Dimensional Repeatability, Fitment Evaluations, and Internal Defect Detection using CT Scanning

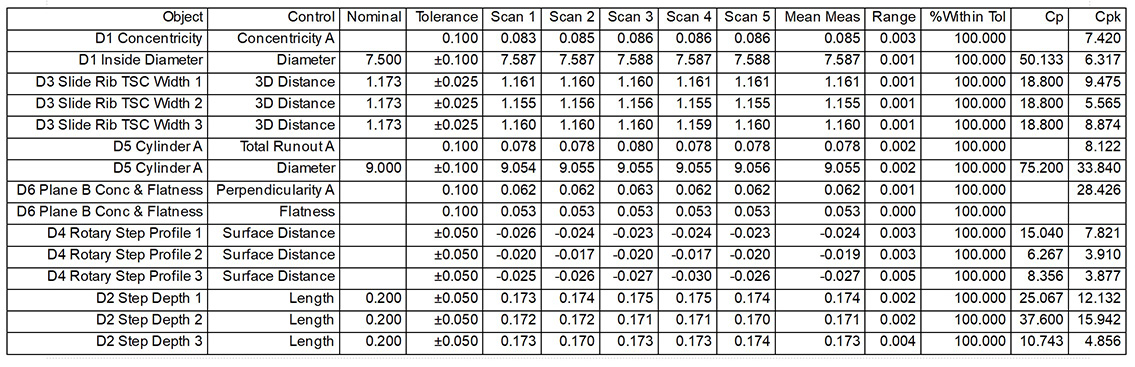

In this validation study we performed five independent CT scans of a small injection-molded rotary housing to assess process repeatability. The results confirm the exceptional stability and consistency of our ISO17025 accredited CT metrology process. This repeatability is critical for applications requiring high-accuracy quality control, reverse engineering, or first article inspection of polymer components with challenging geometries.

Cp (Process Capability) is a statistical measure that indicates how well a process can produce outputs within specified limits, specifically focusing on the potential capability of the process. It assesses whether the inherent variability of the process is narrow enough to consistently meet customer specifications.

Cp < 1: The process is not capable of meeting specifications, meaning the process variation is too wide relative to the specification limits.

Cp > 1: The process is capable of meeting specifications, with the process variation being narrower than the specification limits. A higher Cp value indicates amore capable process.

Cp ≥ 1.33: A highly capable process, meaning the process variation is significantly narrower than the specification limits.

