FILM & IMAGE REVIEW

At Industrial Inspection, we specialize in data analysis for all modalities of industrial radiography. Need NAS-410 inspectors to come to you? Or do you want to send us your images? Either way is fine with us. Just need a 2nd opinion or a 3rd party check? No problem. All you have to do is tell us what procedures and acceptance criteria are applicable to your job and we can ensure that your images meet the requirements.

Our team of experienced inspectors meticulously analyze each image to ensure the integrity and reliability of your materials and structures. Whether you’re in aerospace, manufacturing, oil and gas, or any other industry requiring NDT inspections, we’re here to support your quality assurance efforts.

Why Choose Industrial Inspection for NDT Image Review Services?

- Expertise: Our inspectors are highly trained and certified in radiographic testing techniques; with years of experience reading film, phosphor image plate images, DDA images, and CT datasets. We have NAS-410 & SNT-TC-1A certified inspectors. We have ASNT Level 3’s with niche qualifications such as Honeywell SCA and Pratt & Whitney certifications.

- Quality: We meticulously review each radiographic image to detect flaws, image quality and anomalies with precision and attention to detail. Ensuring that they meet all of your customer’s requirements.

- Efficiency: We have the certified personnel & technology to deliver timely results without compromising on quality, helping you minimize downtime and maintain productivity.

- Comprehensive Reporting: Our detailed reports provide clear and actionable insights, empowering you to make informed decisions about the integrity of your materials and structures.

- Customer Satisfaction: We prioritize customer satisfaction and are committed to exceeding your expectations with our professionalism, reliability, and dedication to excellence.

Film Radiography Image Review

-

- Film quality verification:

- Density checks.

- Sensitivity checks.

- Contrast Measurement.

- ID verification.

- Artifact checks.

- Detection and characterization of part defects. Categorizing relevant and non-relevant discontinuities.

- Detailed reporting with annotated images and recommendations for remedial actions.

- Film quality verification:

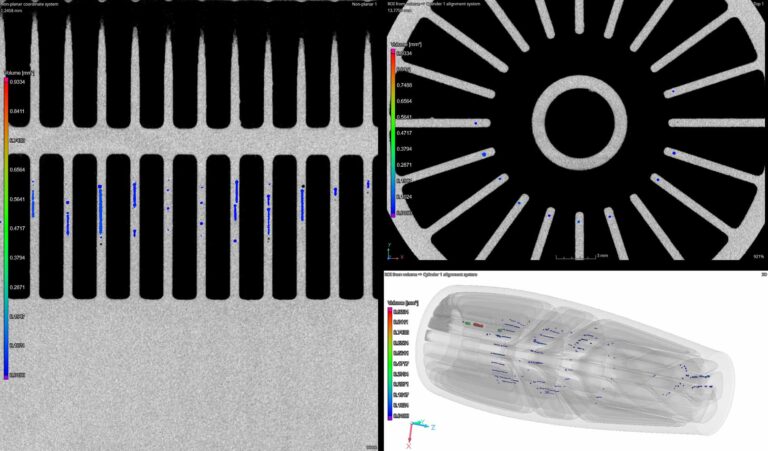

Digital Radiography Image Review

- Image quality verification by performing:

- Sensitivity checks.

- Contrast-to-noise ratio measurements.

- Signal-to-noise ratio measurements.

- Basic spatial resolution measurements.

- Total unsharpness calculations.

- Maximum geo-mag calculations.

- Image qualification and duplex phantom plate checks.

- DICONDE compliance.

- Detection and characterization of part defects. Categorizing relevant and non-relevant discontinuities.

- Detailed reporting with annotated images and recommendations for remedial actions.

- Image quality verification by performing:

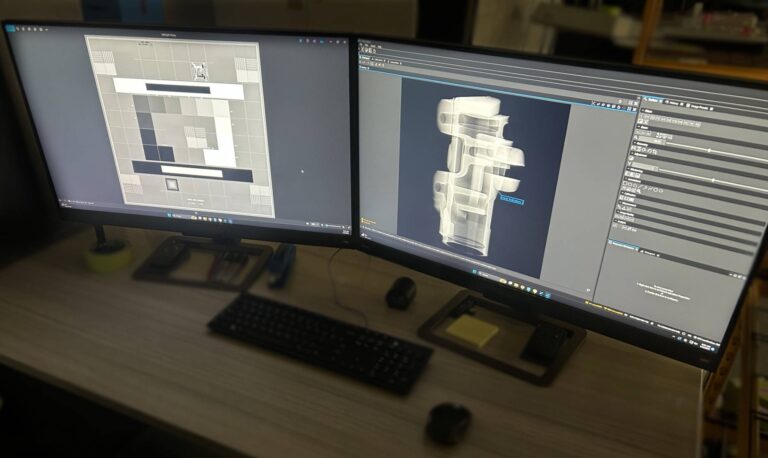

Computed Tomography Data Analysis

- Detection and characterization of part defects. Categorizing relevant and non-relevant discontinuities.

- Advanced porosity/void analysis.

- Custom videos.

- STL file generation.

- Detailed reporting with annotated images and recommendations for remedial actions.

Remote Data Services

- We transfer hundreds of gigabytes of data every day. Ask about our file share to transfer your data.

- Convenient remote image review services, allowing you to submit radiographic images electronically for analysis.

- ITAR complaint facility. Securely transfer data and confidentiality protocols to protect sensitive information.

- Real-time communication and collaboration with our expert inspectors for immediate feedback and guidance.