FAILURE INVESTIGATION OF HUMAN SUPPORT SYSTEM (CHAIR)

Have you fallen and can’t get up?

Are you struggling to return something to Amazon?

Are you tired of finding 3500mm cubed voids in your products?

Do you wonder why everything is more expensive but doesn’t last as long?

Us too.

This case study explores the failure of a human support system (chair.)

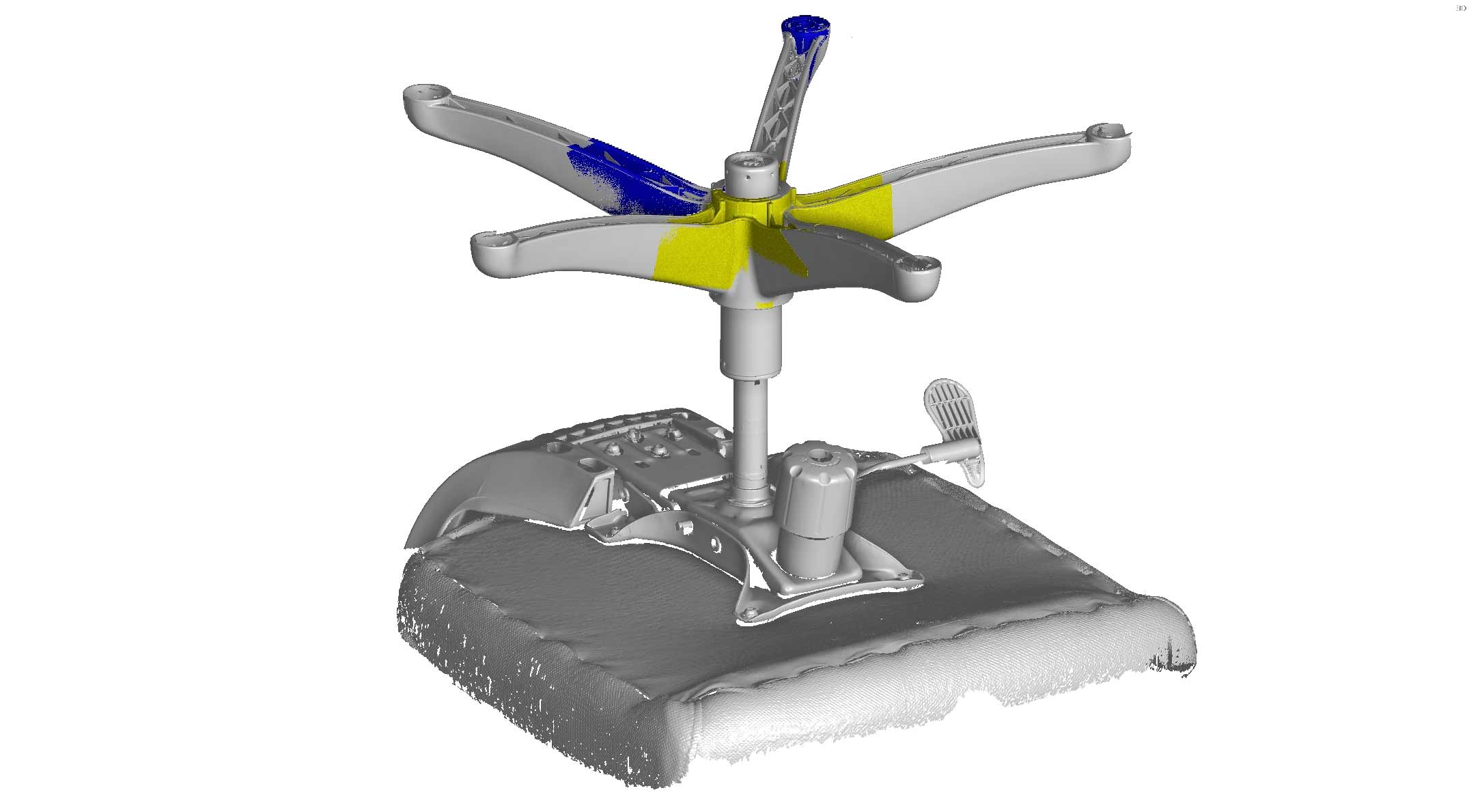

We combine many hardware and software capabilities for the best possible evaluation of products. Because of the size of the chair we used a high accuracy laser scanner (Hexagon Absolute AS1) to capture the overall geometry of a still intact chair. We then created a coordinate system and aligned additional scans of the broken pieces in PolyWorks.

