X-Ray or CT for sorting?

Every sort we receive starts with the same question – is digital radiography or CT scanning the optimal method for this project? This sort focuses on a batch of fuel injectors with pinched wires.

Radiography can be a very fast (less expensive) inspection method with a single frame shot taking just 88 milliseconds. However, if the geometry is complex, sometimes it is not possible to characterize defects in a 2D view.

CT scanning can be a longer process (more expensive – 360 degrees of x-ray shots + data processing) but offers a 3D perspective. This perspective allows a tangible characterization to the inspection method, allowing for higher certainty evaluations.

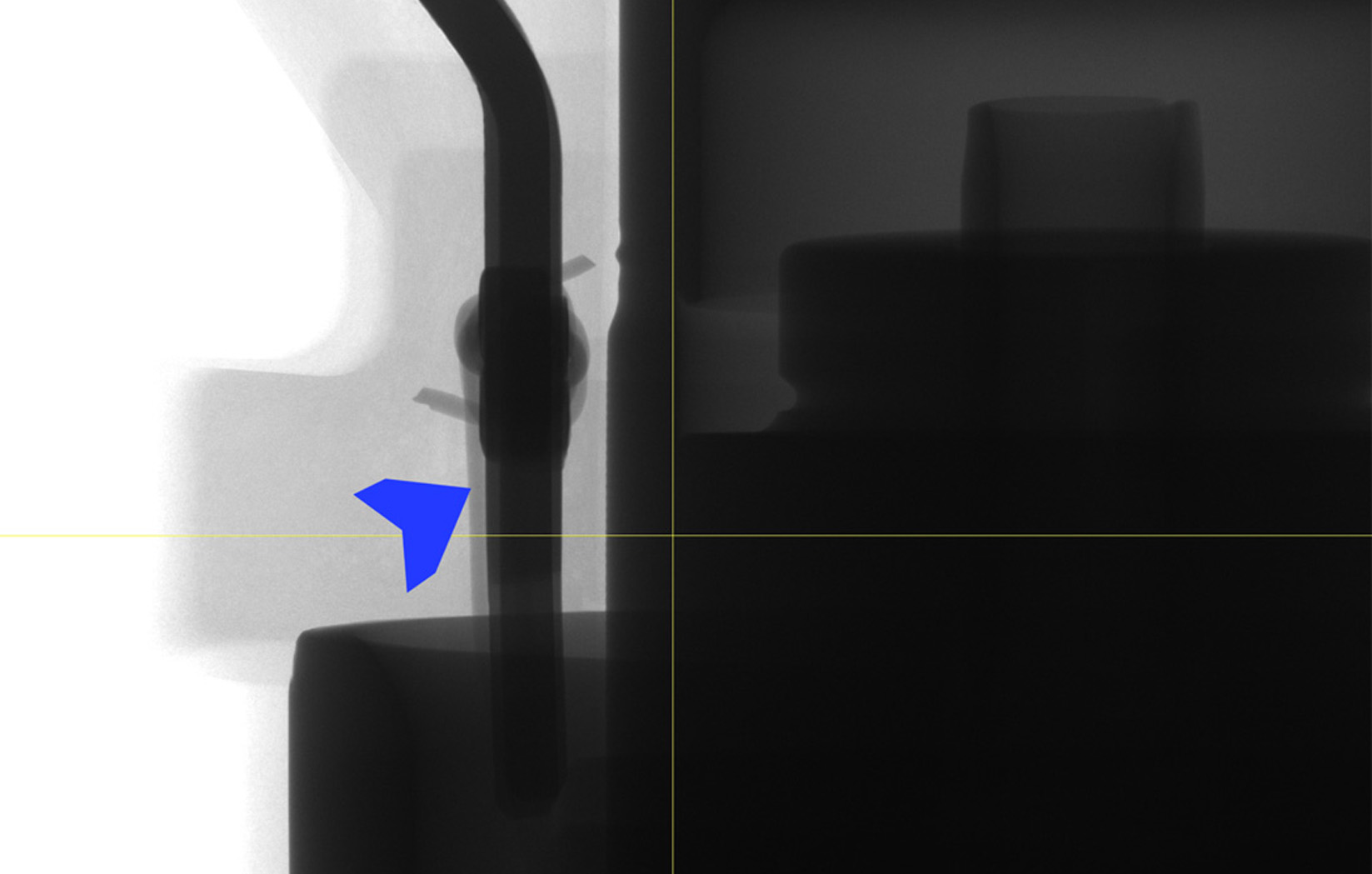

2D Radiography

Because the two wires are in line with each other it is not possible to rotate the sample without the tangs blocking the areas of interest. Rotating the sample 90 degrees also did not work because the copper winding is behind the wires which reduced penetration. If the part configuration were different radiography could have quickly sorted this batch of parts.

