PROGRAMMABLE VISION &

SURFACE FINISH SERVICES

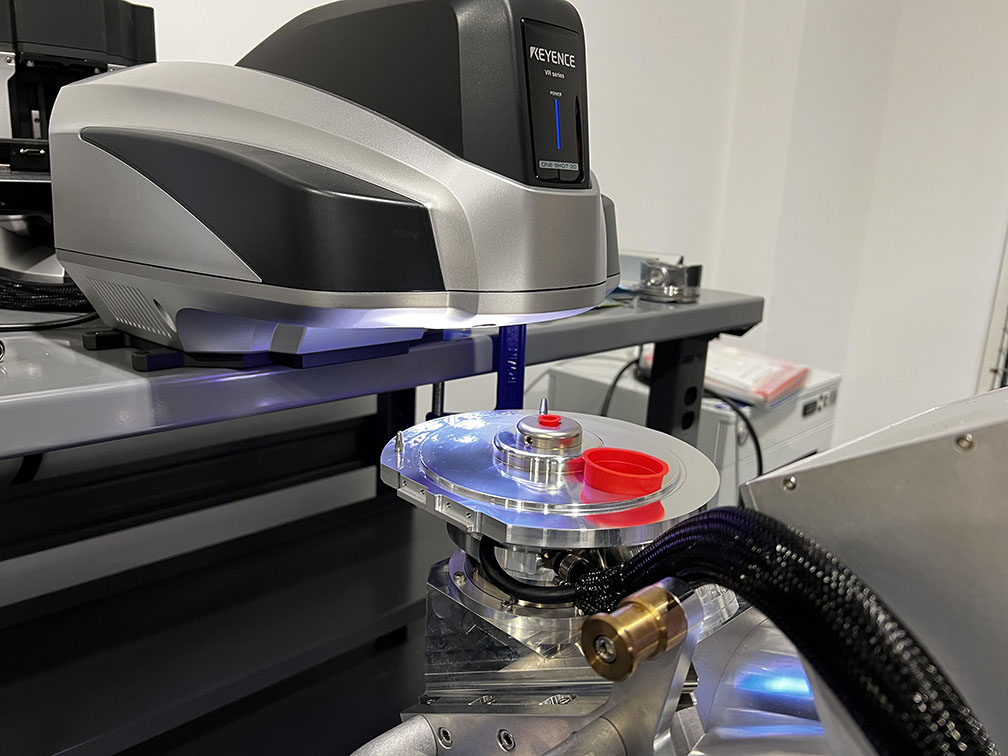

In the fast-paced world of manufacturing and quality control, precision and accuracy are non-negotiable. Our Keyence VR 6000, a cutting-edge optical, non-contact, programmable surface roughness and metrology inspection system is revolutionizing the way our clients approach quality assurance.

Traditional methods of vision and surface inspections can be time-consuming and prone to error, but with the Keyence VR 6000, we offer a powerful tool that delivers unparalleled accuracy and efficiency. This state-of-the-art system allows for high-speed, non-destructive measurements, providing crucial insights into surface finish and dimensional characteristics without physical contact.