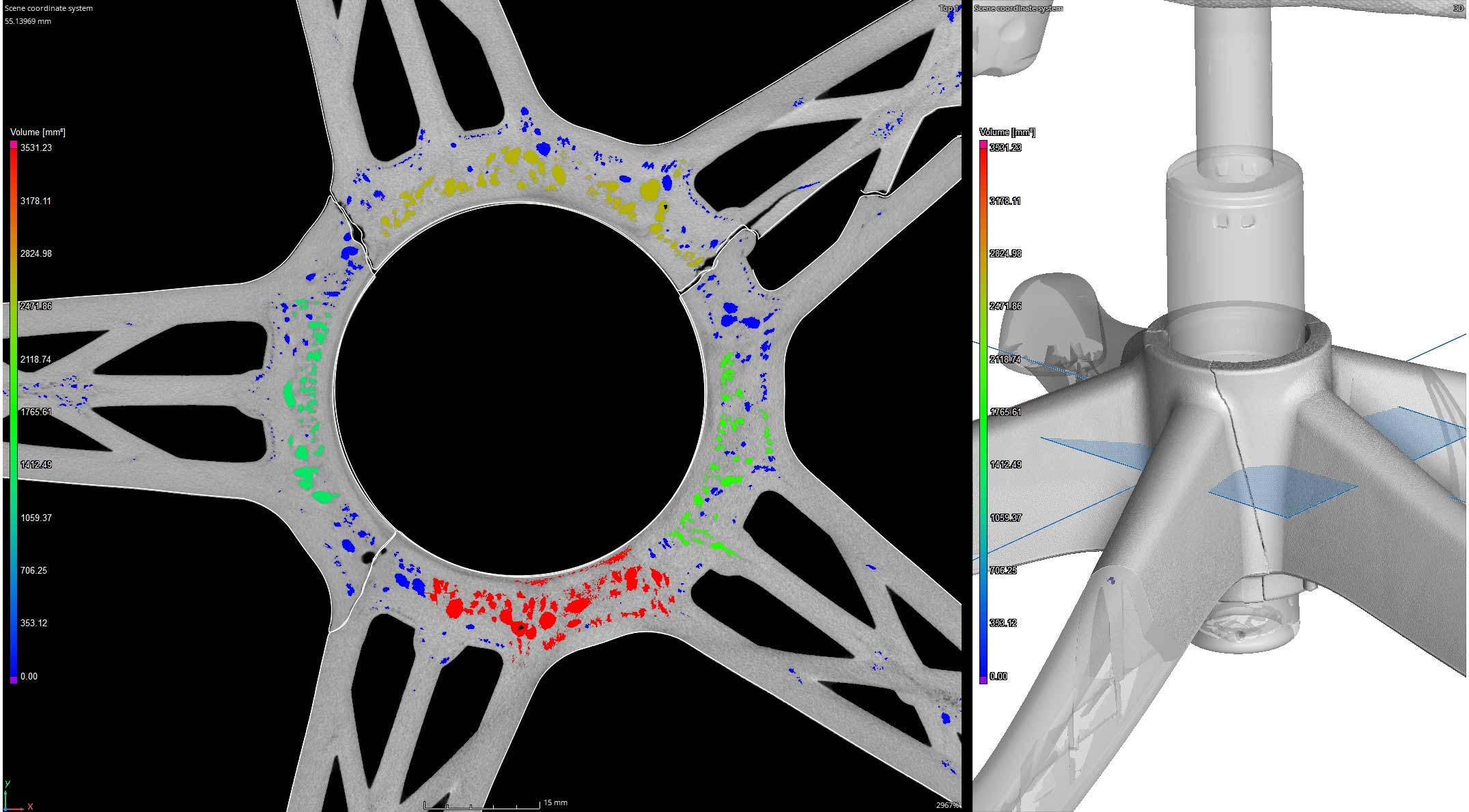

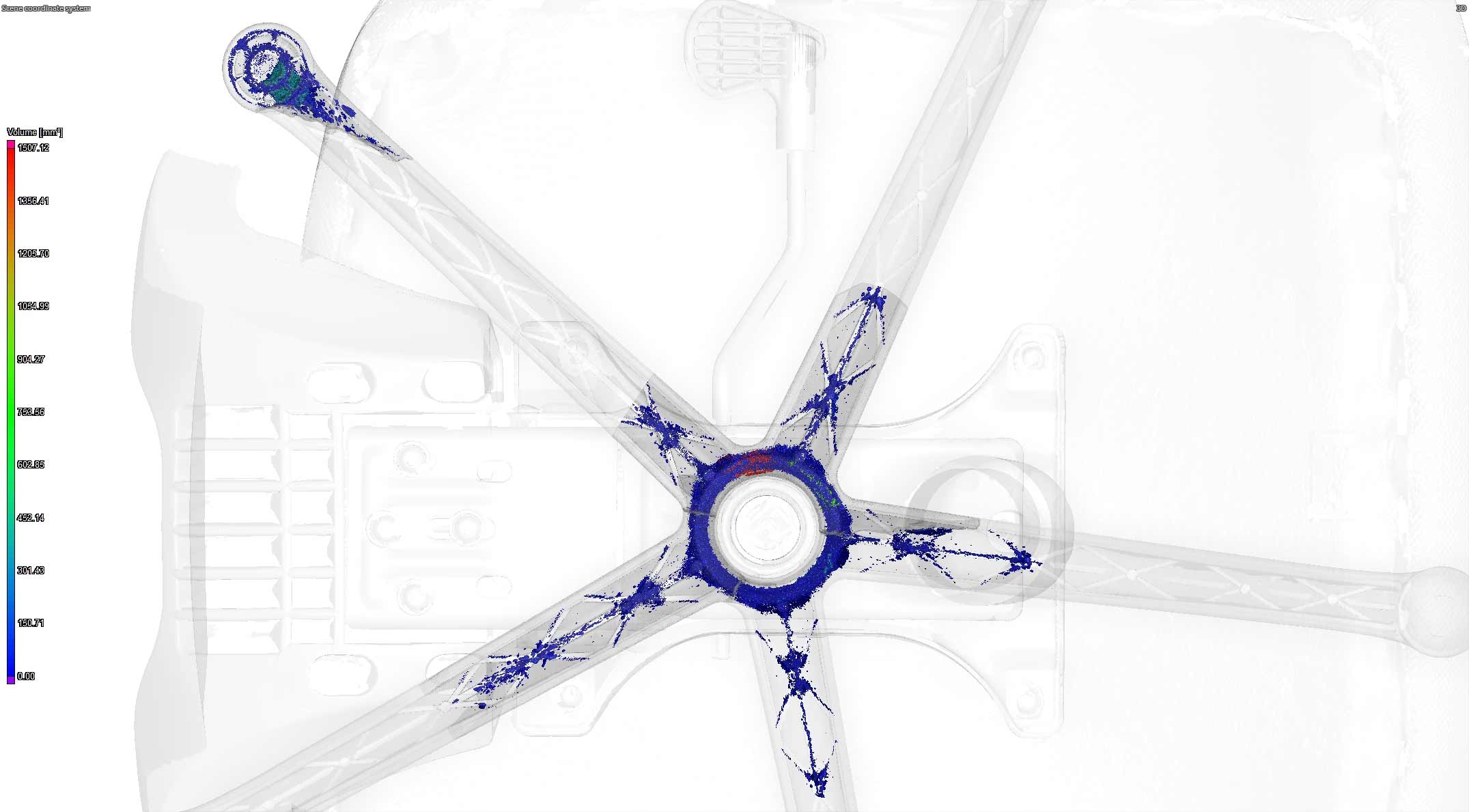

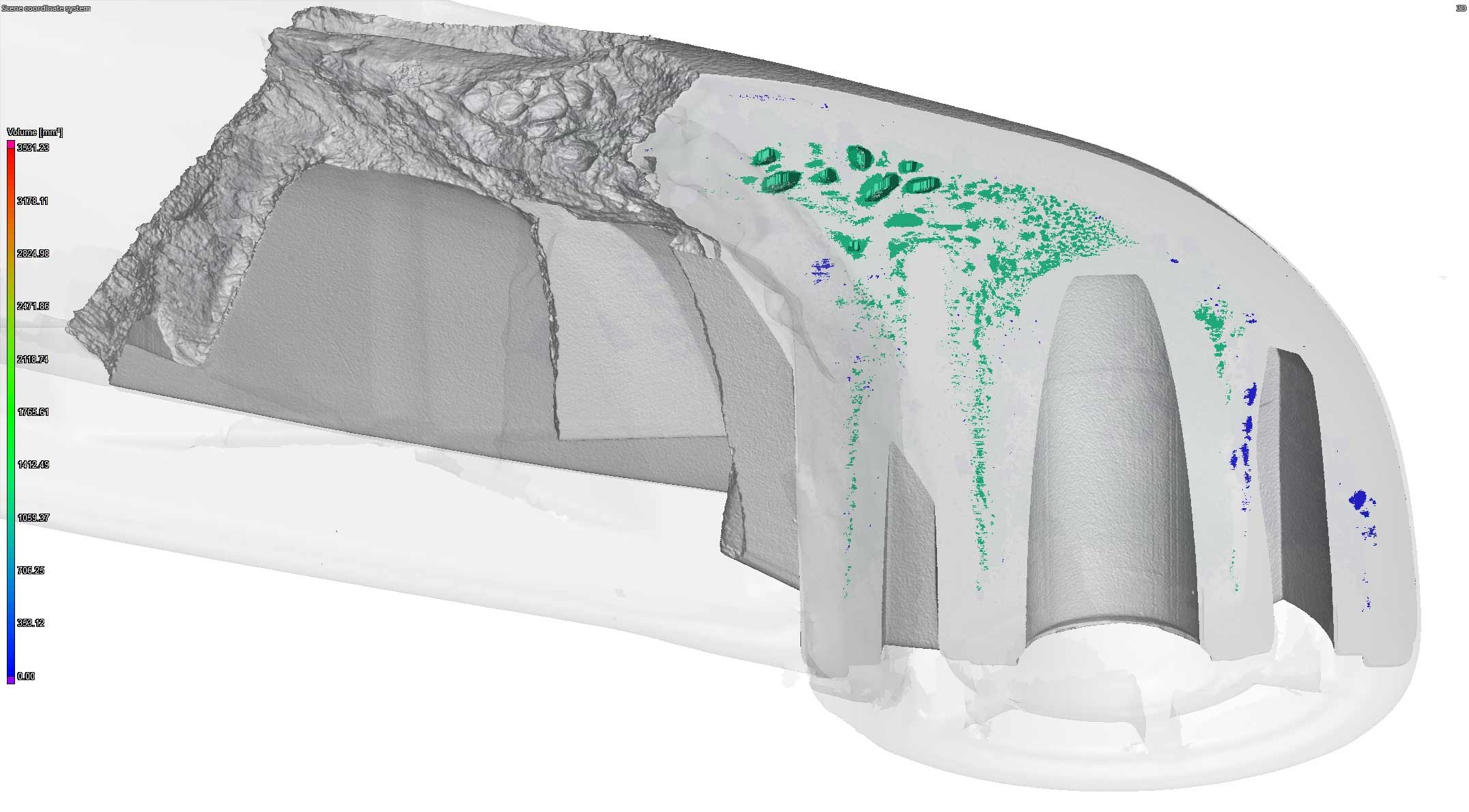