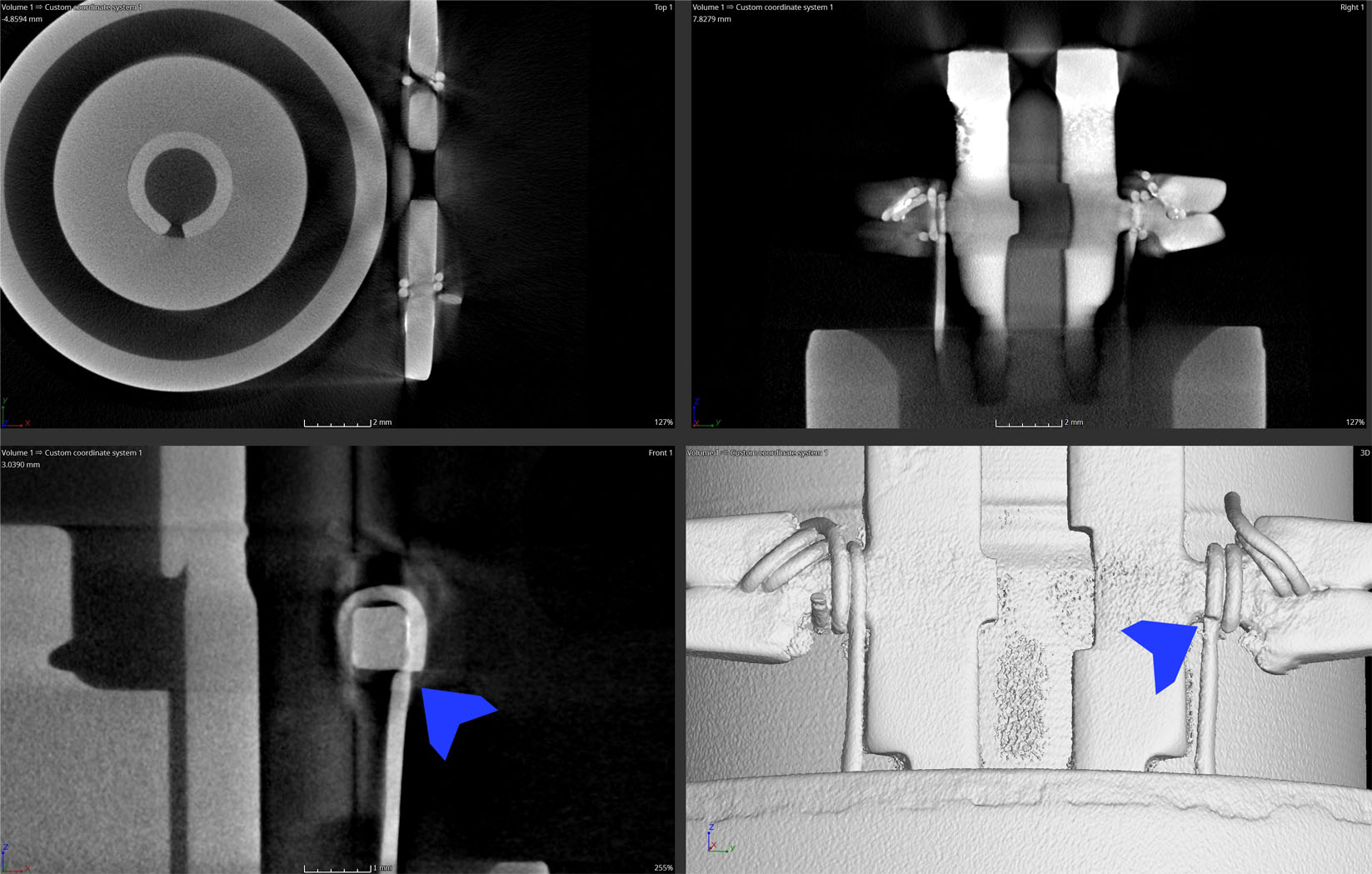

3D CT Scanning

High resolution, high speed CT scanning was the method chosen for sorting this batch of parts. The below views are best effort results from the R&D portion of the project to prove capability. The defective sample was used as a representative quality indicator (RQI – a gauge used to prove the process.) We used this RQI to then adjust parameters for speed to improve run rate and reduce cost. Ultimately, we were able to reduce resolution and batch scan three samples at once in a three minute scan. Parts were serialized, sorted, and returned to the customer with accompanying serialized imaging.