VR 6000 OPTICAL PROFILOMETER

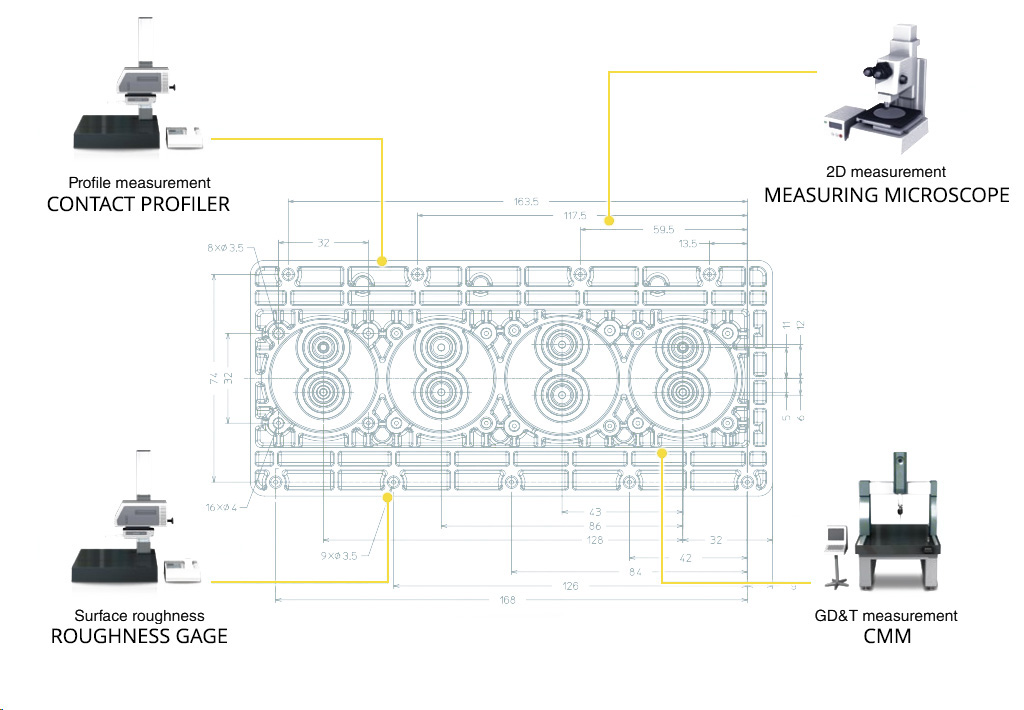

The VR Series offers the best features of multiple measurement systems in one device

