What is 3D Scanning?

In the dynamic landscape of modern manufacturing, precision is paramount. Enter 3D scanning – a transformative technology reshaping the way industries approach quality control, reverse engineering, and dimensional inspection. At its core, industrial 3D scanning utilizes advanced data capture techniques to produce detailed, three-dimensional representations of physical objects with unprecedented accuracy. But what exactly is industrial 3D scanning for, and how is it revolutionizing the manufacturing landscape?

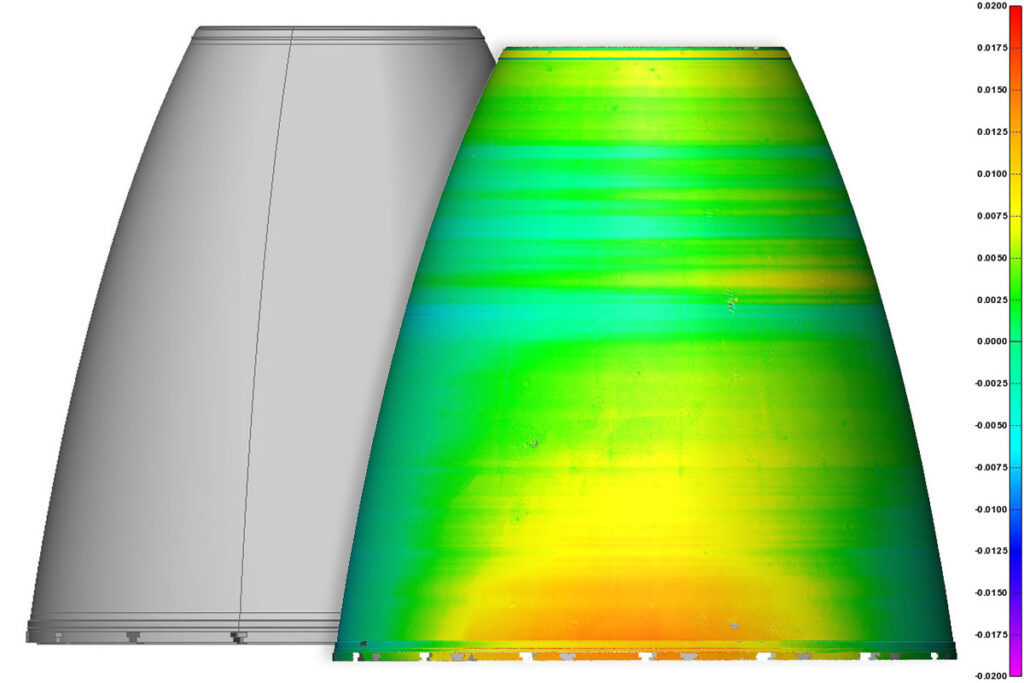

CAD COMPARISONS

In manufacturing, ensuring product quality is non-negotiable. Industrial 3D scanning plays a pivotal role in this endeavor by providing manufacturers with the means to meticulously inspect entire components and assemblies for defects, deviations, and inconsistencies. From intricate aerospace parts to automotive components, 3D scanning offers a comprehensive solution for identifying imperfections early in the production process, minimizing waste, and optimizing product performance.

