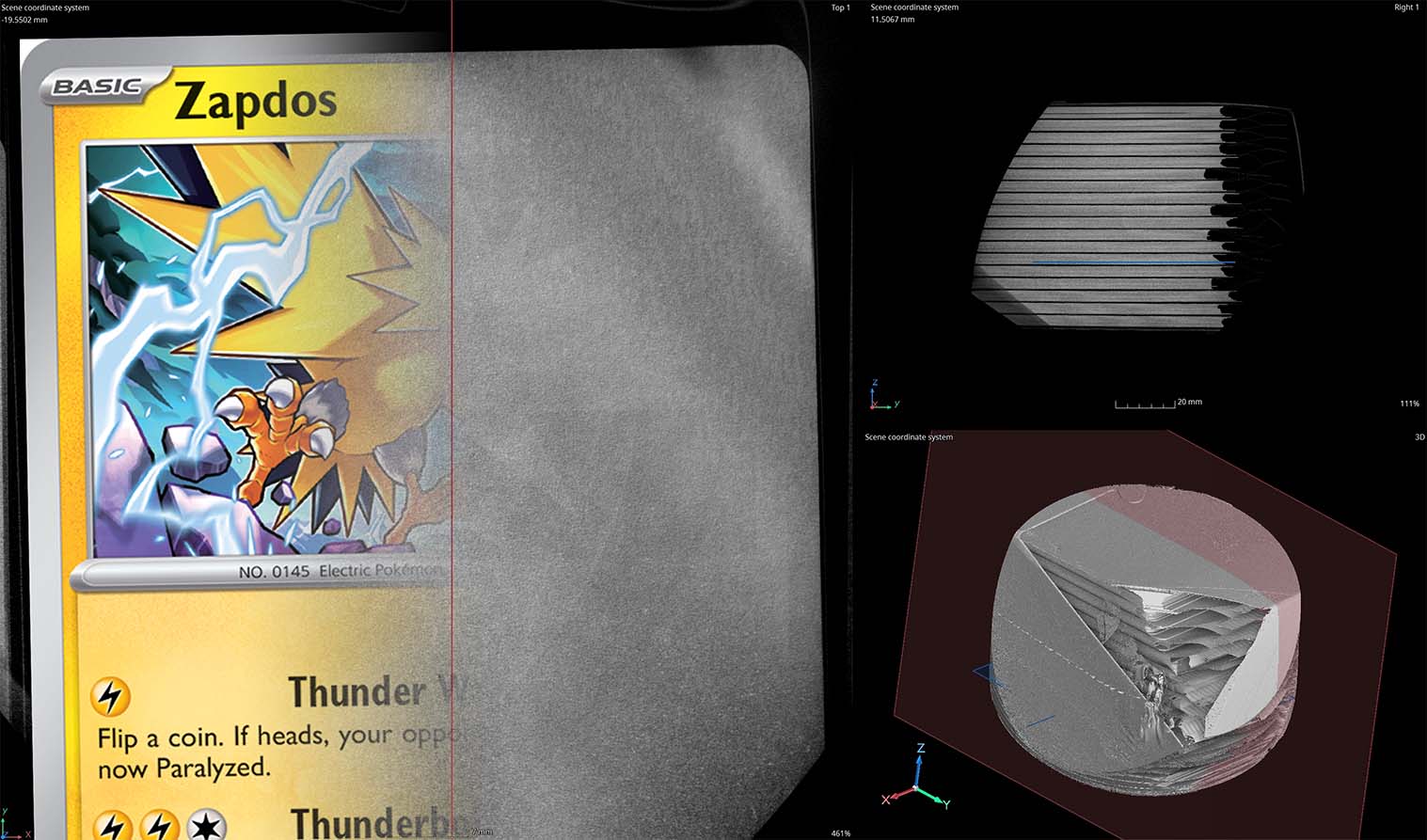

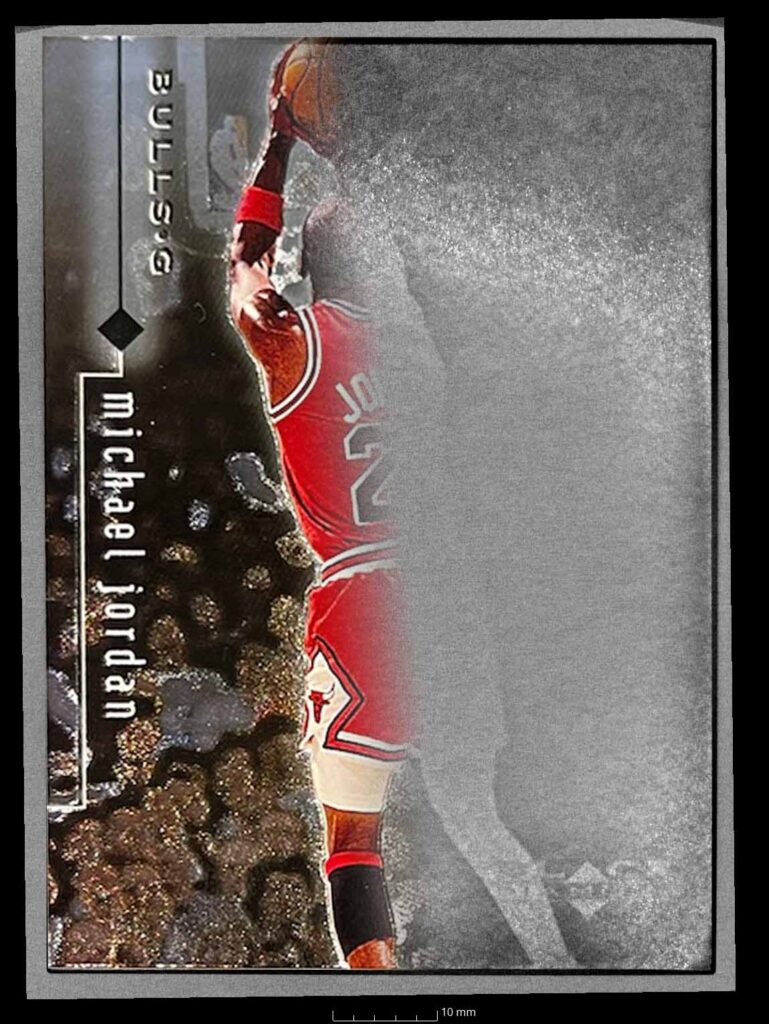

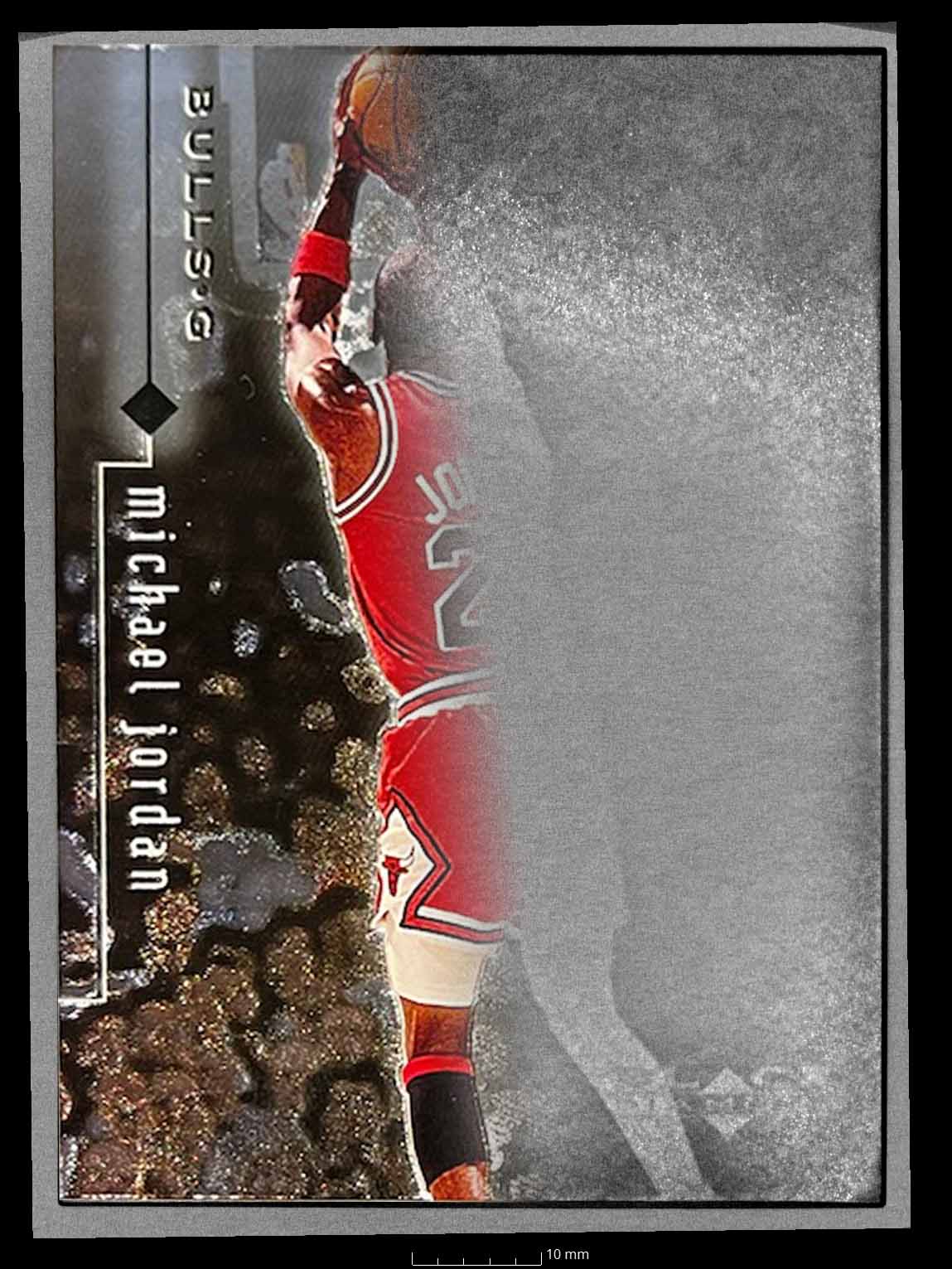

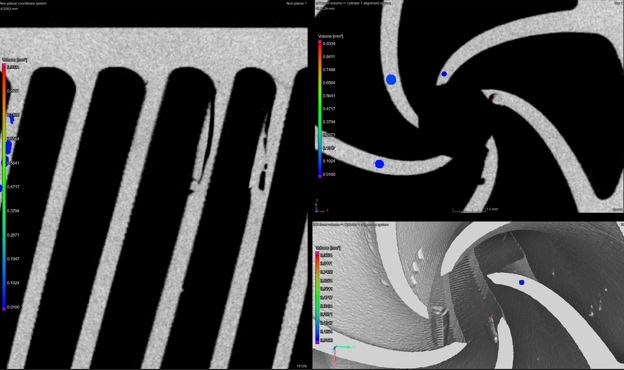

