REVERSE ENGINEERING

SERVICES

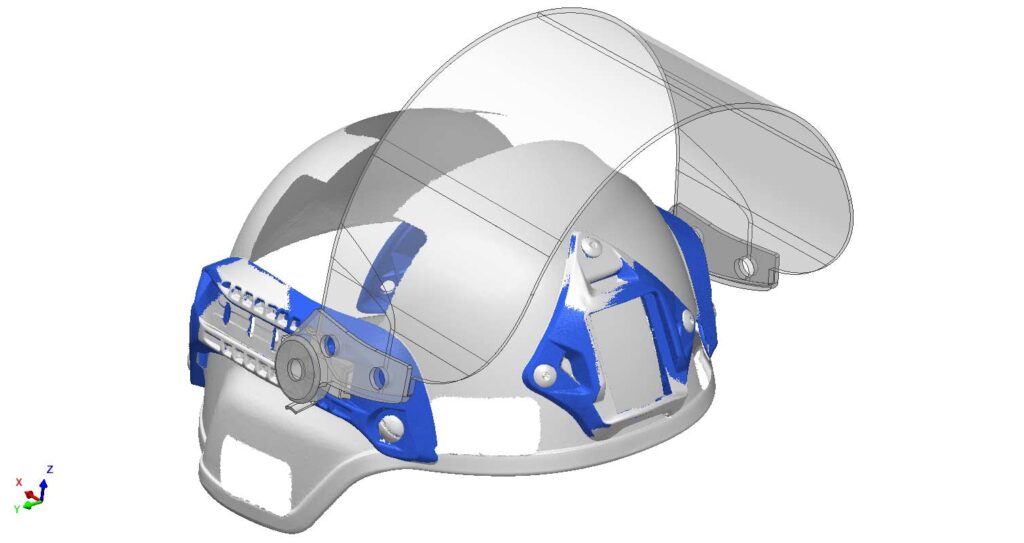

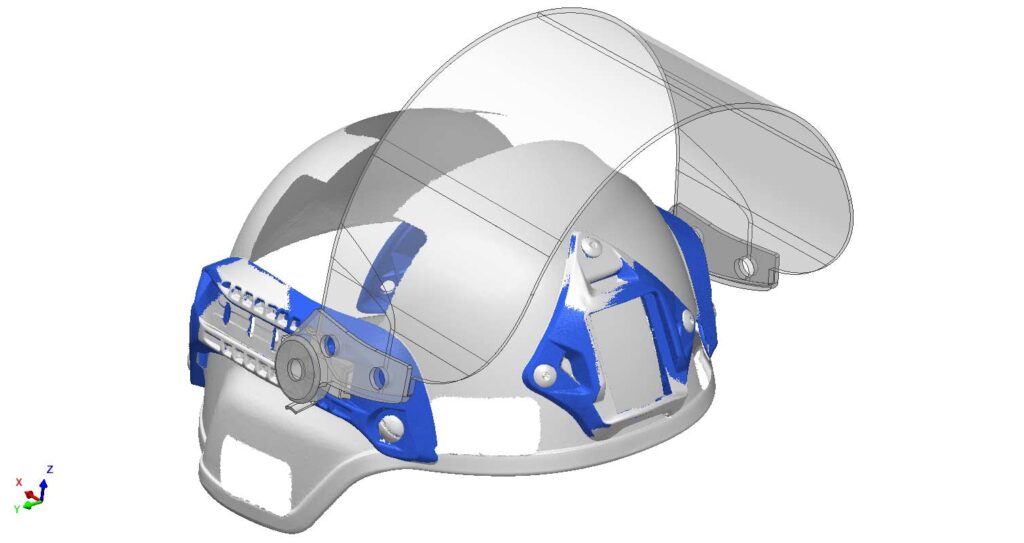

Reverse Engineering

is the process of taking an existing product or part and modifying it for a superior end result. Some practical reasons for this include:

