EDDY CURRENT TESTING

SERVICES

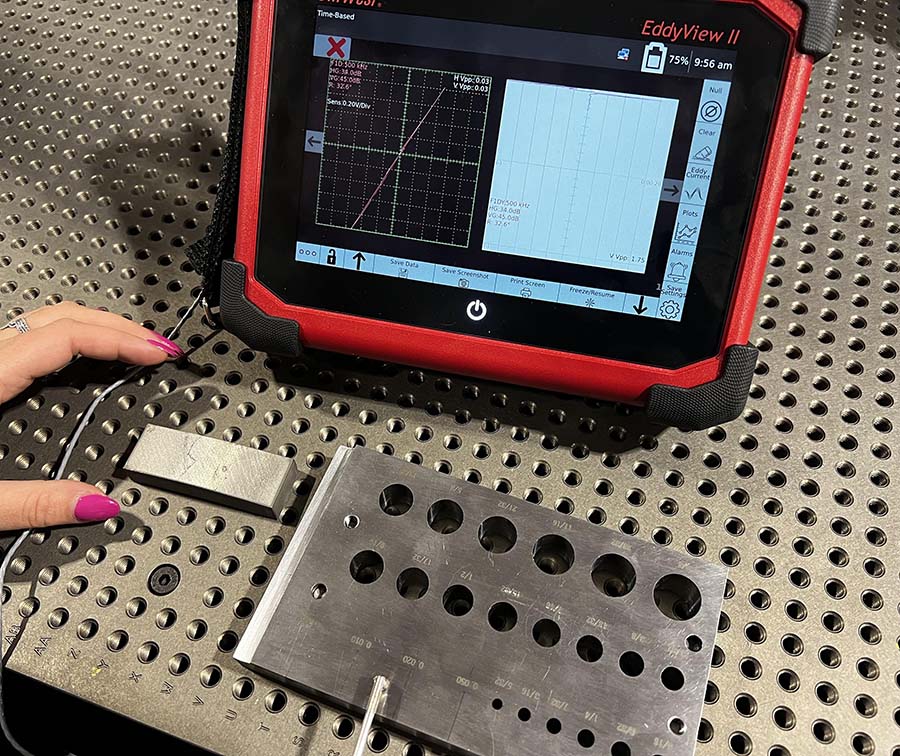

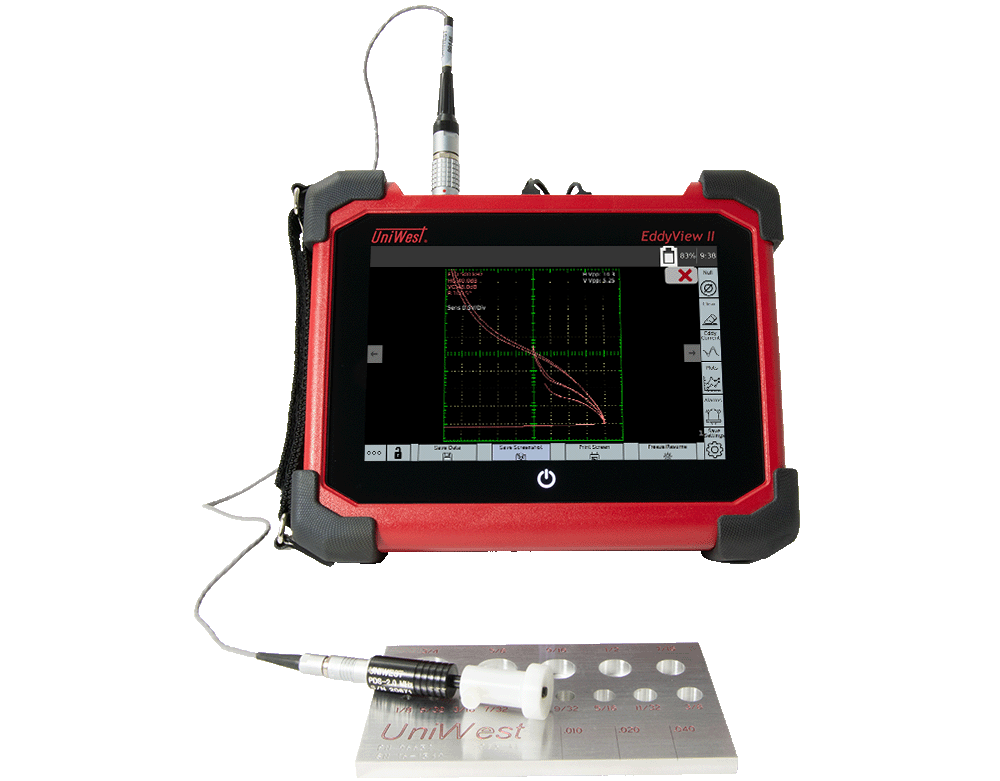

Eddy Current Testing (ECT) is a non-destructive testing (NDT) technique used to inspect a variety of materials for surface and near-surface defects for industries like aerospace, automotive, power generation, and manufacturing. It works by inducing electrical currents (eddy currents) within the material using a probe and then measuring the resulting magnetic field to detect changes in the material’s properties.

Have a question or request for quote regarding Eddy Current Testing?

Common applications of Eddy Current Testing

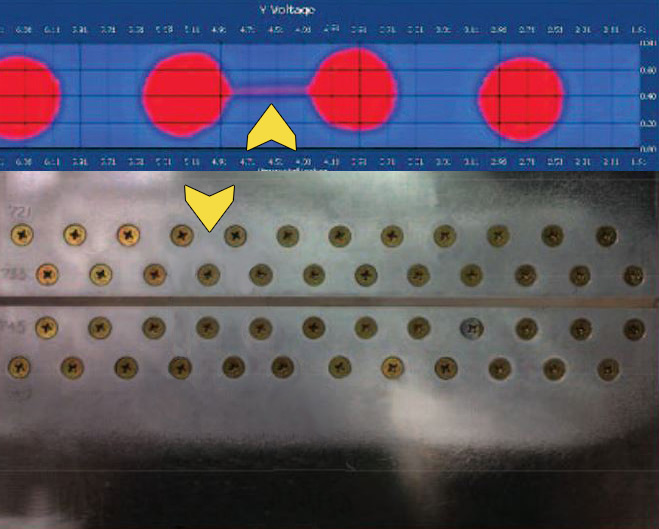

Surface Cracks and Defects:

Eddy current testing is highly effective for detecting surface-breaking cracks, corrosion, and other discontinuities, especially in conductive materials like metals. It is commonly used for inspecting the surfaces of aircraft components, turbine blades, and pipes.

Thickness Measurement:

ECT can measure the thickness of conductive materials, particularly in applications where traditional ultrasonic testing may be less effective (thin-walled parts or when access to both sides of a material is limited). It is used for monitoring the wall thickness of pipes or tanks subject to corrosion or erosion.

Coating Thickness:

Eddy current testing is used to measure the thickness of non-conductive coatings on metals (such as paint or anodizing) without damaging the coating itself. This is important in industries such as automotive or aerospace, where precise coating thickness is critical.

Material Conductivity:

ECT can assess the electrical conductivity of a material, which is useful for identifying material composition or detecting heat treatment conditions (like hardness or aging) that affect conductivity.

Heat-affected Zones (HAZ):

It can detect changes in material properties in the heat-affected zone (HAZ) of welded parts, which may lead to defects or weakened areas. This is useful in welding inspections where structural integrity is critical.

Tubing and Heat Exchanger Inspections:

Eddy current testing is commonly used to inspect heat exchangers, boiler tubes, and other types of tubing for pitting, cracking, or corrosion, especially in the nuclear, power generation, and chemical industries.

Material Sorting:

The technique can be used to sort materials by detecting differences in conductivity, helping with the classification of alloys or identifying counterfeit materials.