3D Printing

& Fixturing

3D & CT SCANNING HOLDING FIXTURES

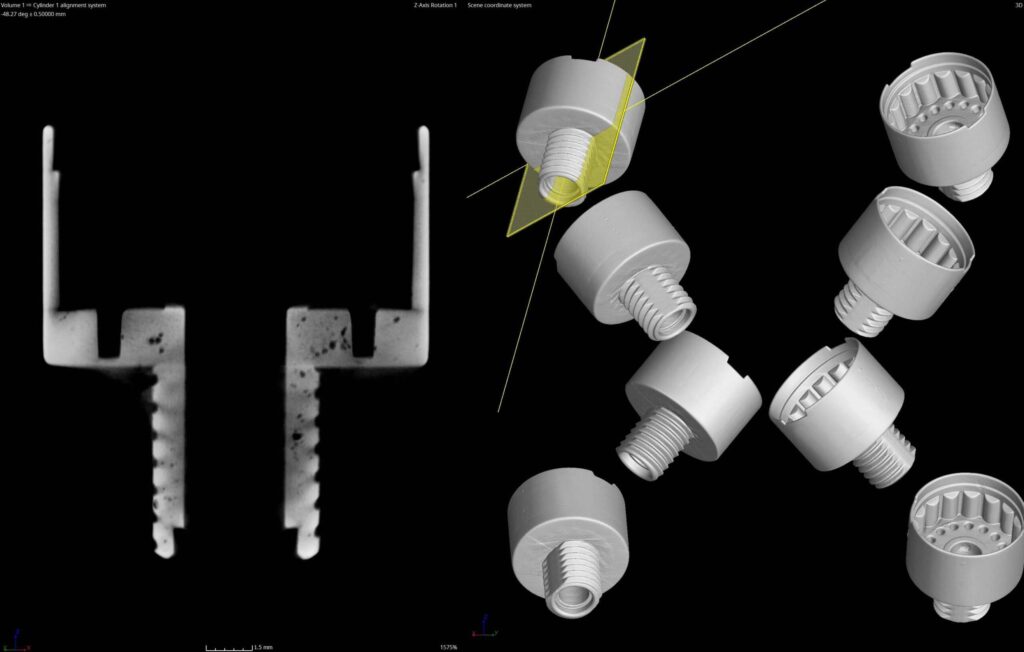

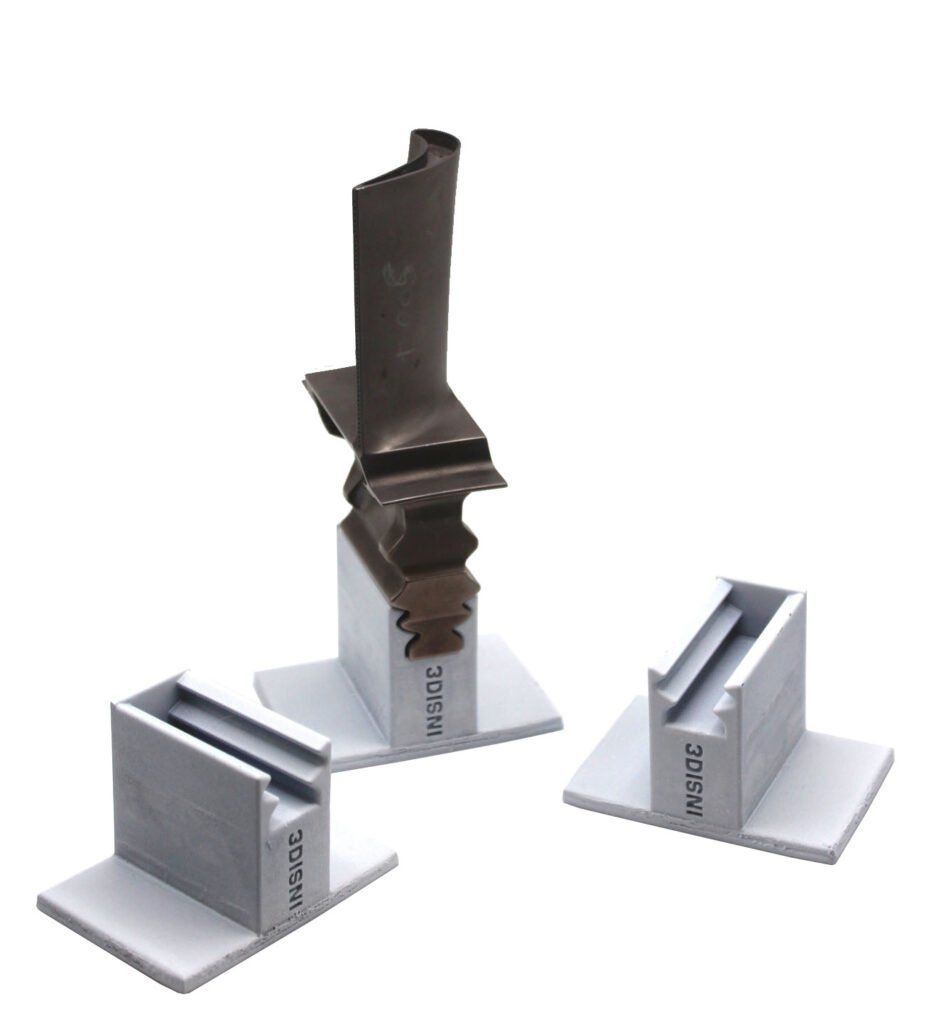

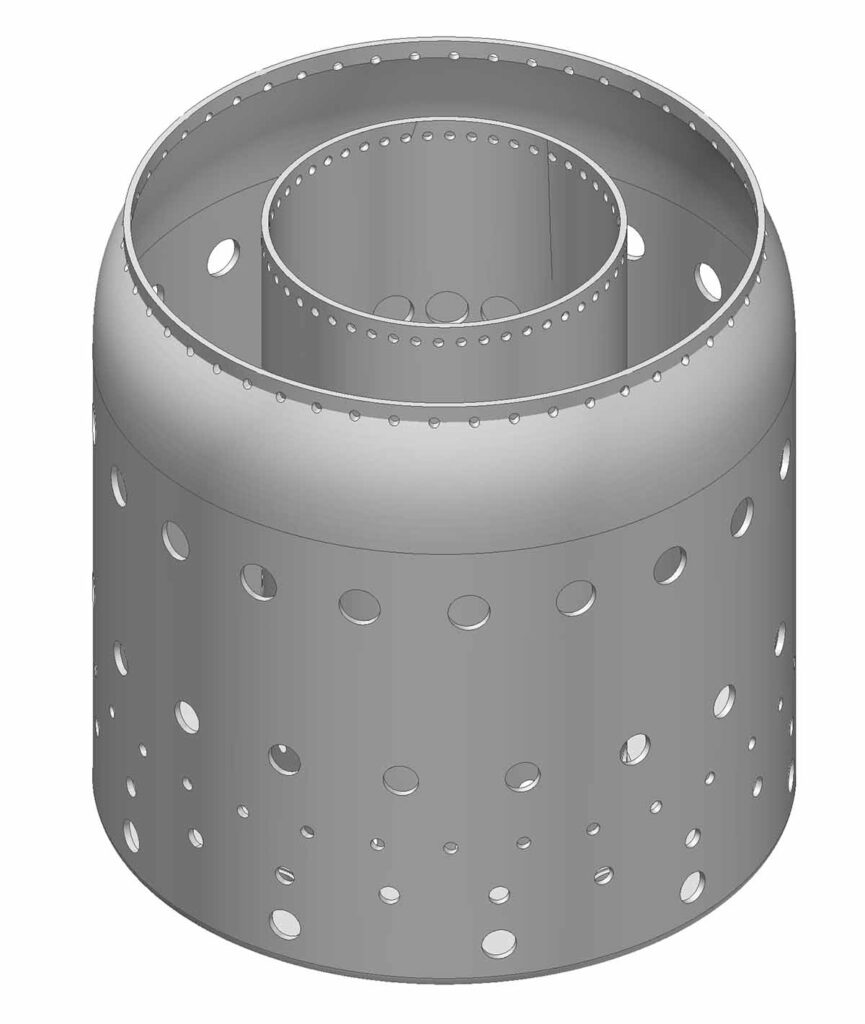

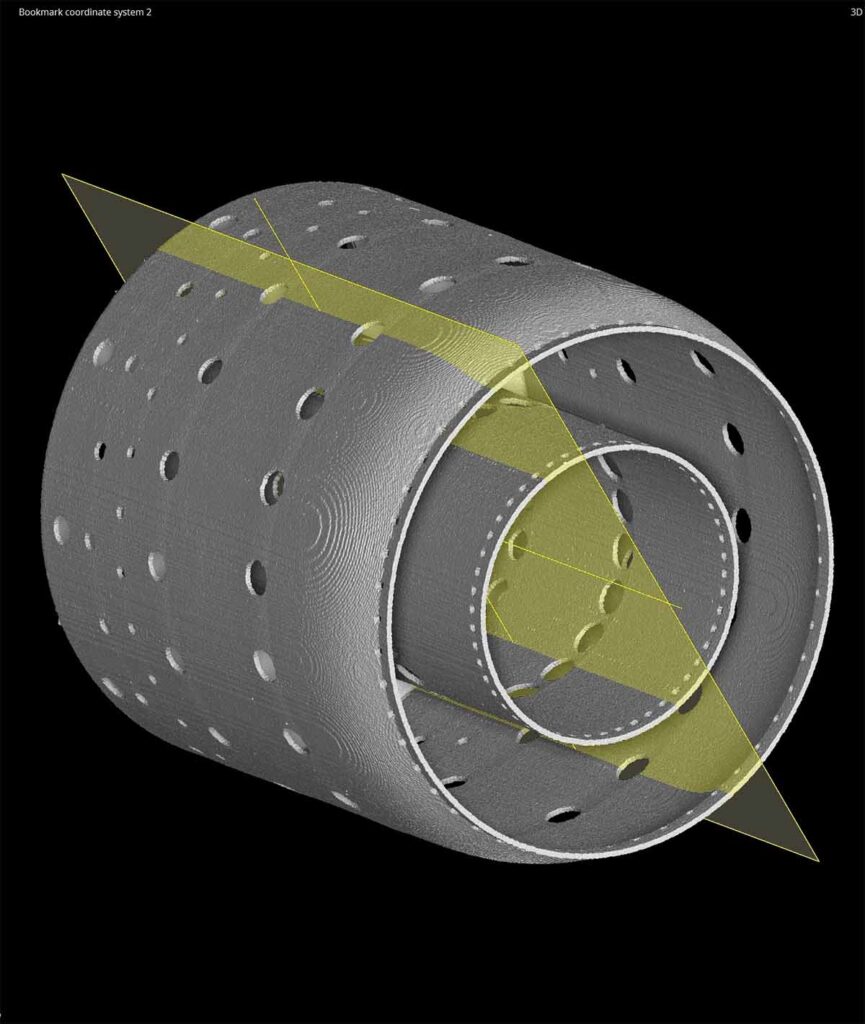

Fixturing is used for 3D scanning, CT scanning, and radiography to hold components in specific positions that are optimal for data acquisition. Optimal positions include repeatable locations, specific angles, and batch scanning parts to improve output and reduce cost for clients.

For example, we designed a fixture to hold eight of these small castings at optimal angles in a single batch scan. This optimization significantly reduces run rates and costs for our clients.

CUSTOM TOOLS & GADGETS

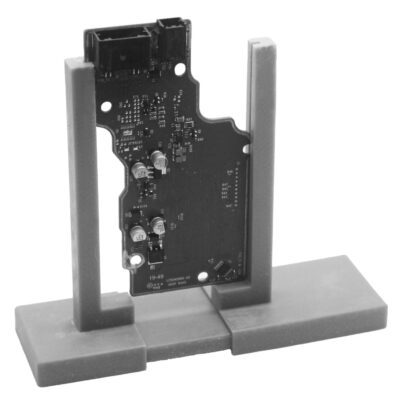

We design and build custom tools and gadgets for practical applications. For example, over the years it has been a challenge holding PCBs that come in various shapes and sizes. We created an adjustable PCB holder that sleeves over the edges and opens for various sizes.