- You have a historical part but no design CAD is available

- Designing a new product that requires a perfect fit to function

- Incorporating changes from a modified part that works better

- Replacing individual, unknown parts in an expensive assembly

- Reducing or simplifying assemblies through part elimination

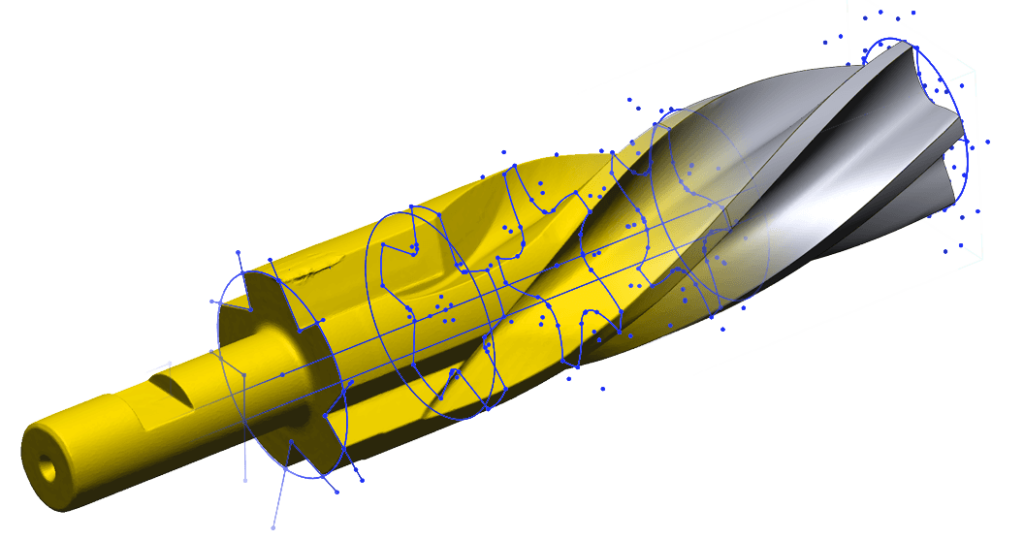

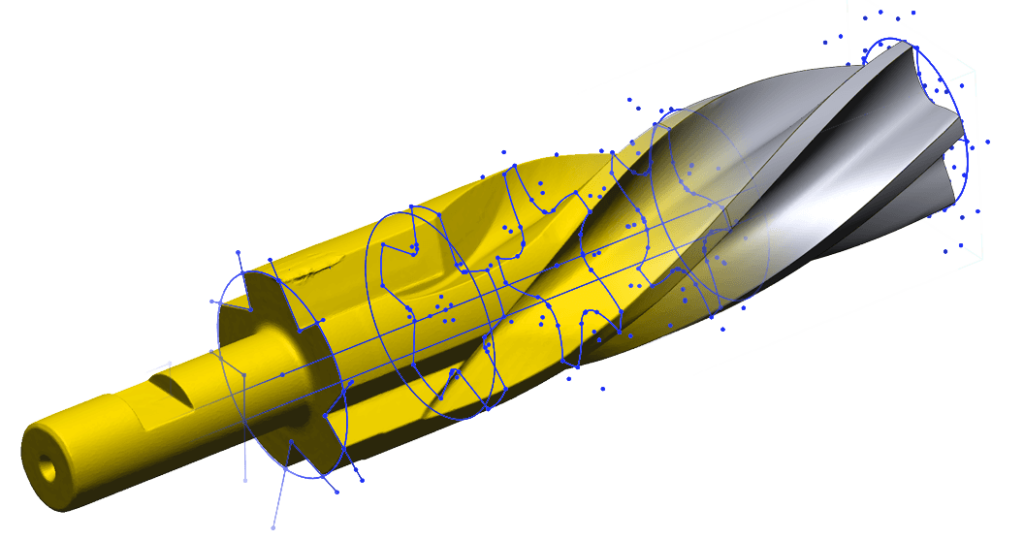

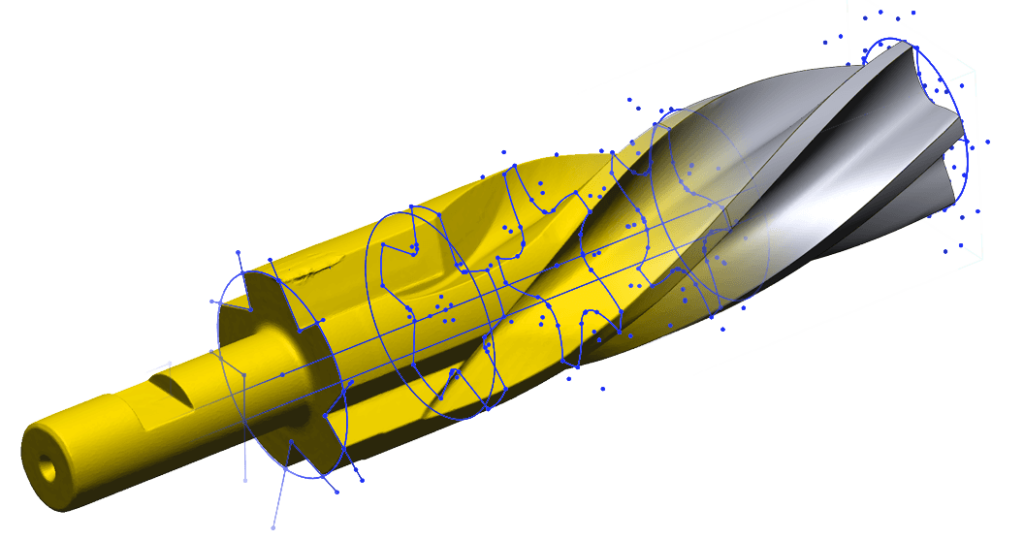

Combining premier hardwares and softwares, we can reproduce just about anything. Some examples of work include complex assemblies like optical lens housings, process critical tooling rework, and entire engine blocks. The endmill on showcase was a part replacement procedure. The client did not have historical documentation for the tool and, instead, chose to recreate it before it wore or broke.

