THE BASICS OF INDUSTRIAL CT SCANNING

Industrial CT scanning systems have revolutionized the way we inspect and analyze objects in a wide range of industries, from aerospace to automotive and beyond. At the heart of these systems lies a remarkable technology that enables us to peer inside solid objects with unprecedented clarity and detail. So, how exactly do industrial CT scanning systems work?

THE HARDWARE

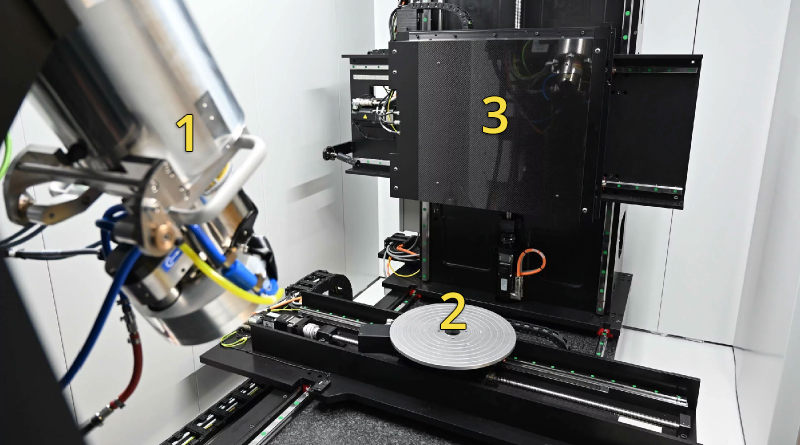

At its core, industrial CT scanning operates on principles similar to medical CT scans but tailored for industrial applications. The process begins with the object of interest being placed on a rotating platform within the CT scanner. Next, a powerful X-ray source emits radiation, which penetrates the object as it rotates. The radiation that passes through the object is captured by a detector on the other side. This interaction results in a series of 2D X-ray images, or “slices,” which collectively provide a comprehensive view of the object’s internal structure.

1. X-Ray Source, 2. Part Manipulator, 3. X-Ray Detector

THE SOFTWARE

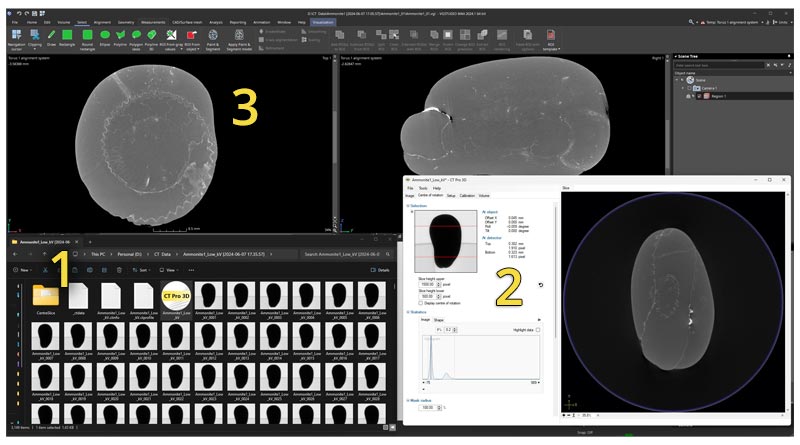

But here’s where the magic truly happens: sophisticated software algorithms reconstruct these individual slices into a 3D model, akin to assembling a virtual puzzle. This 3D model reveals intricate details such as internal features, defects, and material density variations that are crucial for quality control, defect analysis, and product optimization.