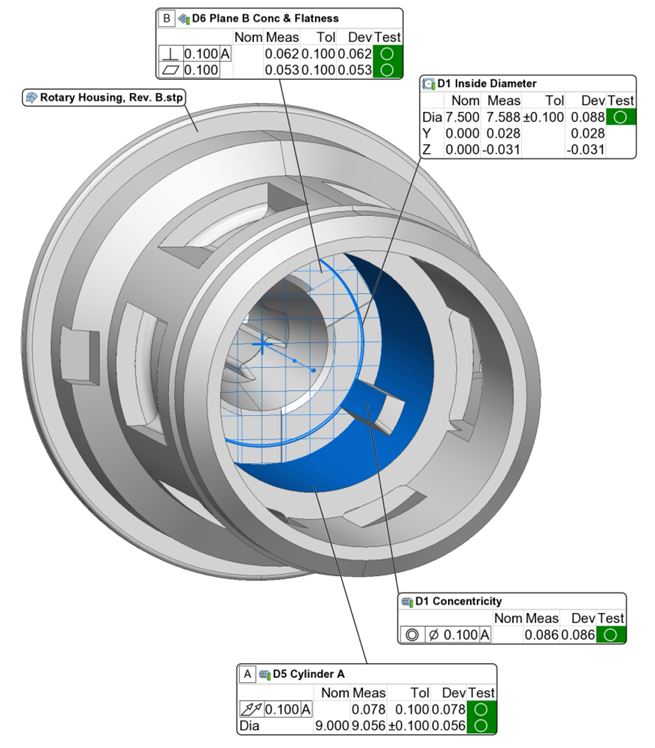

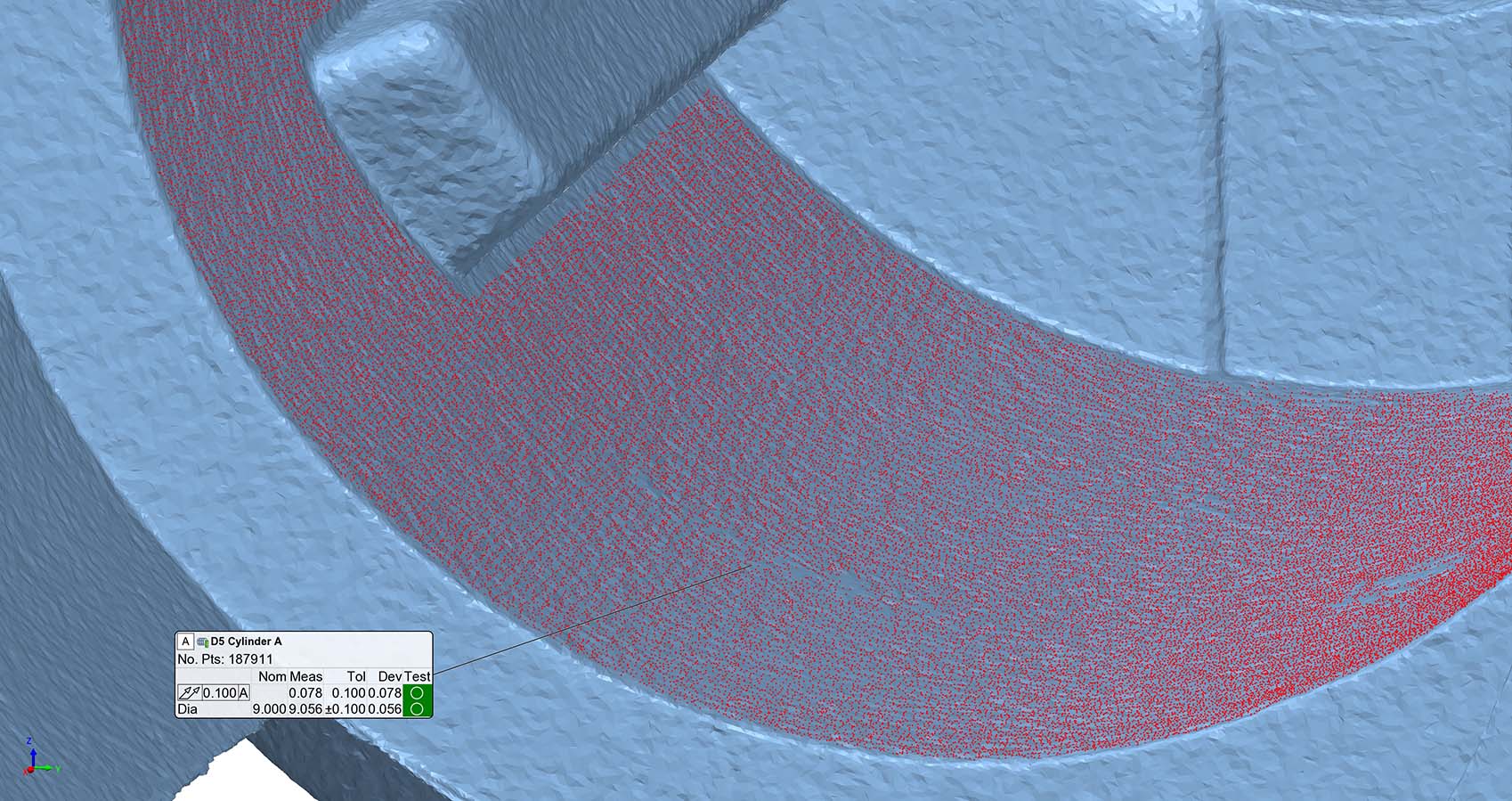

CT scanning generates an exceptionally high-density point cloud, enabling precise feature extraction far beyond the capabilities of traditional tactile metrology. For example, one of the cylinders extracted in our rotary housing study used 187,911 surface points compared to just 6 probed points typically used in a CMM inspection. This point density allows for robust statistical analysis, minimizes sensitivity to local surface anomalies, and captures form deviation in a way that tactile probing cannot.