Scan to CAD Workflow

> Scan object and capture all necessary data

>> Repair data and create coordinate system

>>> Build geometric surfaces, export as .step

>>>> Compare deviation of model back to scan file

Have a question or request for quote regarding Reverse Engineering?

REBUILDING WORLD WAR 2 PROPELLER HOUSING

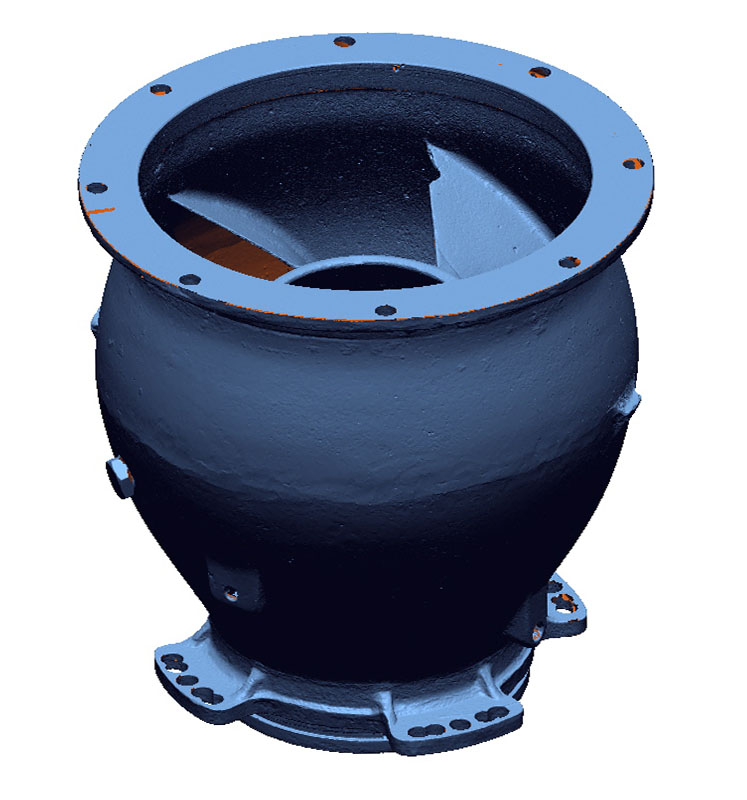

This propeller housing comes from a river patrol boat used in the Vietnam War. Only a handful of these exist anymore, and one happens to be located in West Michigan. Unfortunately, due to age and old manufacturing techniques the housing fractured while on an excursion on Muskegon Lake.

