CERTIFIED RADIOGRAPHY OF CASTINGS

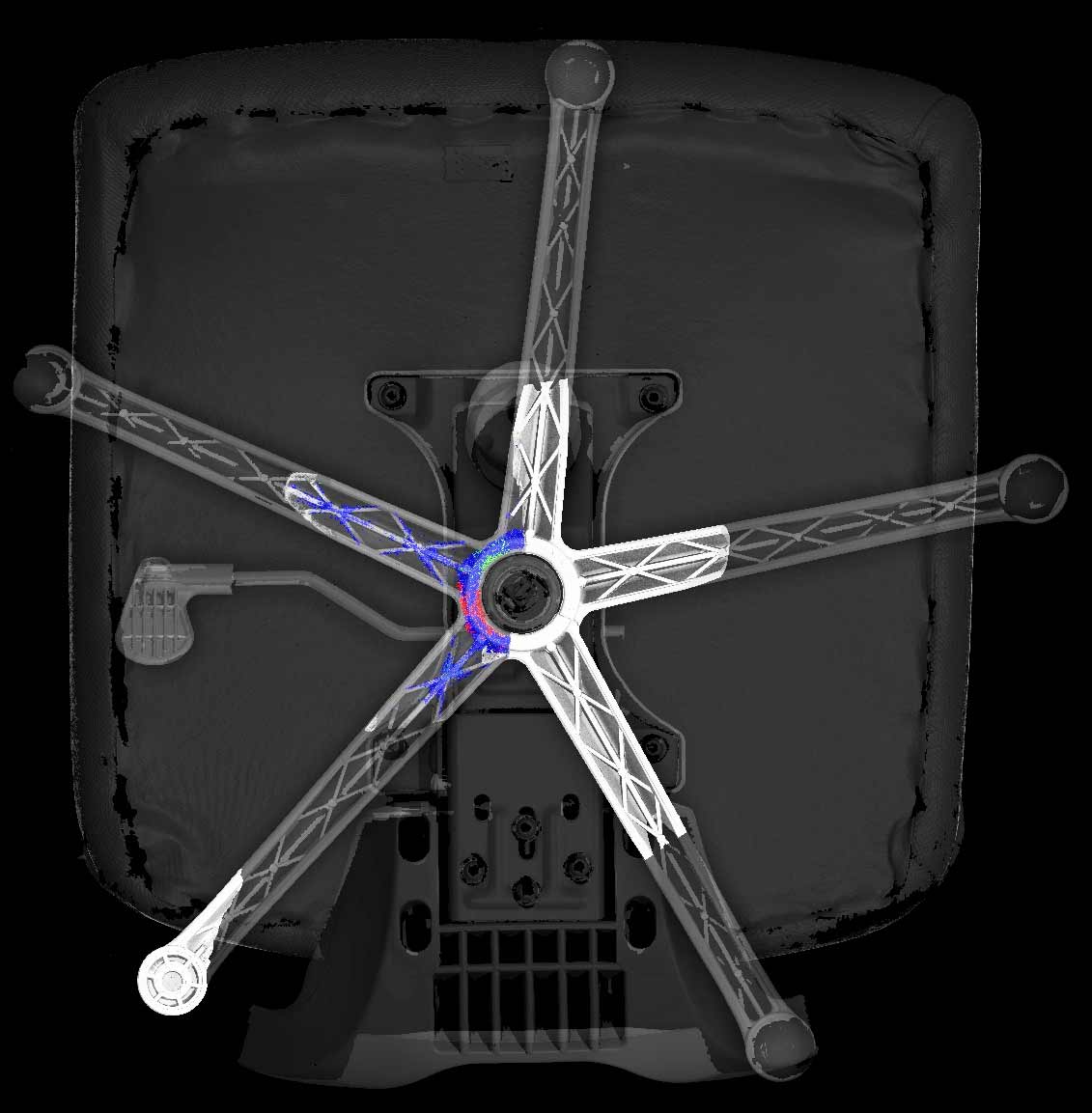

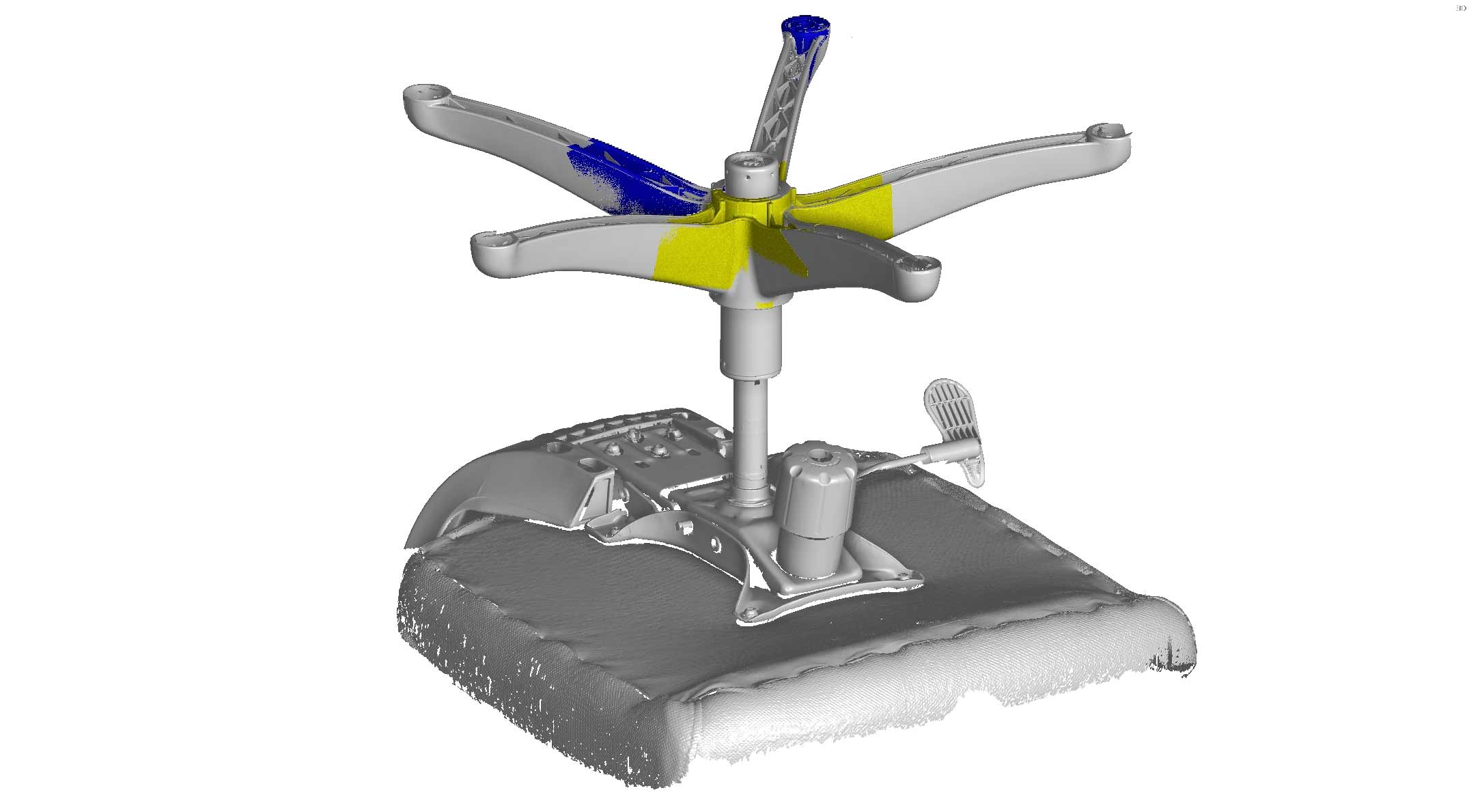

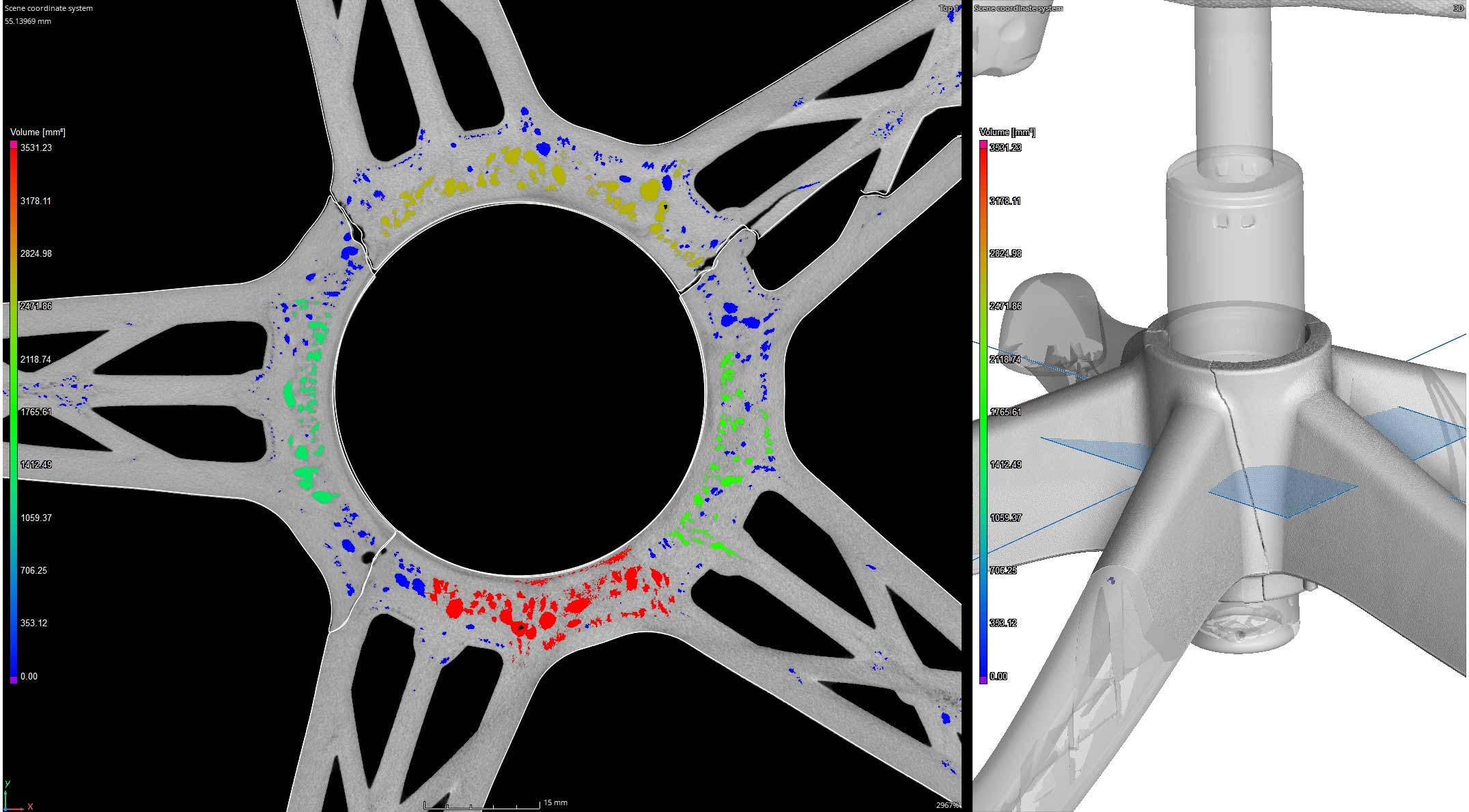

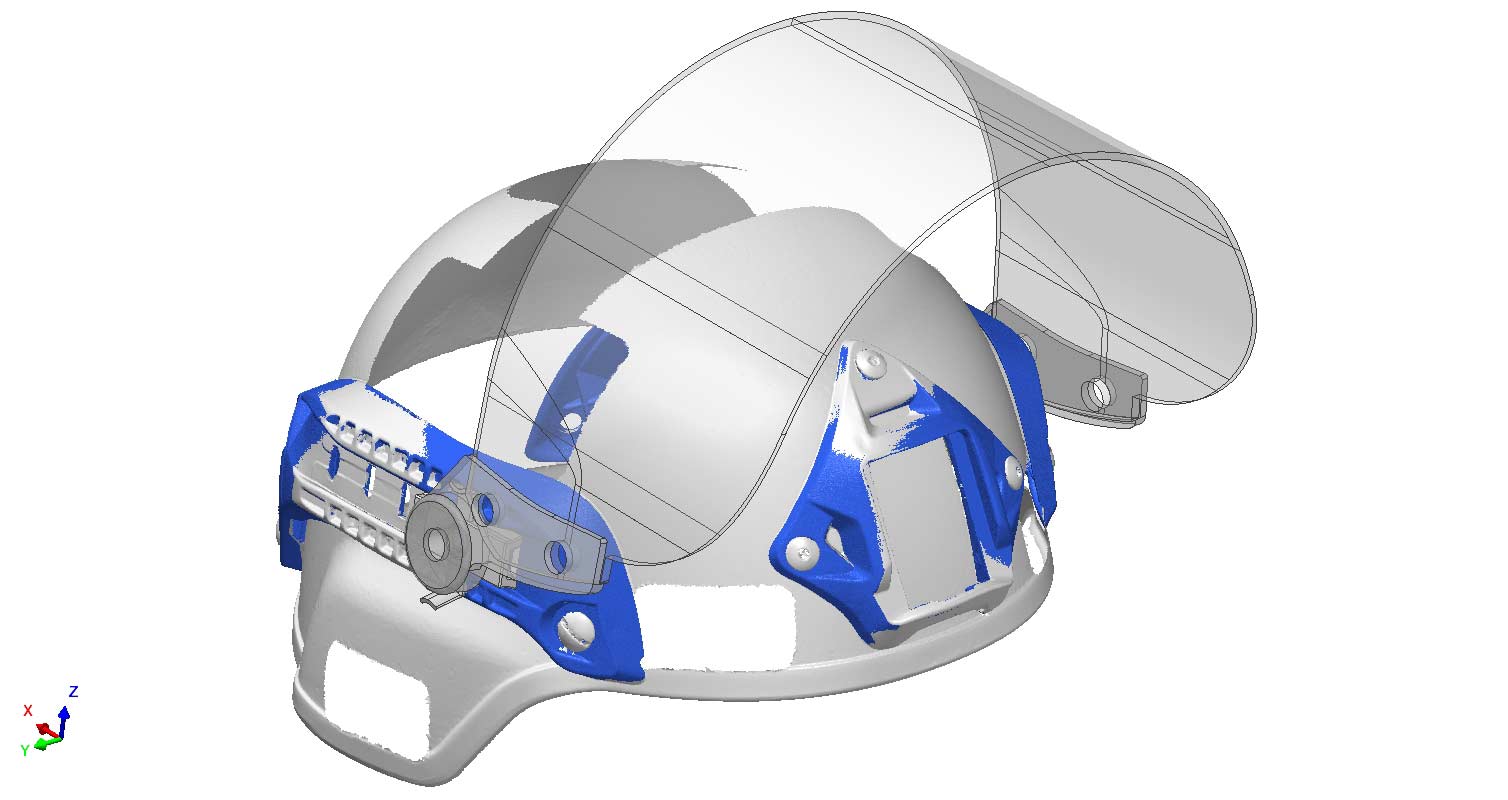

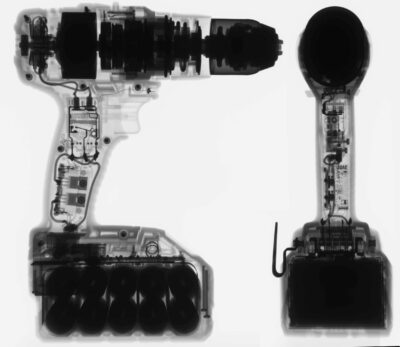

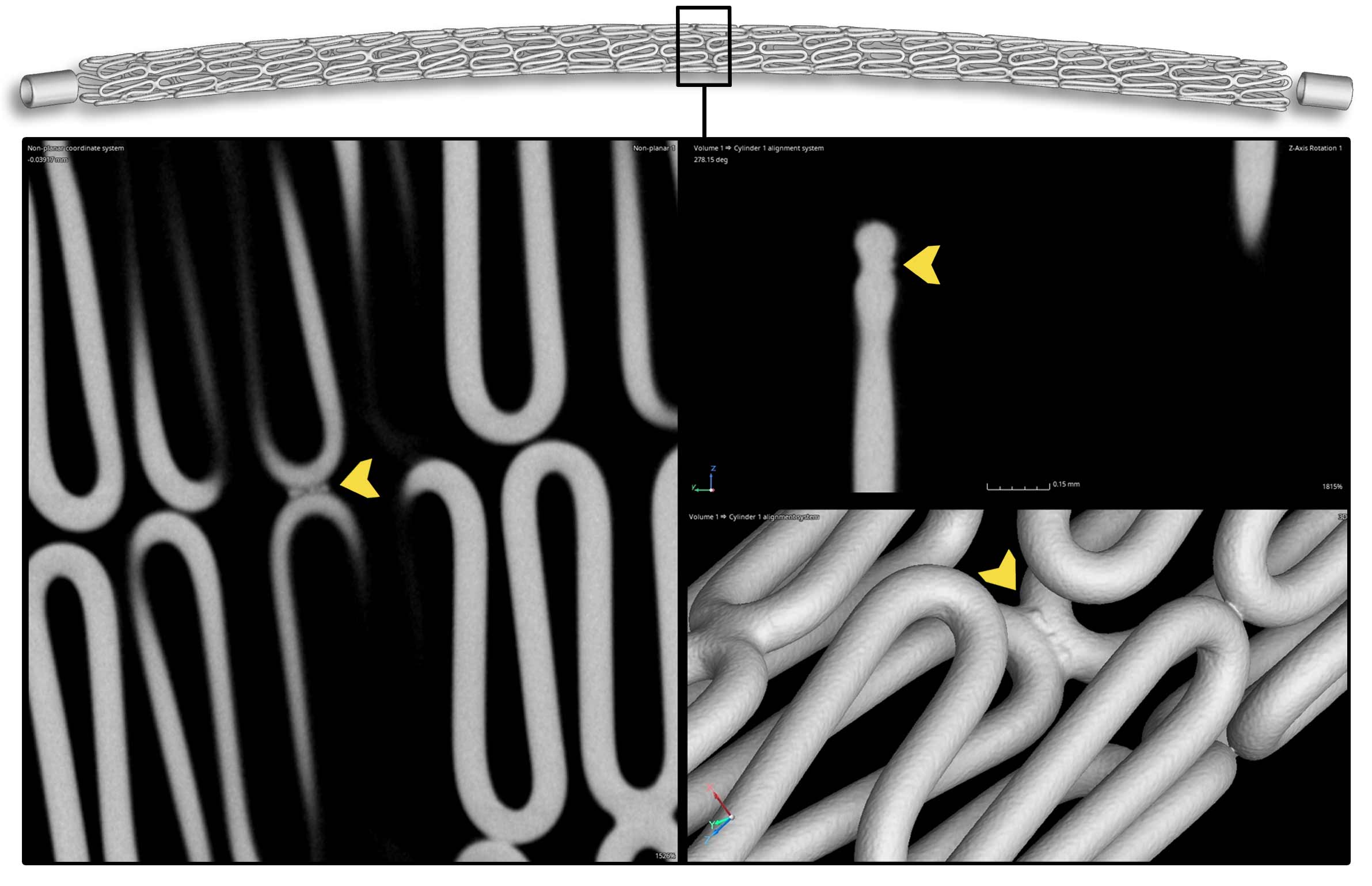

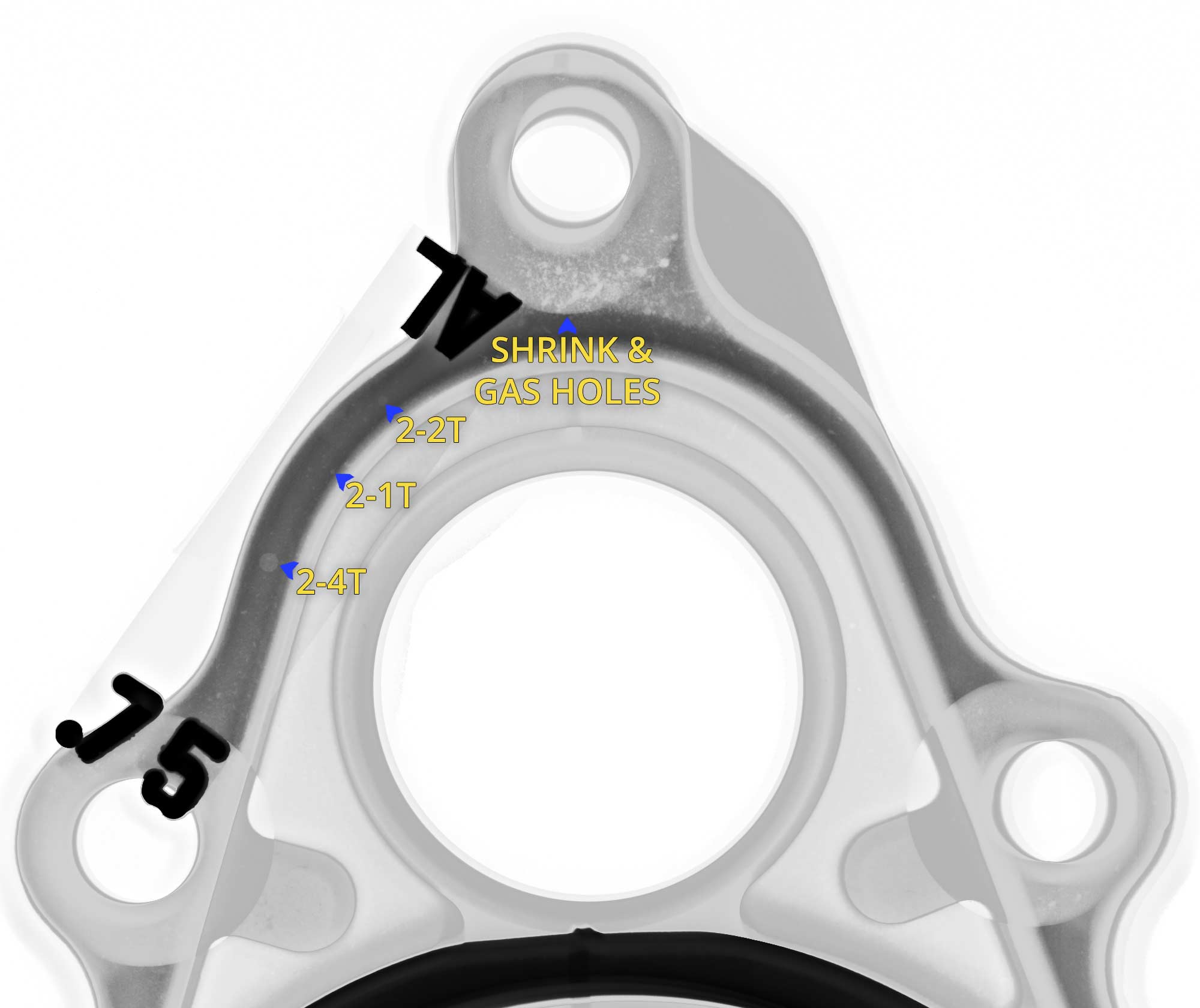

X-ray inspection is a non-destructive testing method, meaning it allows for the examination of castings without causing damage to the parts. This is especially important for expensive or critical components where destructive testing methods would be impractical or cost-prohibitive. X-ray examination allows for the detection of part flaws or defects like gas porosity, shrinkage cavities, cracks & hot tears, inclusions, and voids.

Industrial Inspection offers a roster of technicians certified per the American Society for Nondestructive Testing (ASNT / SNT-TC-1A) and National Aerospace Standards (NAS-410). Our technicians have x-rayed everything from infrastructure pipework, automotive components, and rocket manifolds.

