3D Scanning &

Dimensional Inspection

DIMENSIONAL INSPECTION

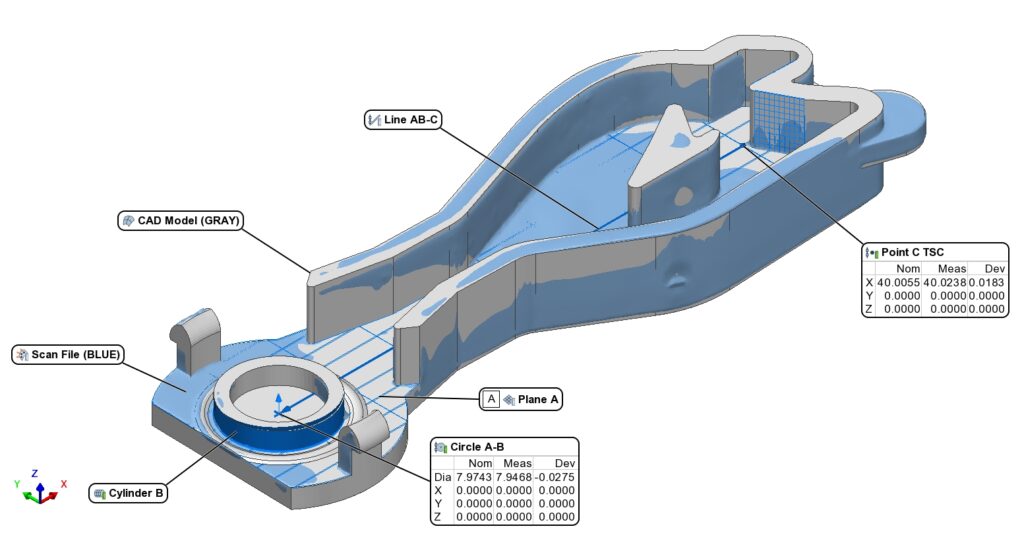

Dimensional inspection is the process of verifying manufactured products meet design requirements. The process includes receiving product data (CAD models, drawings, and measurement plans), devising the best method for data acquisition (scanning, probing, or hand tools), collecting the data, and reporting the data against nominal values and tolerances.

Industrial Inspection’s GD&T experts write complex, automated dimensional programs and offer GD&T consulting and software training.