VISION & SURFACE FINISH CASE STUDIES

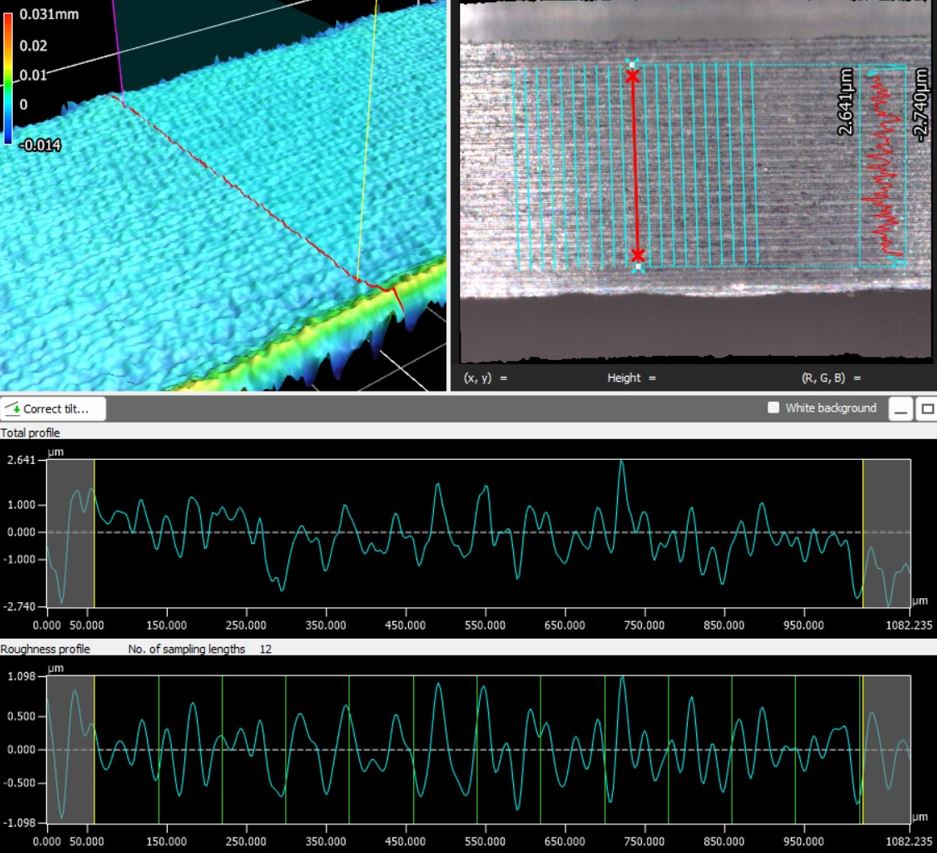

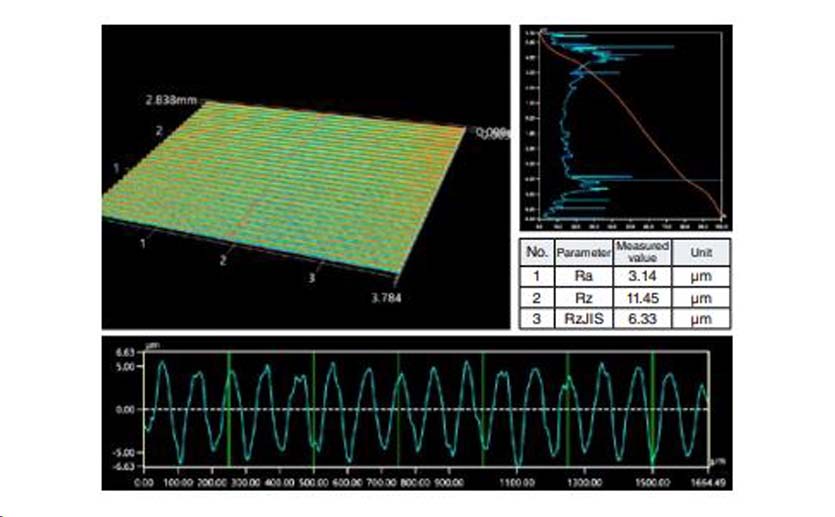

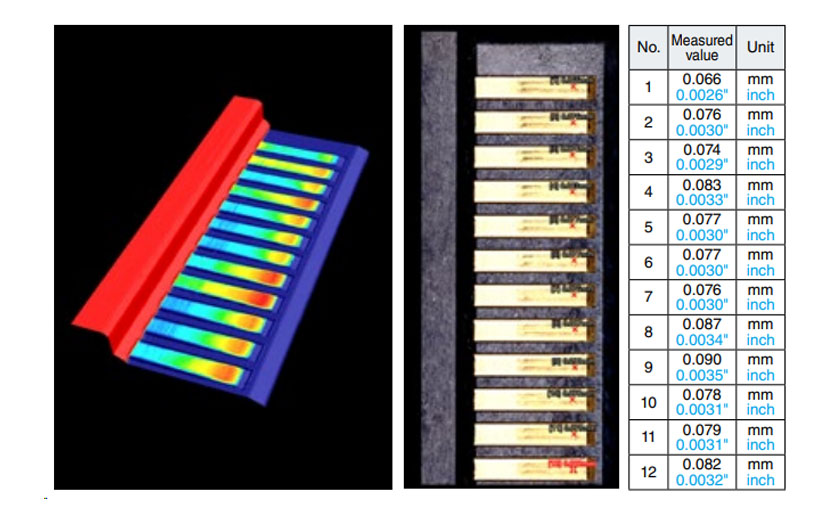

SURFACE FINISH & COATING THICKNESS

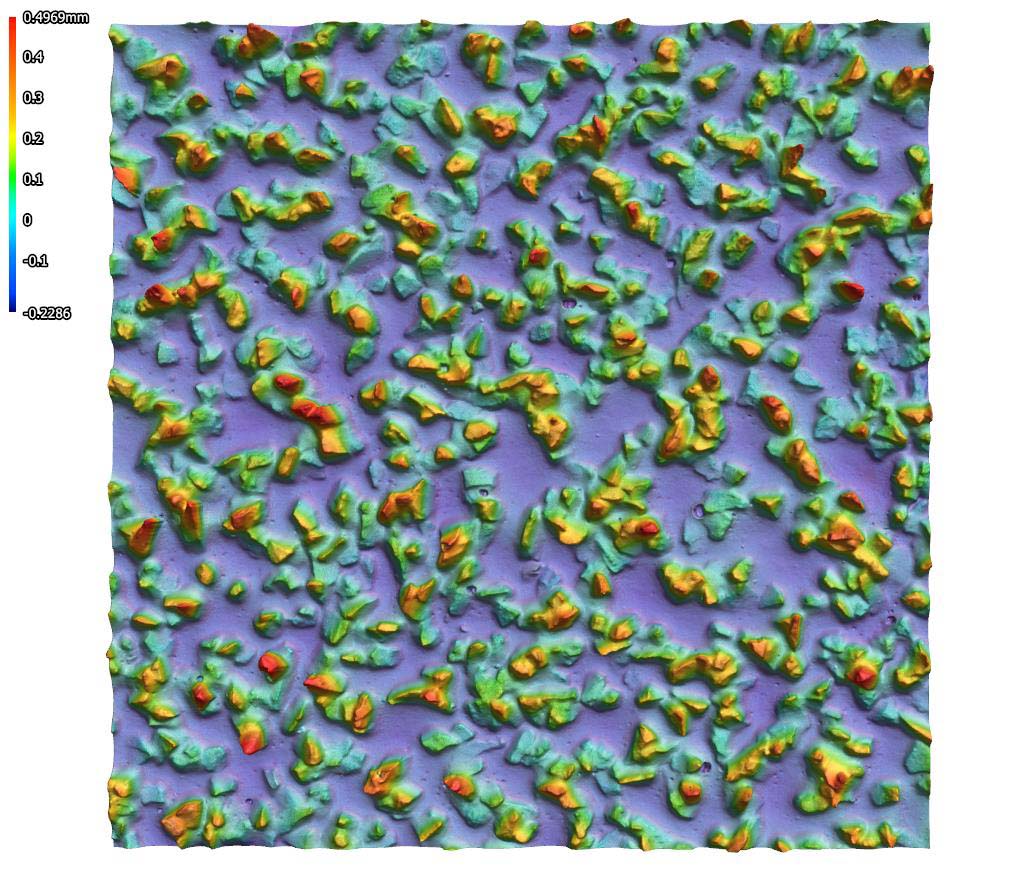

By capturing full surface data with 0.1 µm resolution, we quickly and repeatably measure roughness parameters, such as Ra and Rz, to JIS and ISO standards. And with some coating thicknesses being 3 microns thick