TRAINING

COURSE LIST

Our NDT (Non-Destructive Testing) training courses offer a comprehensive blend of classroom instruction and hands-on practical experience. Participants will gain a solid understanding of key inspection methods such as ultrasonic, magnetic particle, radiographic, dye penetrant testing, metrology & GD&T, with expert guidance in both theory and real-world applications. Classroom sessions cover fundamental concepts, safety protocols, and industry standards, while practical training allows learners to apply techniques on actual materials and equipment, ensuring they are well-prepared for professional certification and work in the field.

- Film & Non-Film Radiography

- CT Scanning

- Ultrasonics

- Liquid Dye Penetrant

- Magnetic Particle

- Eddy Current

- Radiation Safety

- Refresher Courses

Have a question or request for quote regarding training & certifications?

Radiographic testing (RT) Level I

This course provides the foundational knowledge of industrial radiographic testing (RT). Students learn about the properties of matter, the production and characteristics of radioactive materials, including concepts like ionization, shielding, and exposure measurement. They are introduced to radiographic equipment, including X-ray machines and radioactive sources, and the principles governing their operation. Emphasis is placed on radiation safety, ensuring compliance with regulatory standards, and understanding essential practices like shielding, and safe handling of radioactive materials.

This 40-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

Radiographic testing (RT) Level II

This course builds upon foundational knowledge, focusing on advanced principles and practical applications of industrial radiographic testing (RT). The curriculum delves deeper into radiographic interpretation, image quality analysis, and defect evaluation. The course covers advanced topics such as geometric unsharpness, exposure techniques, and radiographic sensitivity, including the use of image quality indicators (IQIs). Students learn to select and optimize radiographic equipment and techniques for various materials and component geometries, and how to apply relevant codes and standards.

This 40-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

Magnetic Particle Testing (MT) Level I & II

The Magnetic Particle Testing (MT) Level I and II courses provide a structured progression in understanding and applying this nondestructive testing method. Level I introduces the fundamentals of magnetic particle testing, including the principles of magnetism, magnetic fields, and material magnetization. Participants learn essential skills such as surface preparation, proper application of magnetic particles, identifying indications, and distinguishing between relevant and non-relevant indications. Safety considerations and equipment handling are also emphasized. Building on these basics, the Level II course advances into technique selection, defect evaluation, and determining the suitability of MT for various materials and components.

This 32-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

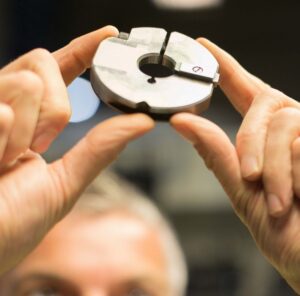

liquid Penetrant Testing (PT) Level I & II

The Liquid Penetrant Testing (PT) Level I and II courses provide comprehensive training on the principles, techniques, and applications of this nondestructive testing method. Level I focuses on the fundamentals, including the theory of liquid penetrant testing, surface preparation, application of penetrants, removal techniques, developer application, and identifying indications of surface-breaking defects. Level II builds upon this foundation with advanced training in interpreting and evaluating indications, selecting appropriate techniques for various materials and defect types, and ensuring compliance with industry standards.

This 32-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105)

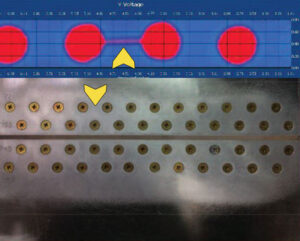

Electromagnetic testing (ET) Level I

This course introduces participants to the foundational principles and techniques of this nondestructive testing method. The course covers the basic theory of electromagnetism, including the generation of eddy currents, the interaction of electromagnetic fields with conductive materials, and the factors influencing test results. Participants learn about the operation and calibration of electromagnetic testing equipment, as well as the proper use of probes and coils.

This 40-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

Electromagnetic testing (ET) Level II

In this course students deepen their understanding of electromagnetic principles, including impedance plane analysis, phase relationships, and advanced eddy current techniques. The course covers the selection and configuration of probes, coils, and frequencies to detect and evaluate surface and subsurface defects in various materials and geometries. Emphasis is placed on signal interpretation, distinguishing between defect signals and material variations, and performing detailed evaluations in accordance with applicable standards.

This 40-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

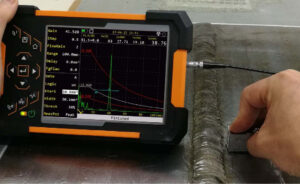

Ultrasonic testing (UT) Level I

In this course students learn the basics of sound wave propagation, including concepts like reflection, refraction, and attenuation, as well as the characteristics of different materials that affect wave behavior. The course covers the operation and calibration of ultrasonic testing equipment, including transducers and flaw detectors, and introduces common techniques such as pulse-echo and through-transmission.