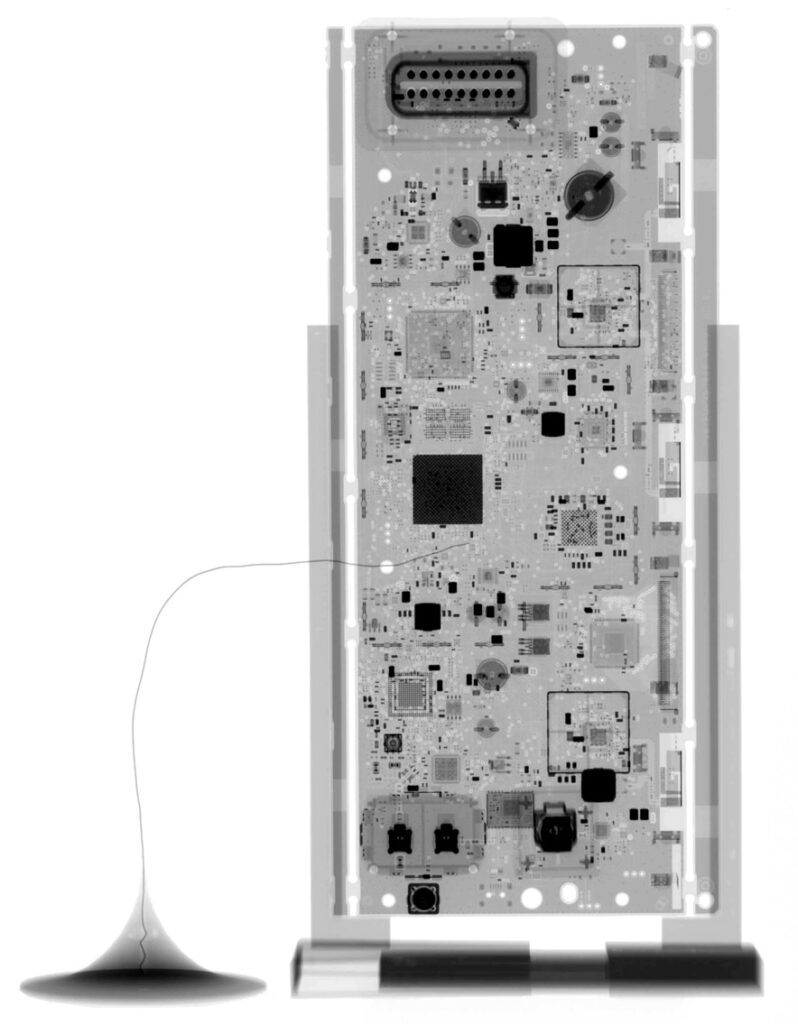

Another challenge with component-rich PCBs is that it can sometimes be challenging finding an area of interest when the geometries all appear similarly. This wire indicator allows us to point at areas of interest to quickly locate them while moving parts inside our x-ray systems.

PROTOTYPING & TESTING

We offer 3D printing, prototyping, and inspection services. If you have a new design that you’d like a prototype of to test for fitment, we can quickly produce it and inspect it for flaws and verify its dimensional characteristics.

DESIGN FILE

Send us a design .STEP or .STL. We can also modify existing parts with new designs.

3D PRINT

We will optimize and print the file or a batch of files for inspection and to ship to the client.

CT SCAN

Using 3D scanners like our Industrial CT Scanners we can collect water tight, high resolution data of the part.

