Inspecting Microfluidic Mixers

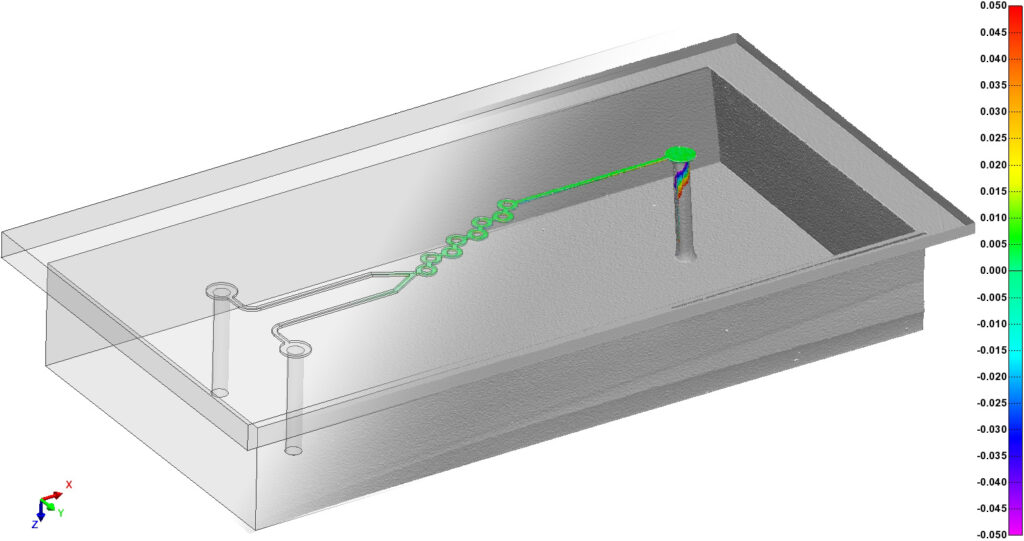

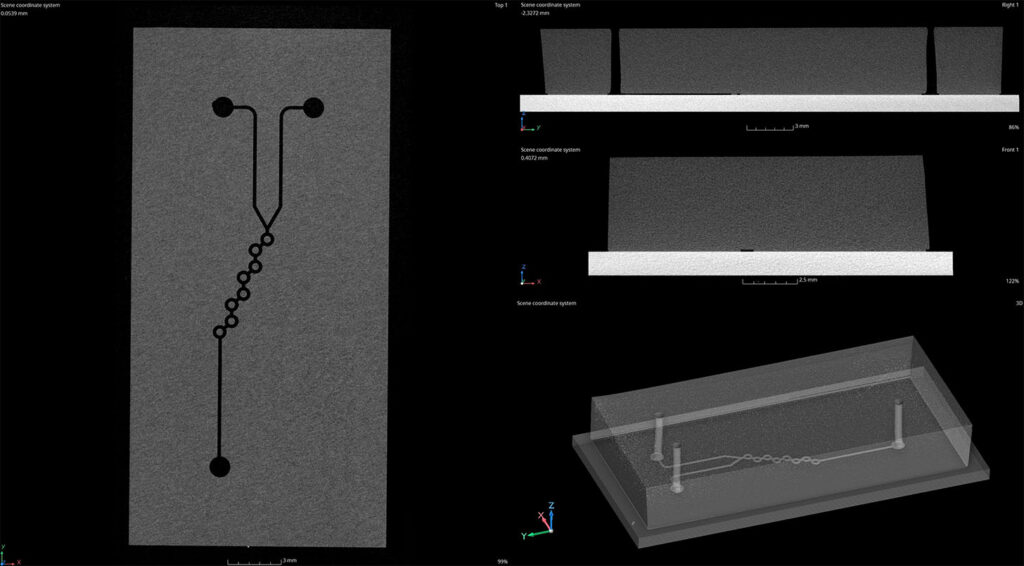

Industrial CT scanning is a powerful tool for inspecting microfluidic mixers, especially in industries where performance and reliability are critical such as medical diagnostics, pharmaceuticals, biotechnology, and chemical processing. These mixers often feature complex internal channels and structures that are impossible to evaluate with traditional inspection methods without cutting or destroying the part.

CT scanning provides a fully non-destructive way to see inside a microfluidic device and verify that it was manufactured correctly. It could even remain in its sealed packaging.

For example, it can detect internal blockages, trapped air bubbles, or incomplete bonding between layers, all of which can compromise fluid flow or lead to device failure in the field.

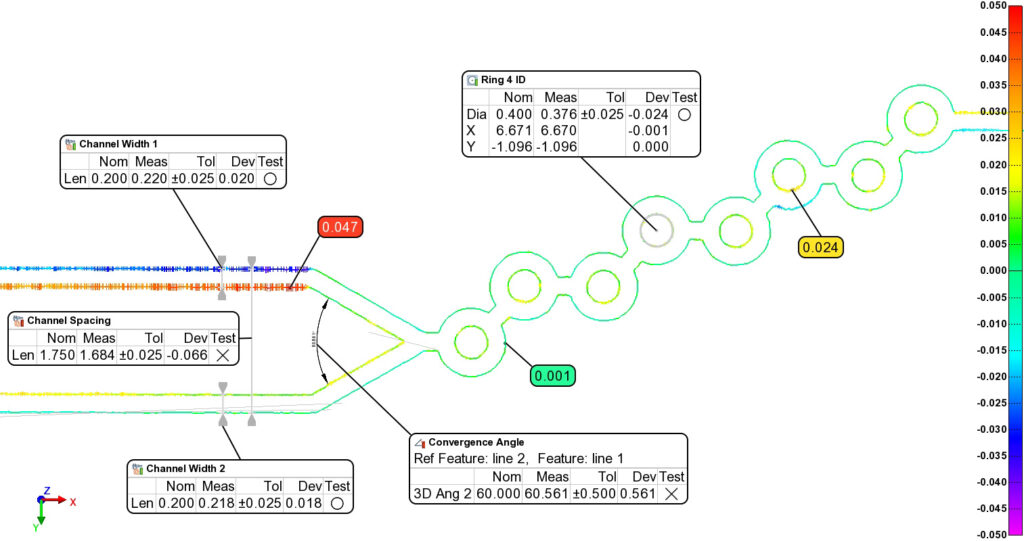

In addition to assembly inspection, CT scanning is used for high-precision dimensional analysis. It allows inspectors to measure internal features like channel widths, wall thickness, and GD&T like flatness and concentricity with micron-level accuracy. This is especially important in devices where small variations can affect flow behavior, mixing efficiency, or the timing of chemical reactions.