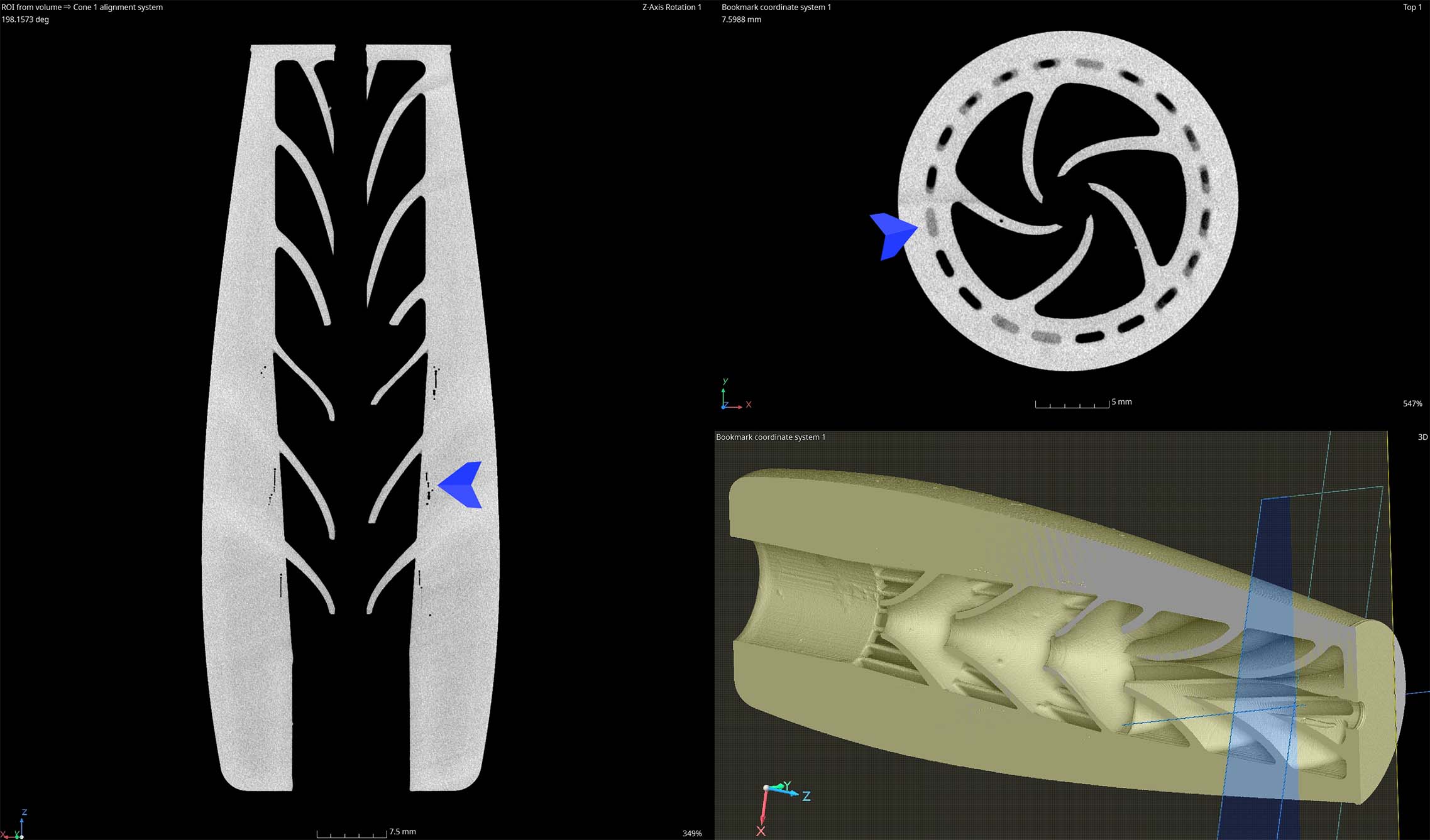

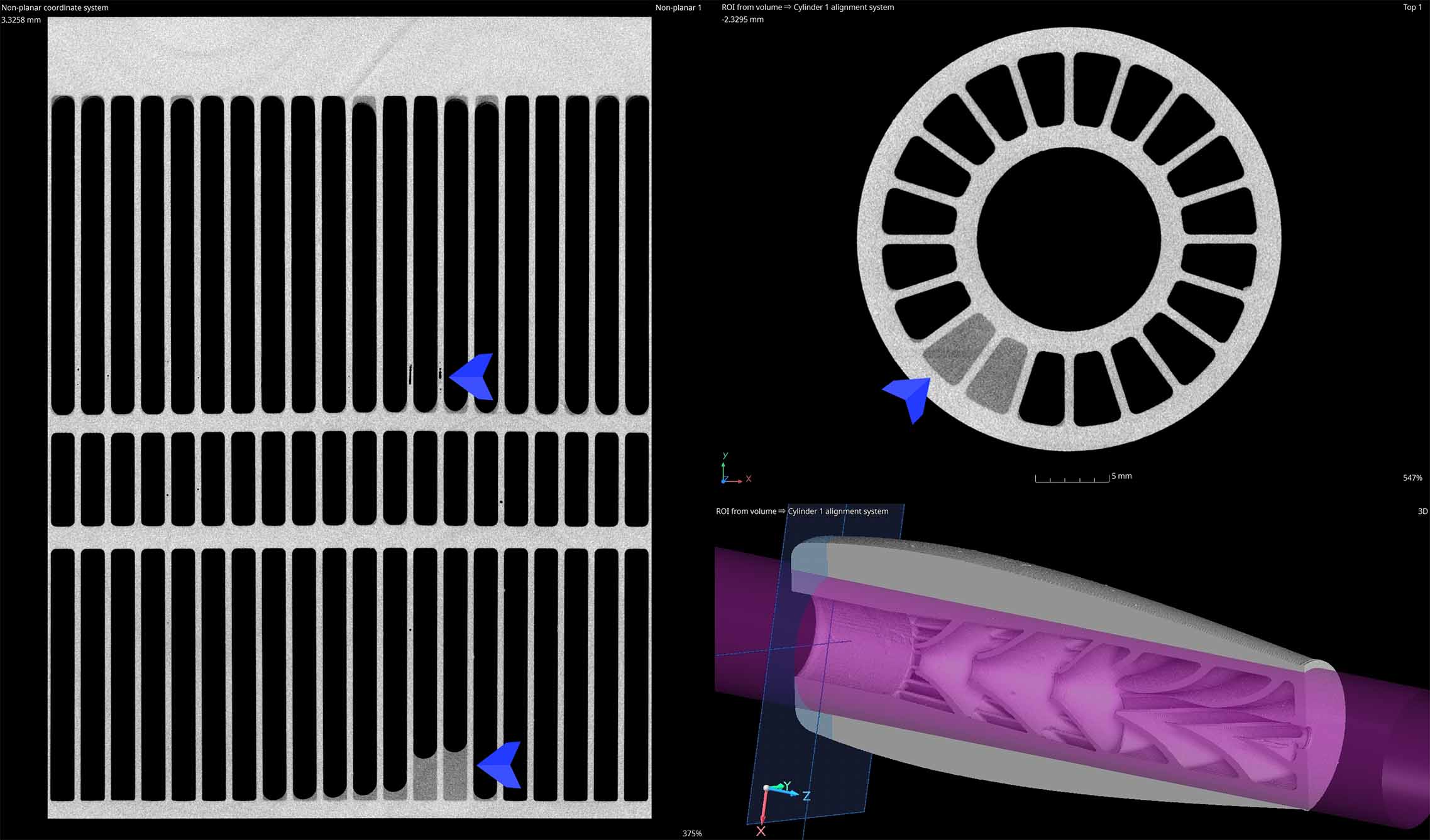

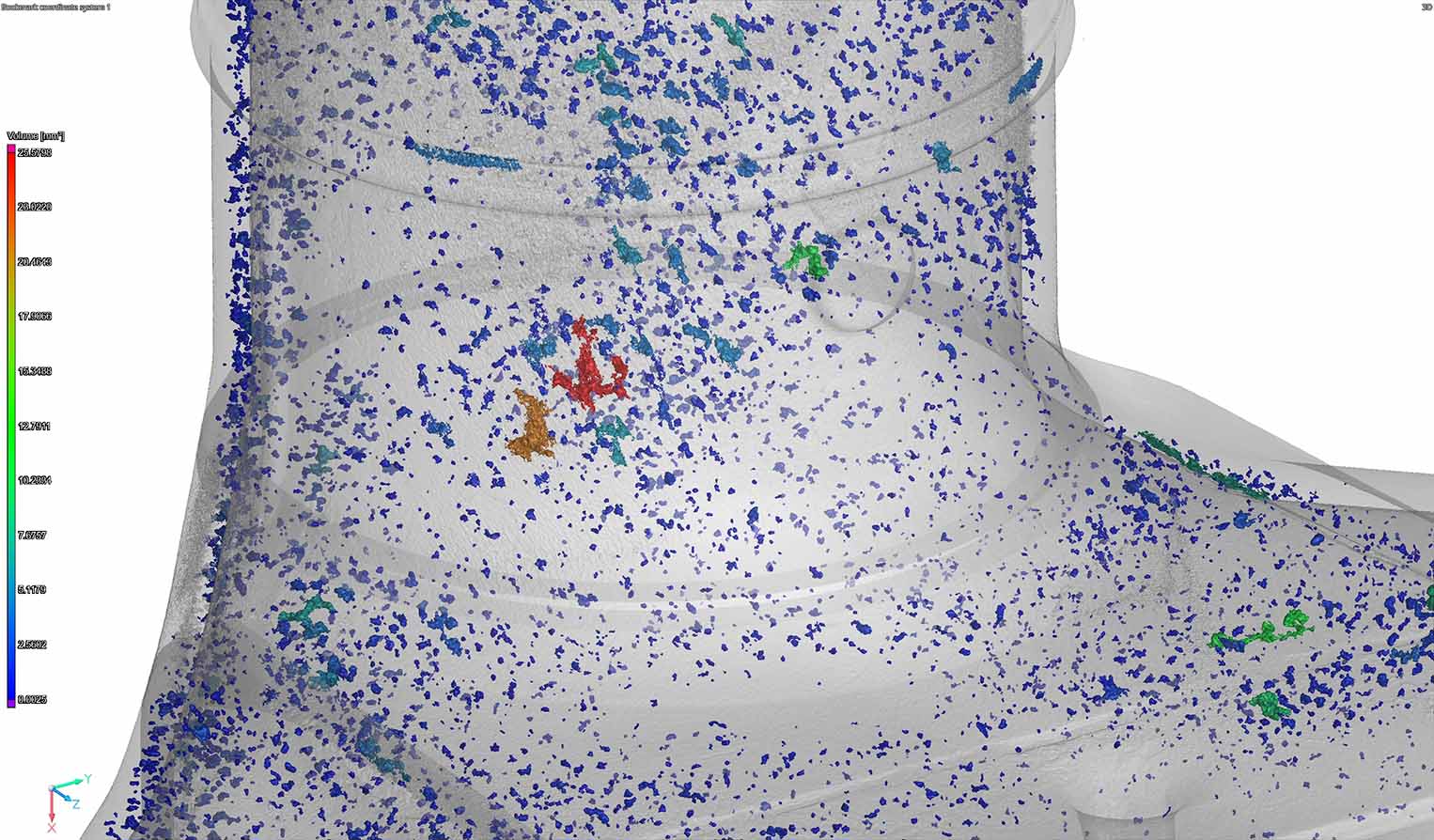

