CT SCANNING MICROFLUID ASSEMBLIES

CT scanning is used to inspect stainless steel micro connectors and valves for internal weld defects and dimensional accuracy. It reveals voids, cracks, or misaligned welds that aren’t visible from the outside, while also confirming that tight tolerances are met. The process is non-destructive and ideal for quality control in precision manufacturing. Traditional methods require sectioning samples for internal evaluations, which could damage or eliminate critical areas of interest.

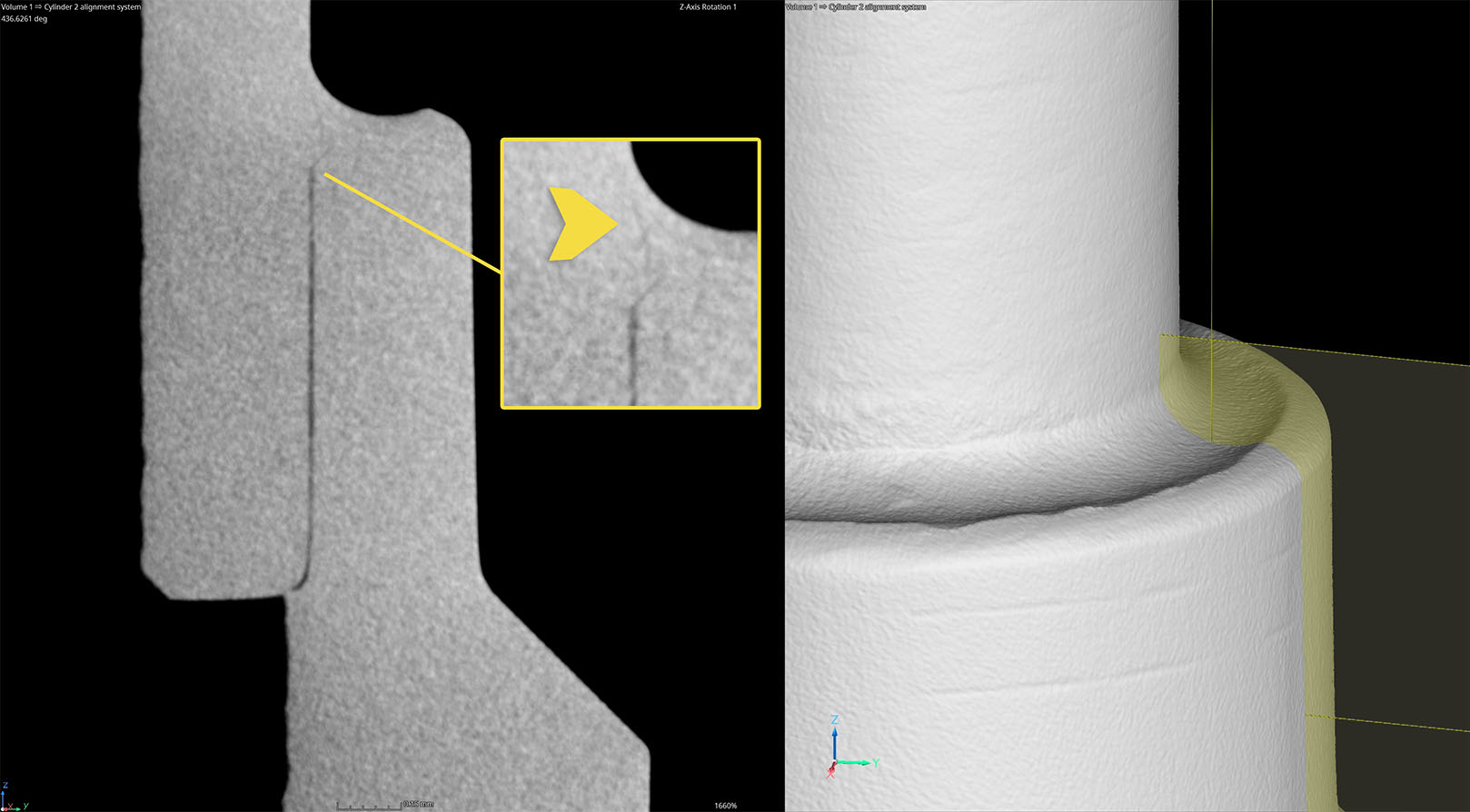

Crack in micro-weld

CT scanning revealed the linear, cracklike indication in the weld below, which was undetectable by visual inspection and dye penetrant. The scan provided exact location, length, and depth, allowing for targeted evaluation of the weld quality and potential failure risk. Early detection like this is critical in high-precision or pressure-sensitive applications, where even small defects can compromise performance and mission integrity.