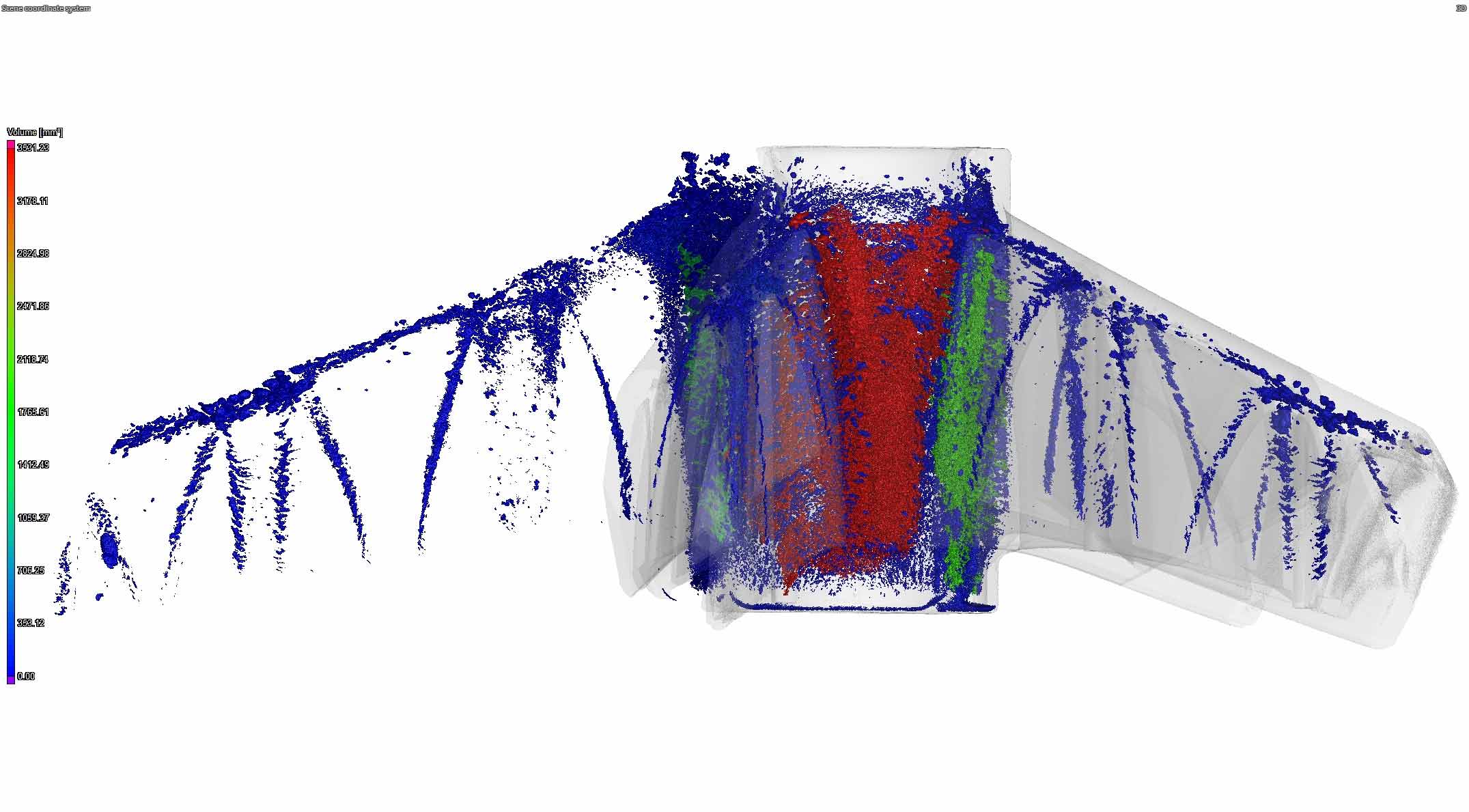

Once everything was aligned properly we imported the .STL mesh files into Volume Graphics to begin aligning the individual CT scans. The CT scans were acquired using our Nikon Microfocus X-Ray & CT cabinet. After the alignments were complete we extracted the volumetric porosity to find voids and cavitation as large as 3500mm3 and found a significant concentration at the base of the chair.