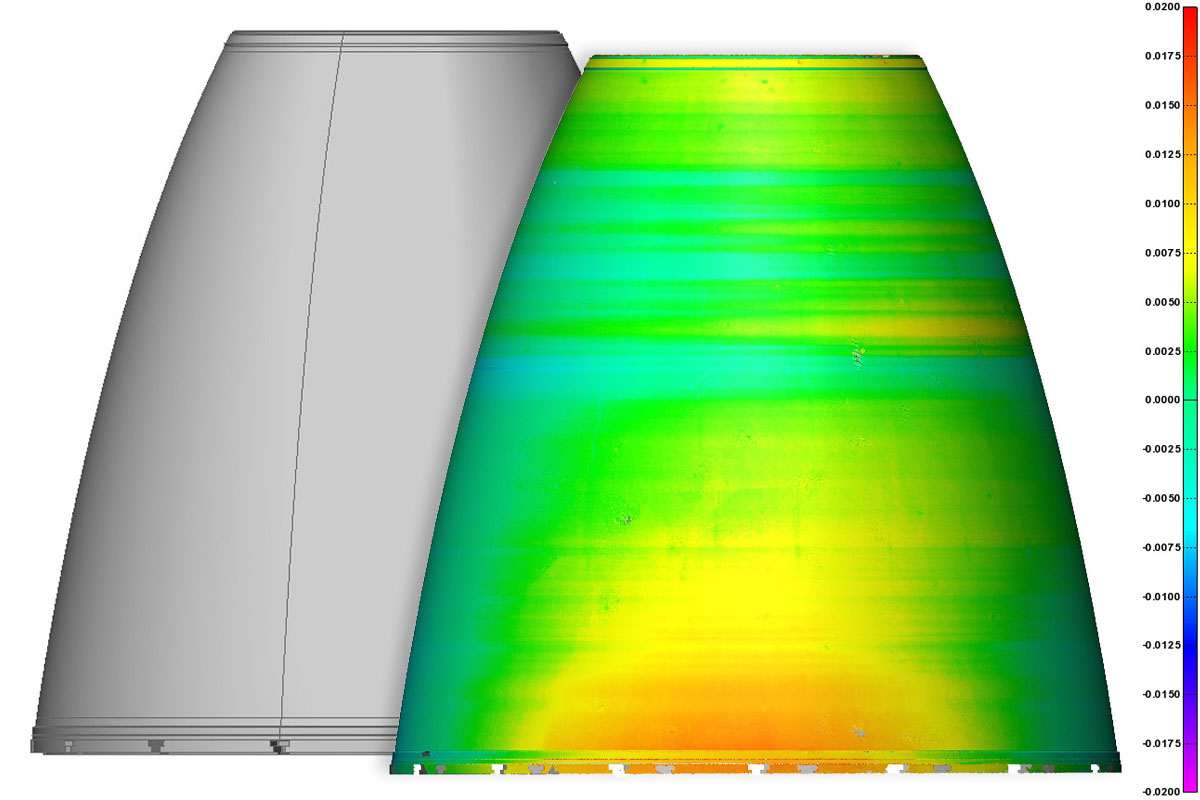

3D PROFILING

Scan to CAD deviation comparisons use color coded heat maps to quickly show any areas of concern.

GD&T & Dimensional Metrology

Perform complex, programmable GD&T like datum reference frames, profiling, positions, and more.

Have a question or request for quote regarding 3D scanning?

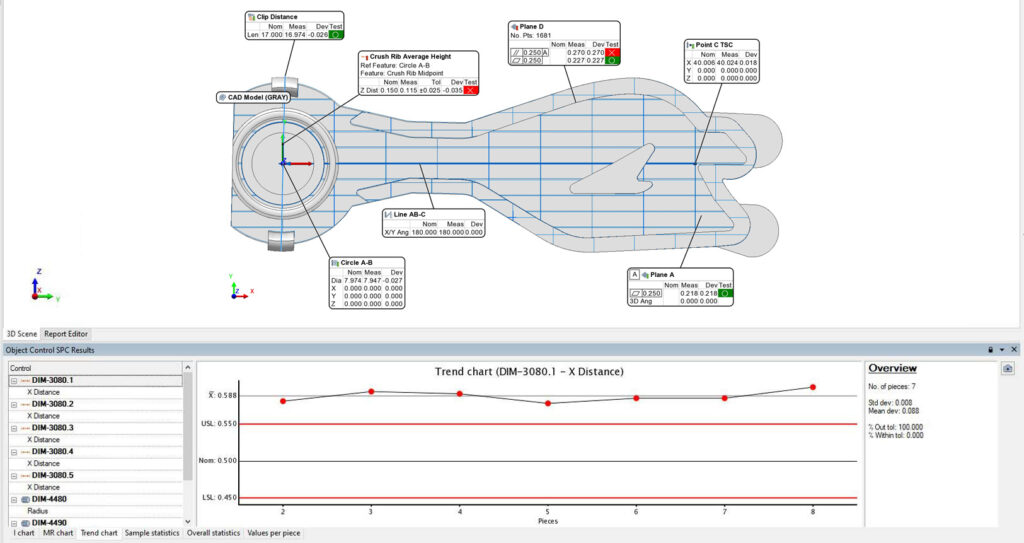

SPC DATA

Use statistical techniques to control your production method including trend charts and general statistics like mean and deviations and Cpk.

