Step Scanning FOR VARIOUS CONDITIONS

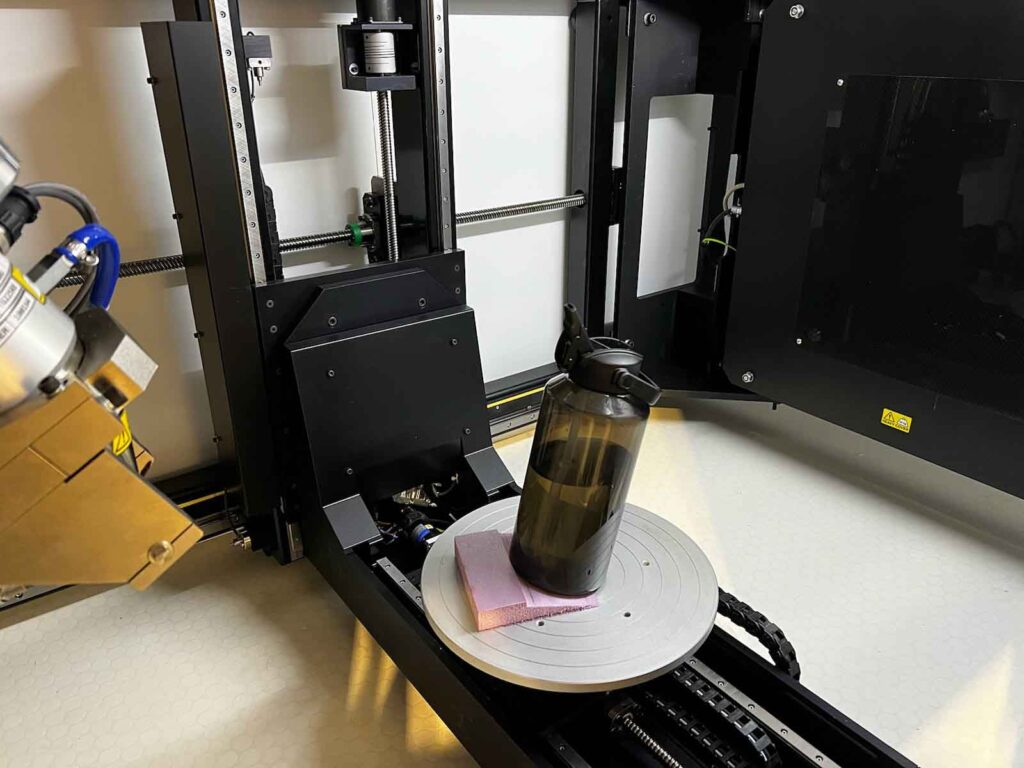

Step scanning, often referred to as “4D CT”, is the process of collecting several CT datasets at various product conditions, aligning those datasets to a common datum reference frame, and saving images to demonstrate product changes.

This practice is commonly used for parts or products that actuate or have several functioning positions. For example, this water bottle has multiple sealing interfaces that change depending on the valve / straw configuration. Perhaps a leak forms when the valve is at a specific angle, but not when the spout is fully closed or open.

Axially rotating clips about a part are also useful for inspecting an entire gasket to groove relationship.

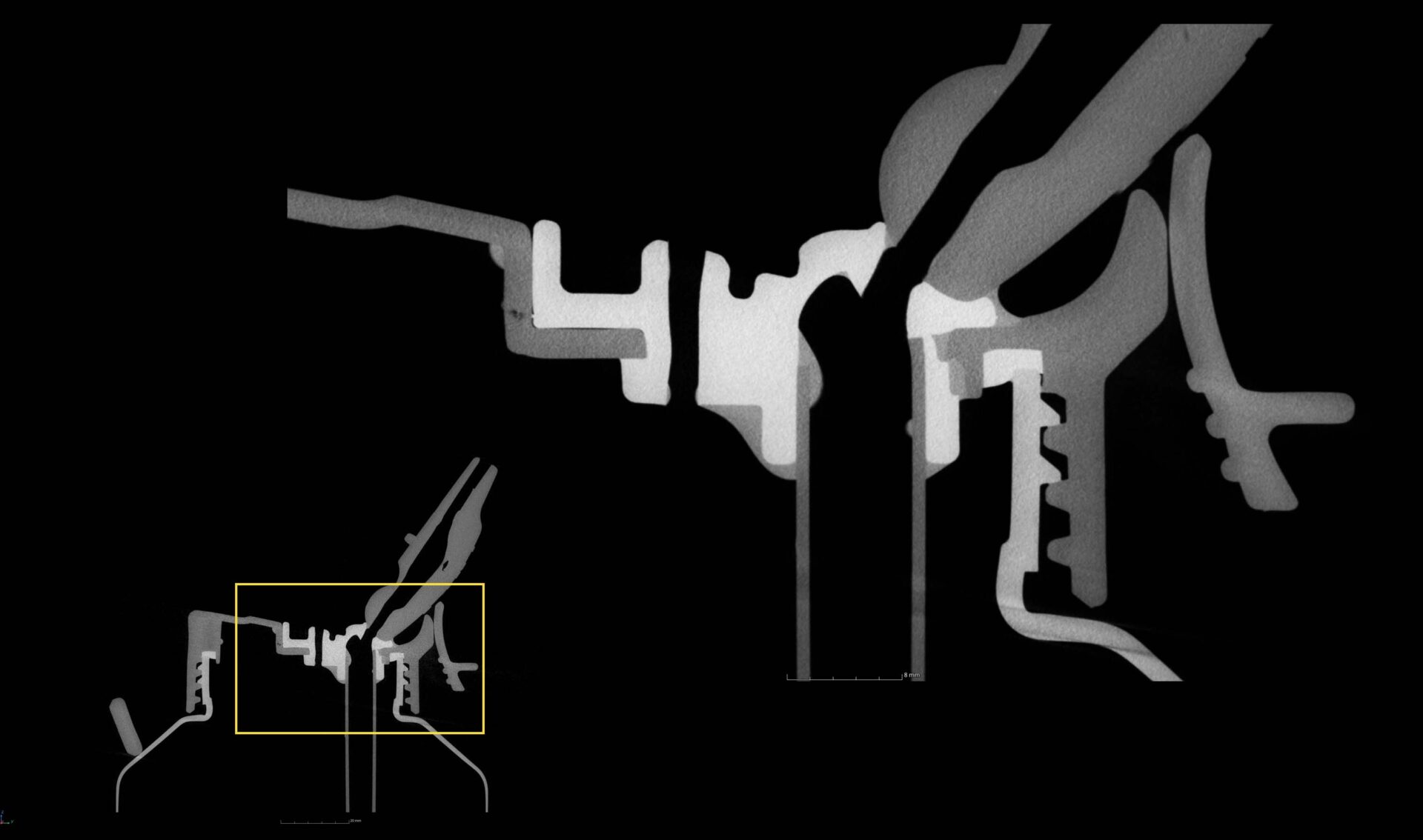

HIGH RESOLUTION CT SLICE IMAGING

CT slice imaging can be measured in Volume Graphics or exported to .stl for use in other softwares for dimensional inspection in PolyWorks, or FEA in Ansys. Scrolling through the part allows us to quickly detect voids, measure wall thickness, locate gaps between materials, and characterize leak paths. pinches, or cracks.