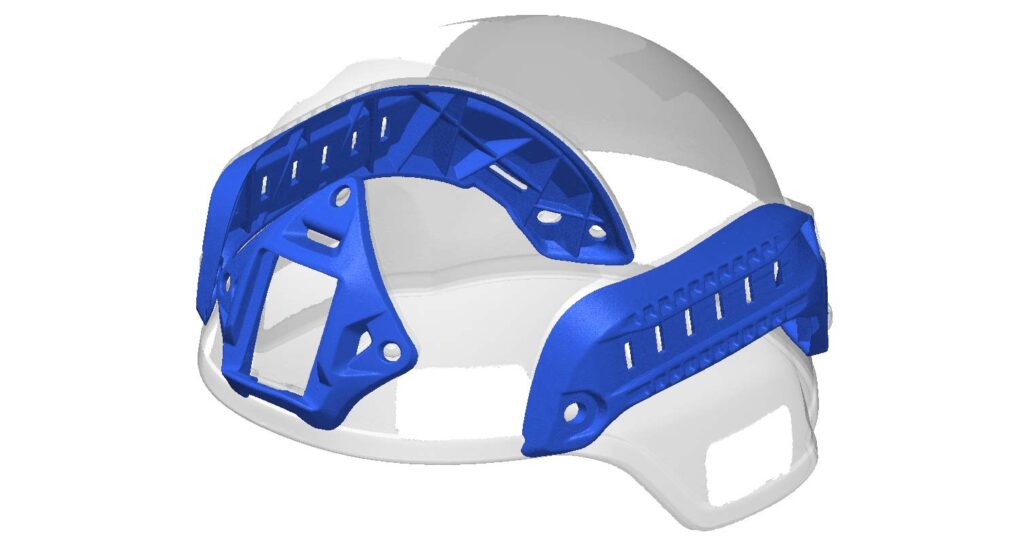

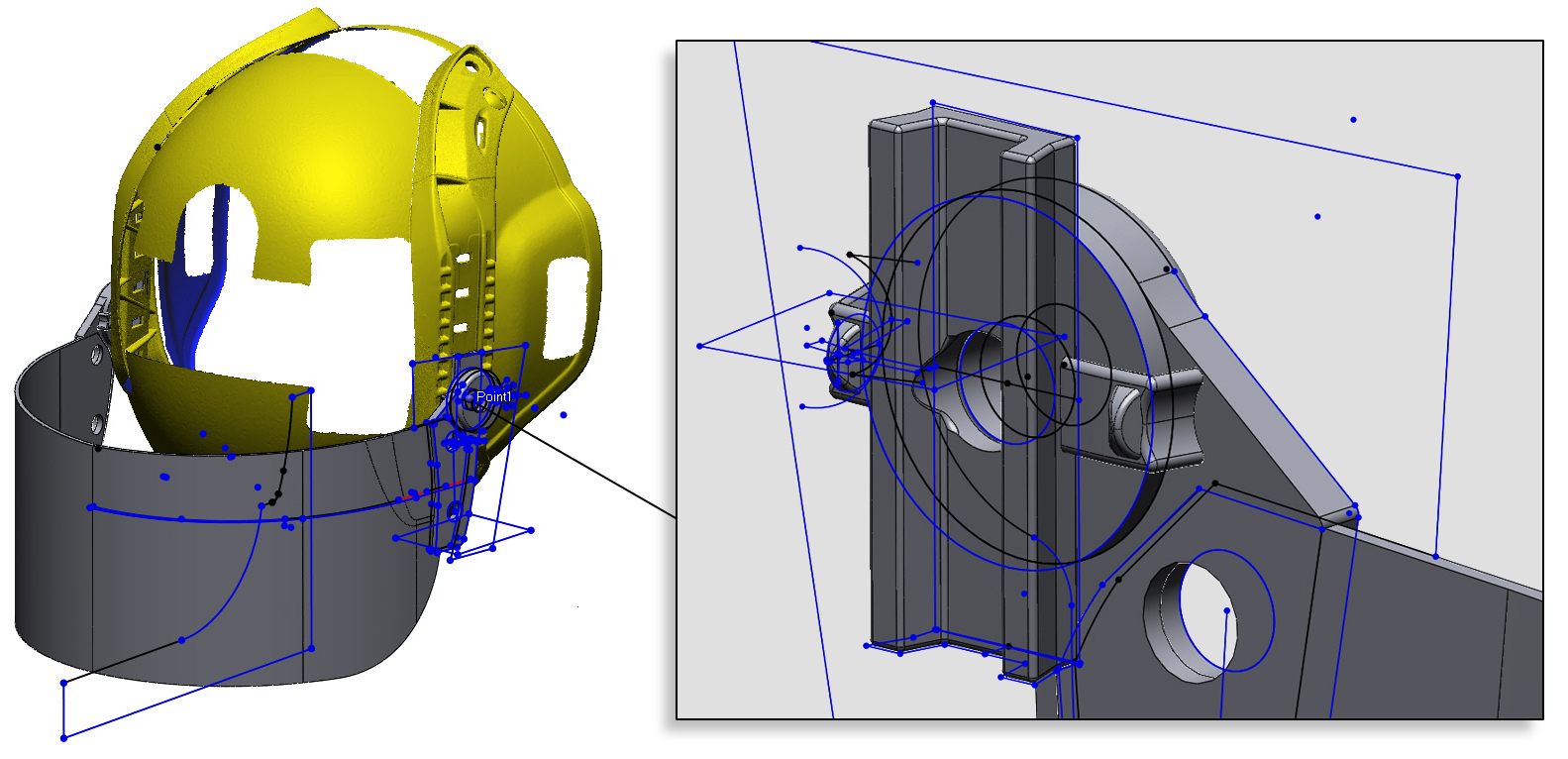

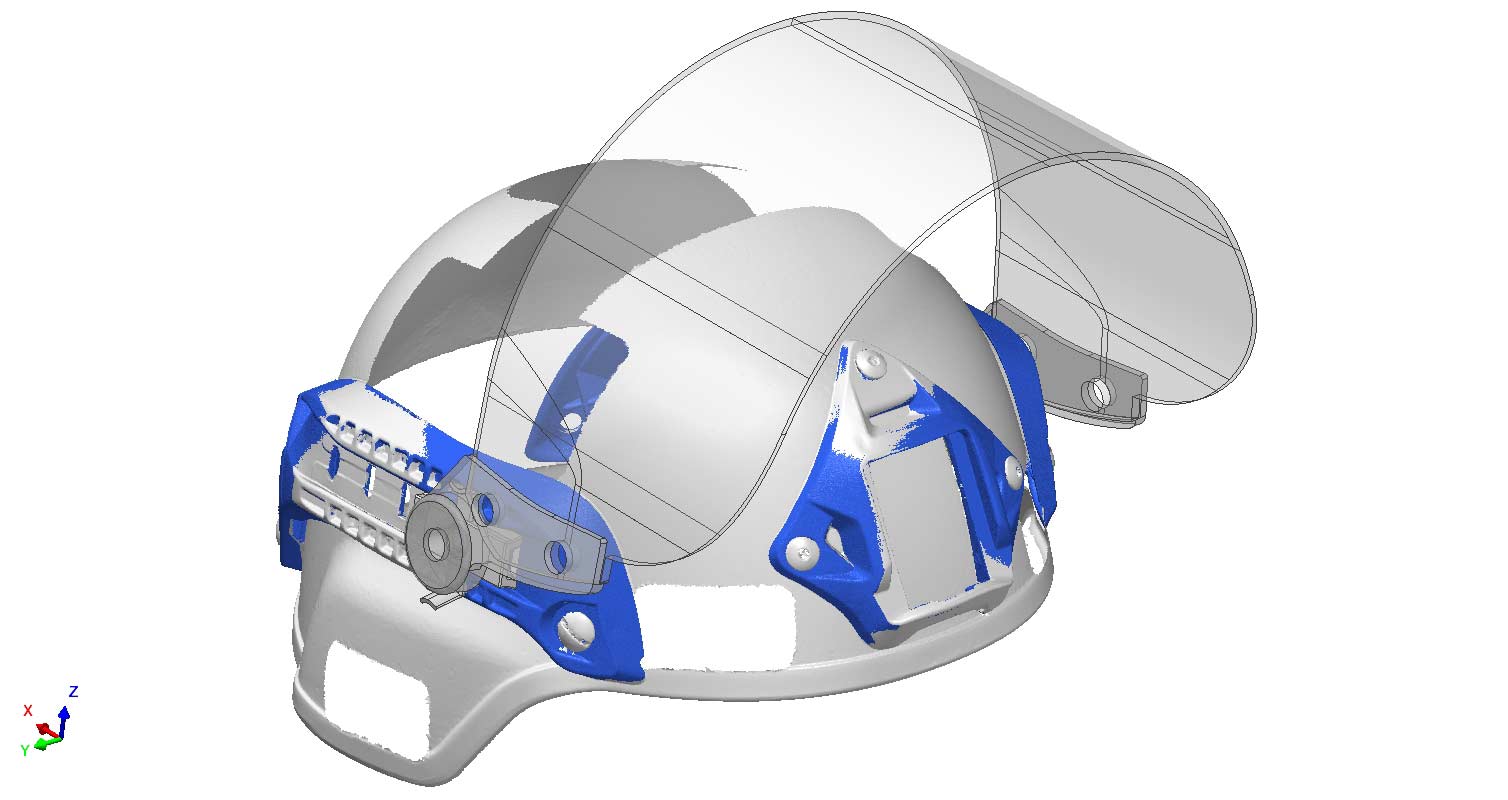

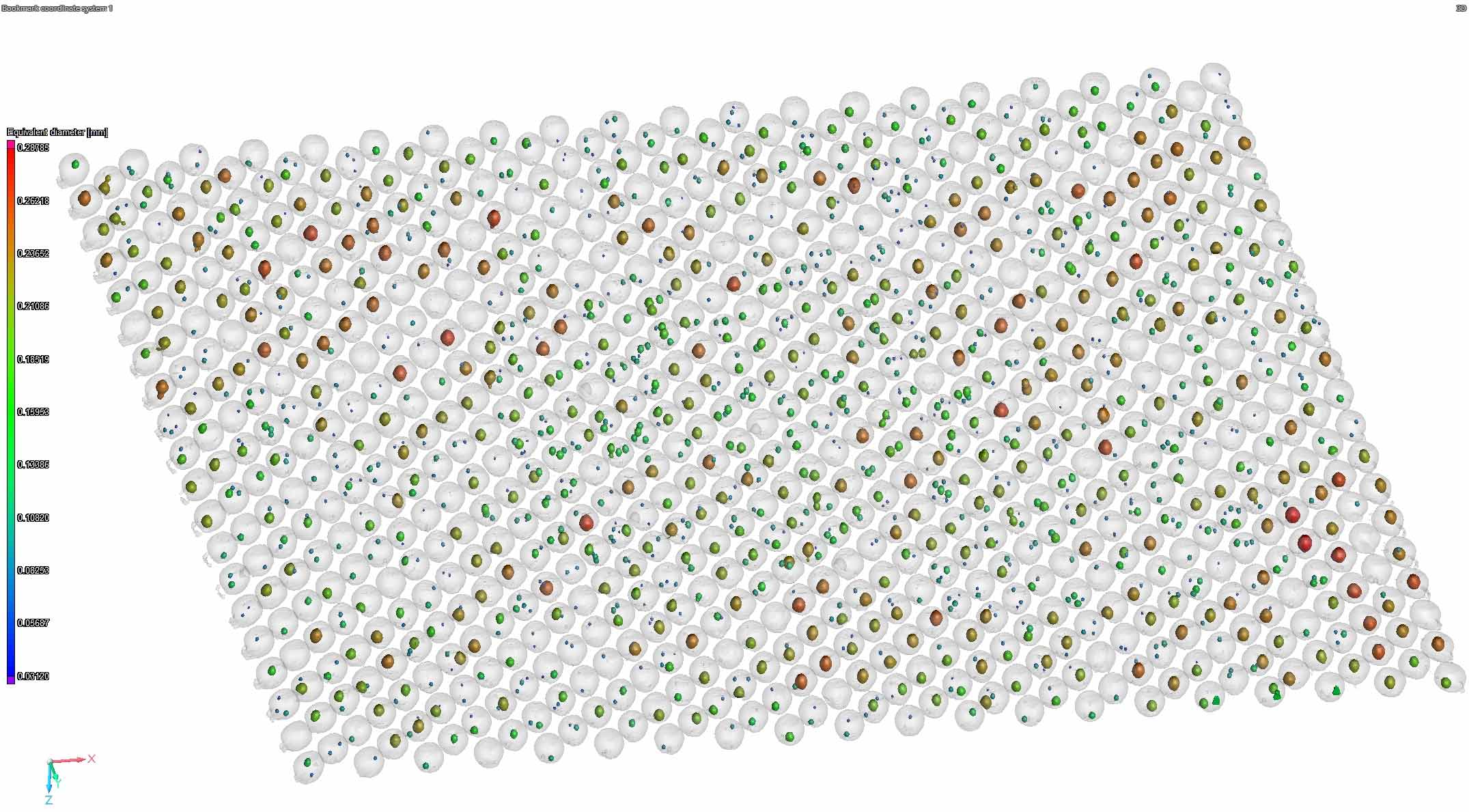

TOOLS & DEVICES

FASTENERS & COVERS

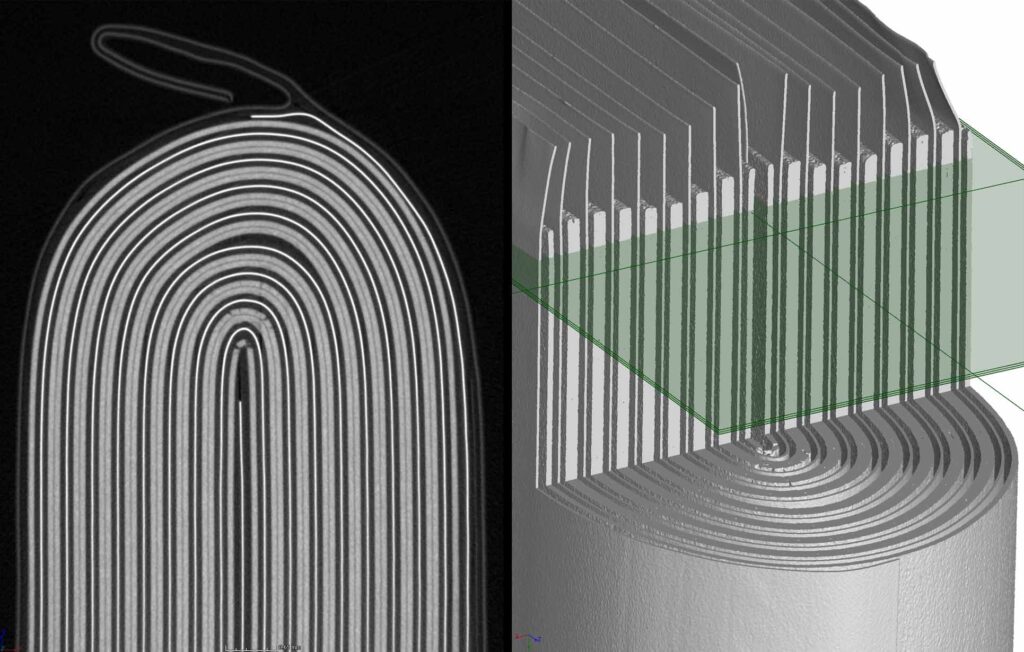

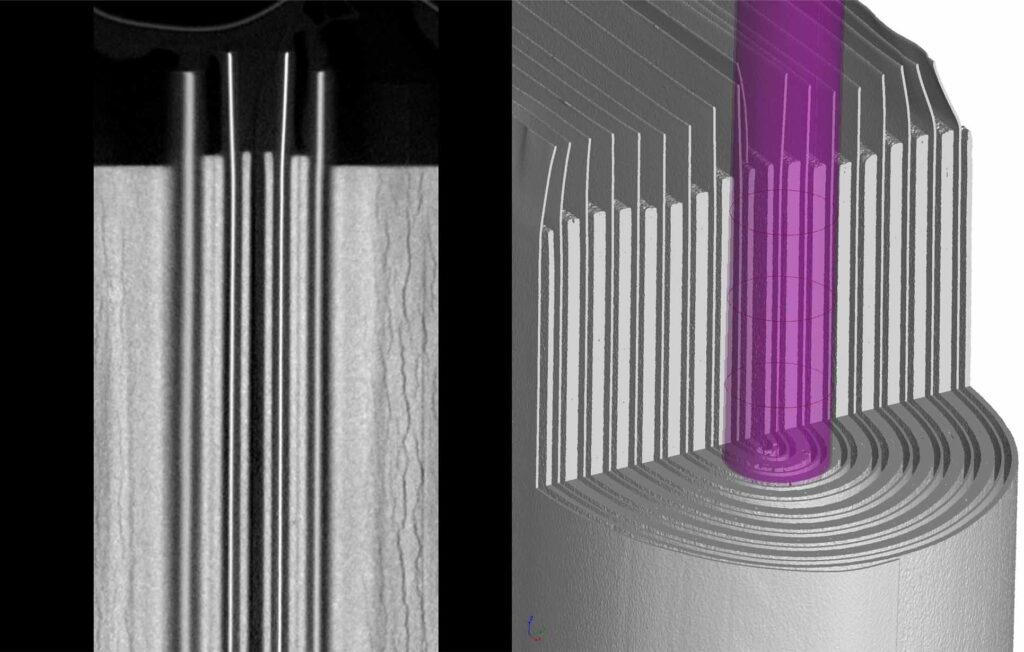

HEAT SINKS & BRACKETS

PUMP HOUSINGS

STEERING KNUCKLES

OIL PANS

TRANSMISSION HOUSINGS

WHEELS

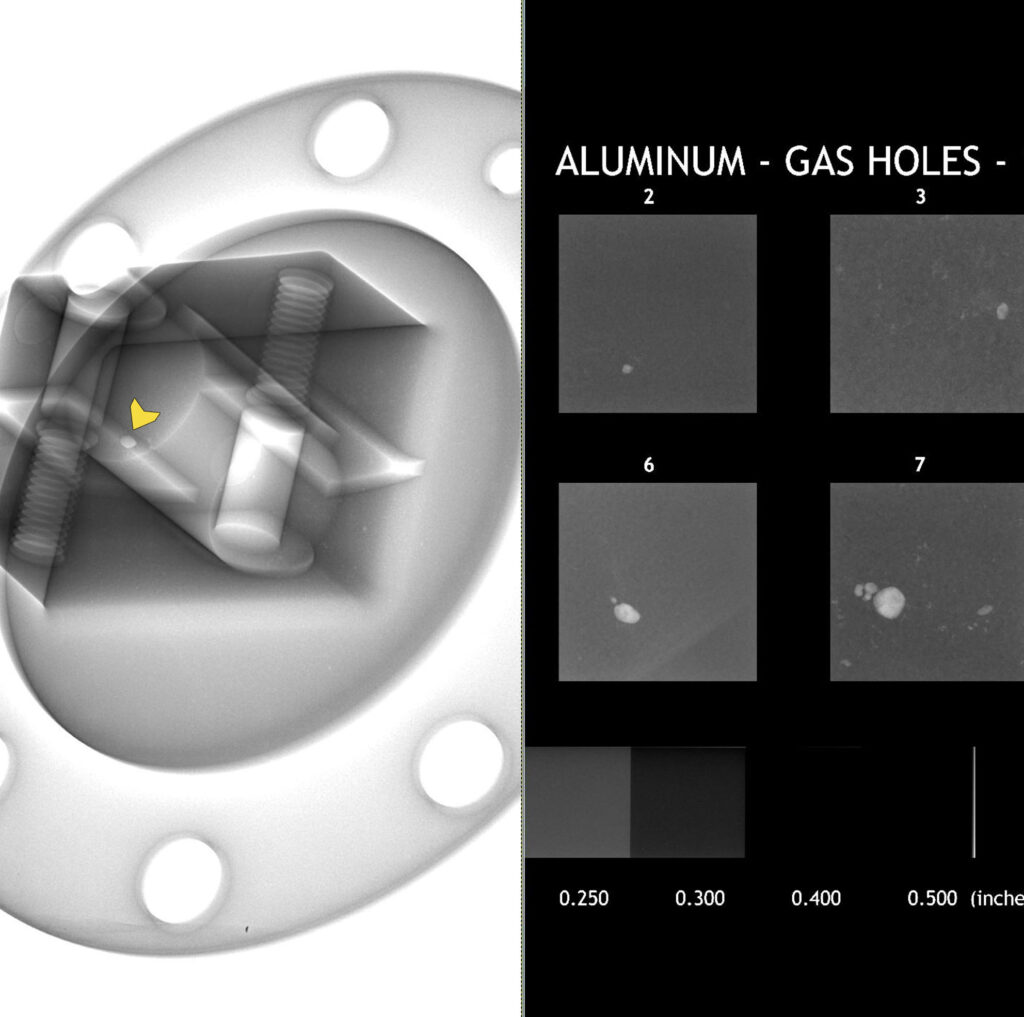

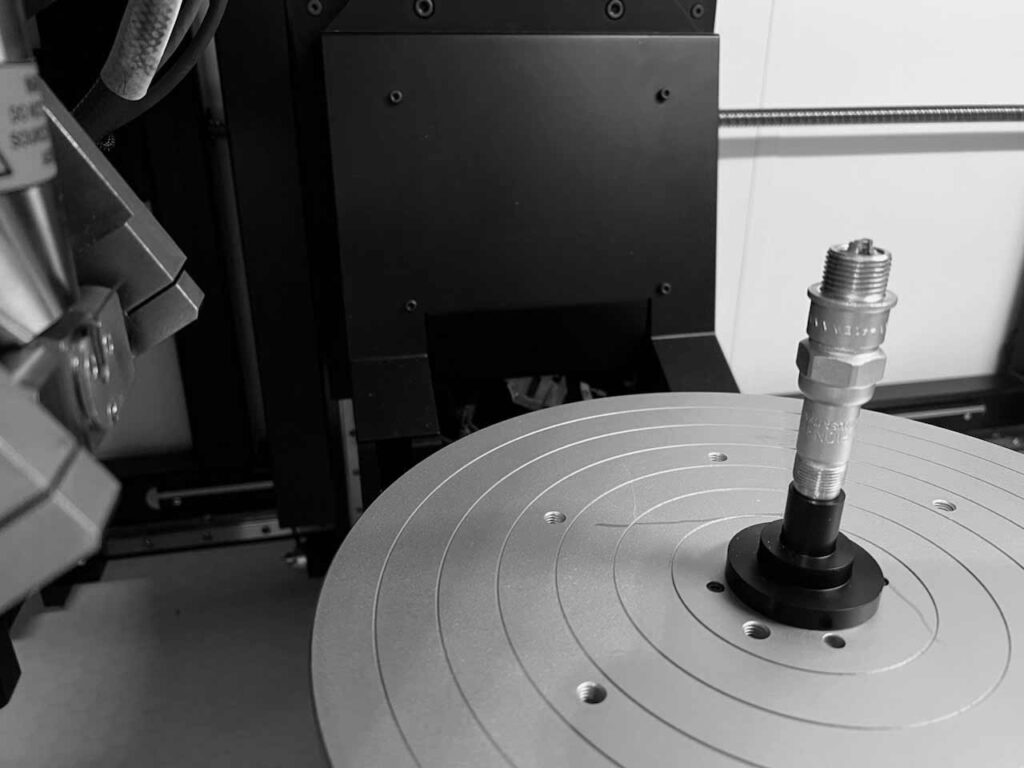

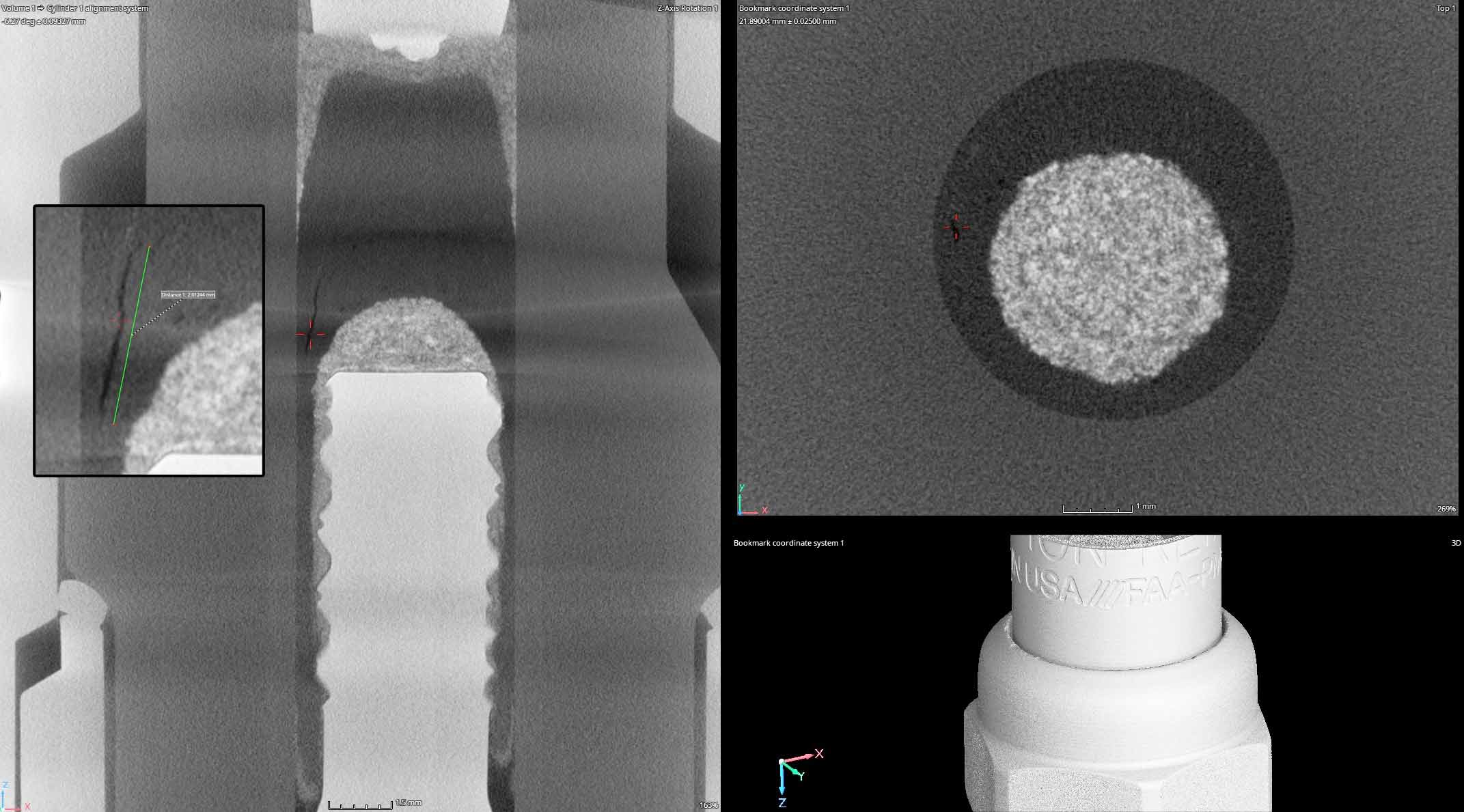

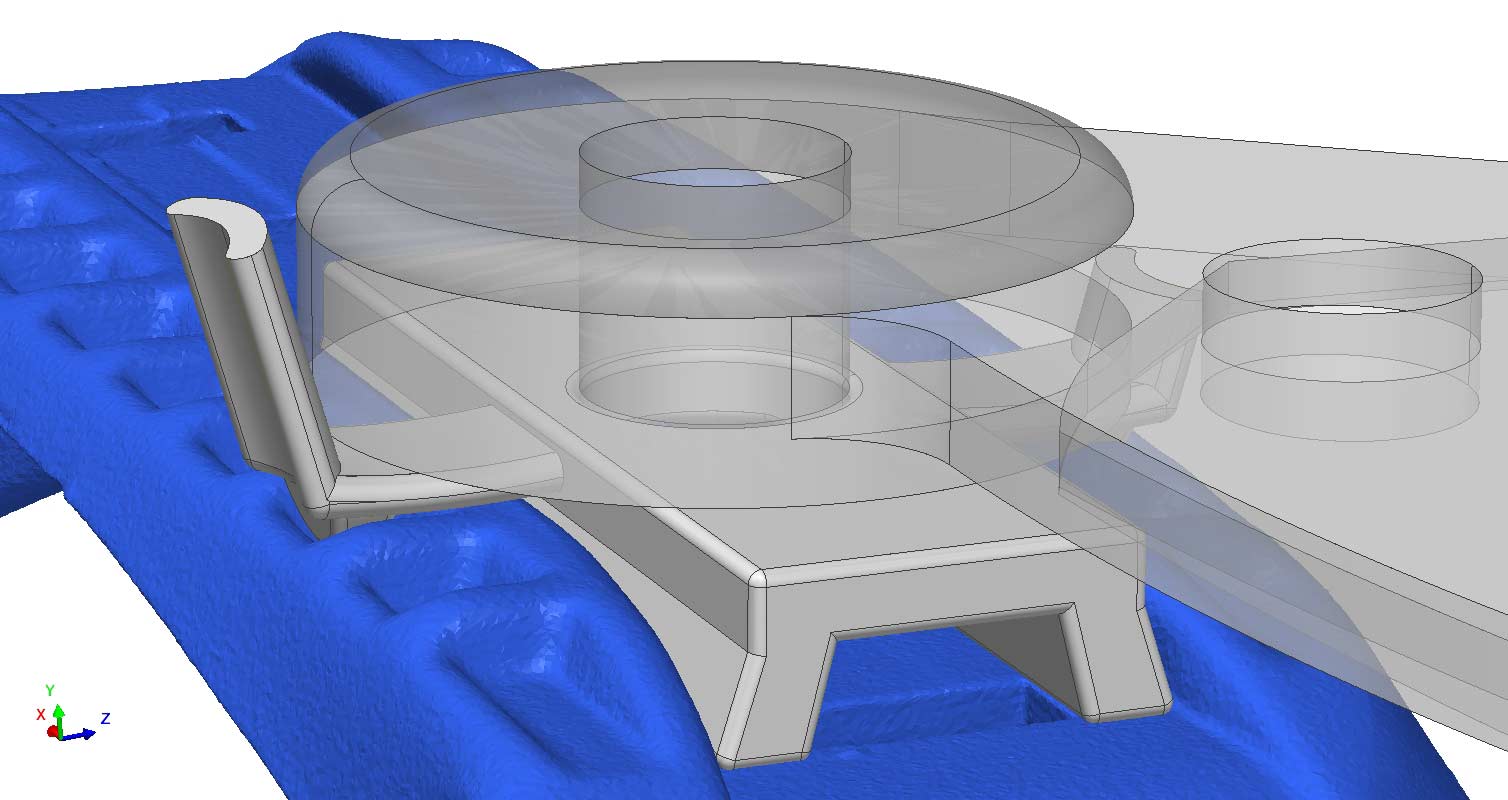