or less, non-contact, optical inspections are the best approach for data acquisiton.

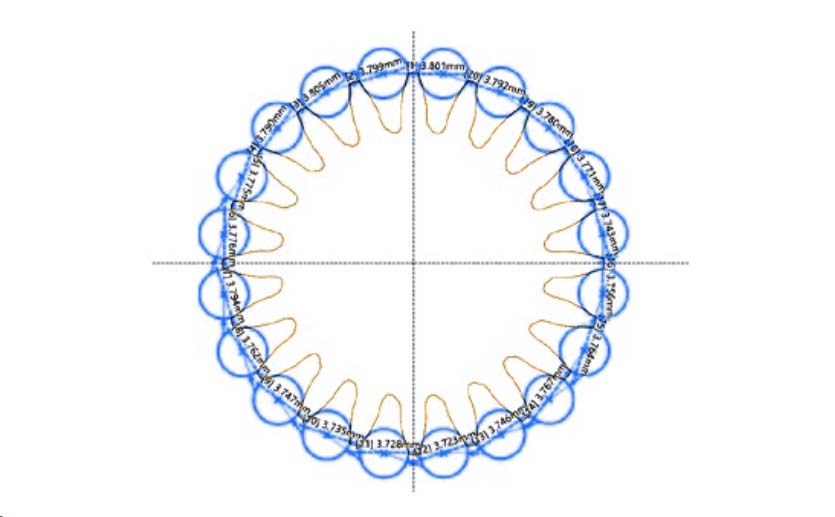

PROGRAMMABLE 2D & 3D MEASUREMENTS

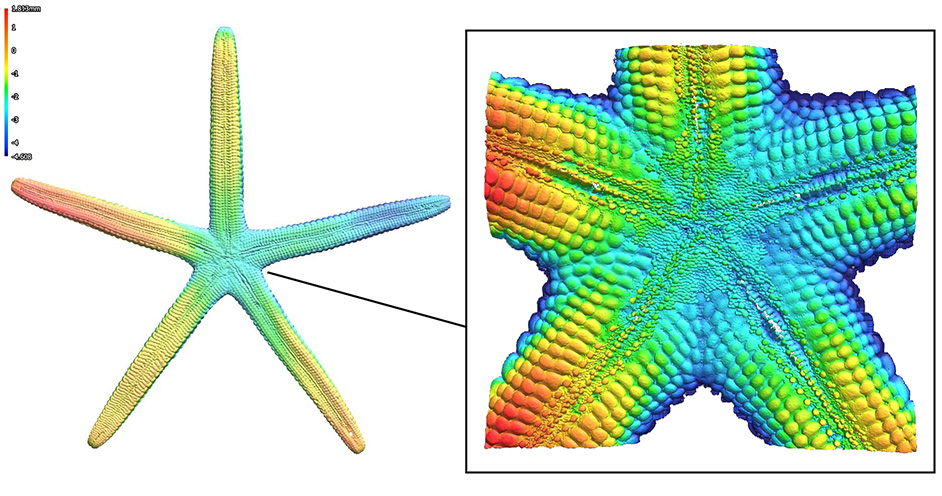

Some geometries, like small metal gear profiles, may be too small to resolve using our standard tactile probe CMMs, laser scanners, or CT scanning systems. The VR 6000 has fully programmable and reportable 2D Vision & 3D scanning capabilities.