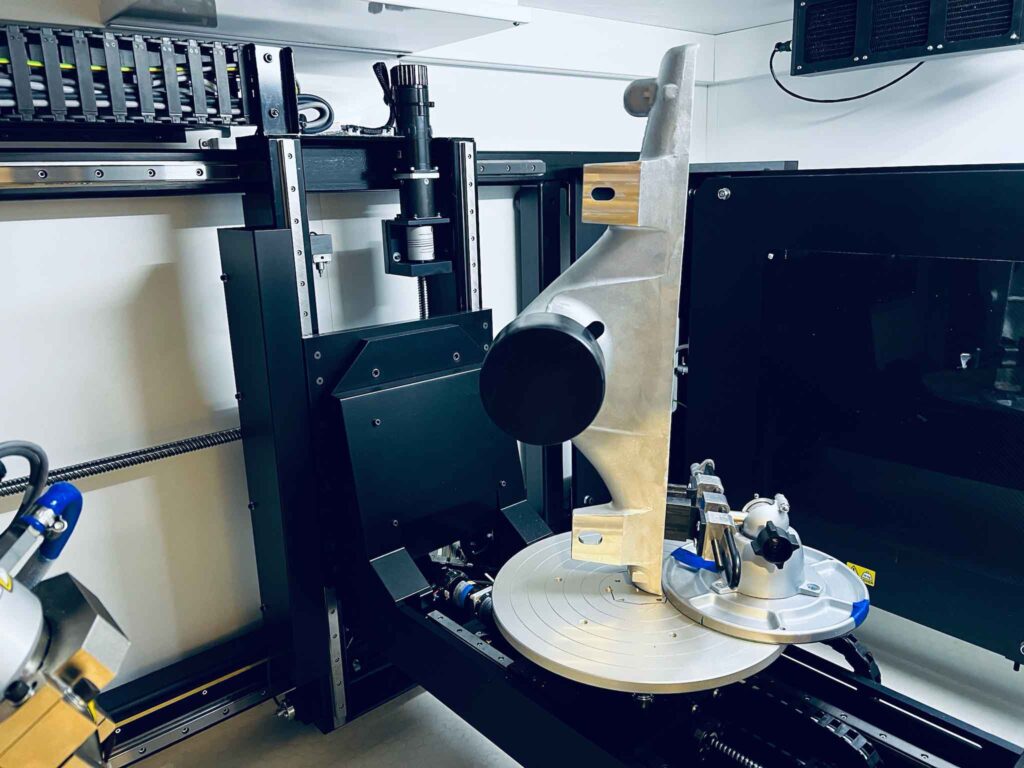

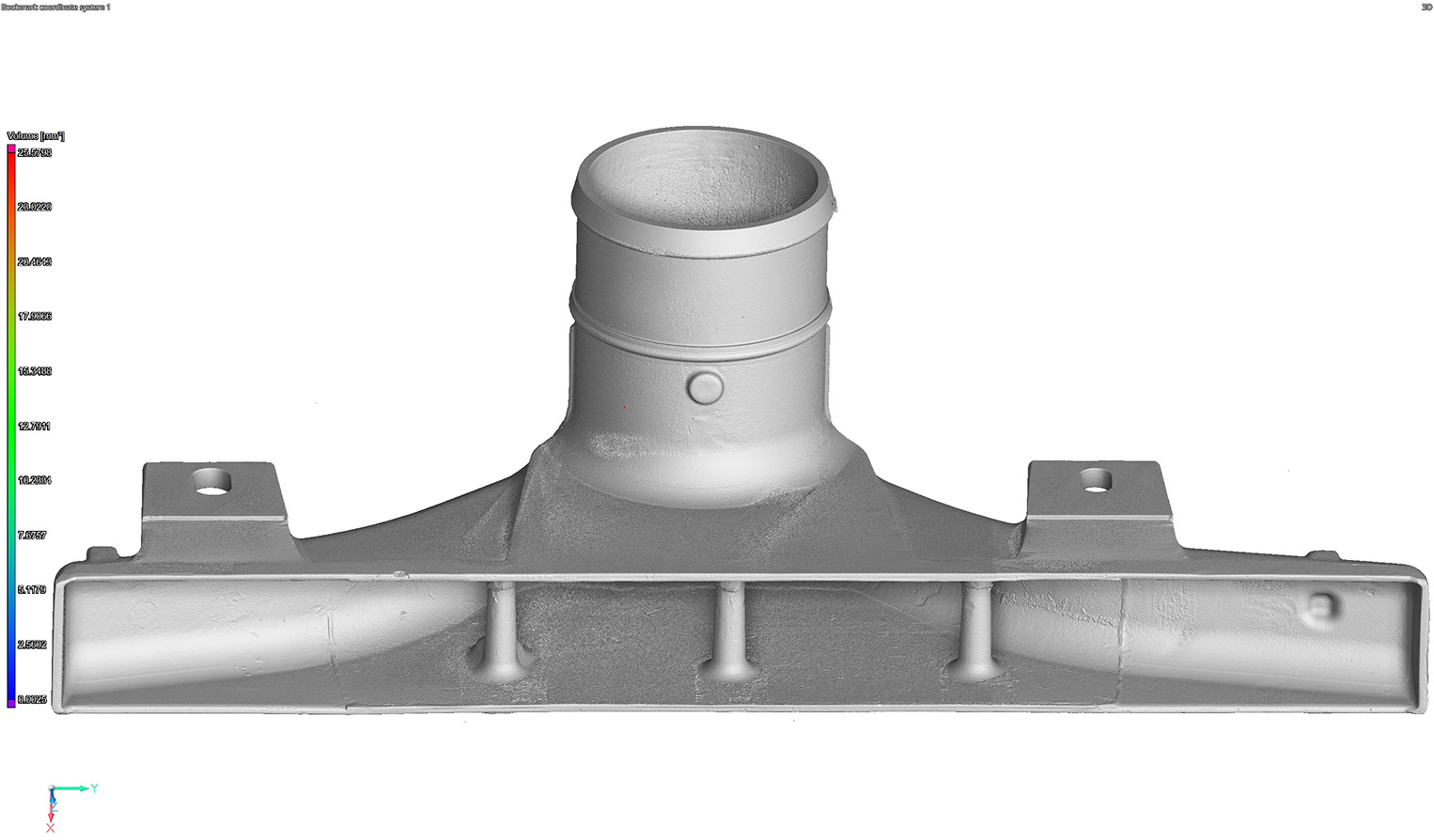

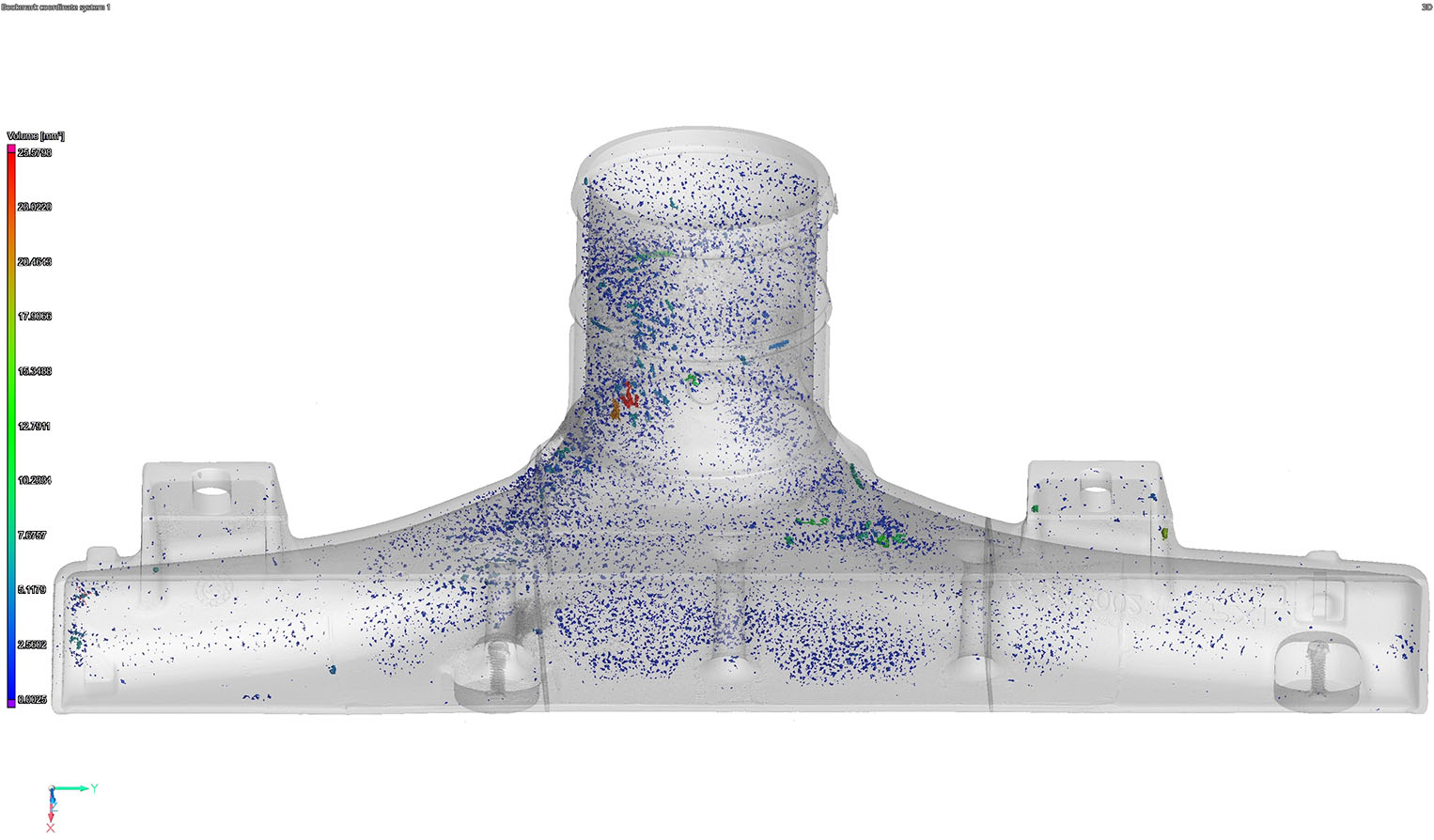

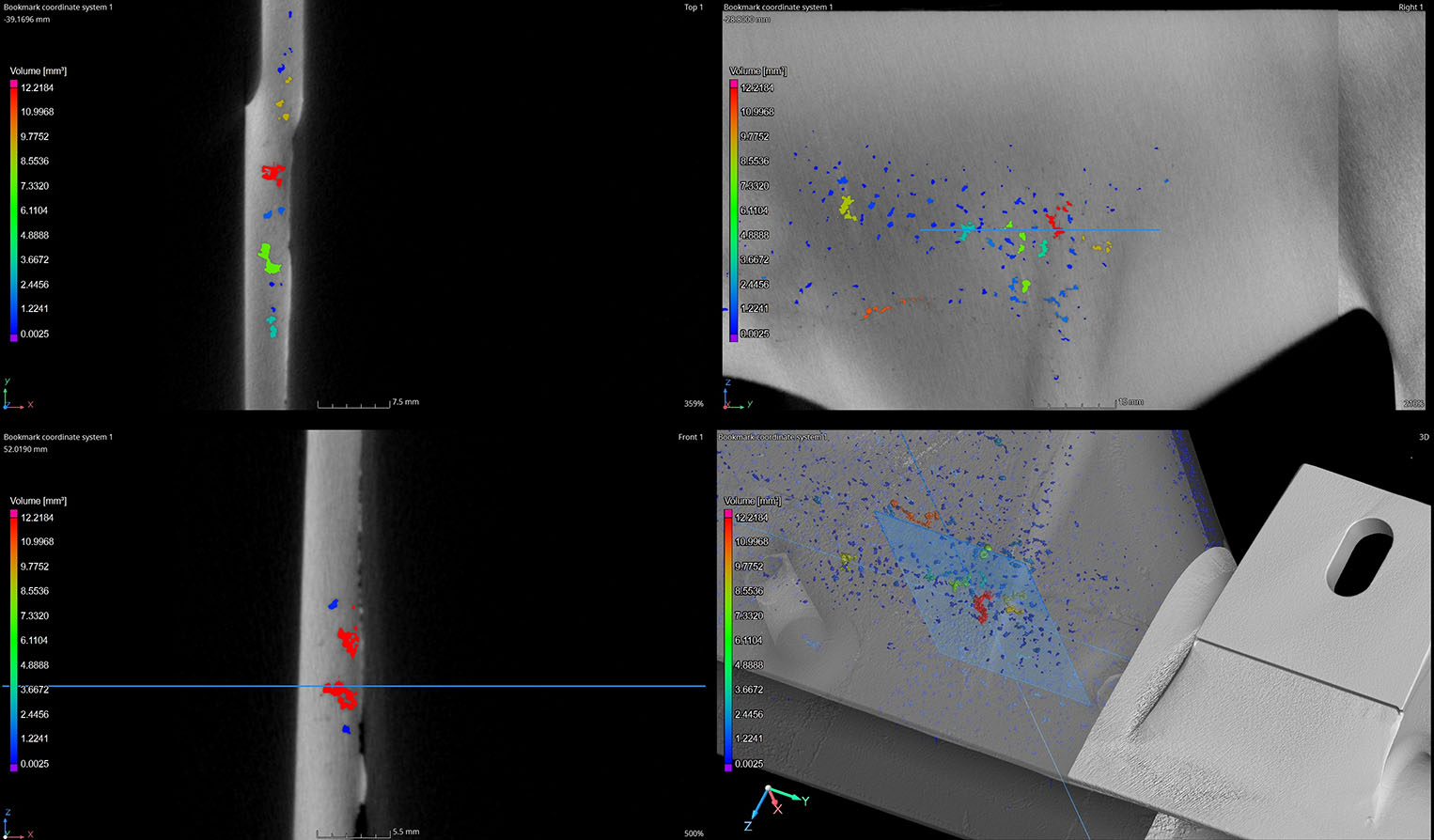