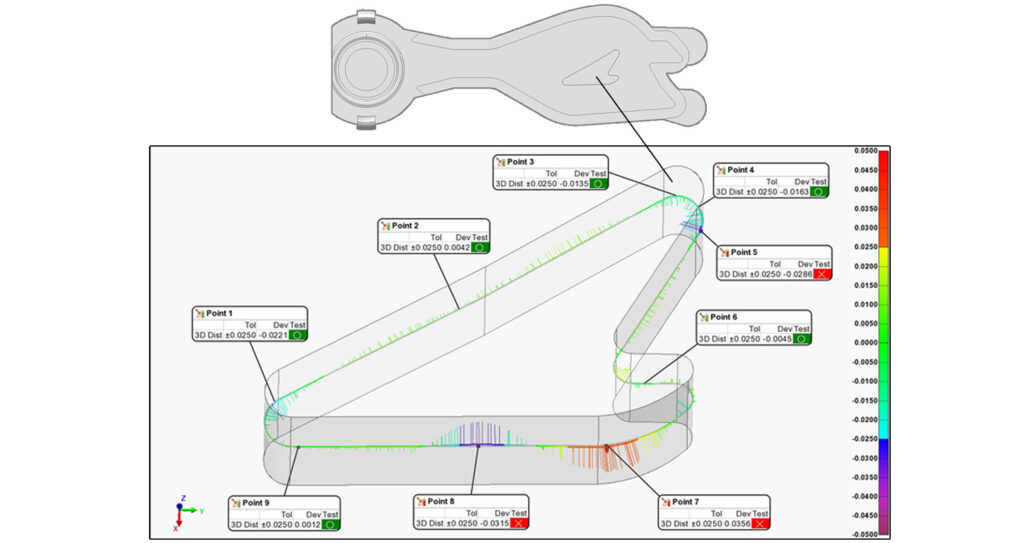

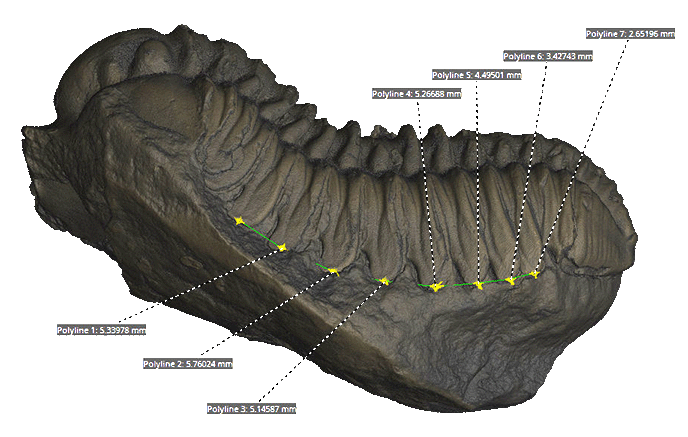

POINT MAPS & BALLOONED DRAWINGS

Point maps are used to show where dimensions are located – an important step for understanding how to fix out of tolerance features.

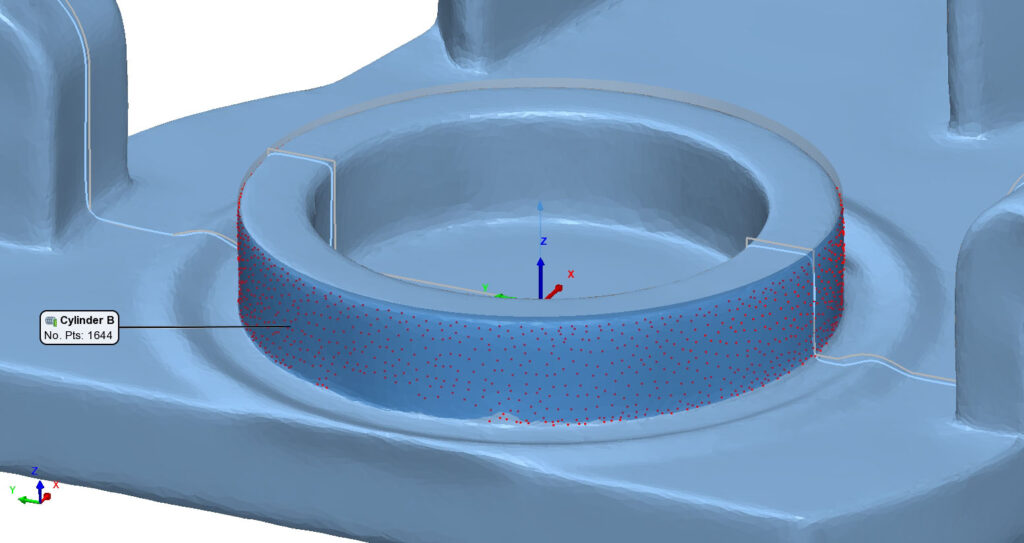

POINT DENSITY

3D Scanning captures entire surfaces rather than a minimal collection of points like stationary CMMs.