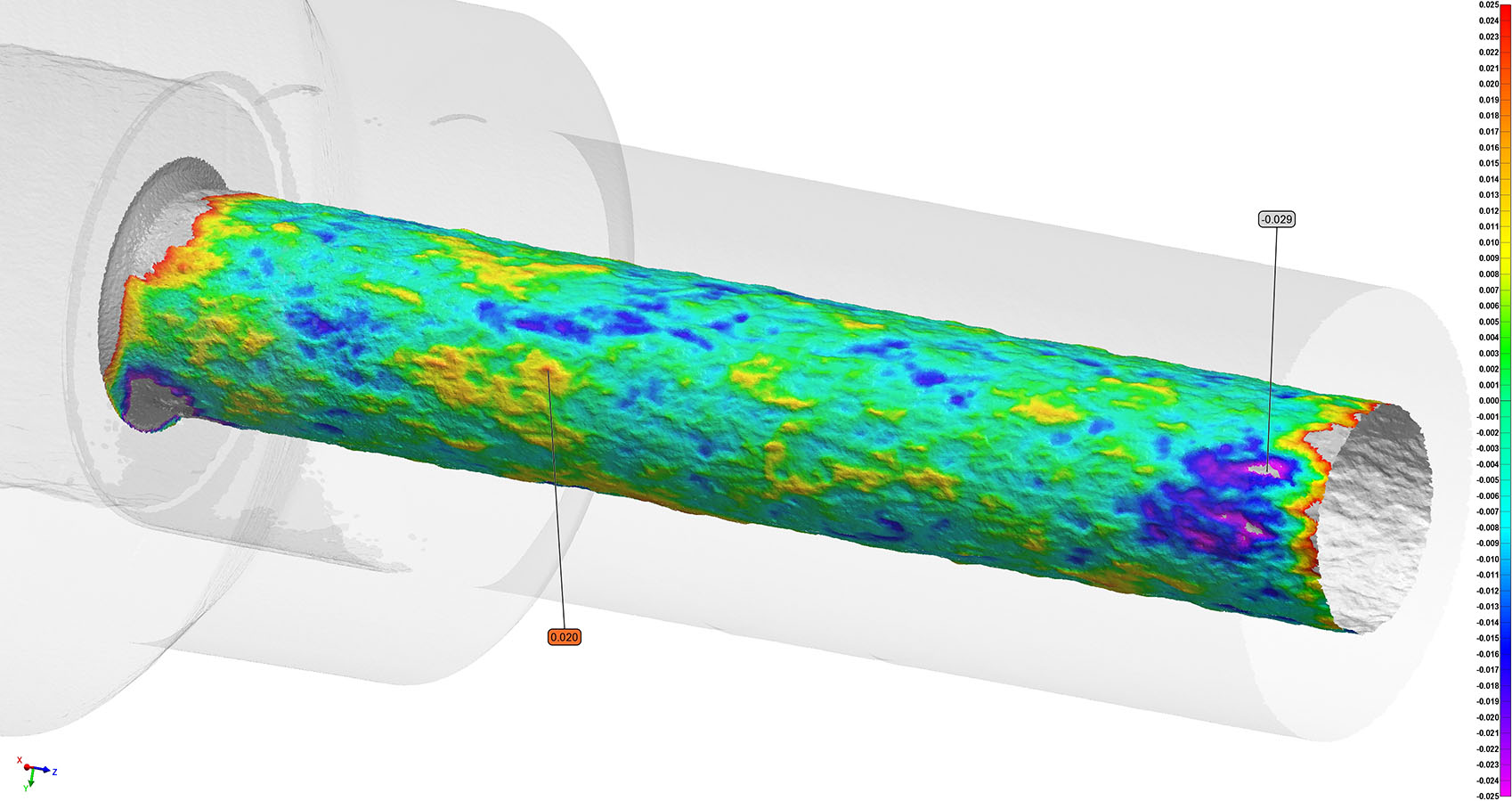

Measuring Internal Profiles

Micro-CT scanning is effective for measuring intentional surface roughness in steel microfluidic components because it captures high-resolution, water-tight, internal and external surface data. This allows engineers to evaluate surface conditions that influence flow behavior, such as turbulence or adhesion, within tiny channels or chambers. Unlike tactile or optical profilers, micro-CT can measure roughness on complex, internal geometries where direct non-destructive access is impossible, ensuring the intended surface characteristics are consistently produced and maintained throughout the part and its production.