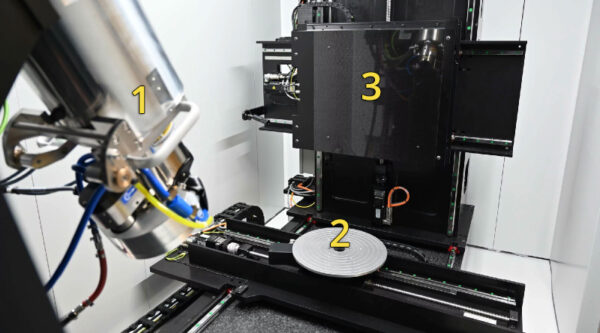

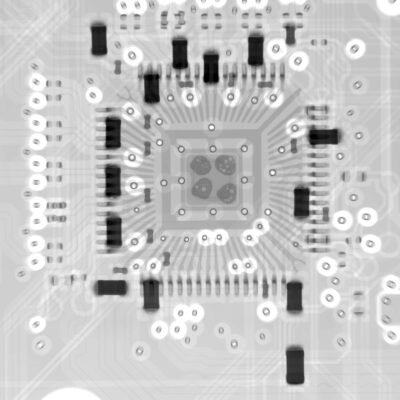

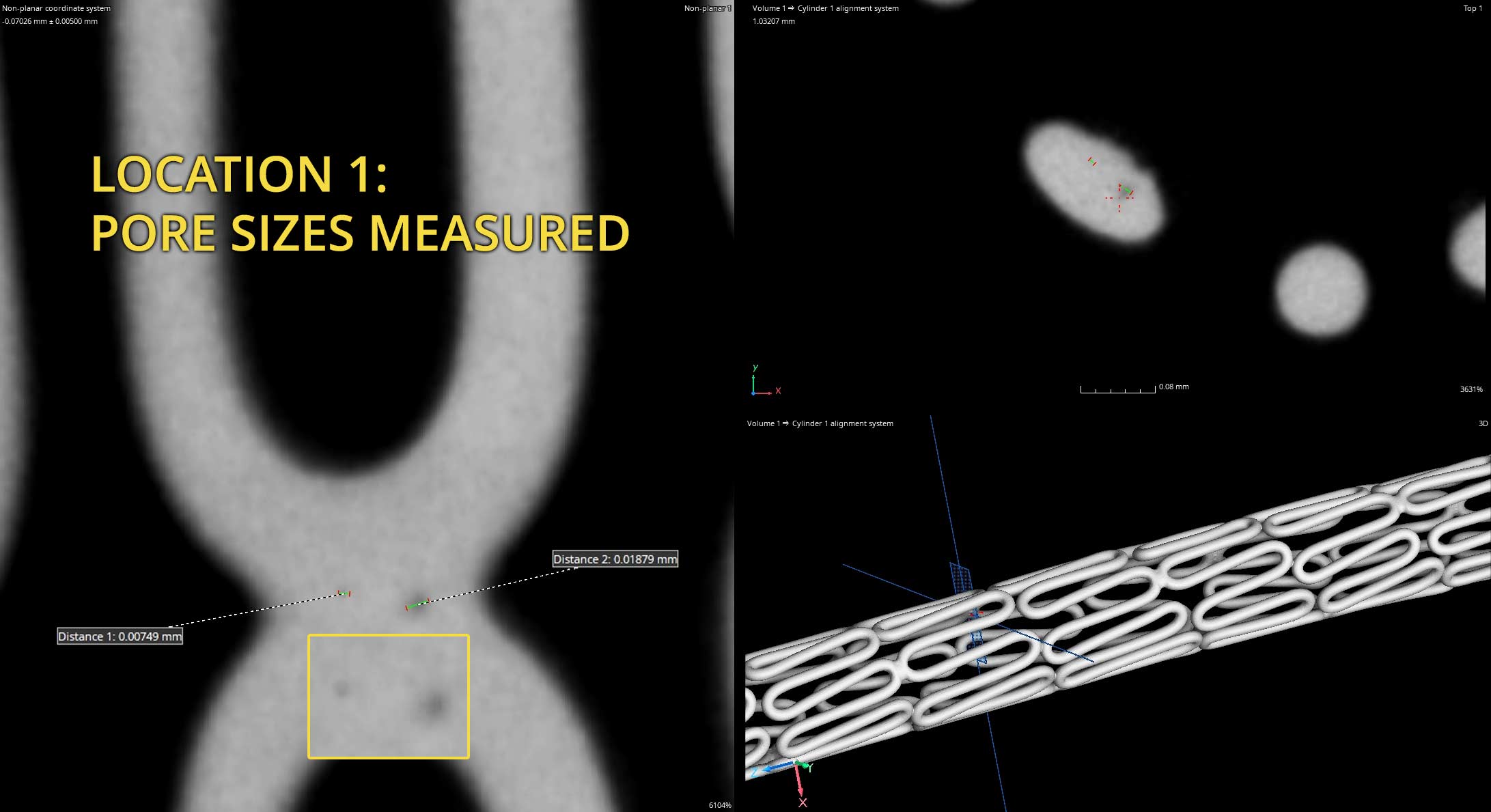

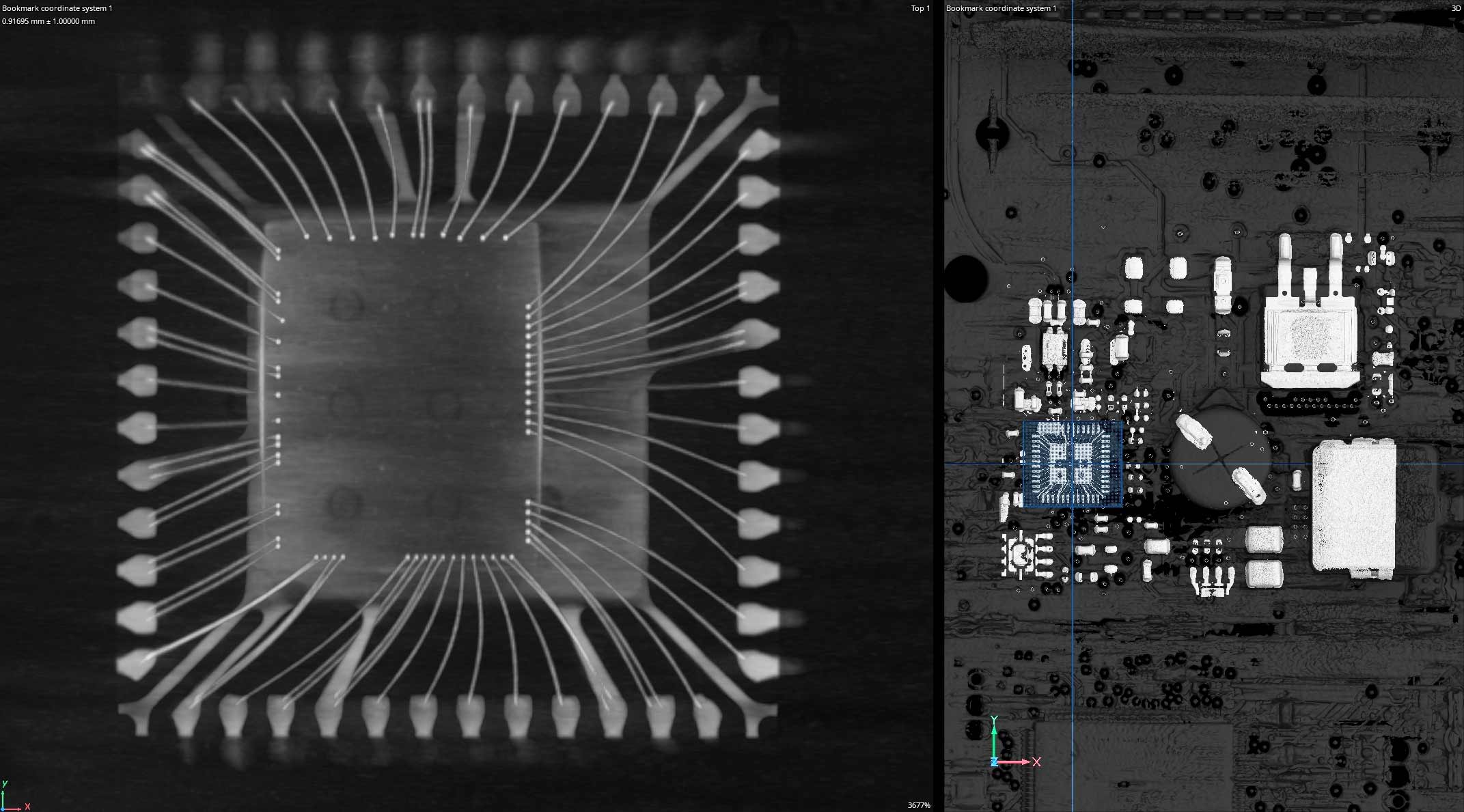

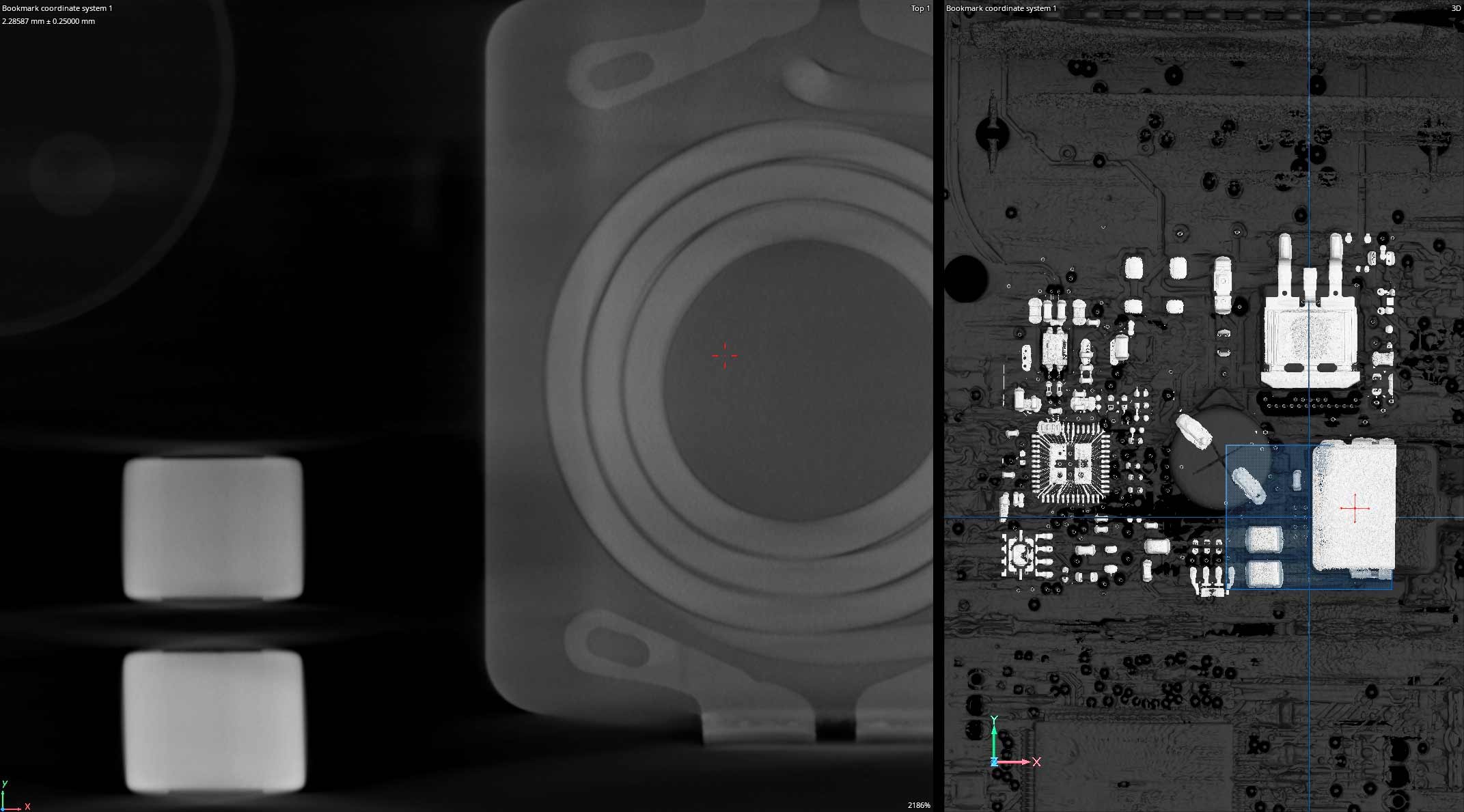

There are a wide variety of standards and gauges used for digital radiography depending on the material type, thickness, and customer driven requirements for sensitivity. Industrial Inspection has a robust library to respond to almost any requirement and, for niche requirements, can order custom gauges within days.