1. Thousands of X-Ray Images, 2. Building 3D File from 2D Images, 3. Analyzing 3D File using Volume Graphics Software

THE PURPOSE

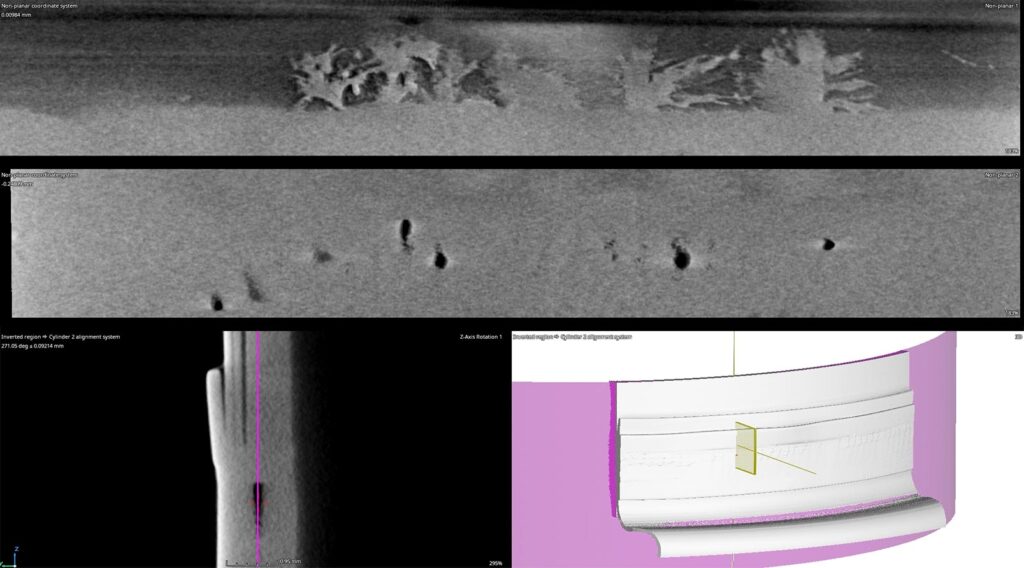

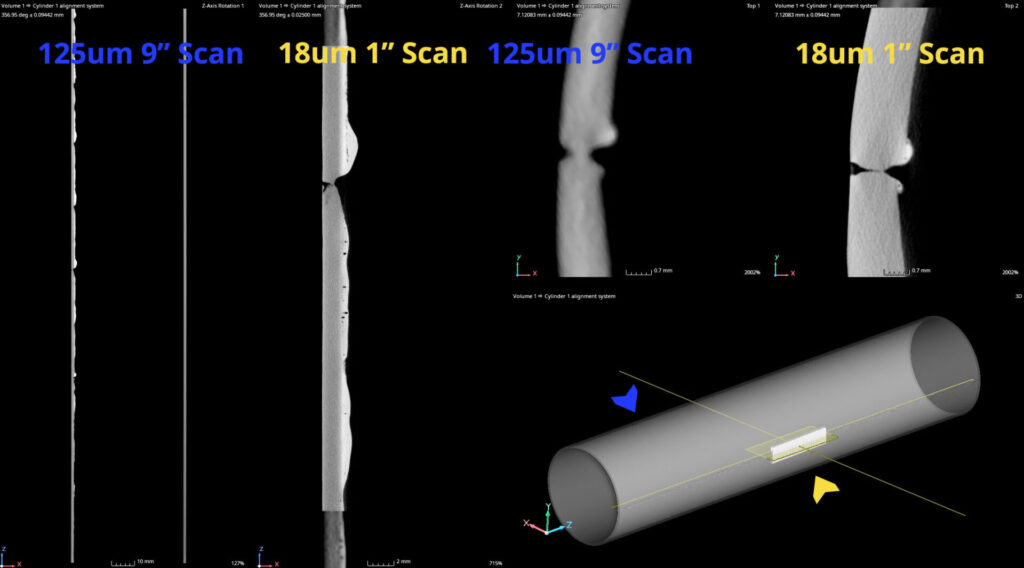

What sets industrial CT scanning apart is its ability to examine objects with complex geometries, varying materials, and internal structures that are otherwise inaccessible to traditional inspection methods. From intricate aerospace components to dense automotive parts, industrial CT scanning offers a non-destructive and highly accurate means of evaluation, saving both time and resources while ensuring product integrity.

Moreover, as technology advances, so do the capabilities of industrial CT scanning systems. With advancements in X-ray sources, detectors, and computational algorithms, these systems can now achieve higher resolution, faster scan times, and enhanced image quality, further expanding their utility across industries.

In conclusion, industrial CT scanning systems represent a groundbreaking advancement in inspection and analysis technologies. By harnessing the power of X-rays and sophisticated software, these systems enable us to see beyond the surface and delve into the inner workings of objects, paving the way for safer, more efficient, and higher-quality products across diverse industries.