MAGNETIC PARTICLE (MT)

SERVICES

MAGNETIC PARTICLE TESTING SERVICES

We perform Dry Powder and Wet Fluorescent Magnetic Particle testing (MT) inspection services to find surface & near-surface defects in ferromagnetic materials.

Magnetic particle testing (MT) is a nondestructive testing method used to identify defects on the surface, and subsurface, of ferromagnetic materials by running a magnetic current through them. When the current is interrupted by a defect the magnetism behaves irregularly from that point, allowing the inspector to determine the indication’s exact location.

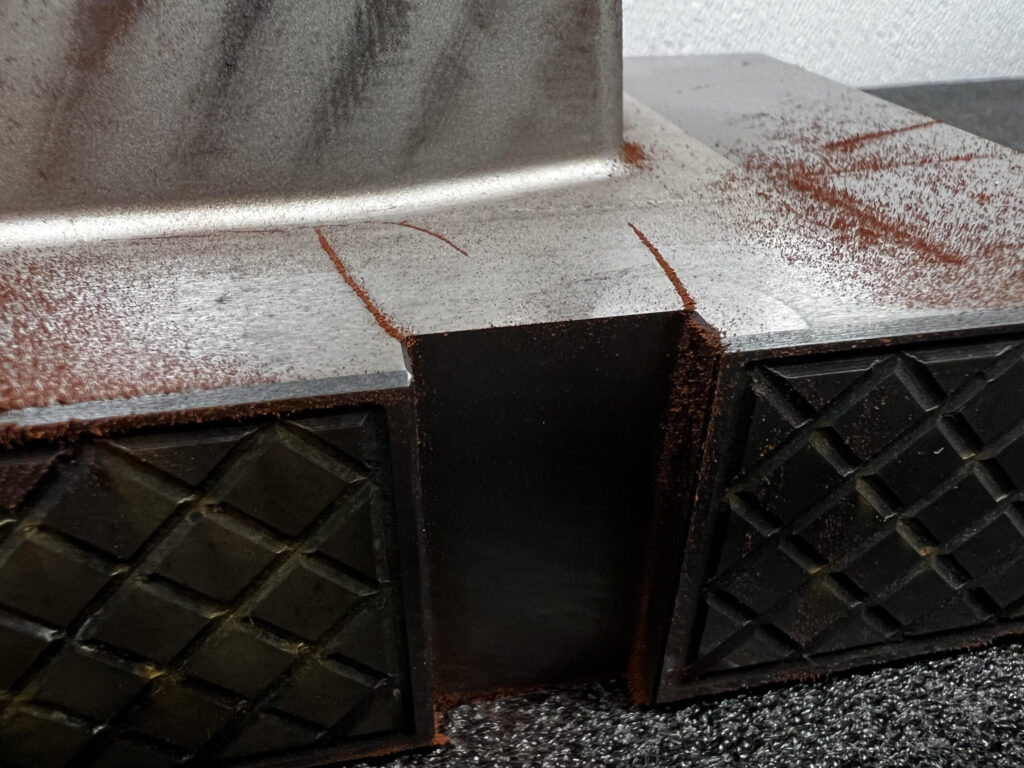

As seen in this image, when an object is magnetized and defects have created these current irregularities, magnetic particles are spread over the surface, accumulating around the irregularities.

- Experienced NDT professionals certified in accordance with NAS-410 and SNT-TC-1A.

- Compliance to industry standards and regulations (e.g., ASTM E1444, ASME V).

- Customized testing plans & detailed reports to fit your project’s unique requirements.

- Utilization of advanced magnetic particle testing equipment and techniques.

- On-site field testing for quick, real-time assessments of non-transportable assets.

- In-lab testing for in-depth analysis and controlled conditions.

Have a question or request for quote regarding Magnetic Particle Testing?

Dry Powder Applications

- Defects in Rough Surfaces

- Lack of Fusion in Welds

- Root Penetration

- Shallow Cracks

Wet Fluorescent Applications

- Fatigue Cracks

- Flakes

- Grinding Cracks

- Inclusions in aerospace blooms, billets, and bars

- Laps

- Quenching Cracks

- Seams

- Shrink Cracks

- Stress Corrosion Cracking

- Tears

- Welding Defects