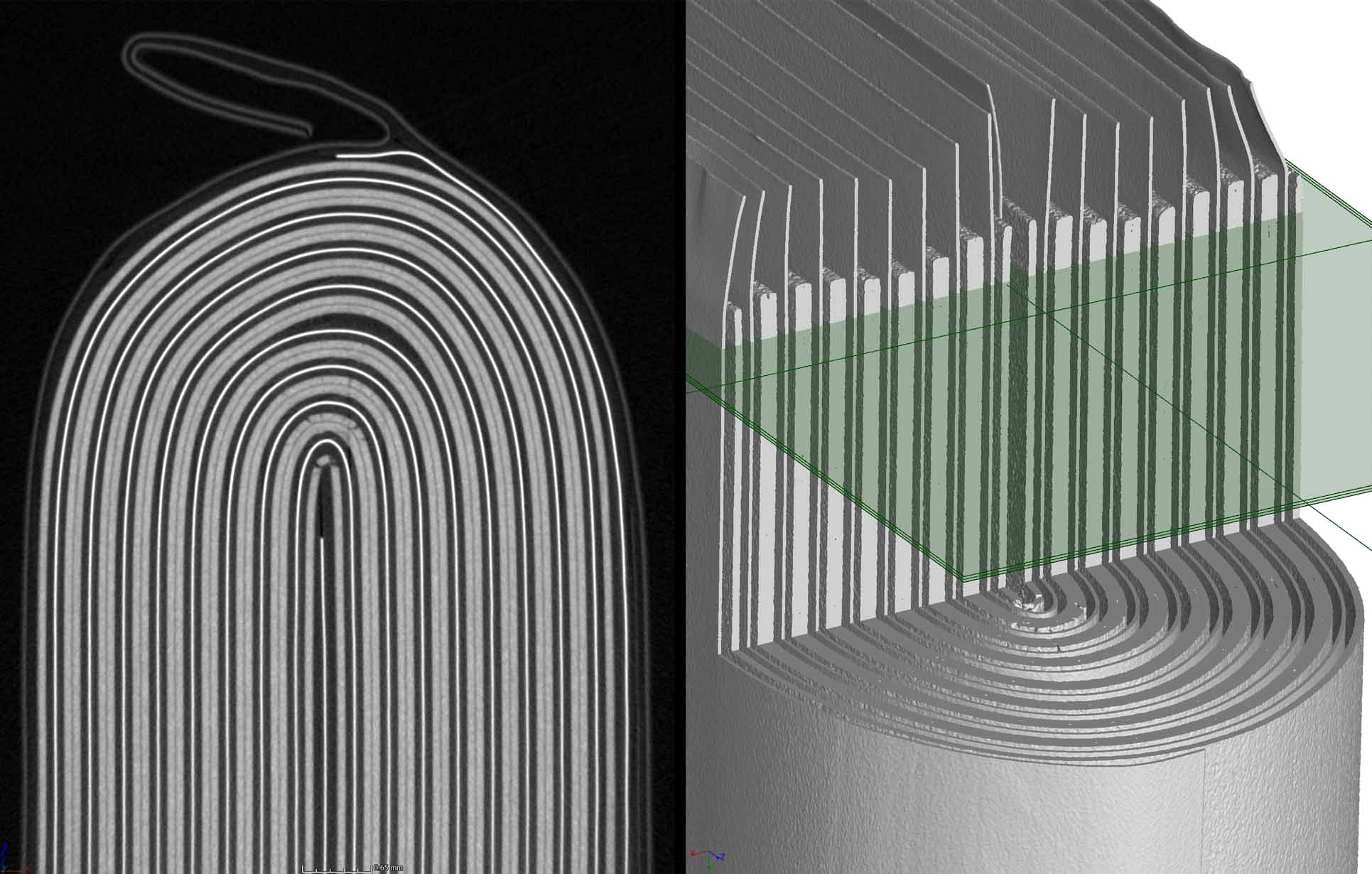

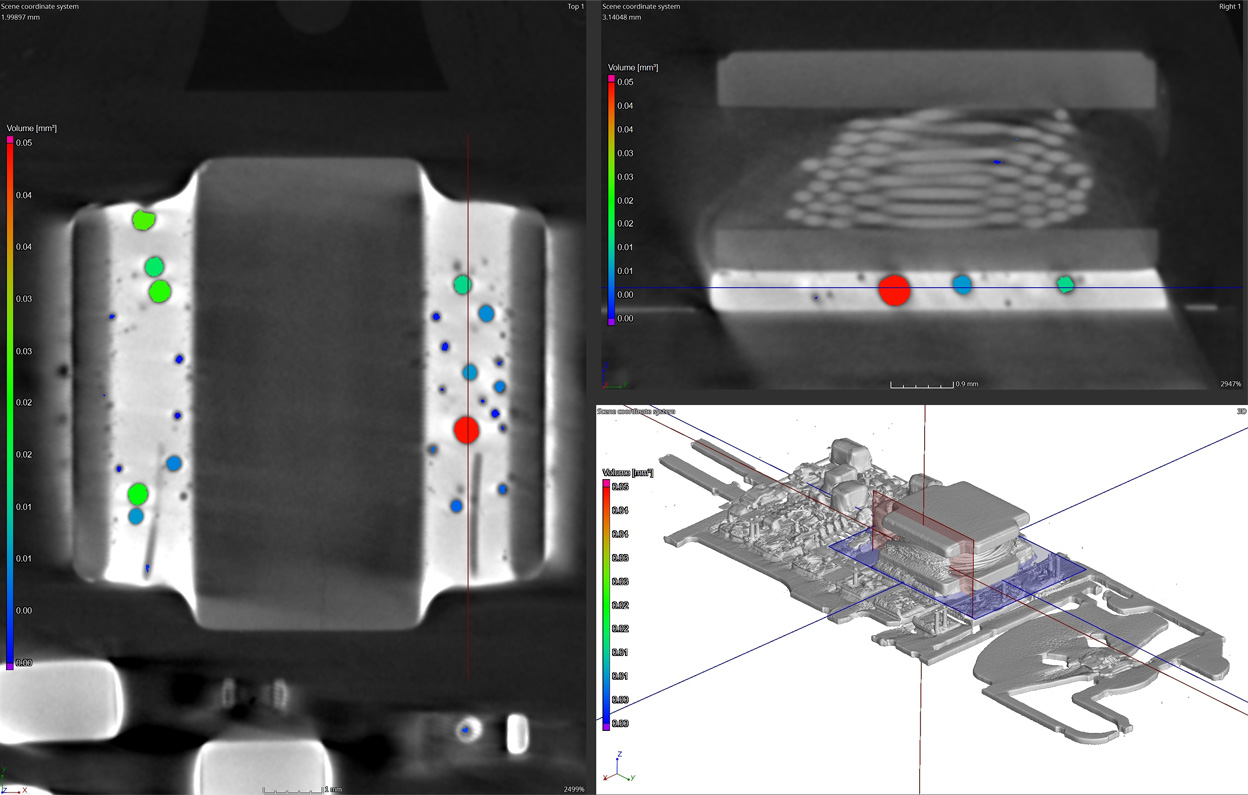

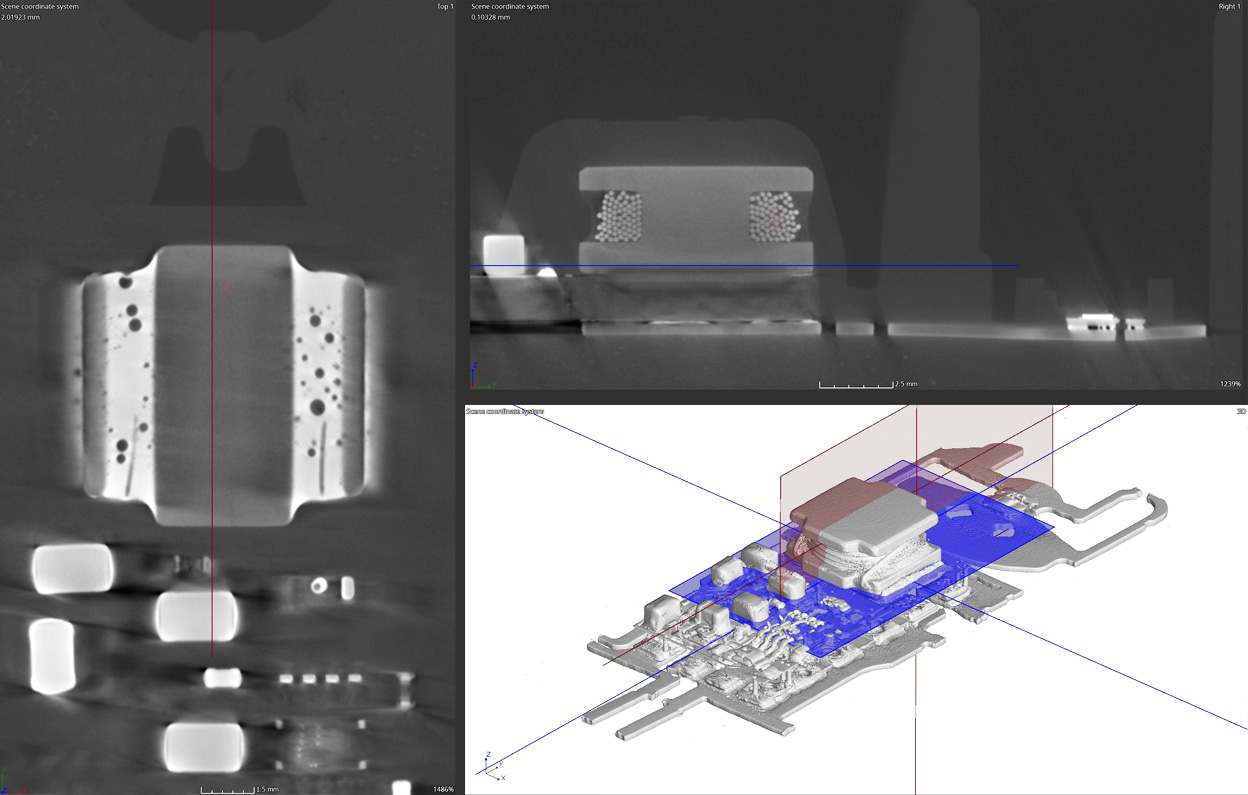

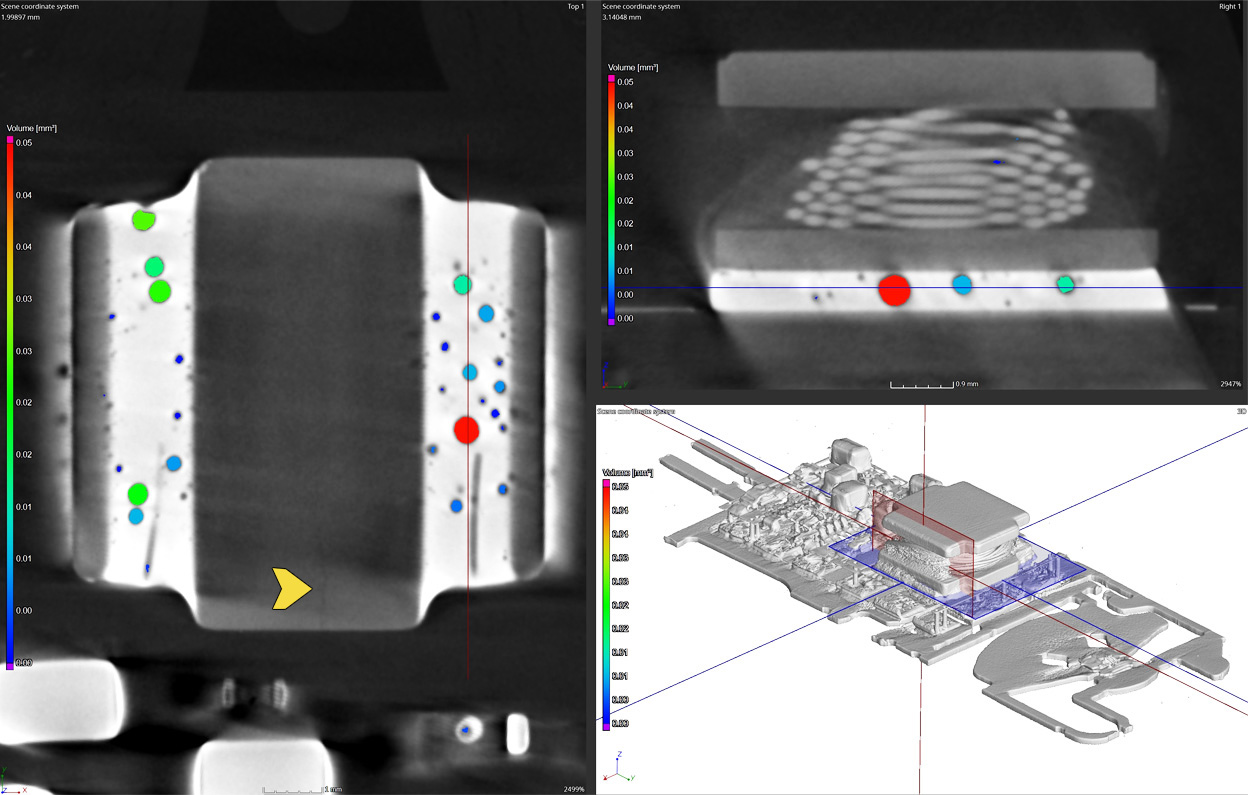

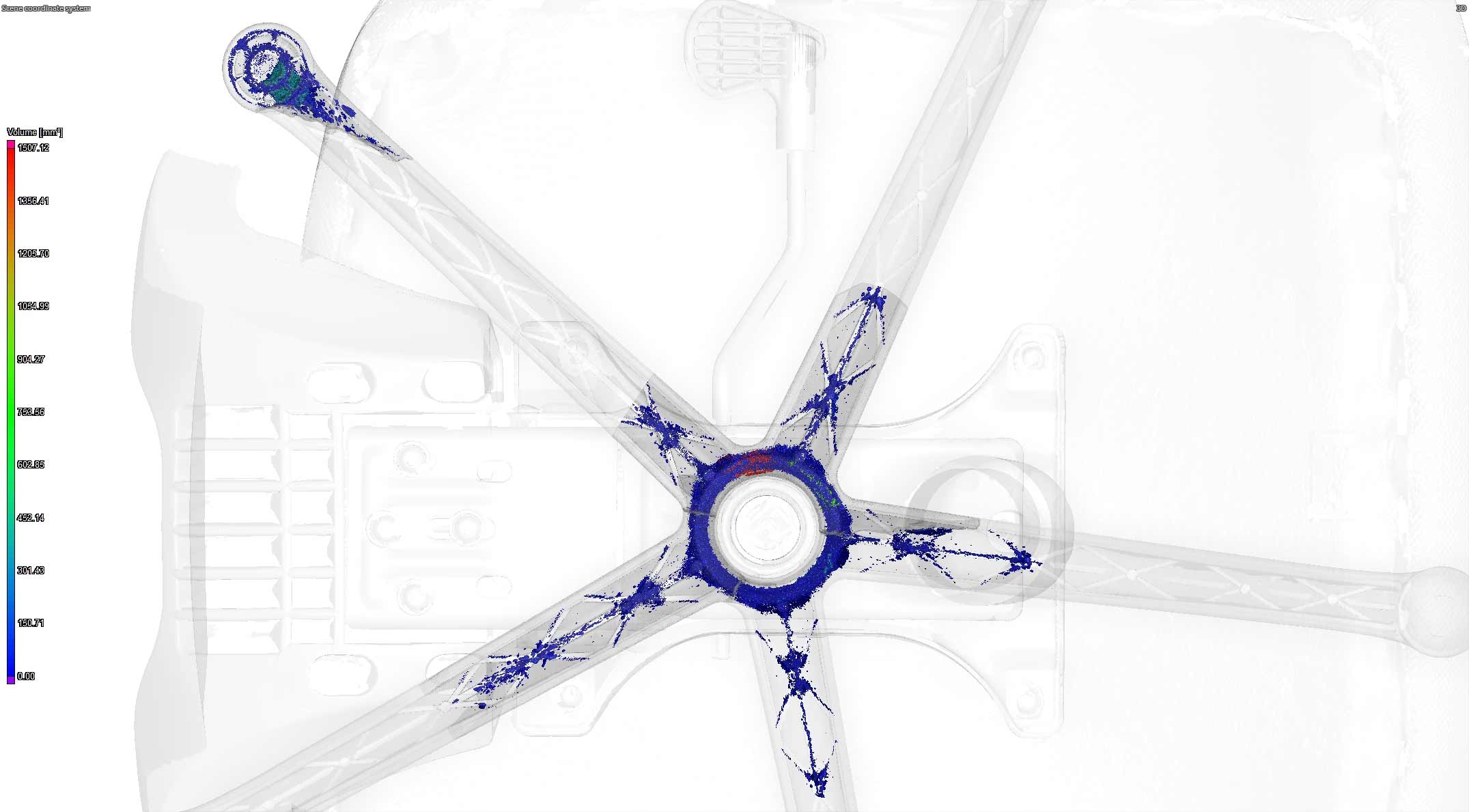

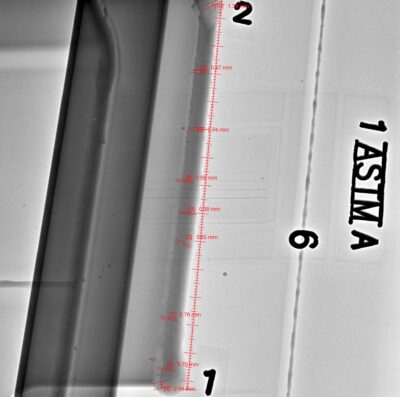

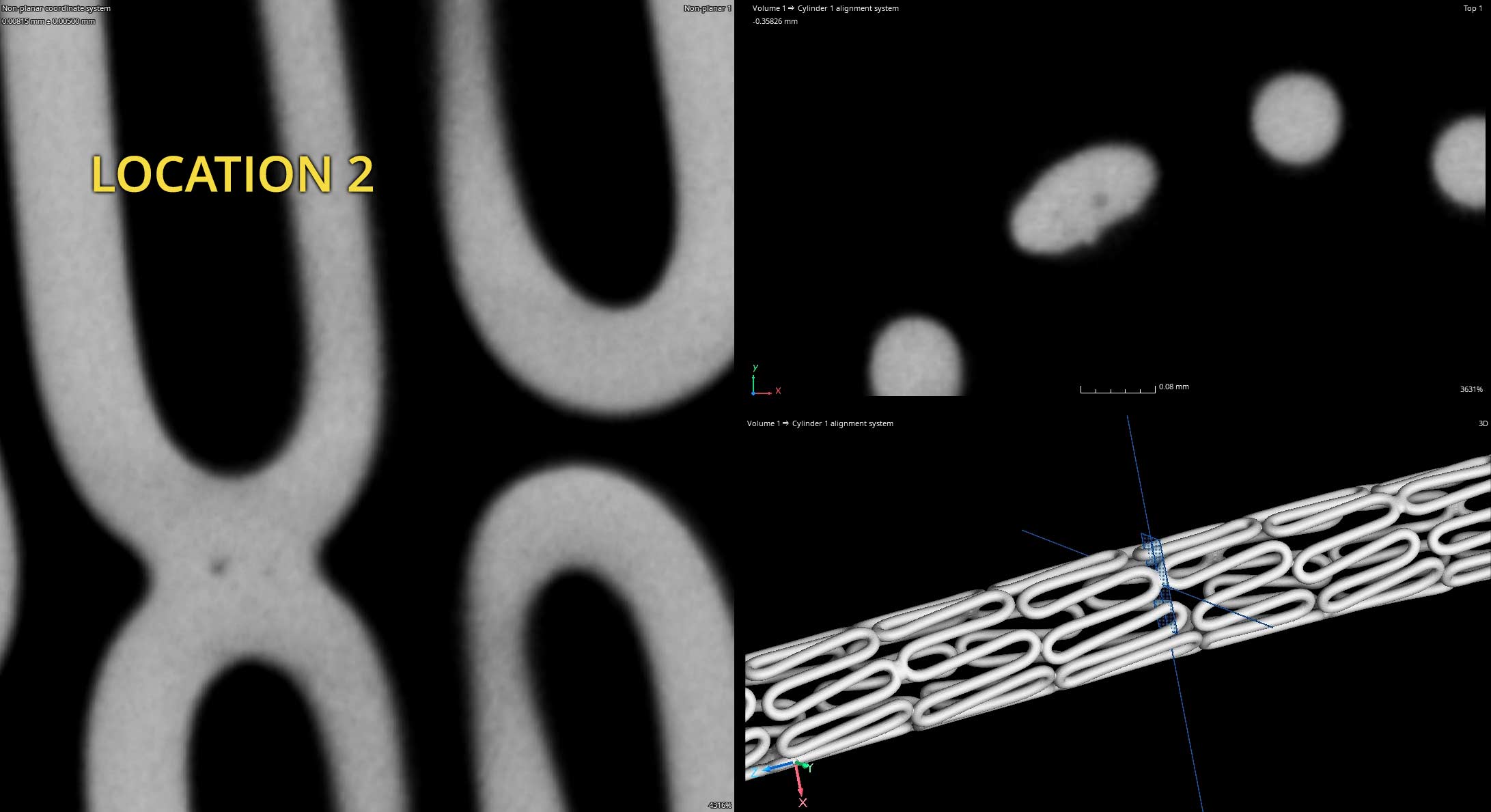

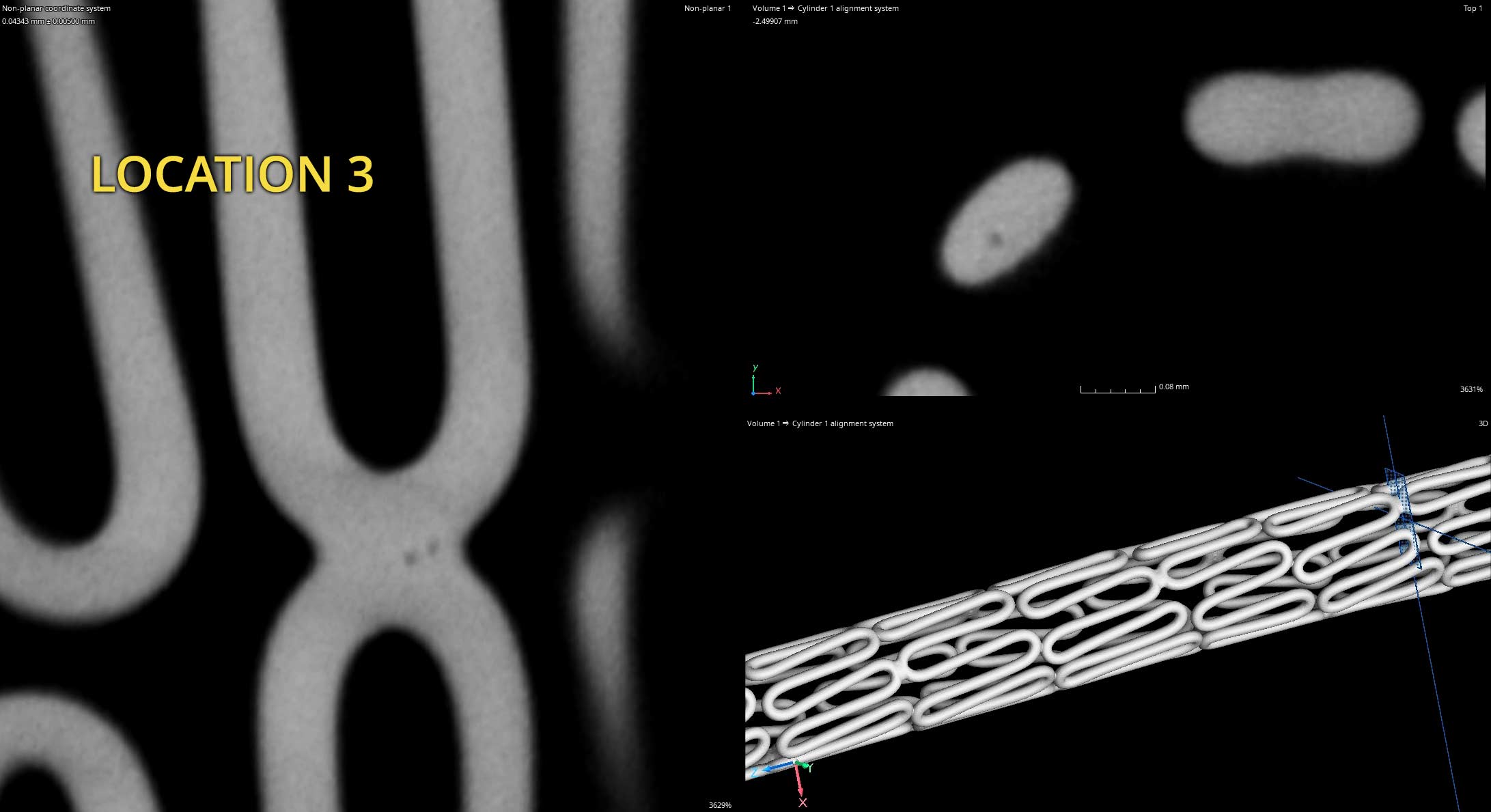

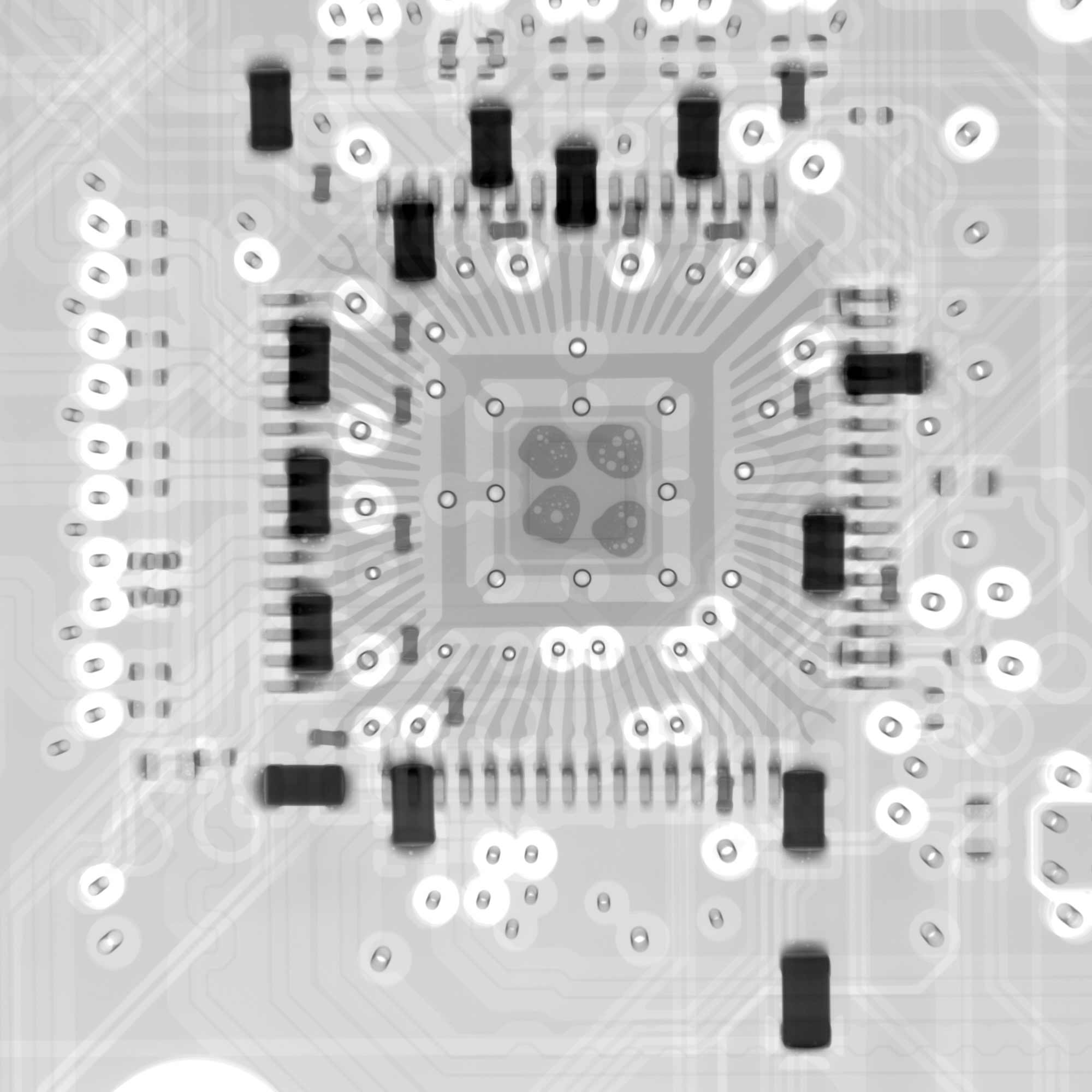