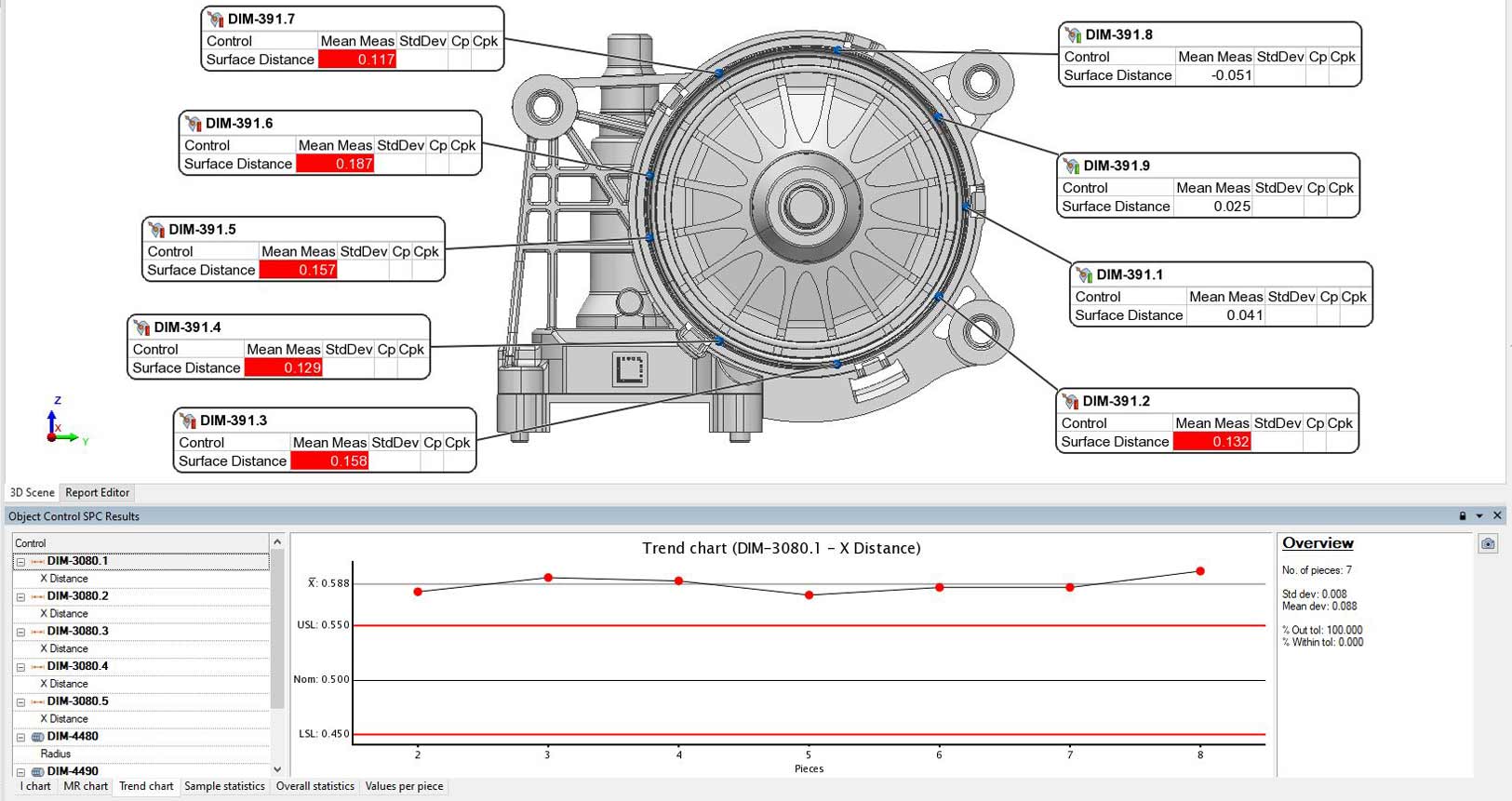

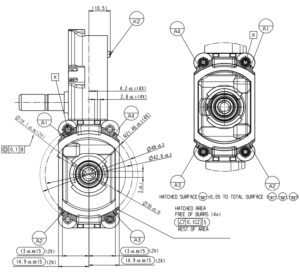

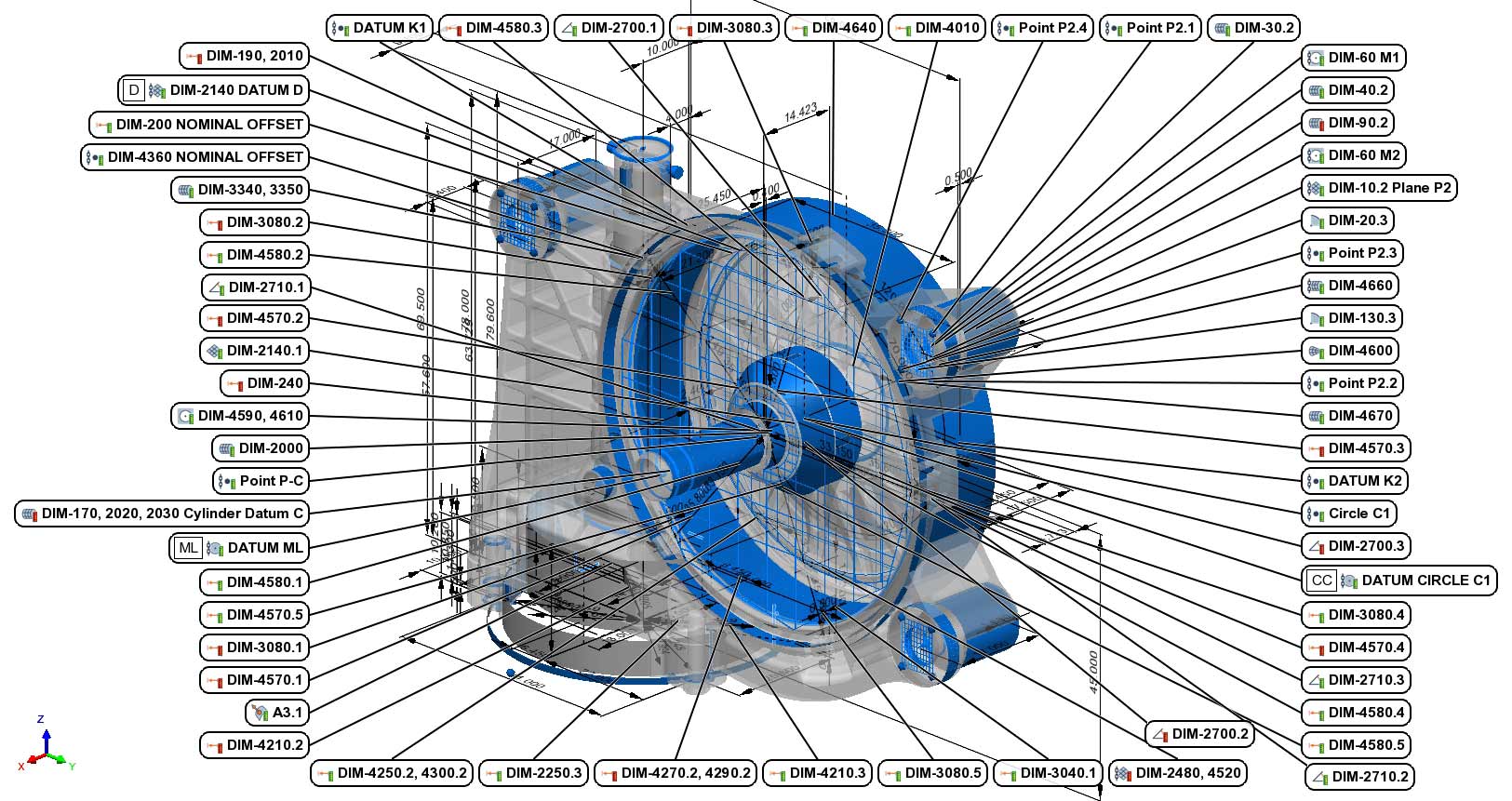

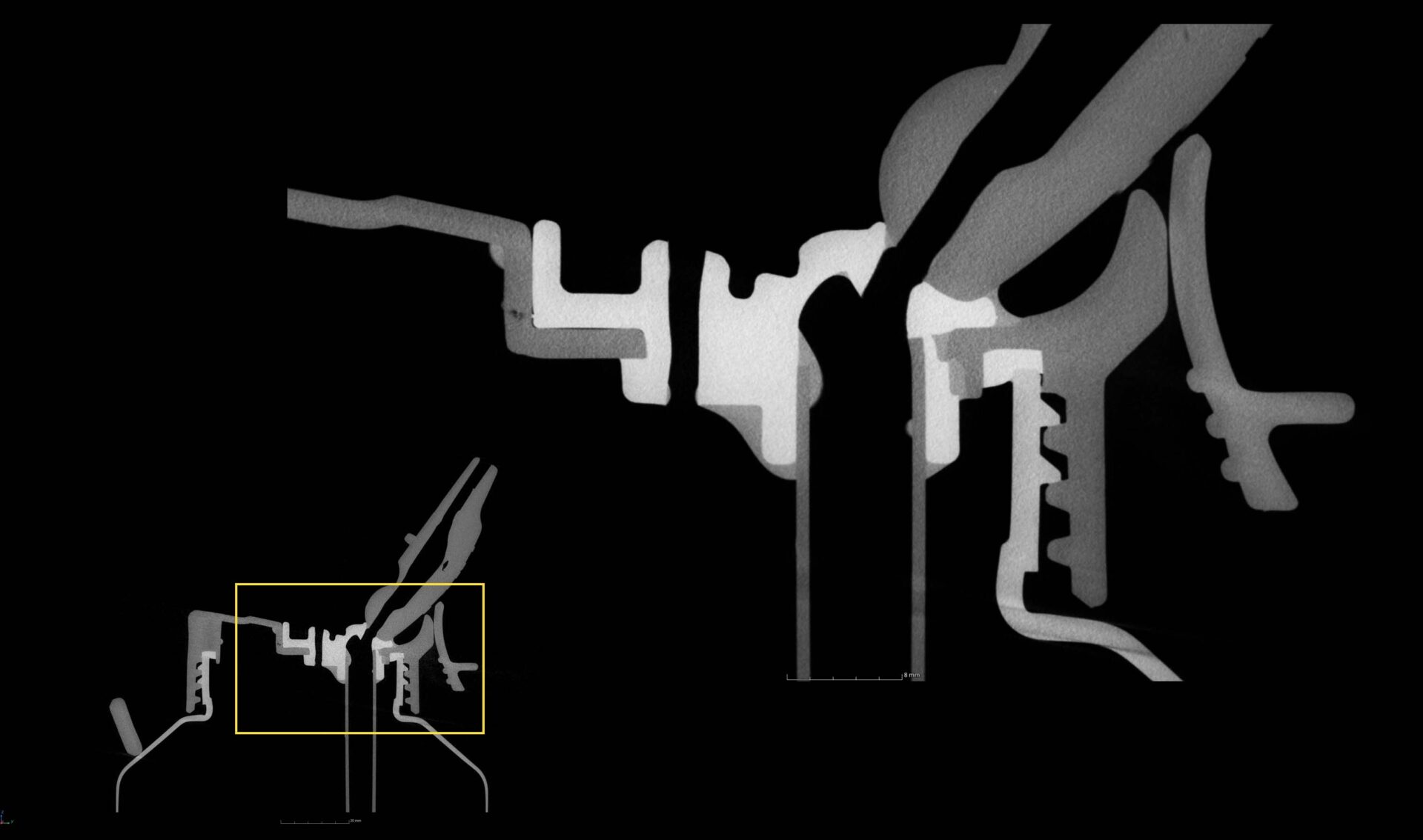