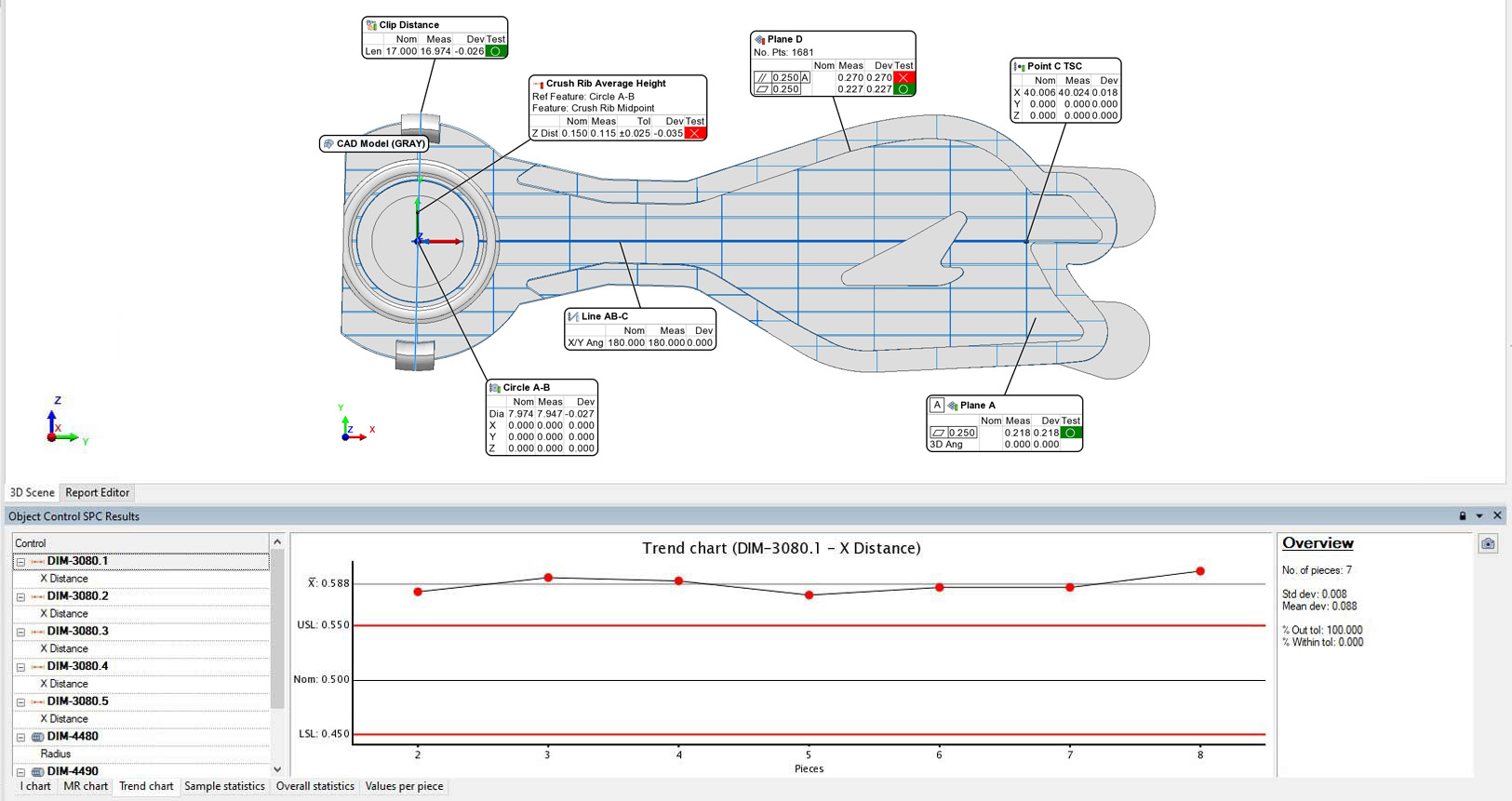

DIMENSIONAL INSPECTION

Precision is the hallmark of quality, and dimensional accuracy is a critical aspect of manufacturing excellence. Industrial 3D scanning provides manufacturers with a reliable method for verifying the dimensional integrity of components and assemblies, ensuring they meet tight tolerances and specifications. By comparing scanned data to CAD models or reference standards, manufacturers can confidently validate the accuracy of their products, safeguarding against costly errors and rework.

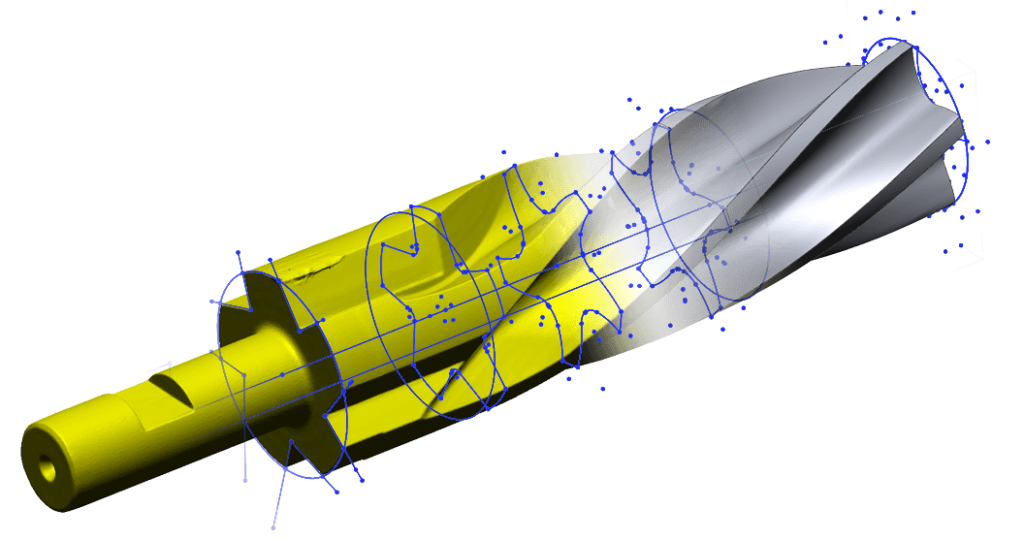

REVERSE ENGINEERING

The ability to replicate and improve upon existing designs is a cornerstone of innovation. Industrial 3D scanning facilitates this process by capturing the exact geometry of physical objects, allowing engineers to create digital models that can be modified, optimized, or reproduced as needed. Whether it’s redesigning legacy components or enhancing product functionality, 3D scanning enables manufacturers to unleash their creativity and drive continuous improvement.

In conclusion, industrial 3D scanning is a versatile and indispensable tool that empowers manufacturers to achieve new levels of precision, efficiency, and innovation. Whether it’s enhancing product quality, accelerating design iterations, or ensuring dimensional accuracy, 3D scanning is reshaping the manufacturing landscape and driving advancements across industries. As technology continues to evolve, the potential of industrial 3D scanning to unlock new possibilities and propel us towards a future of manufacturing excellence is boundless.