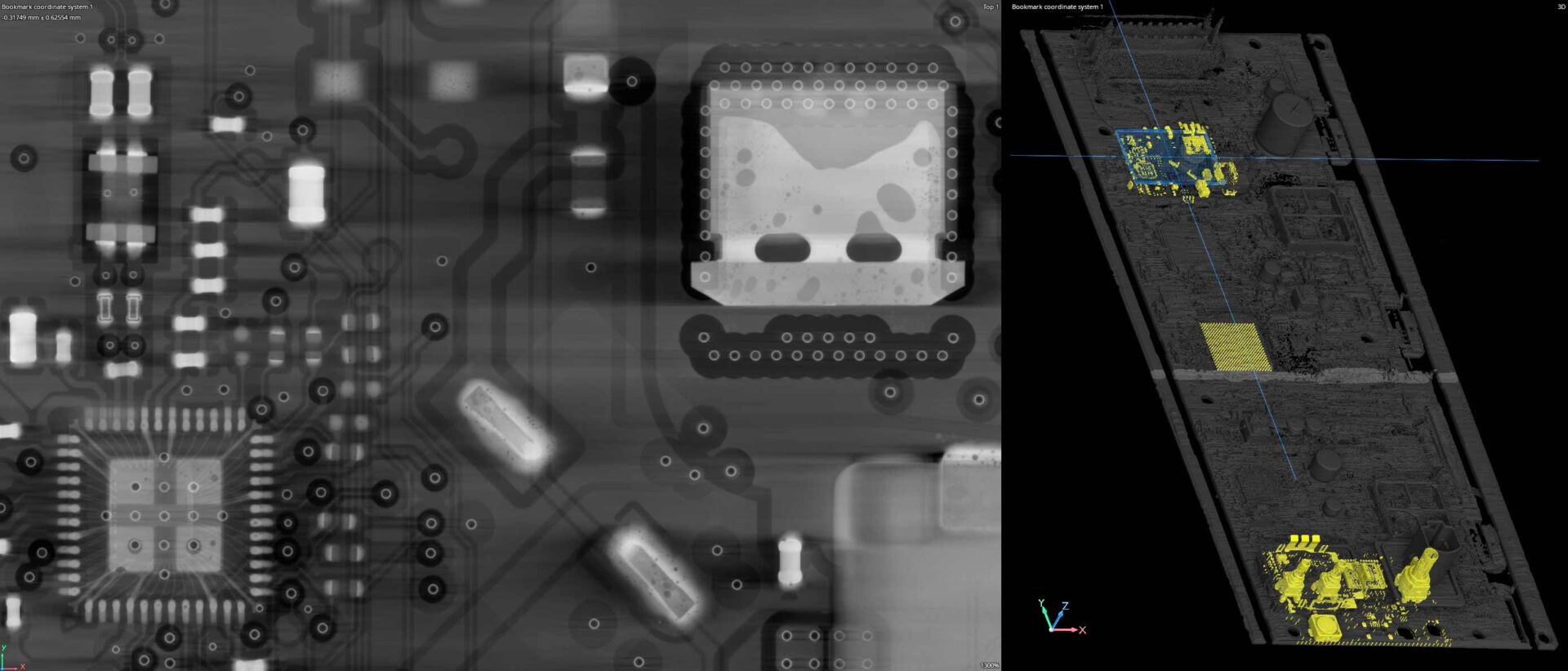

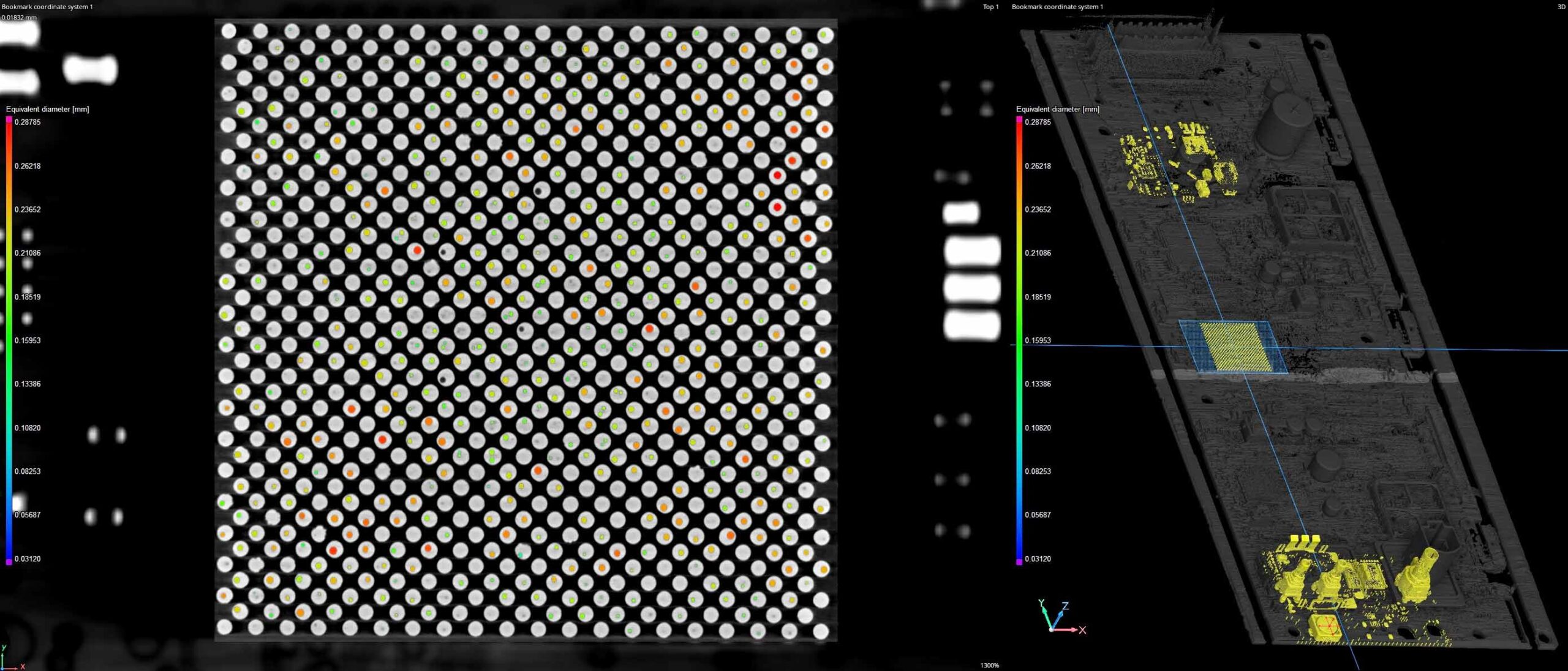

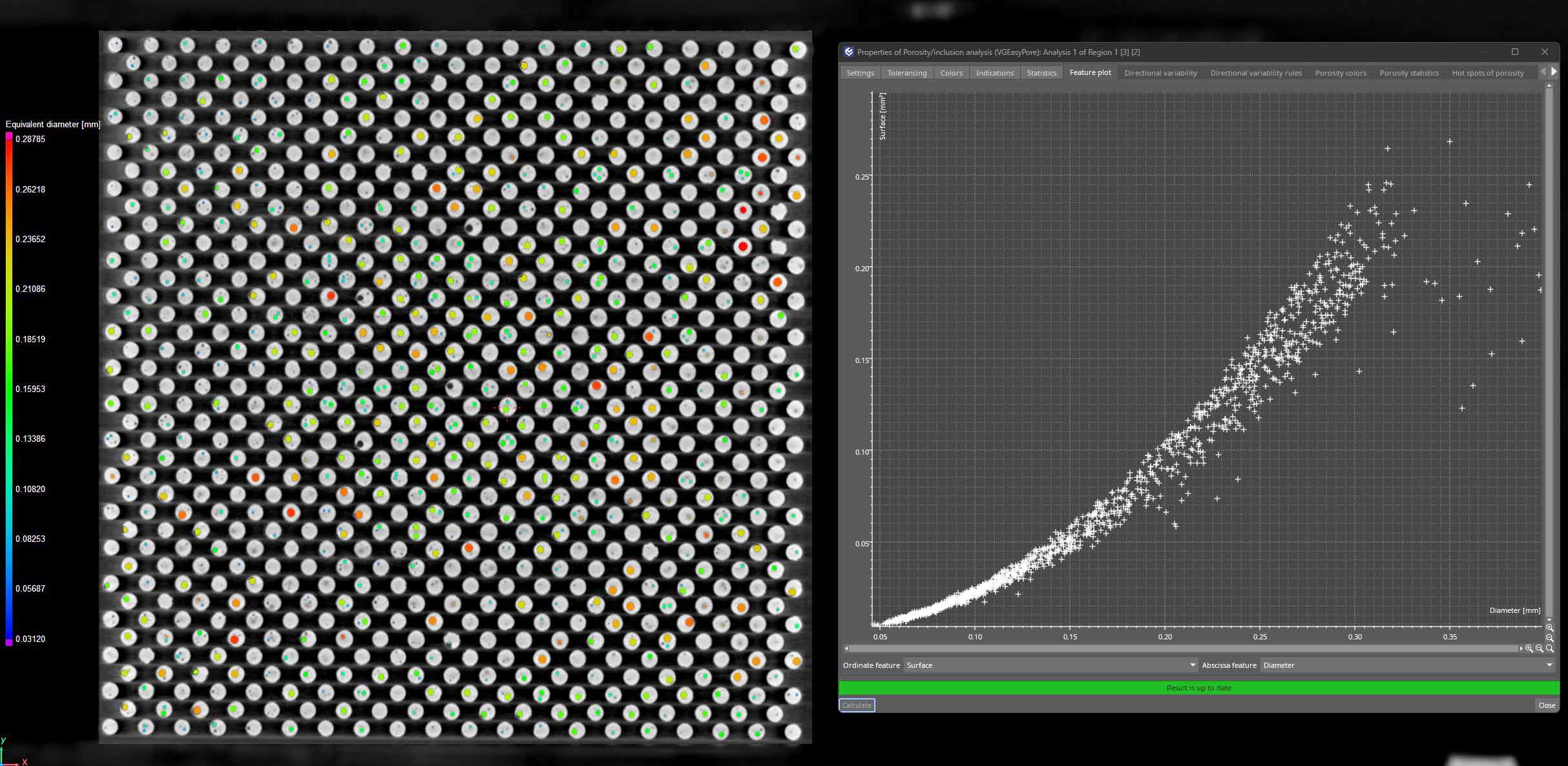

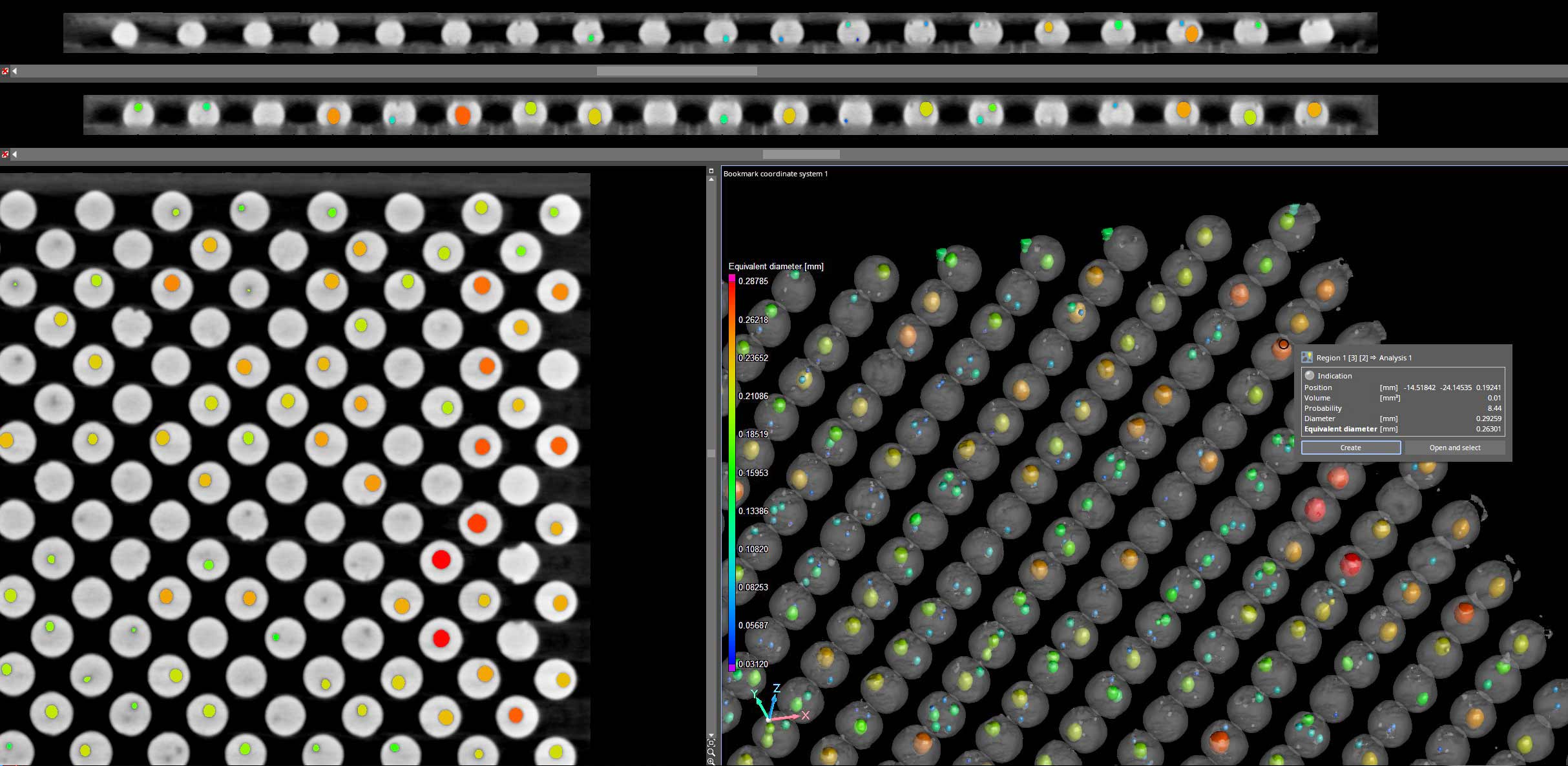

We use industry standard software for image processing, evaluation, and grading. To the left is a casting being compared to ASTM E2422 Digital Reference Images for a gas hole in proximity to the edge of a machined surface.

