Surface Roughness of Large Components

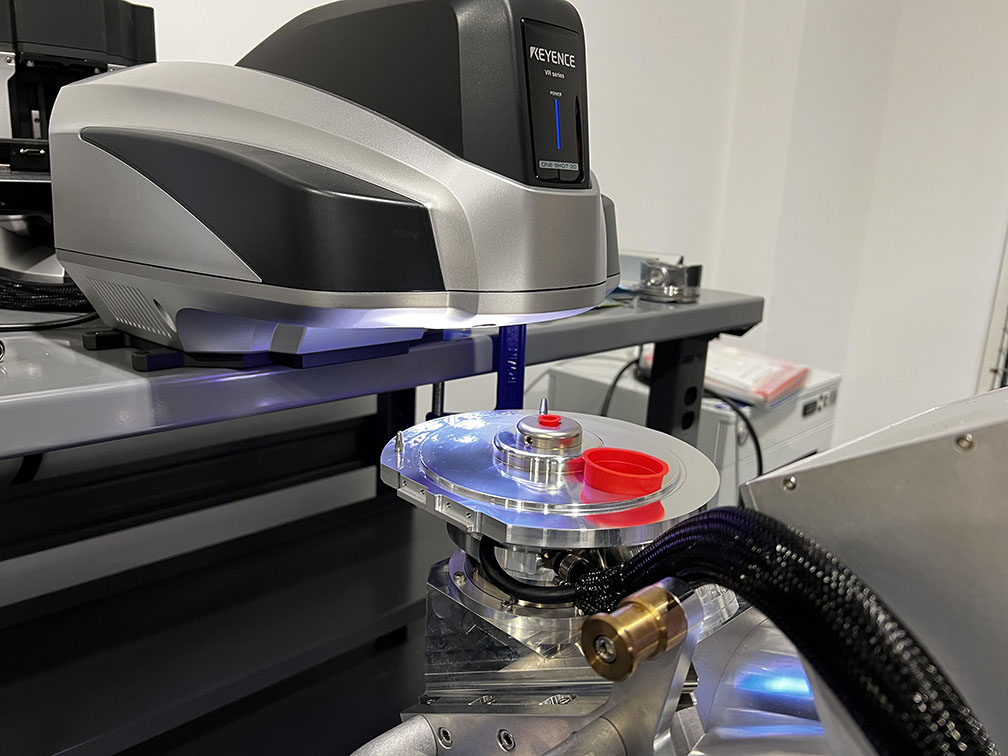

Our modular & portable Keyence optical scanner offers significant advantages for surface roughness mapping of large components. Its high-precision laser scanning enables detailed, accurate measurements across expansive surfaces, ensuring consistent quality control.

The modular design allows for flexible data acquisition, making it suitable for various industrial applications and capable of handling components of different sizes. Its ability to produce high-resolution, 3D surface profiles enhances the detection of minute imperfections and variations.