However, extracting meaningful and repeatable geometry from such dense data requires careful control of software parameters. In PolyWorks, refinement settings like boundary exclusion distance help remove edge effects and noise from the fitted region, critical for features near parting lines or transitions. Feature constraints, such as enforcing symmetry or axis alignment, improve consistency across parts and scans. The fit type (best-fit, least squares, maximum inscribed) directly influences how the software interprets the feature’s true geometry, which can impact tolerancing and GD&T evaluations.

Without careful tuning of these parameters, high-density data can lead to misleading results. But when properly configured, CT combined with advanced feature extraction provides unmatched insight and repeatability.

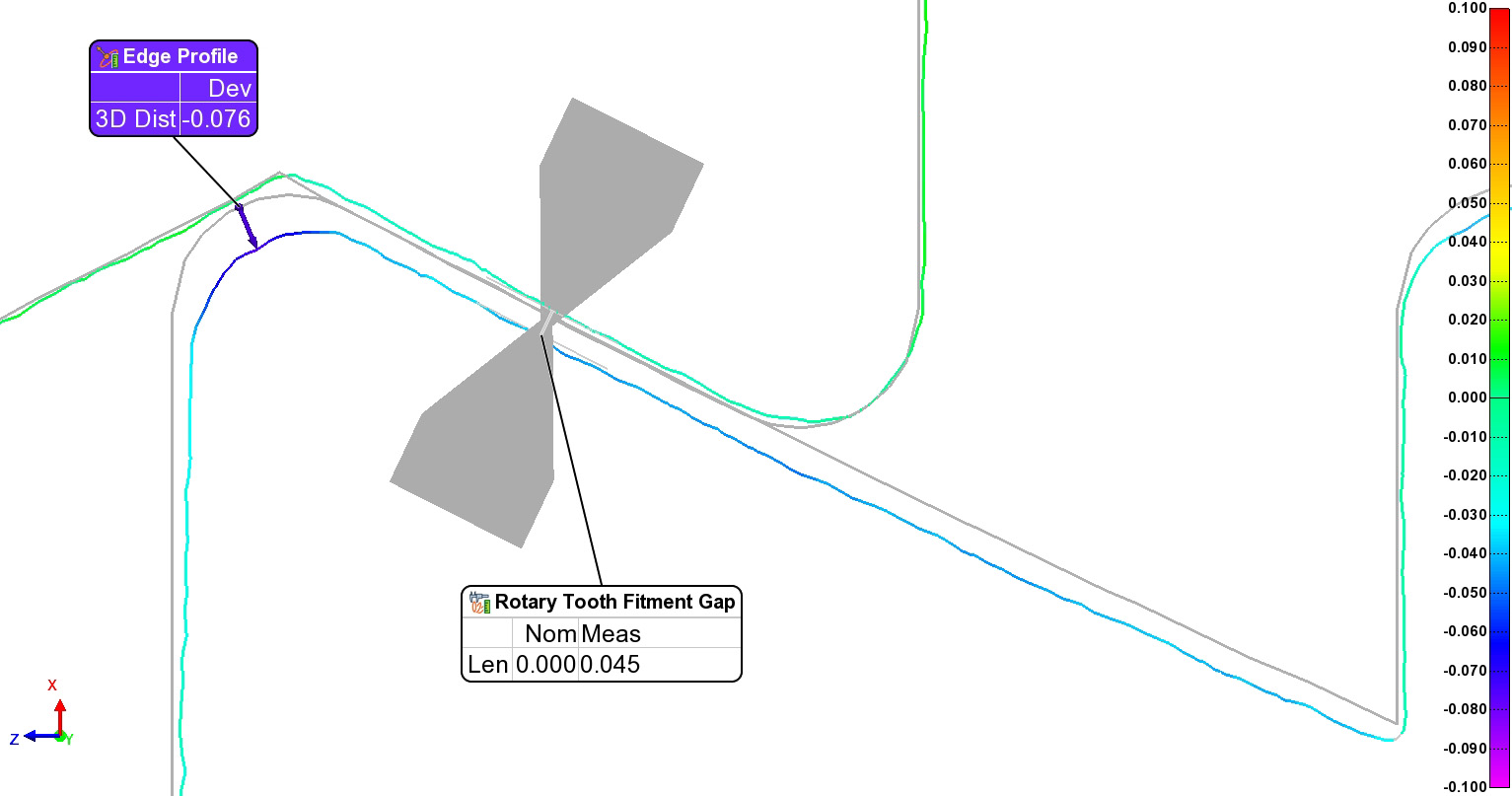

Beyond conventional variable metrology and PPAP dimensional inspection, CT scanning provides a deeper layer of insight, particularly when it comes to understanding real-world fitment and assembly behavior. While datum alignments are essential for establishing measurement frameworks, they don’t always fully capture how parts truly mate and interact in assembled conditions.