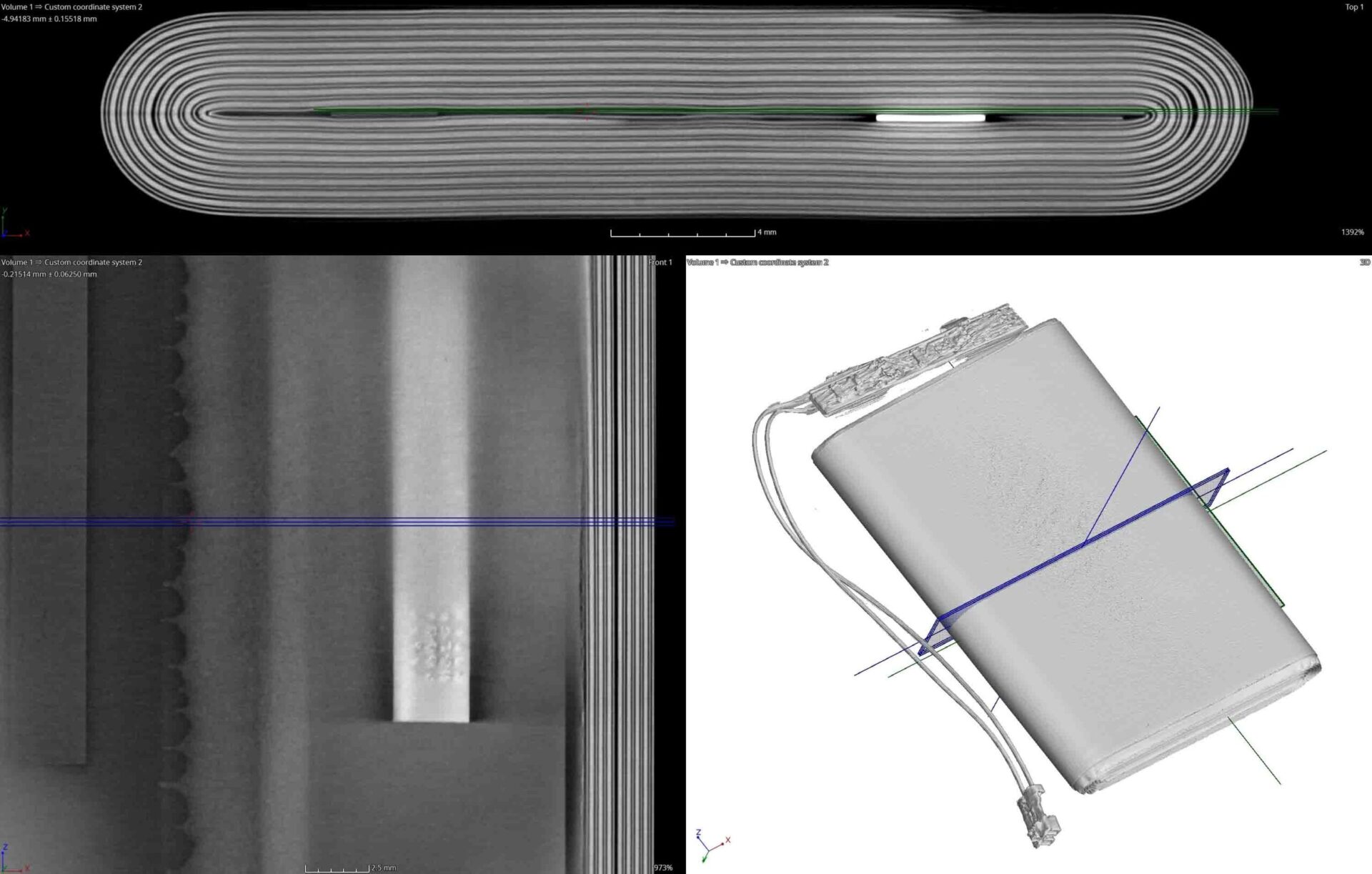

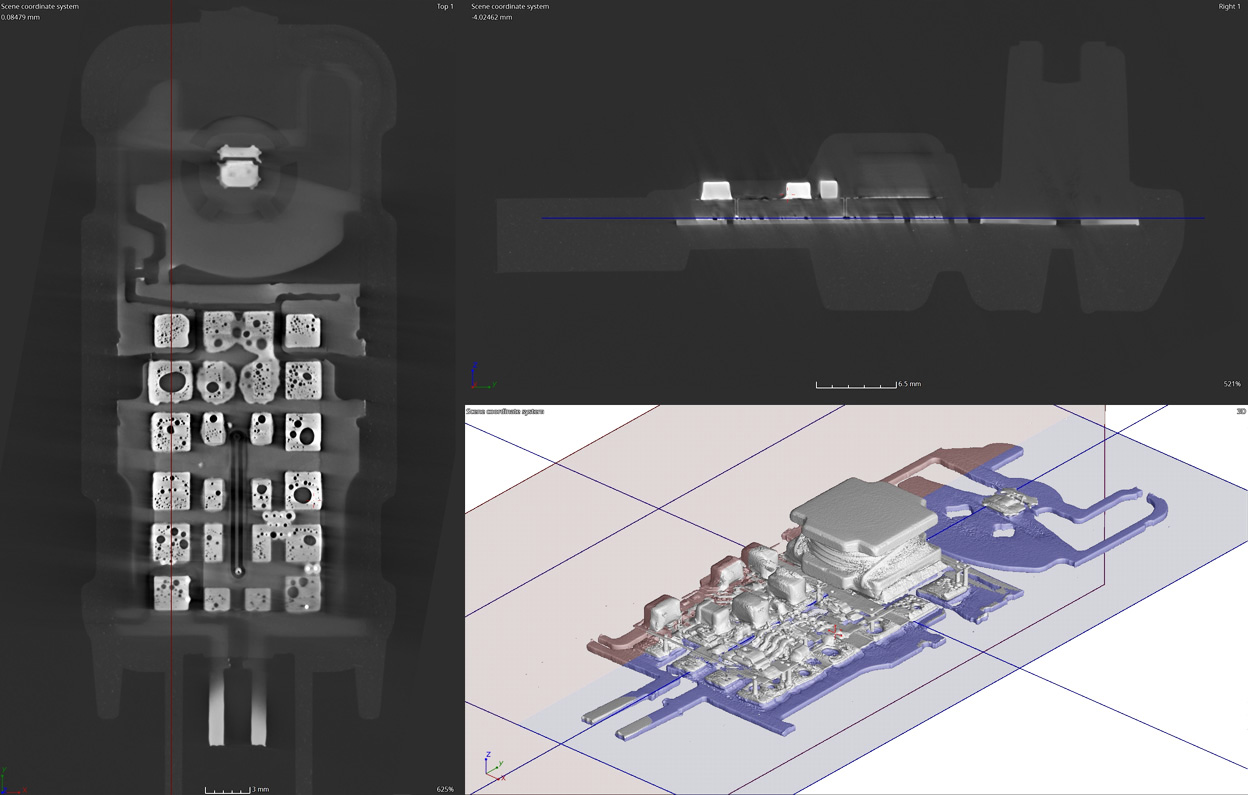

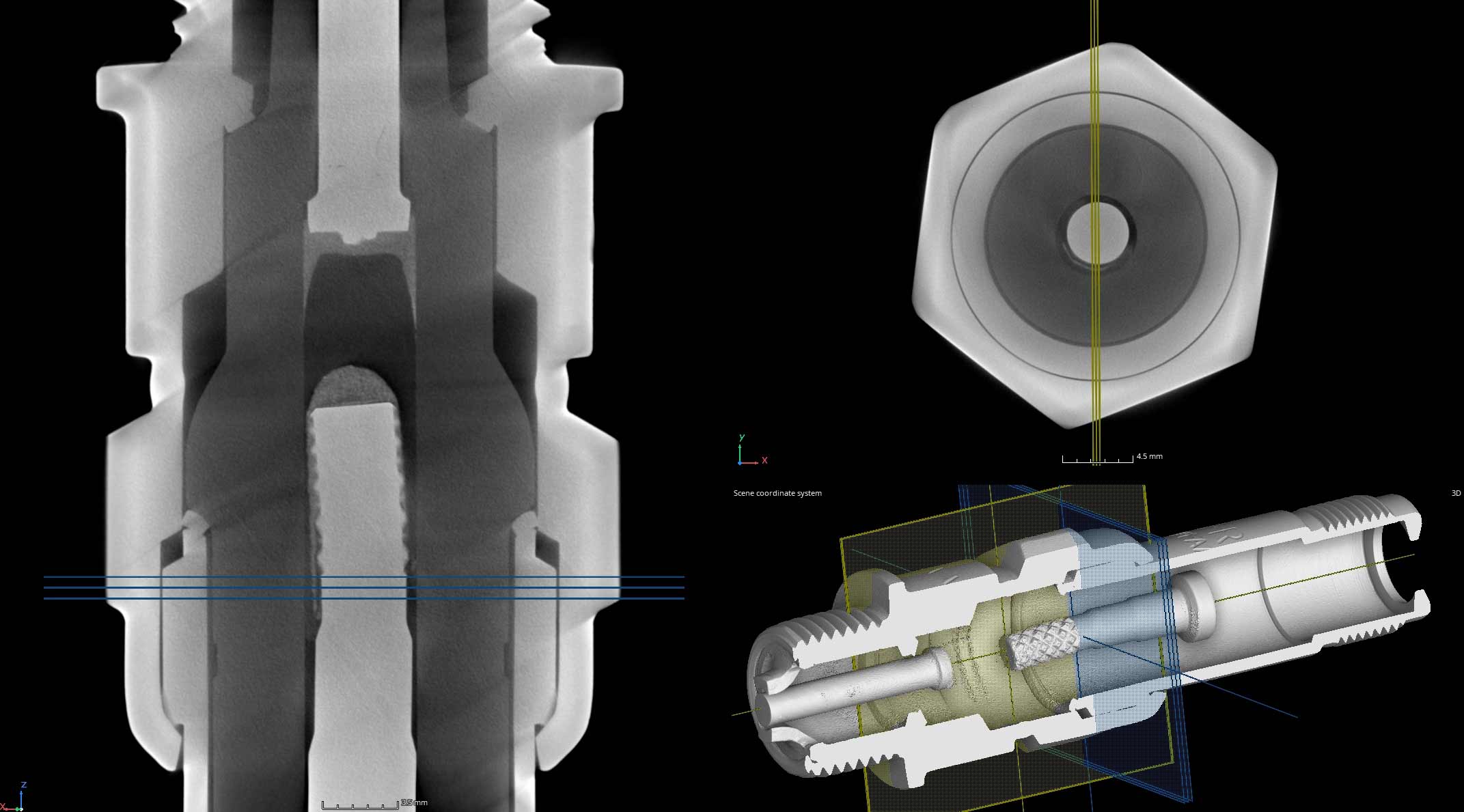

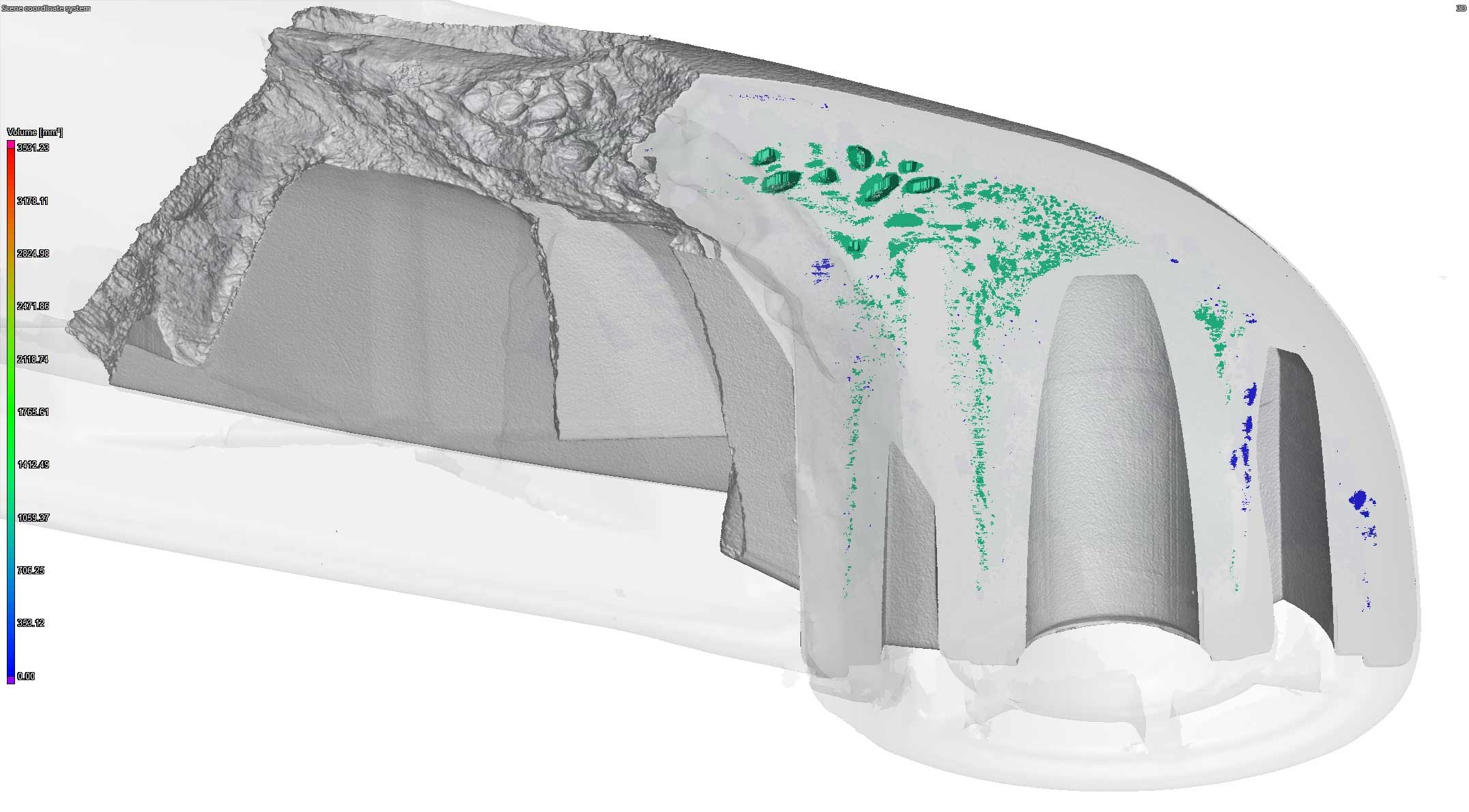

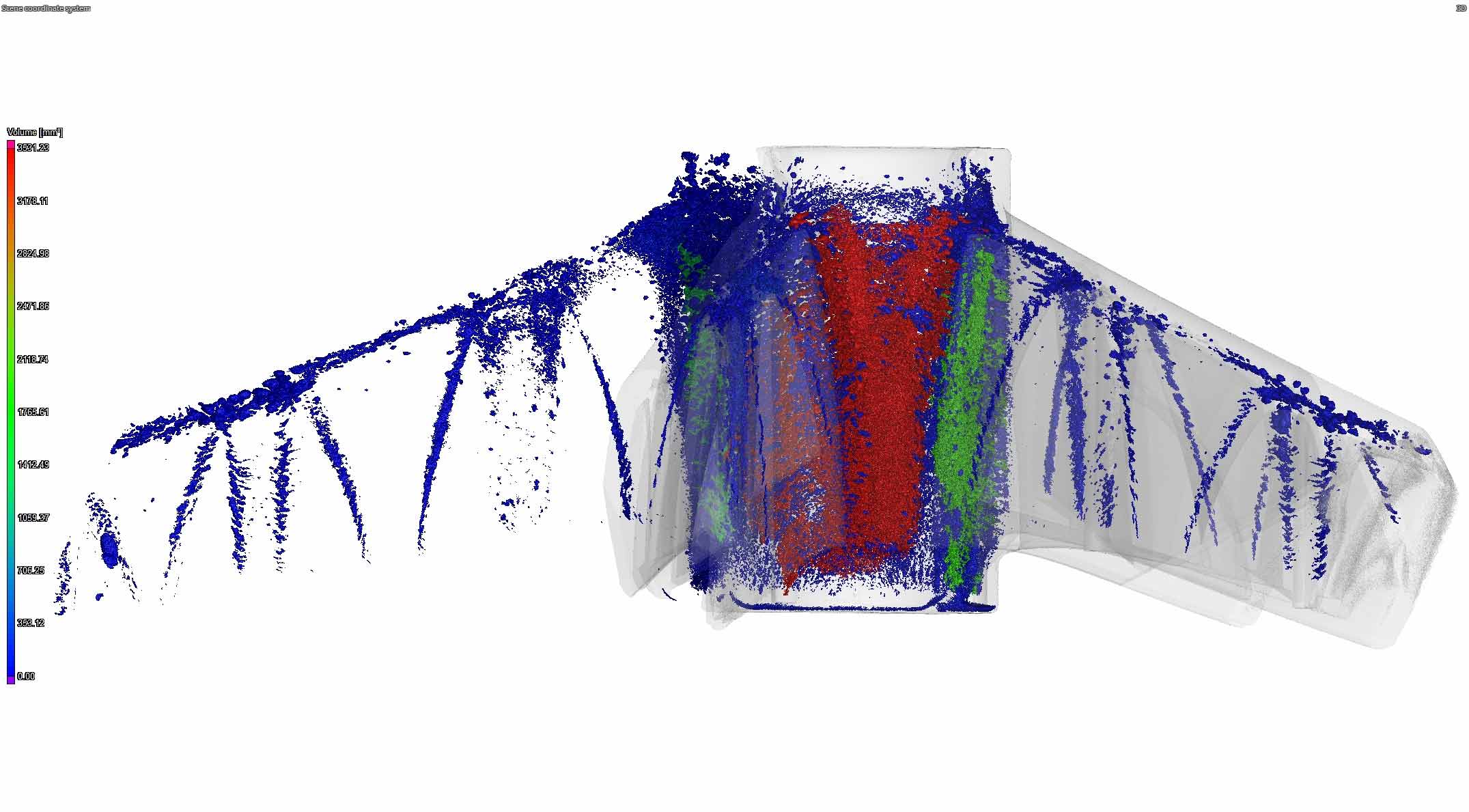

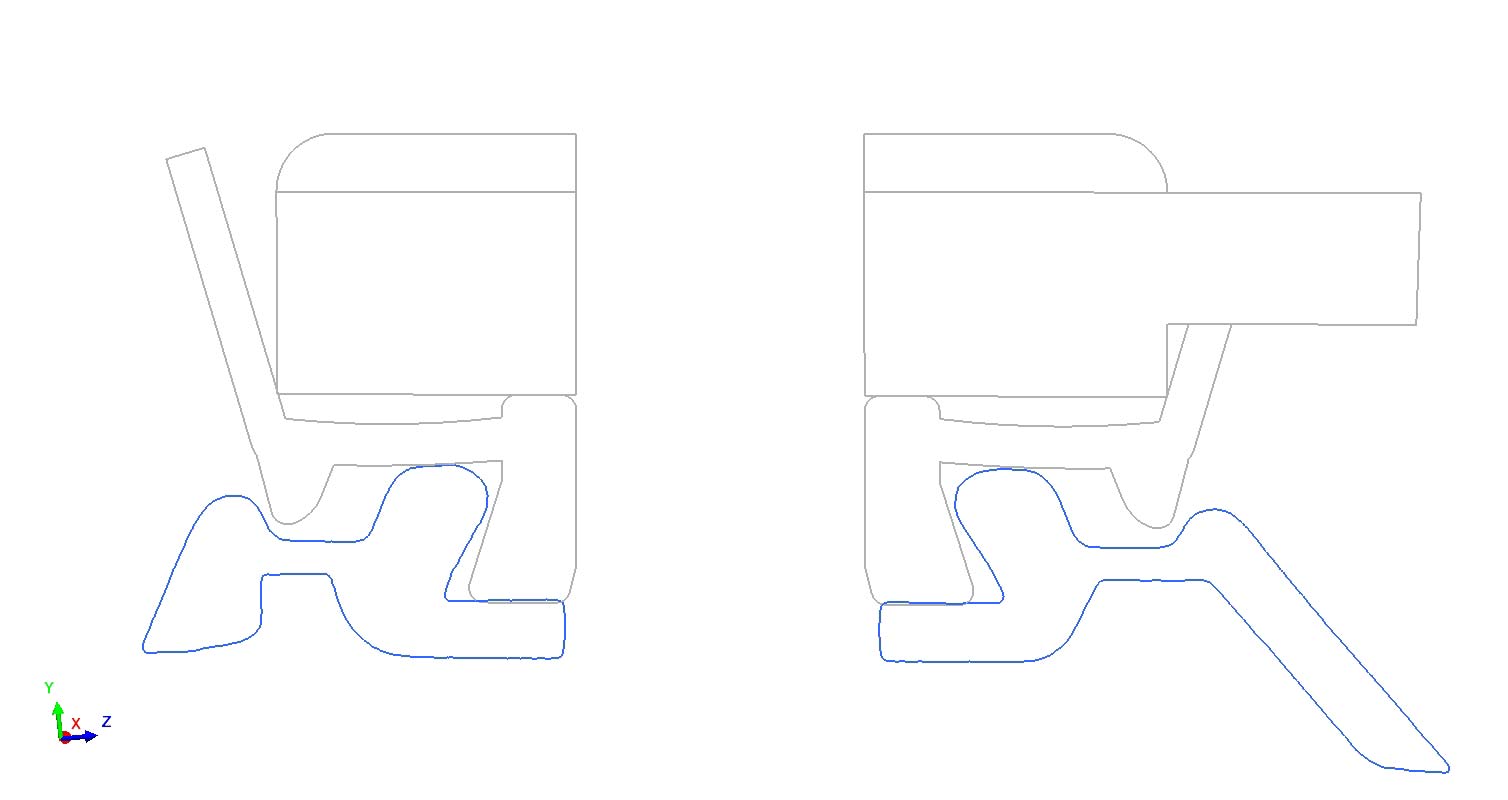

