CT Scanning 3D Printed Steel Tooling for Leak Paths

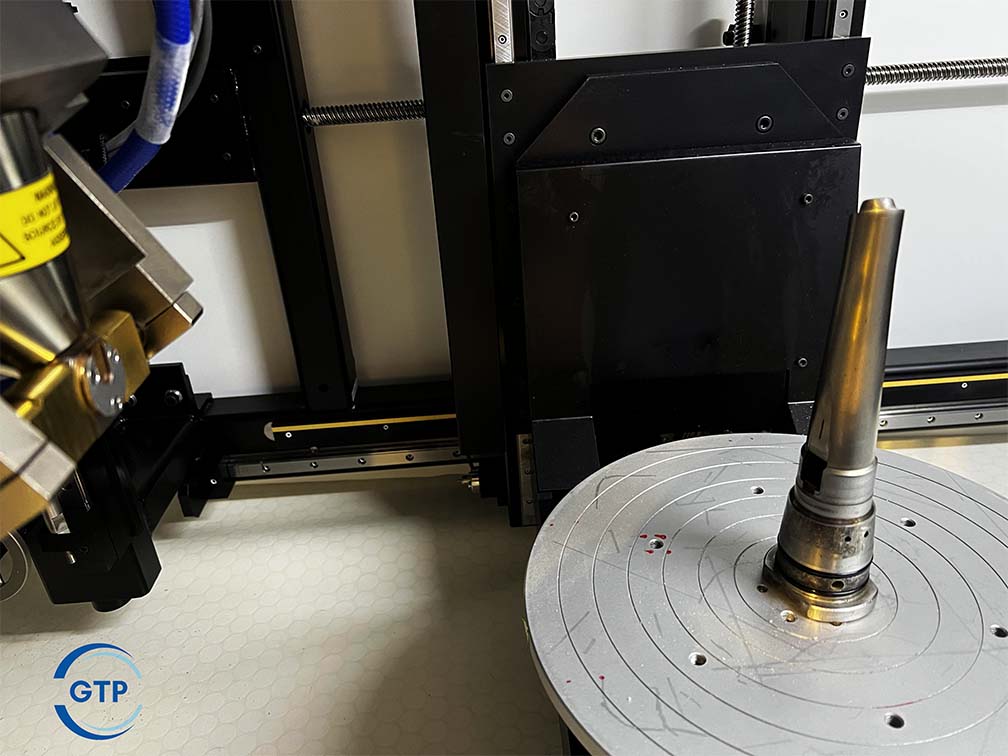

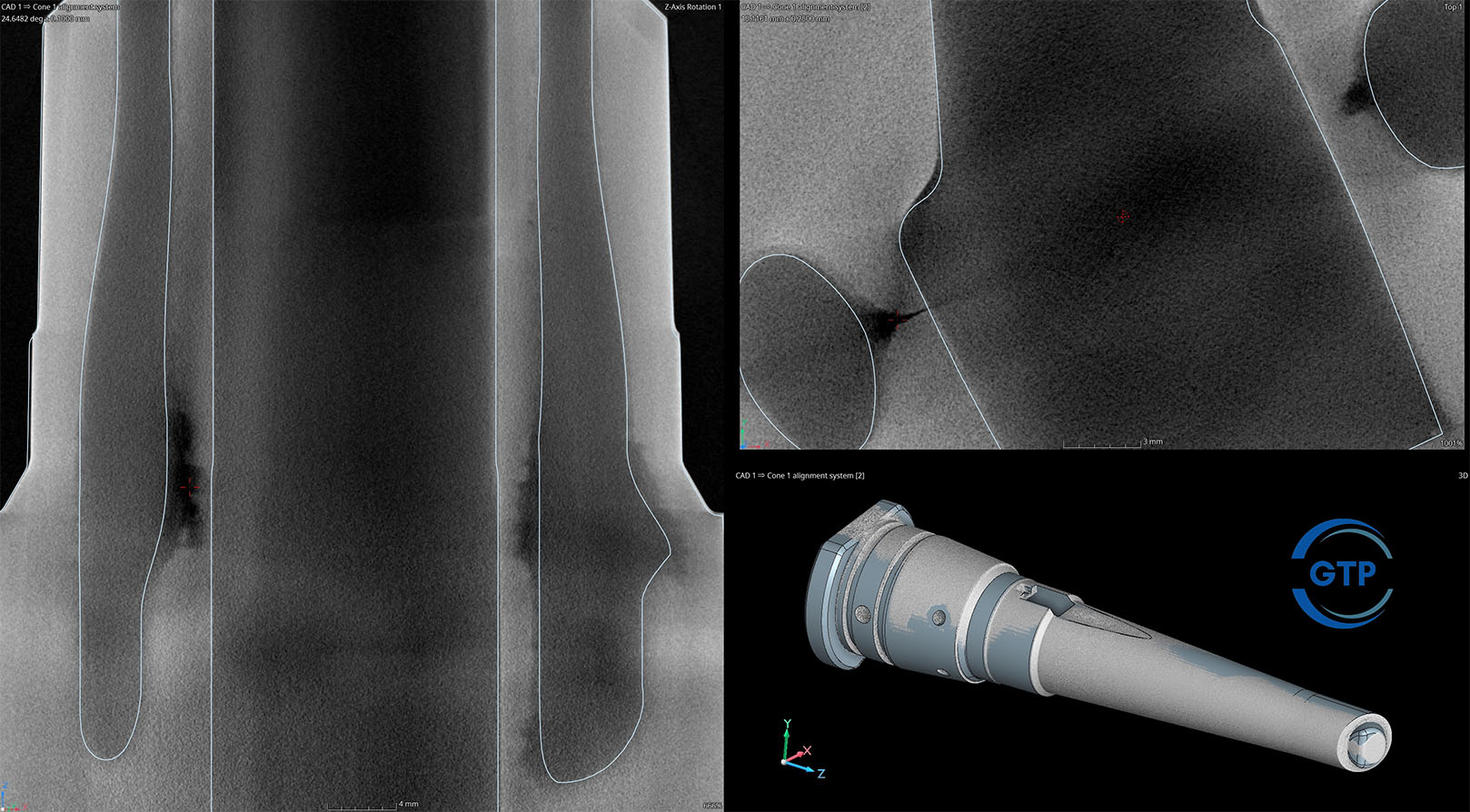

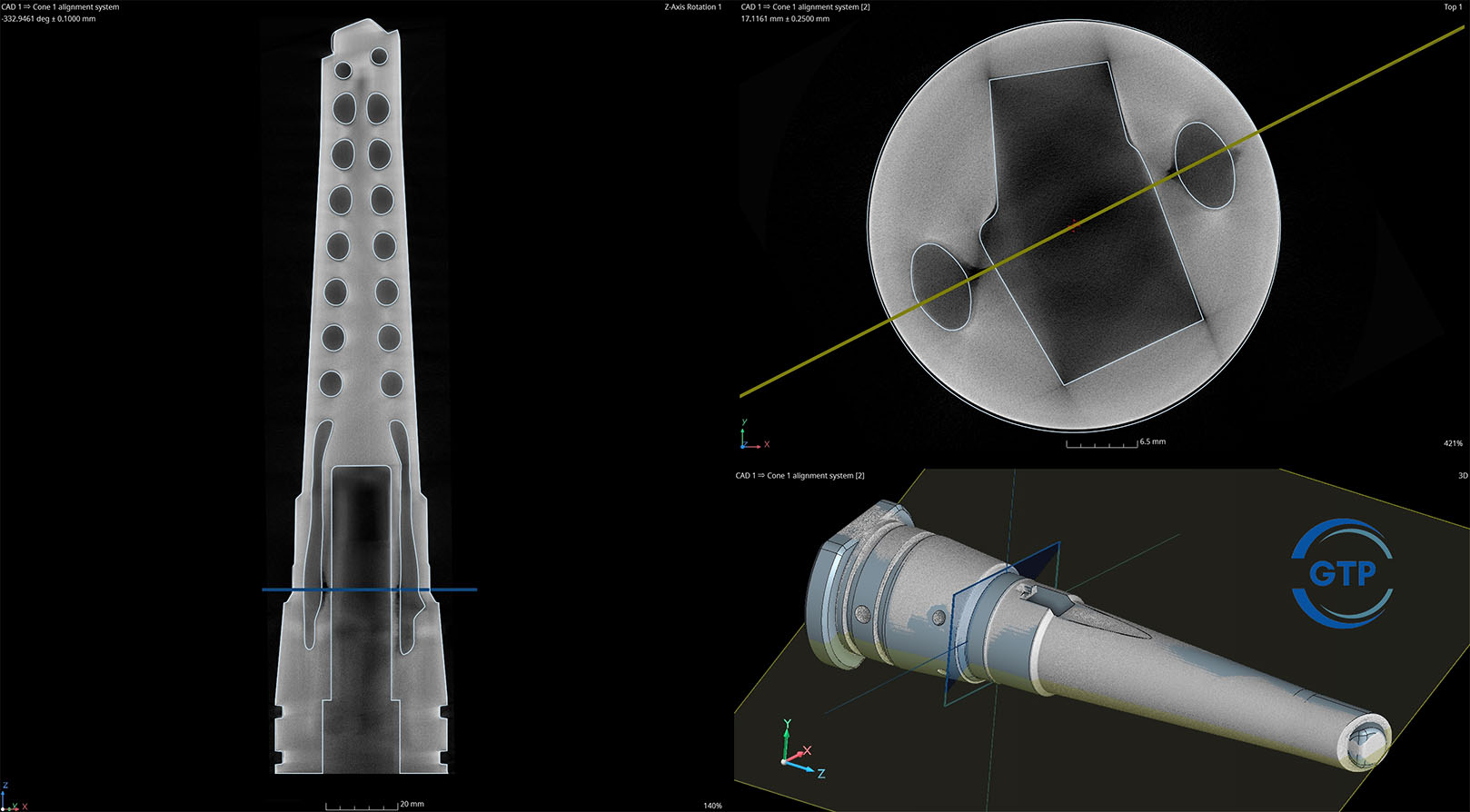

One of our clients had issues with undetected internal leak paths within complex 3D printed steel tooling, compromising tool integrity and performance. Traditional inspection methods failed to reveal subsurface defects, prompting the use of industrial computed tomography scanning.

The high-resolution CT scans enabled non-destructive, full-volume analysis of the tooling, revealing internal porosity, profile deviations, and wear from water pitting. By visualizing and precisely locating these hidden defects, engineers have a better understanding for repair and corrective actions to mitigate future leakage risks. This application of CT scanning significantly improves quality assurance, reducing failure rates and increasing tool reliability.

This tooling and imaging is shared with permission by Grand Traverse Plastics.