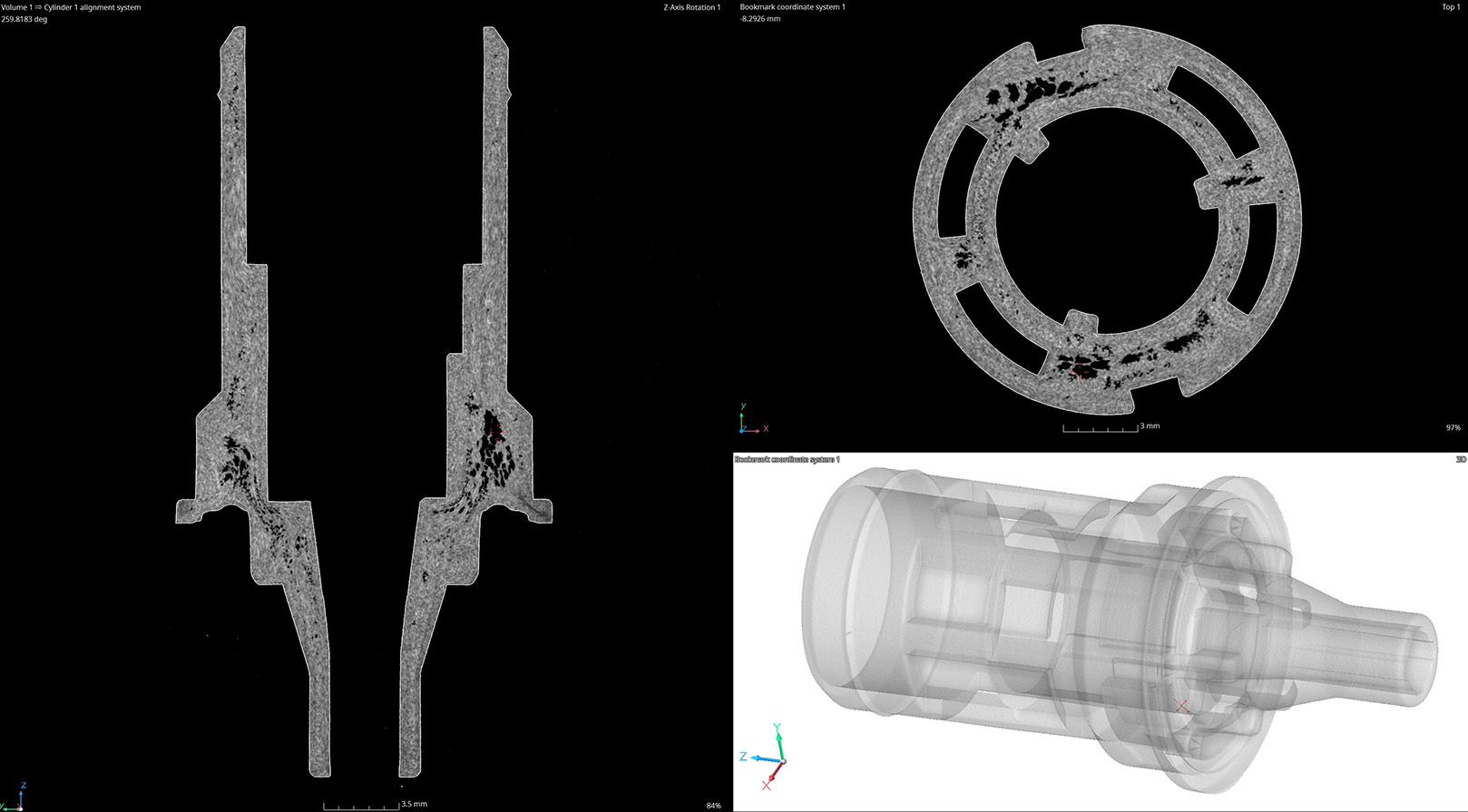

In this case, we scanned a partial assembly of a rotary housing components and were able to analyze the clearance between the rotary teeth – features that are inaccessible to CMMs or optical scanners due to line-of-sight and probe access limitations.