REVERSE ENGINEERING

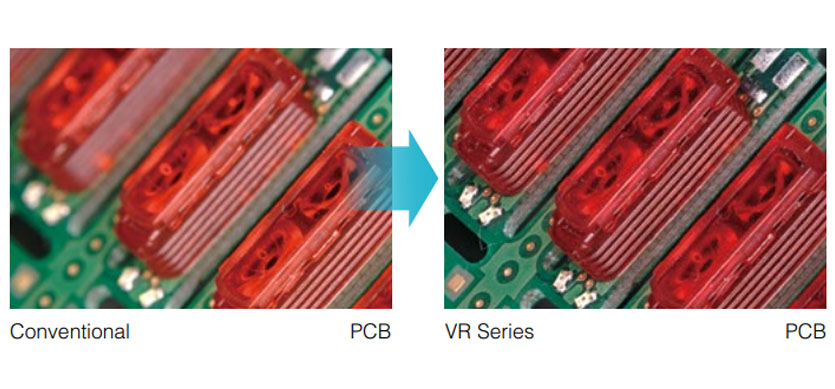

Optical vision systems aid in reverse engineering CAD projects by providing precise measurements and detailed visual data of physical objects that more traditional, lower resolution systems cannot characterize. For example, a laser scanner or tactile probe is incapable of measuring PCB pin perimeters.

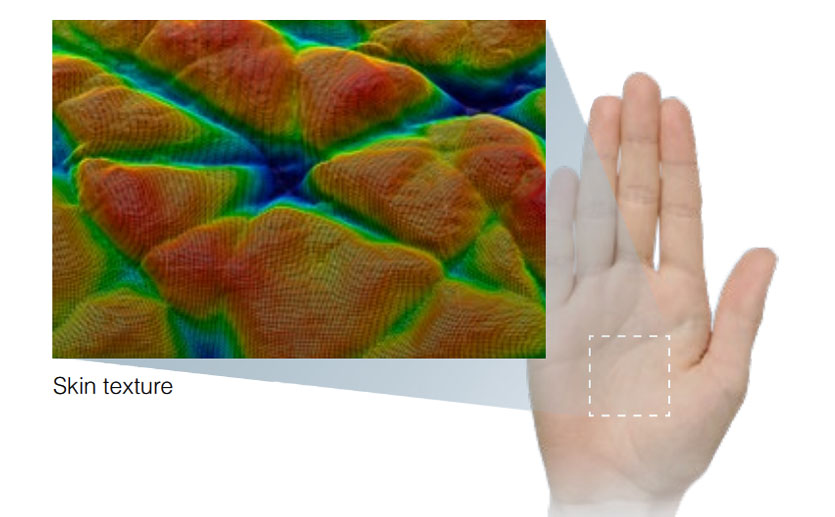

NANOMETER RESOLUTION STL OUTPUT

Nanometer resolution STL files are used for highly detailed and precise 3D modeling and manufacturing tasks for industries such as nanotechnology, microelectronics, semiconductors, scientific instrumentation, photonics, and material science.