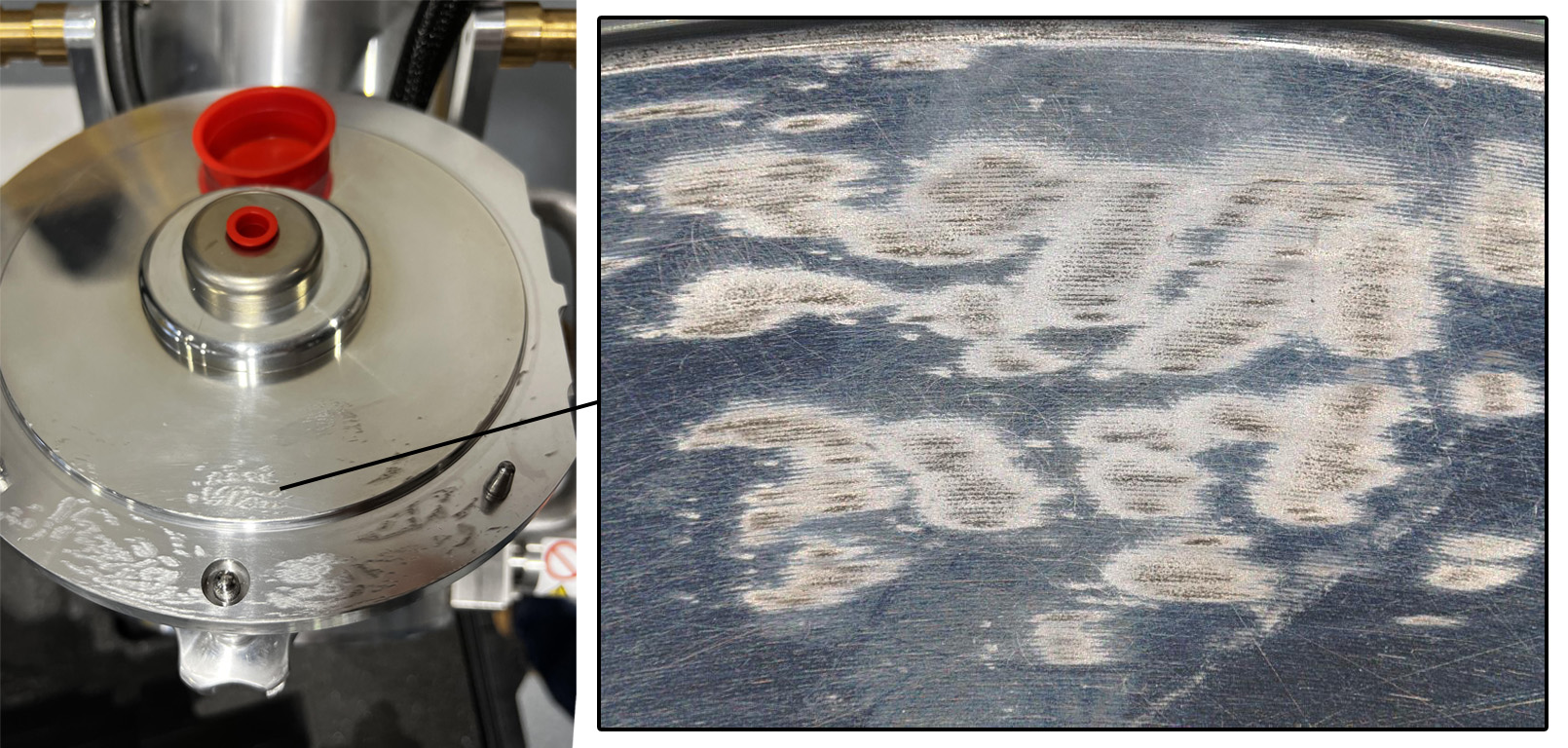

This case study demonstrates the scan head fixed to the edge of a table with the test specimen lifted into focus below the scan zone. The test specimen is an x-ray source with a peculiar roughness condition near a vacuum sealing surface.

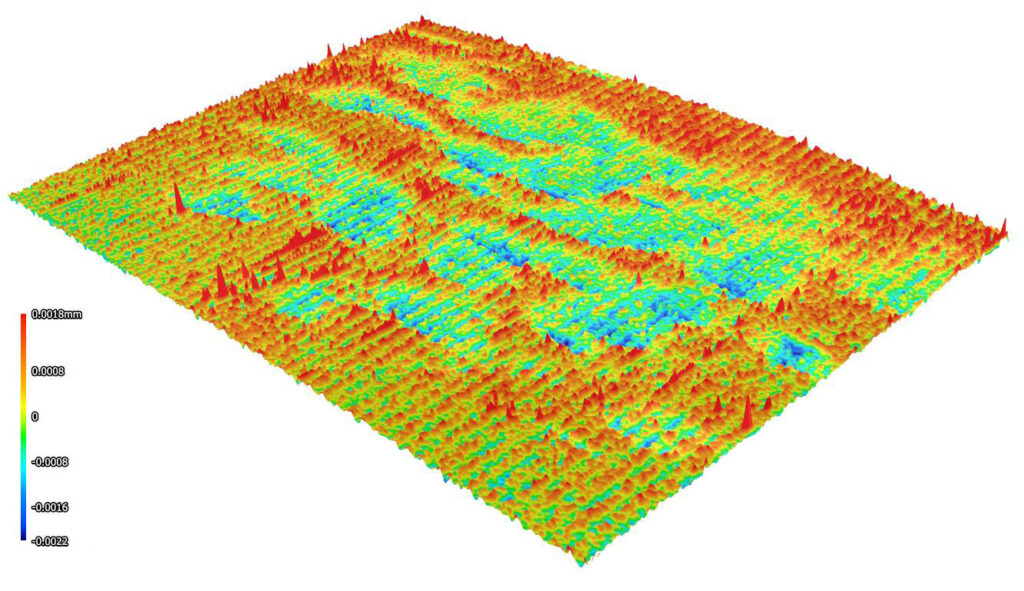

SURFACE ROUGHNESS MAP +-.002 MICRONS

The below 3D scan shows a range of surface deviation between +.0018mm and -.0022mm.