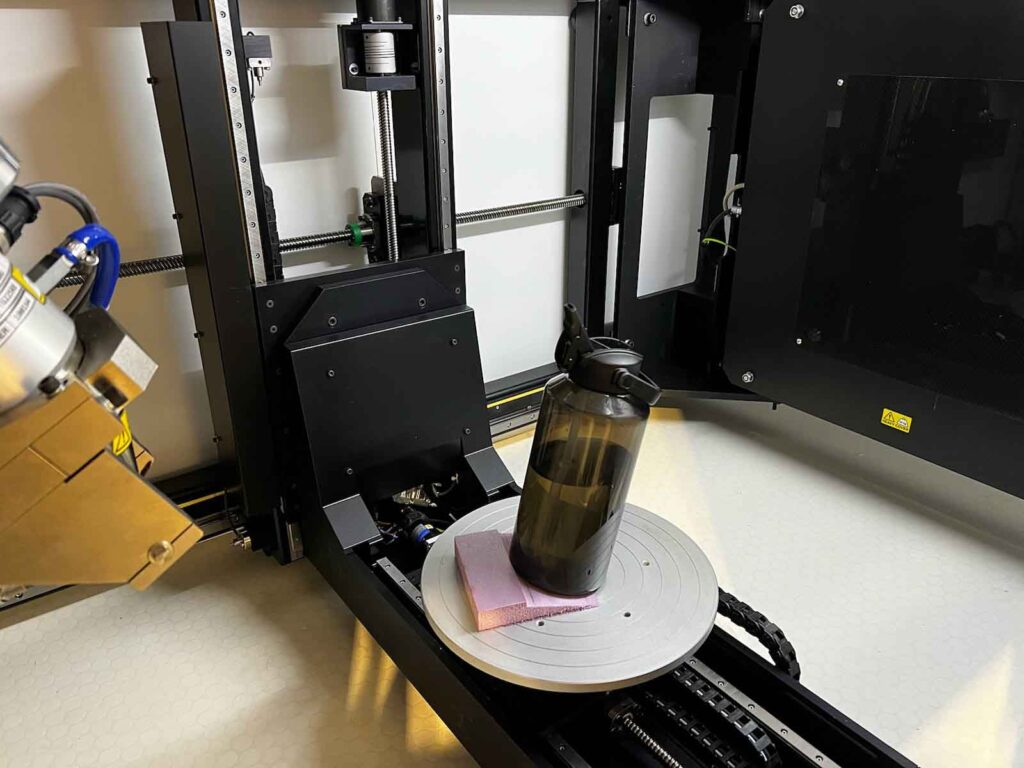

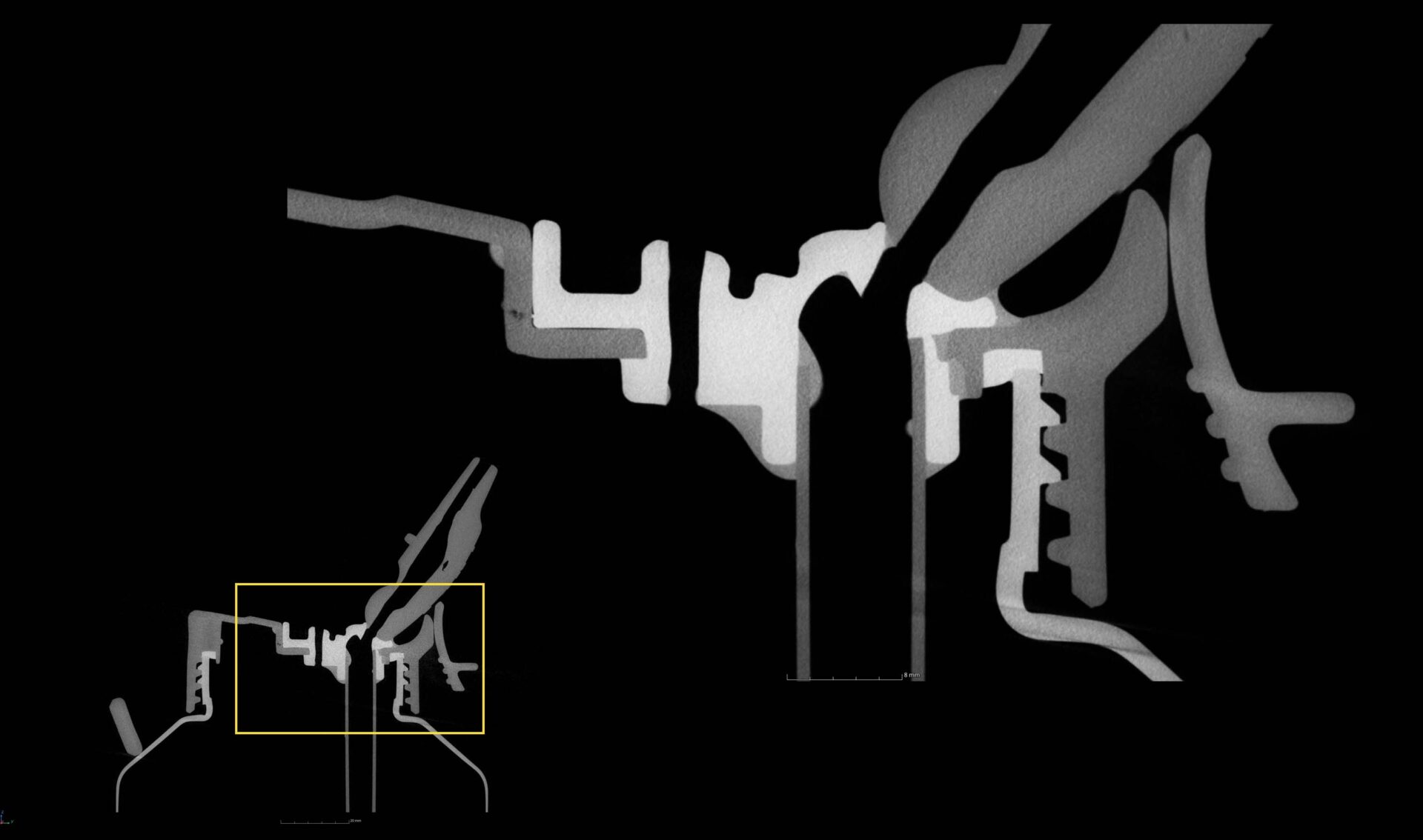

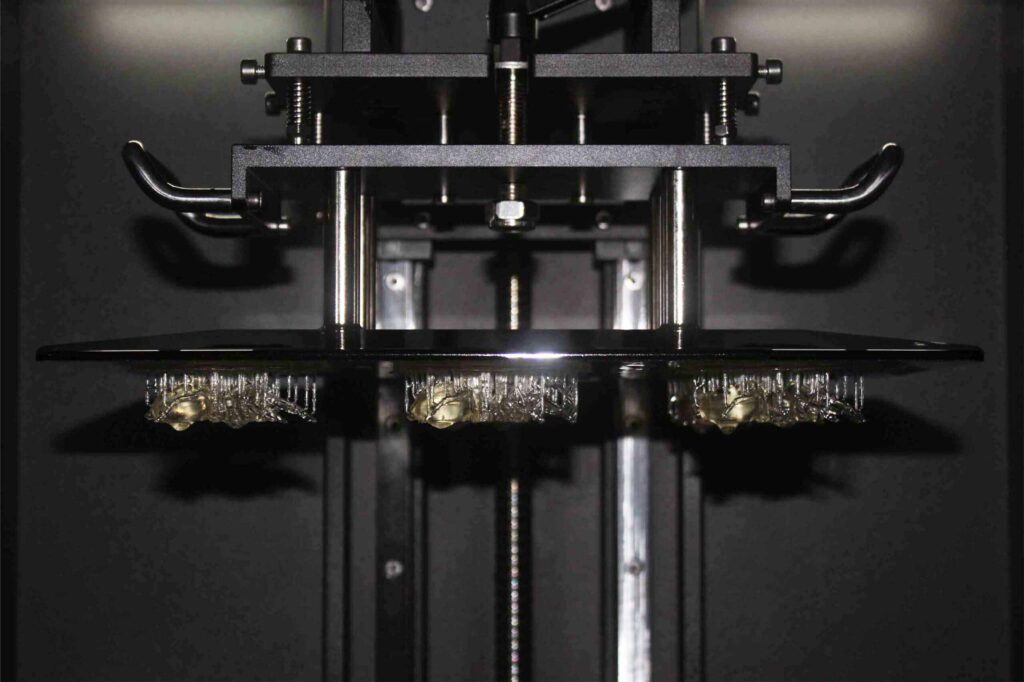

INDUSTRIAL INSPECTION BECOMES THE WORLD'S FIRST COLLECTOR CARD CT SCANNING SERVICE

First, we made public what’s been happening in secret. Now, we are bringing x-ray vision to the masses – quickly, affordably, and reliably. Preserve your investments, maintain your edge against wealthy investors and bad actors, and understand the value of what you own. We can image everything from packs to booster boxes for sports and card games.

To learn more check out our Collector Card CT Scanning Page here: