Eddy Current Inspection Services of Cracked Steel Plates

Eddy Current Testing (ET) is a powerful & value-saving nondestructive method for ensuring product quality and providing failure analysis.

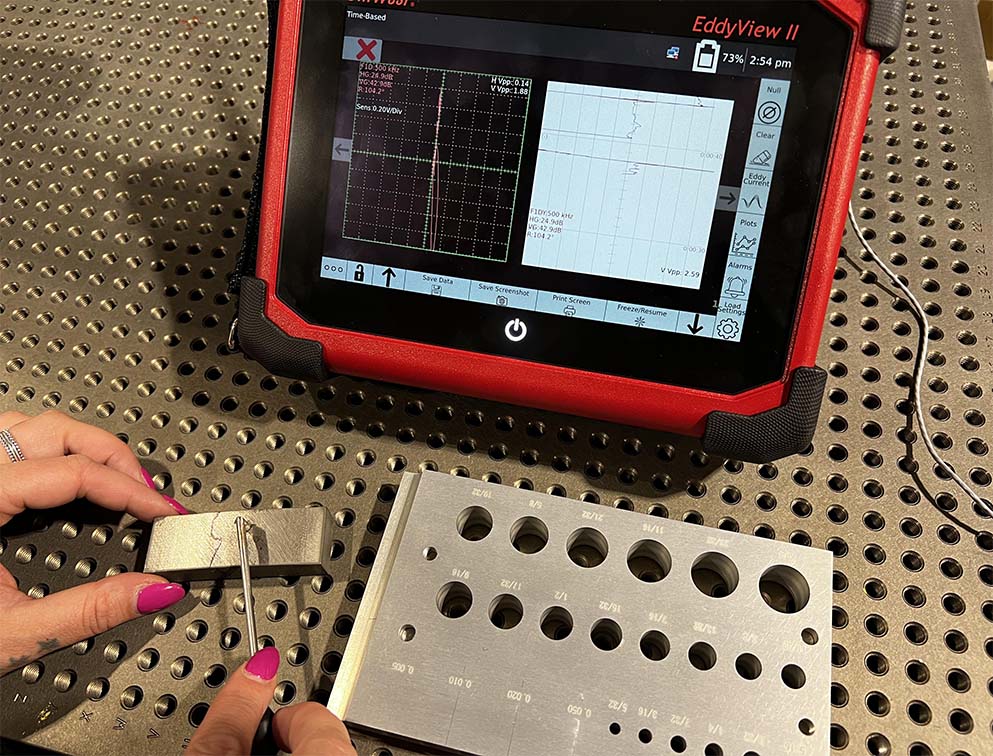

Recently, we inspected steel test bars using a 500 kHz pencil probe. This high-frequency setup concentrates eddy currents at the surface, making it ideal for detecting fine, surface-breaking flaws in ferromagnetic materials like steel.

During inspection, we identified a series of circumferential indications—micro-tears that could have easily gone unnoticed. Based on signal response and calibration, we were able to estimate the depth of the surface-breaking flaws to be approximately 0.02 inches, providing critical insight into the severity of the damage.