TOOL MATURATION

Free viewers like PolyWorks Reviewer & MyVGL allow clients to gather the results they need quickly and at no extra cost.

scan to cad comparisons

They say pictures are worth a thousand numbers. Scan to CAD comparisons are used to understand how a part differentiates from design intent. Sometimes we catch that an entire feature is missing. More typically, surfaces are slightly too high or low in a given area. Color coded heat maps describe these deviations – blue being low and red being high against nominal values.

MACHINE & SYSTEM ALIGNMENTS

Our portable CMMs allow us to travel to client locations to measure complex assemblies and systems. For example, we can help tune in manufacturing lines for better repeatability, come to manufacturers to scan their tooling, and measure infrastructure. We can then bring this data back to our lab for data processing and reporting.

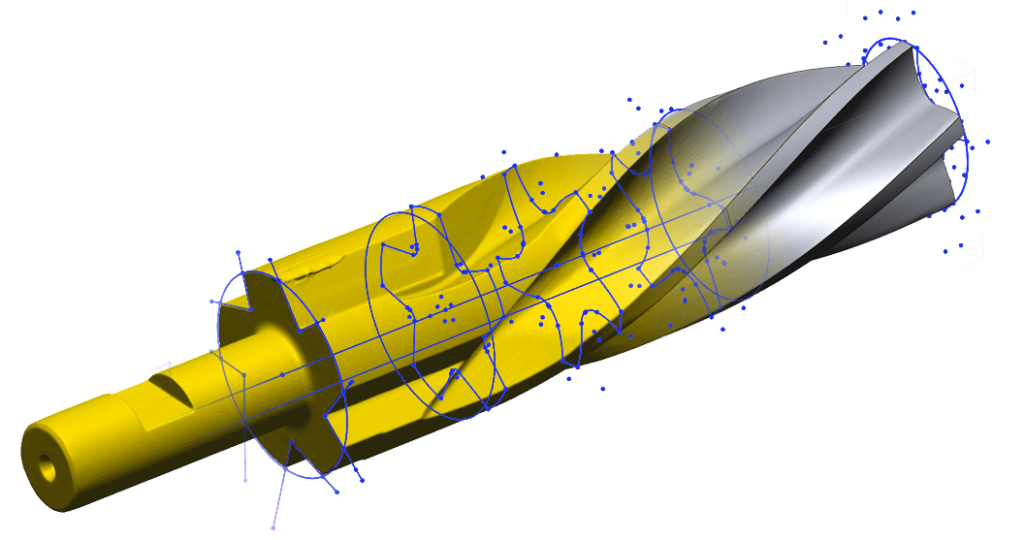

reverse engineering

By acquiring high quality laser or CT scan data, setting up alignments in PolyWorks, and deploying unmatched modeling tools in Geomagic Design X, we can reproduce just about anything into a parametric design .step model.

DIGITAL TWIN SCANNING

Digital twin is the process of creating accurate, high detail digital versions of physical objects. The data is used for a variety of applications like:

Forensics & Historical Archiving – creating digital replicas before the scene or object changes

3D Printing – Reproducing objects with incredible detail at a different scale

Art, Design & Marketing – digitizing hand crafted goods like sculptures for manufacturing or sales purposes

PolyWorks Metrology Suite is the premier software package for scan data acquisition, manipulation, inspection, and reverse engineering. With ASME and ISO implemented standards, the software is capable of producing complex, automated GD&T programs for statistical process control, first article inspections, complex virtual alignments, and more.

Geomagic Design X is the premier software package for scan data manipulation and reverse engineering. It offers the ability to design CAD models while sketching and extracting reference points directly from the scan file. It also offers the ability to incorporate design intent for feature correction like perfect hole patterns and sizes, surface parallelism, and symmetry.