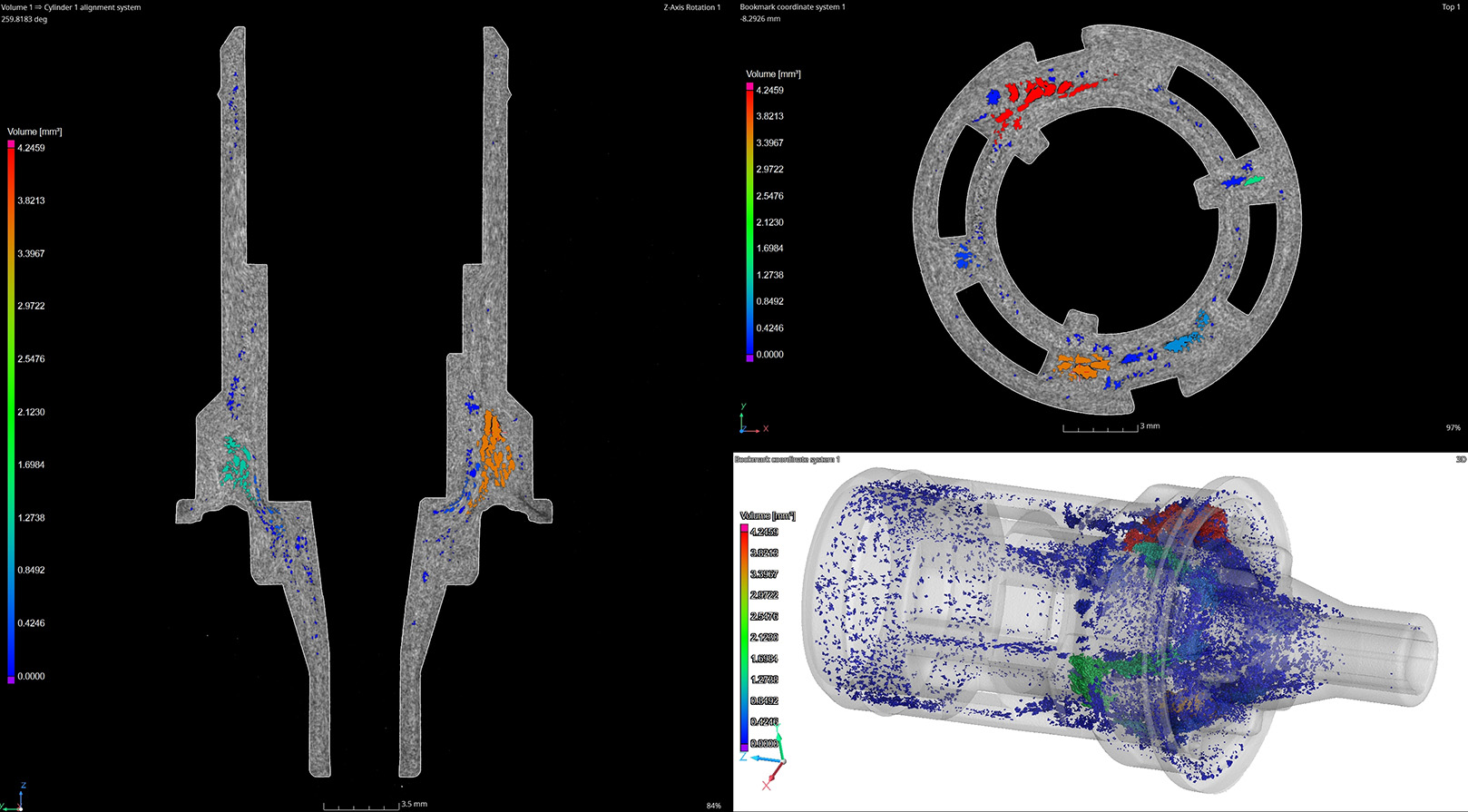

In addition to its metrology capabilities, CT scanning is a powerful tool for evaluating porosity, inclusions, and validating mold flow predictions in plastic and composite components. Its ability to capture full 3D volumetric data non-destructively makes it uniquely suited for analyzing internal material conditions that are invisible to surface-based inspection techniques.