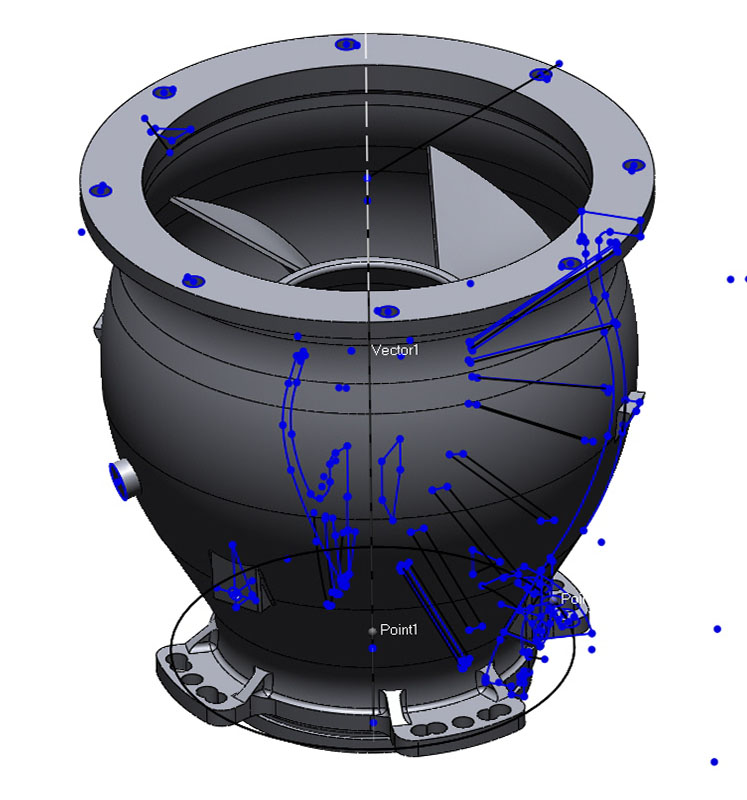

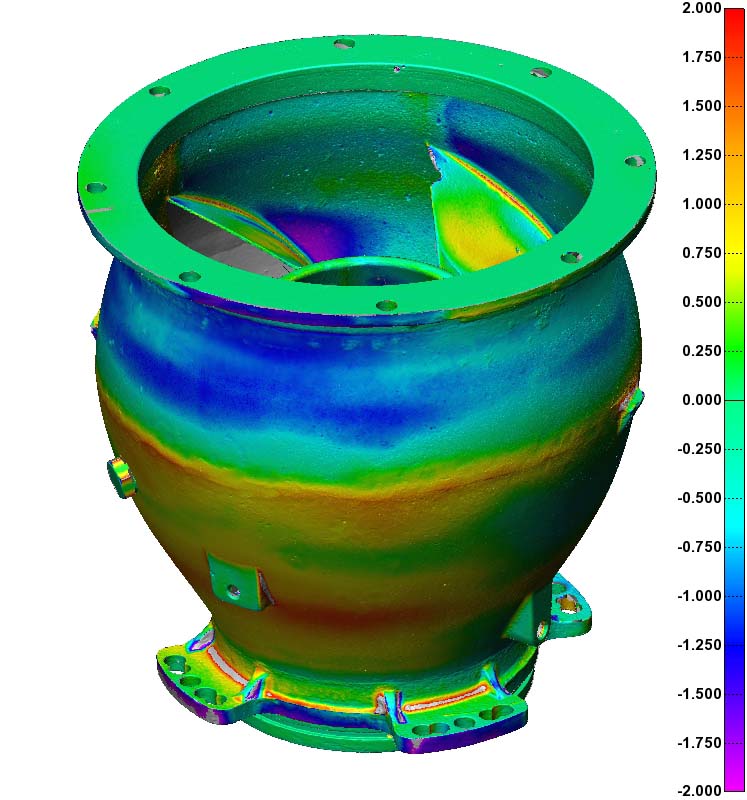

We were commissioned to produce a working model so that local manufacturers could pour and machine this steel casting.

STEP 1 ACQUIRE SCAN DATA

STEP 2 MODEL THE GEOMETRY

STEP 3 COMPARE CAD TO PART

STEP 4 HAVE THE PART MADE