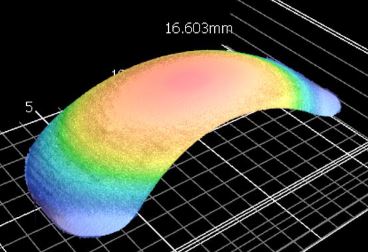

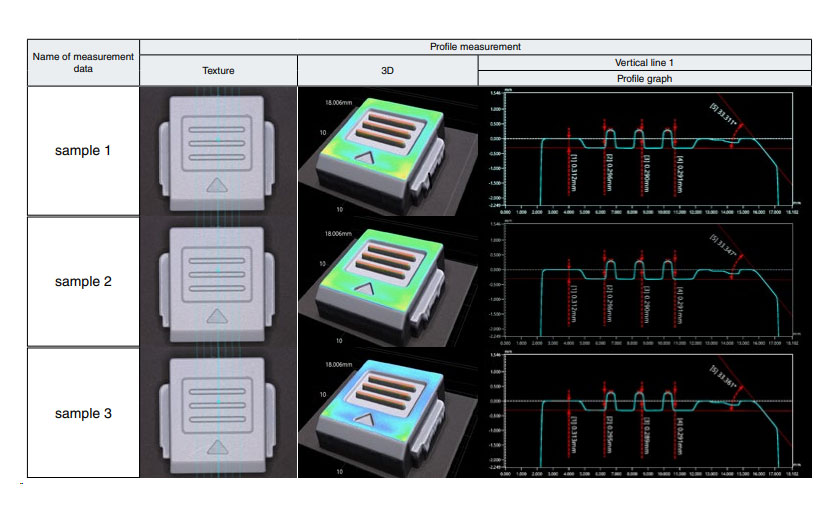

PART TO PART OR CAD COMPARISONS

CAD data can be superimposed on measurement data to determine whether complex profiles match design specifications. Prototypes, manufactured parts, or deviating but better functioning products can be quickly evaluated to numerically define their characteristics.

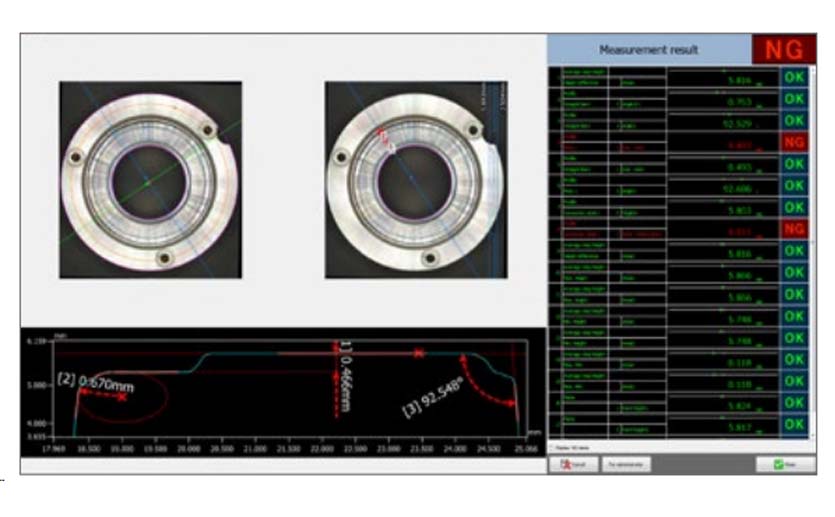

PASS / FAIL SORTING

By setting the measurements and tolerances, we can obtain pass/fail inspection judgements based on the measurement results. All of the pre-configured measurements are performed automatically with the click of a button.

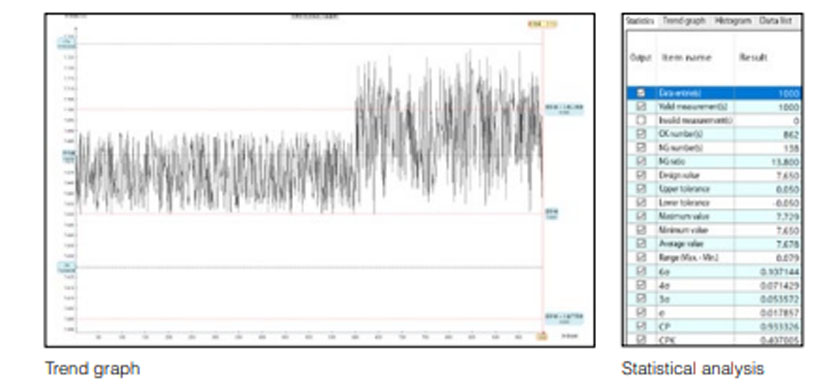

SPC / STATISTICAL ANALYSIS FUNCTIONS

Major statistical values can be automatically calculated and displayed from the inspection results. Information such as the measured date/time and lot number is also automatically saved, so users can easily search for the results of previous measurements. Graphs and histograms are automatically created for quick visualization of trends.

VISUAL OBSERVATIONS (12x-160x mag)

Deploying a telecentric lens, the VR 6000 offers unprecedented visual observations with high resolution, low distortion, and a deep depth of field. When a sample has a large height change the depth composition function can be used to capture multiple images of the sample across different focal planes, creating a fully focused image.