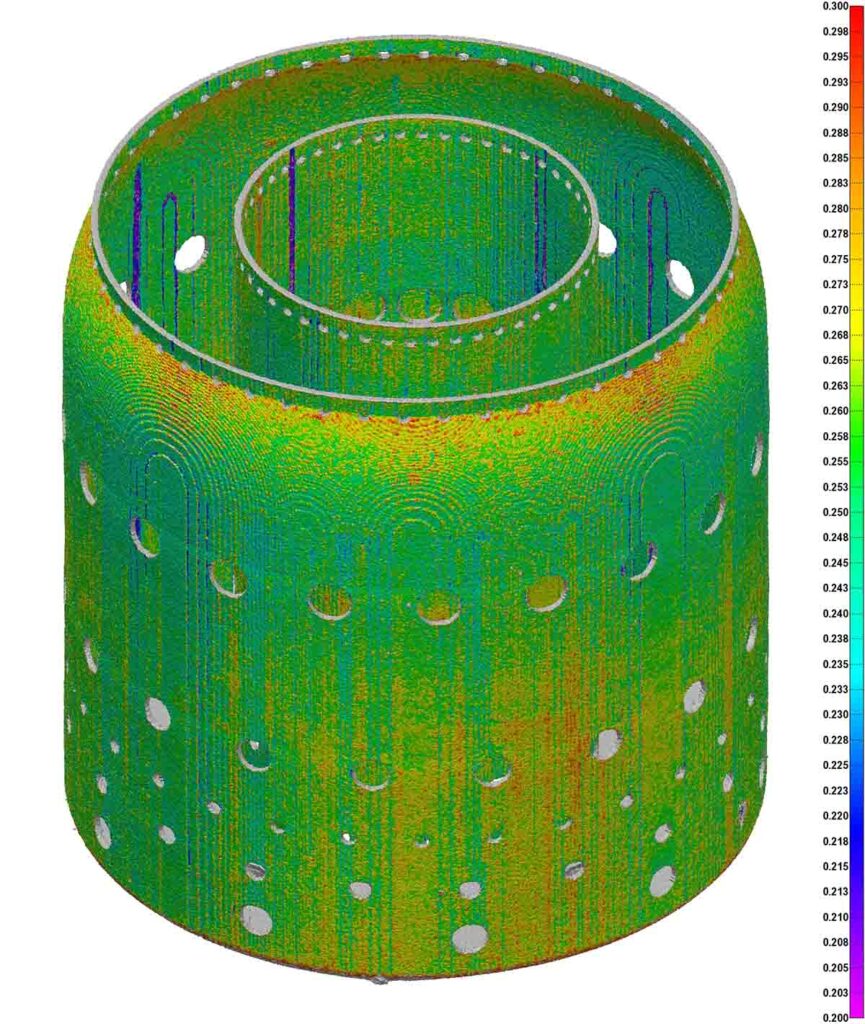

MEASURE

We can measure wall thickness, hole positions, and complex GD&T to confirm design requirements.

COMMISSIONS & ART

We receive commissions for prototyping and building custom orders. CT scan data provides several advantages that other provides cannot provide – very high resolution & water-tight, internal geometry. For example, we CT scanned a spider, extracted its spinnerets, and printed a visually striking, scaled up version.

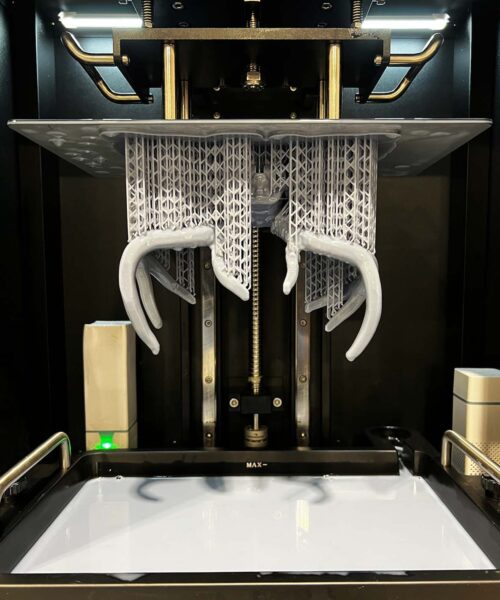

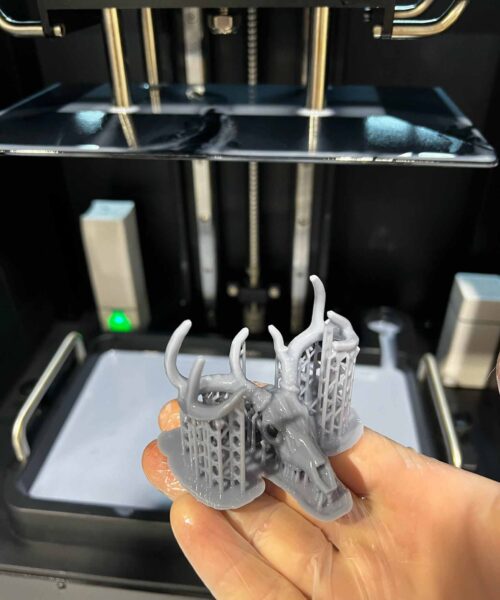

This skull and antlers was commissioned by a client who wanted a desktop replica of his first kill for his dad’s office desk. We created a batch CT scan, simplified the data, scaled it down to fit in the palm of your hand, printed, and painted it.