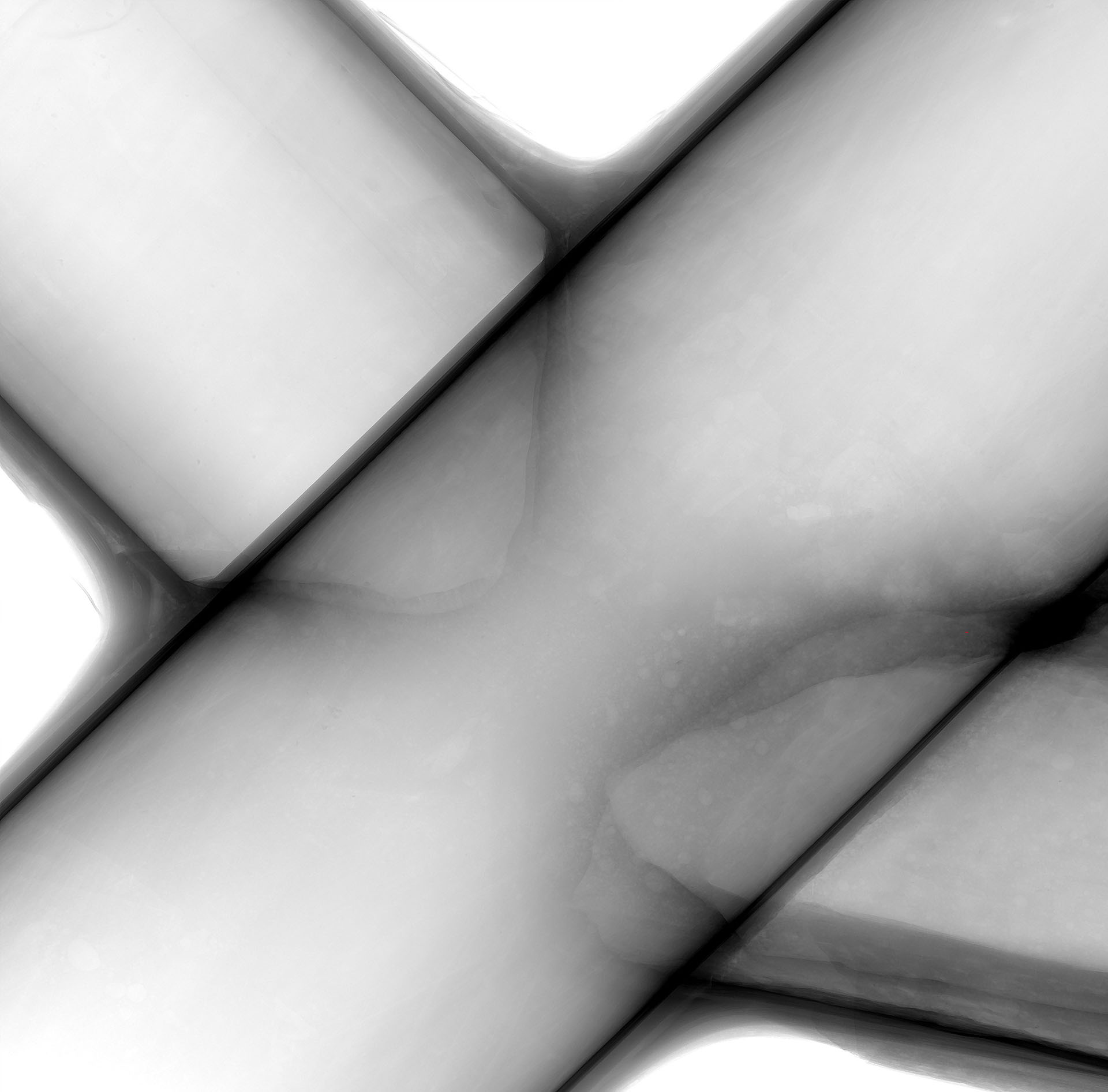

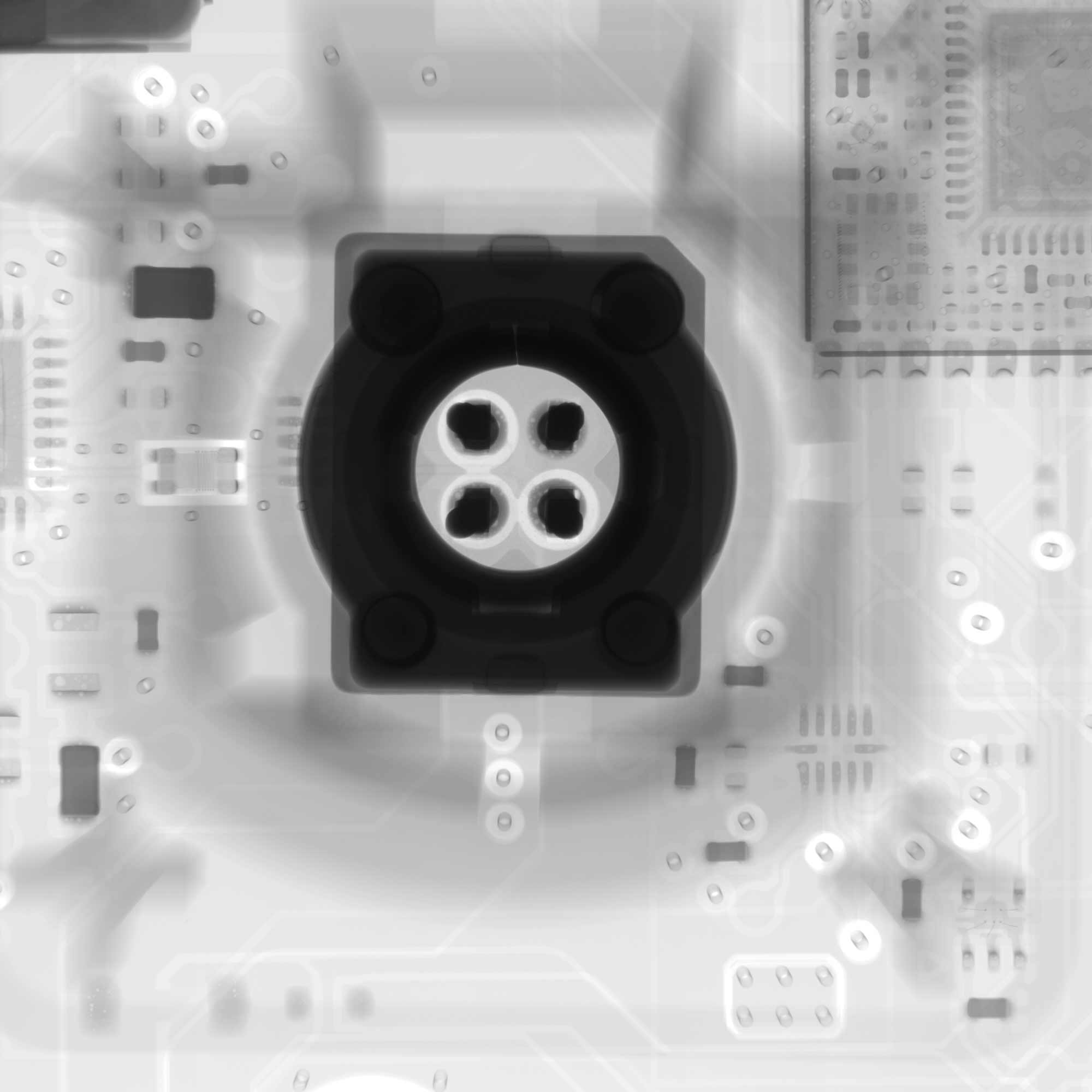

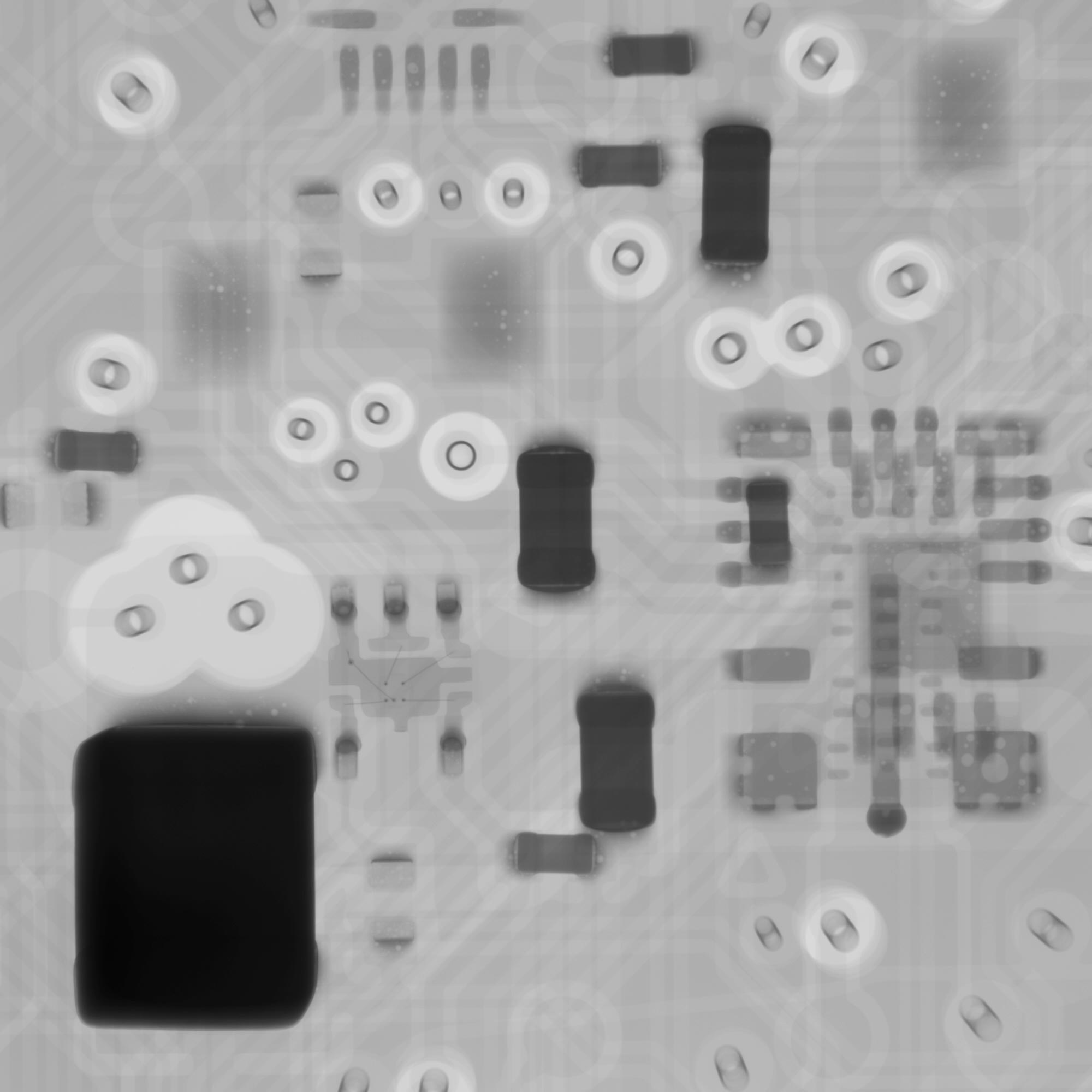

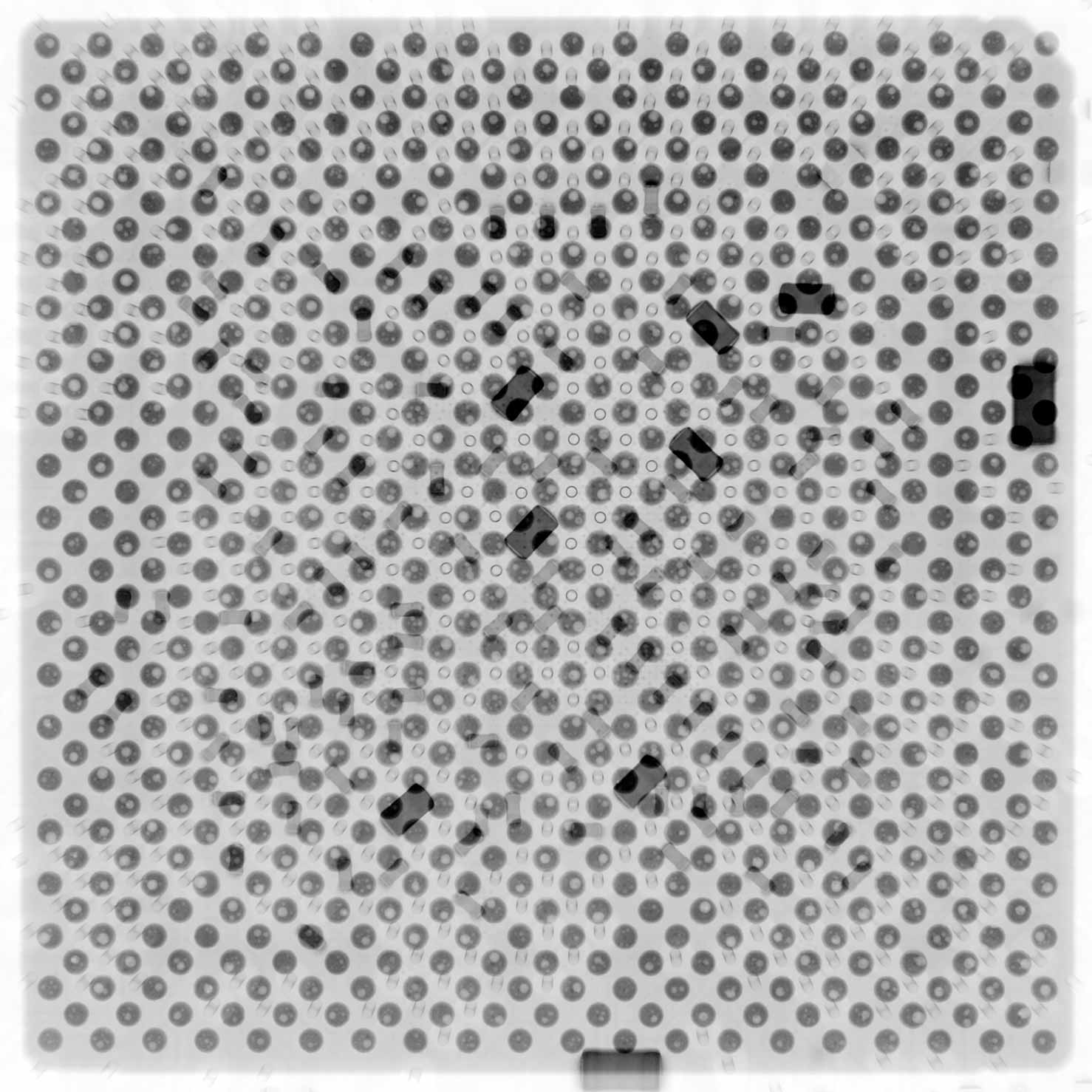

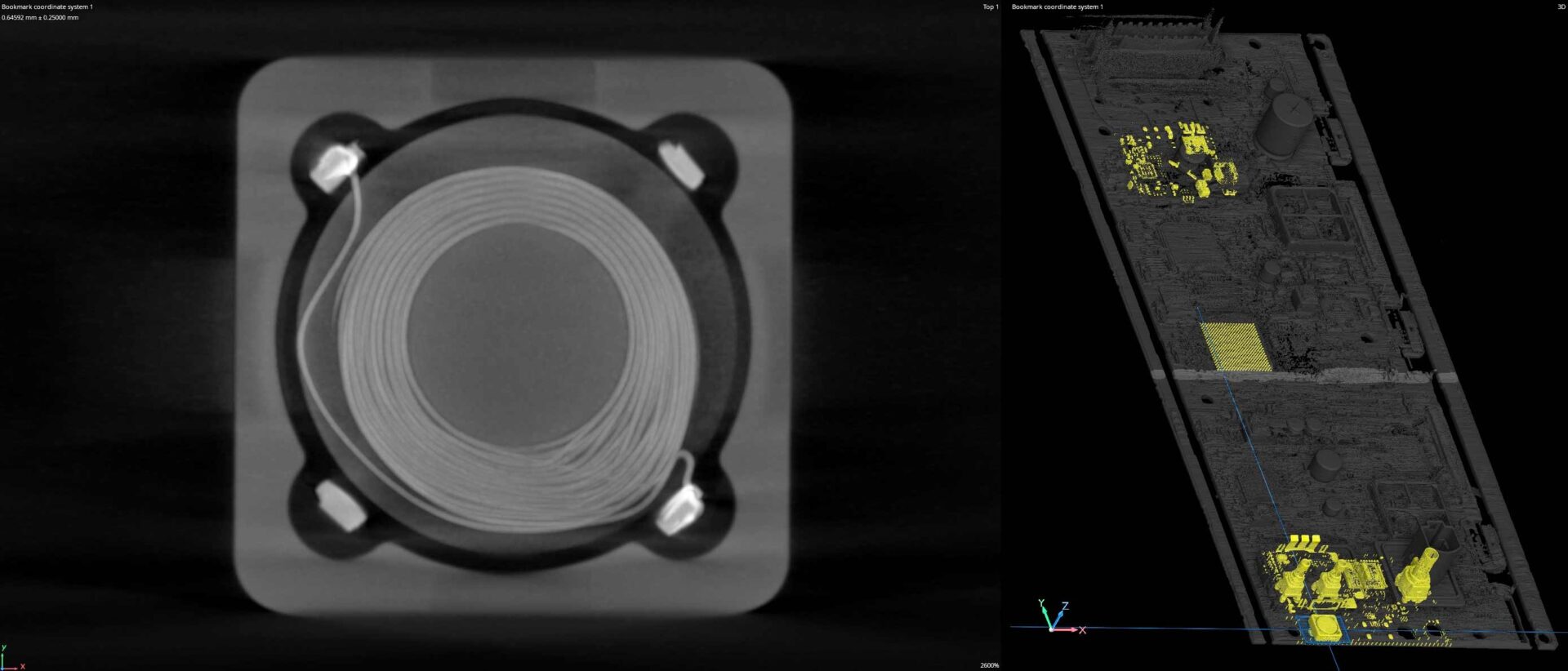

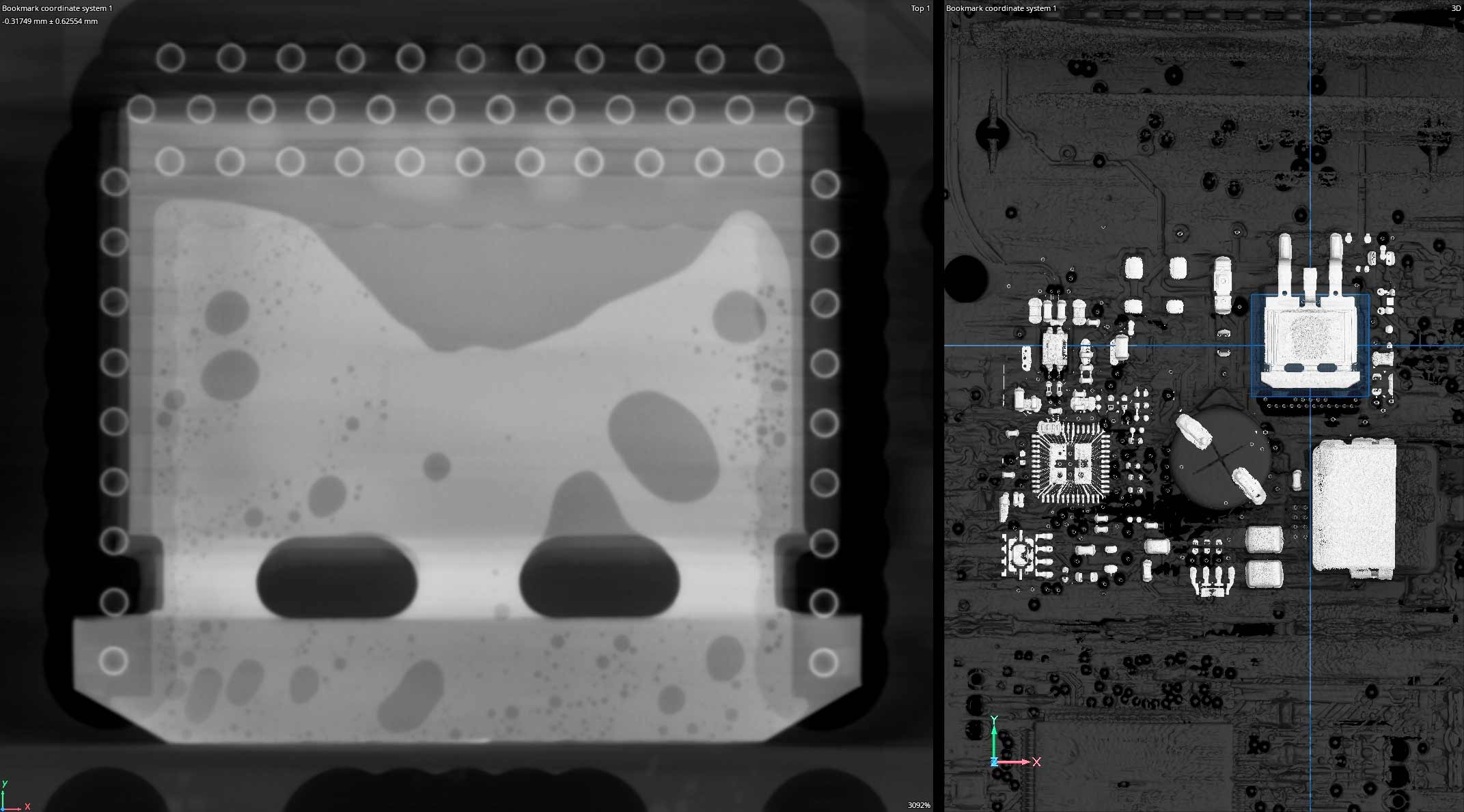

Below is x-ray imaging of a transmission housing before and after contrast adjustment. Penetrameters are used to qualify a technique for adequate penetration through various material thicknesses, and software is used to adjust brightness and contrast to look for defects not seen in the raw image.