This 40-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

Ultrasonic testing (UT) Level ii

This course expands on foundational knowledge and focuses on advanced techniques, defect evaluation, and the independent execution of ultrasonic inspections. Participants gain a deeper understanding of sound wave behavior, including advanced topics like beam spread, mode conversion, and phased array technology. The course covers the selection and calibration of transducers, as well as the development and optimization of inspection procedures for various materials and geometries. Emphasis is placed on interpreting complex signals, ensuring compliance with industry standards, and accurately documenting results.

This 40-hour course meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

Visual testing (VT) Level i & ii

The Visual Testing (VT) Level I and II courses provide comprehensive training on the principles and application of this fundamental nondestructive testing method. The Level I course focuses on the basics of visual inspection, including lighting requirements, surface preparation, and the use of tools such as magnifiers, mirrors, and borescopes. Participants learn to identify and classify surface imperfections, distinguish between relevant and non-relevant indications. The Level II course builds on this foundation, introducing advanced techniques for detailed inspection and defect evaluation. It emphasizes the interpretation of inspection results, the development of inspection procedures, and compliance with applicable codes and standards. Together, these courses equip individuals with the skills to perform and supervise VT inspections across a wide range of industrial applications.

This 24-hour course meets or exceeds the instruction outline and criteria specified in ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

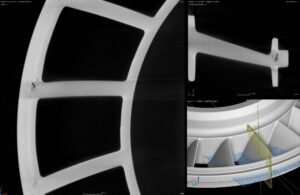

Computed tomography (Ct) – 8 or 40 HOUR options

This course equips participants with the knowledge and skills essential for a comprehensive understanding of Digital Radiography, with a strong emphasis on Computed Tomography (CT), as required in highly demanding industries. Attendees will explore advanced technique development strategies to achieve exceptional results in the most challenging applications.

This 8 hour course, combined with 16 hours of equipment familiarization training, meets the requirements to transition to Computed Tomography from another radiographic technique as stated in SNT-TC-1A, ANSI/ASNT CP-189.

This 40-hour course may be used for the Level 2 transition to non-film from film per NAS-410 and meets or exceeds the instruction outline and criteria specified in NAS-410, ASNT Recommended Practices SNT-TC-1A, ANSI/ASNT CP-189 and ASNT Standard Topical Outlines for Qualification of Nondestructive Testing Personnel (ANSI/ASNT CP-105).

RADIATION SAFETY TRAINING – 8 or 40 hour options

This course is designed to provide comprehensive education and certification for professionals in workplaces that handle radioactive materials or equipment. The course covers key areas of radiation protection, regulatory compliance, and emergency response to ensure safety for both workers and the public.

SCANNING & PROBING – INTRO COURSE – 24 HOURS

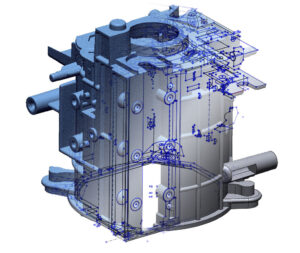

Led by industry and technical experts, our courses teach practical skills and basic techniques. This 24 hour introduction into software and hardware knowledge and training uses a variety of scanning systems and software including PolyWorks & Hexagon Absolute AS1 Portable CMM Scan Arm. Basic functions like alignments, CAD deviation reporting, and dimensional tools will be covered.

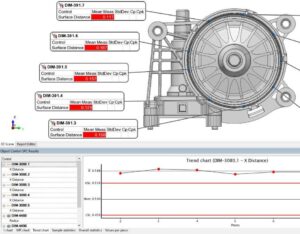

POLYWORKS PROGRAMMING – ADVANCED COURSE – 24 HOURS

This advanced course is designed for experienced PolyWorks users, focusing on mastering PolyWorks tools like feature dependent and independent programming, control views, and workflow enhancing macros. Participants will deepen their expertise by learning to optimize and execute complex PolyWorks programs, incorporating advanced techniques in both probing and laser scanning.

GEOMAGIC DESIGN X – INTRO COURSE – 24 HOURS

Geomagic Design X training is a comprehensive three-day course that explores various scan preparation and modeling techniques. Participants will learn how to transform scan data into “Design Intent” CAD models. Primary focus areas include coordinate system fundamentals, scan data manipulation, effective sketching, conversion to solids, and CAD to native scan comparisons.