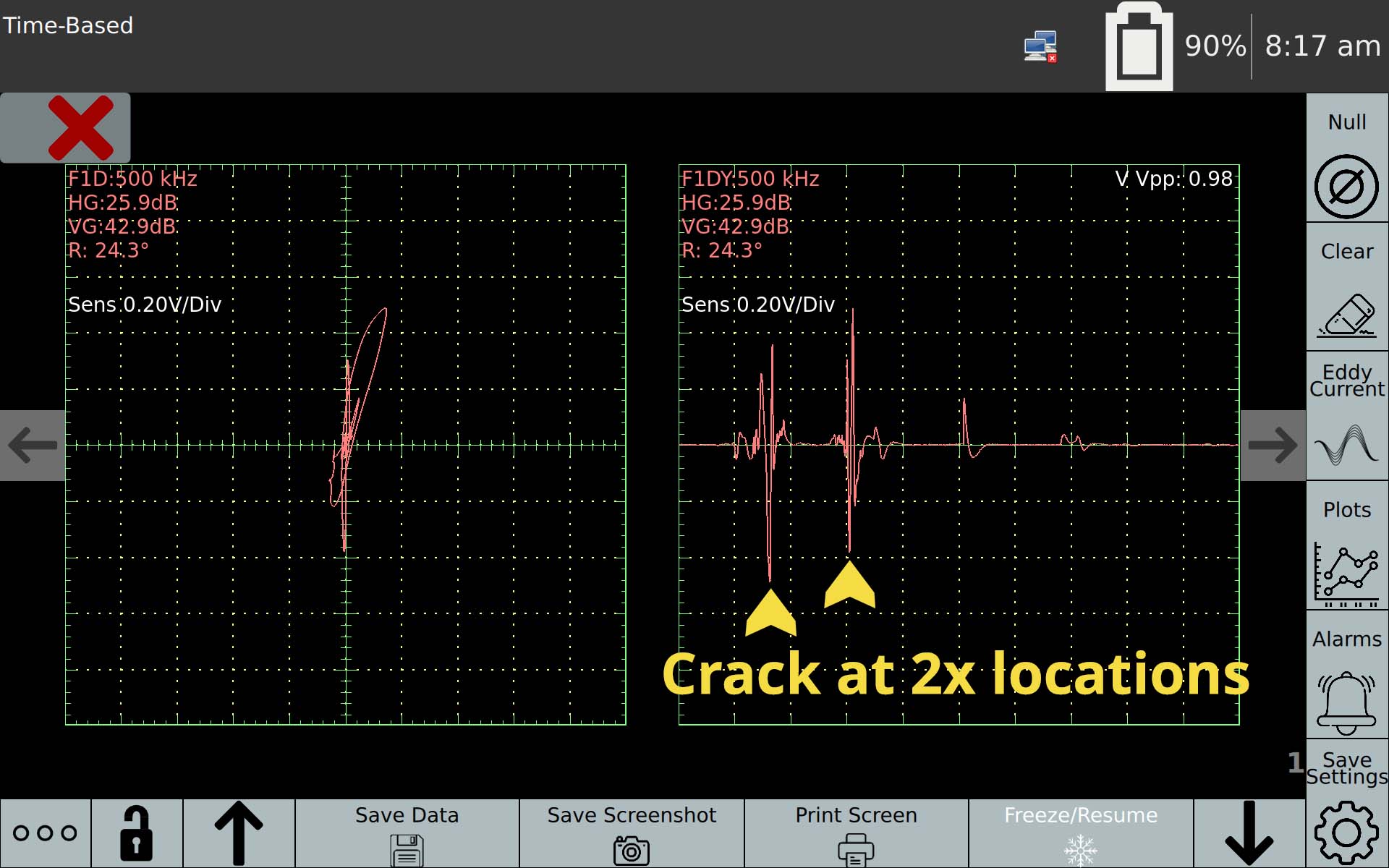

This video demonstrates the eddy current inspection of one of the test bars. Microcracking, undetectable to the naked eye, was identified following a jagged circumferential pattern around the part. These surface-breaking cracks were revealed through changes in signal amplitude and phase shift, with increasing phase lag behavior indicating crack depth and orientation. The observed responses are consistent with fatigue or stress-related discontinuities.

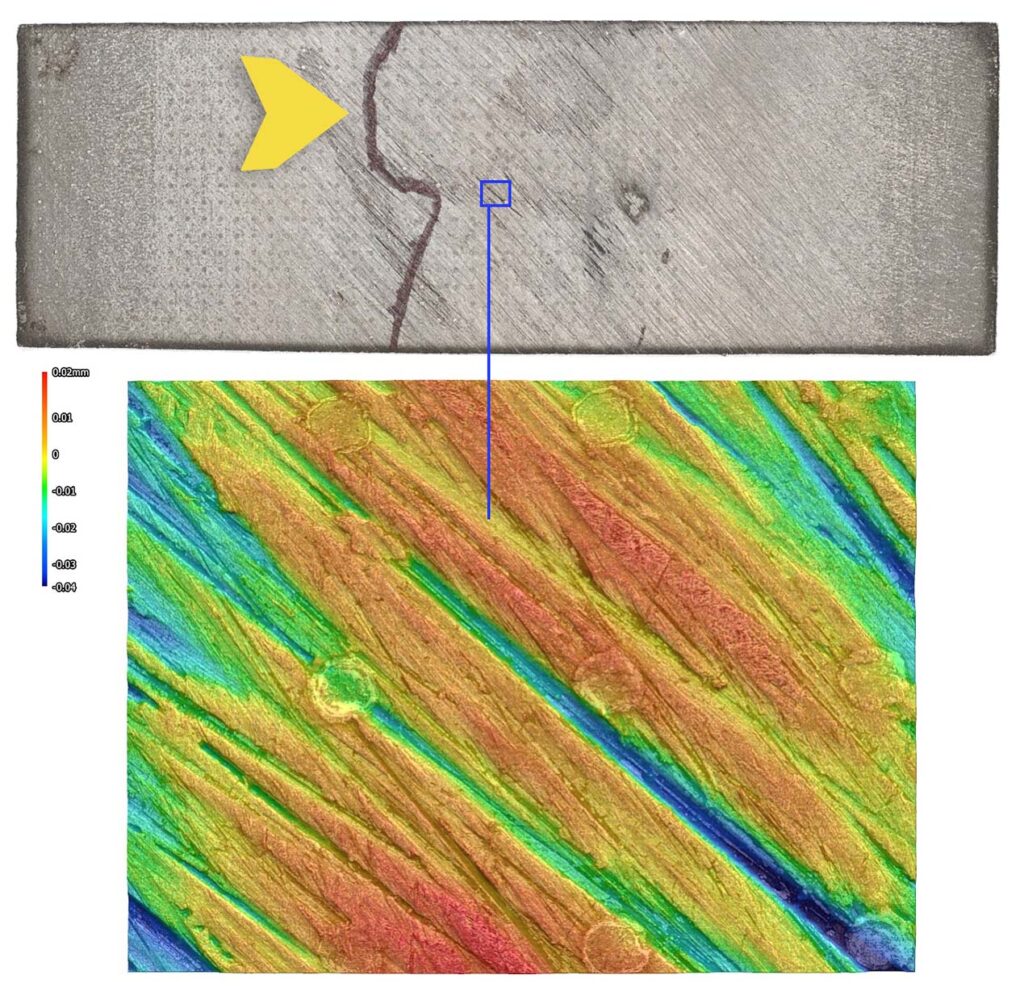

We can also use Eddy Current to map out defects for precise repair. By marking products as we probe (yellow arrow), we can determine point of origin and mark up all pathing. 3D microscopy was also used to evaluate surface quality in proximity to the crack.

Inspection isn’t just about identifying defects. It’s about providing manufacturers with the actionable insight they need to salvage high-value parts, reduce waste, and avoid production delays. With the right tools and expertise, inspection becomes an value saving investment.