Reverse engineering die steels

Scanning technologies are used to reverse engineer tooling die steels. Over time steel wears, breaks, or is modified to produce a better part. Design files become lost or do not match the modifications.

Using our high resolution laser pCMM we can reproduce worn die steels into toolable .step CAD models.

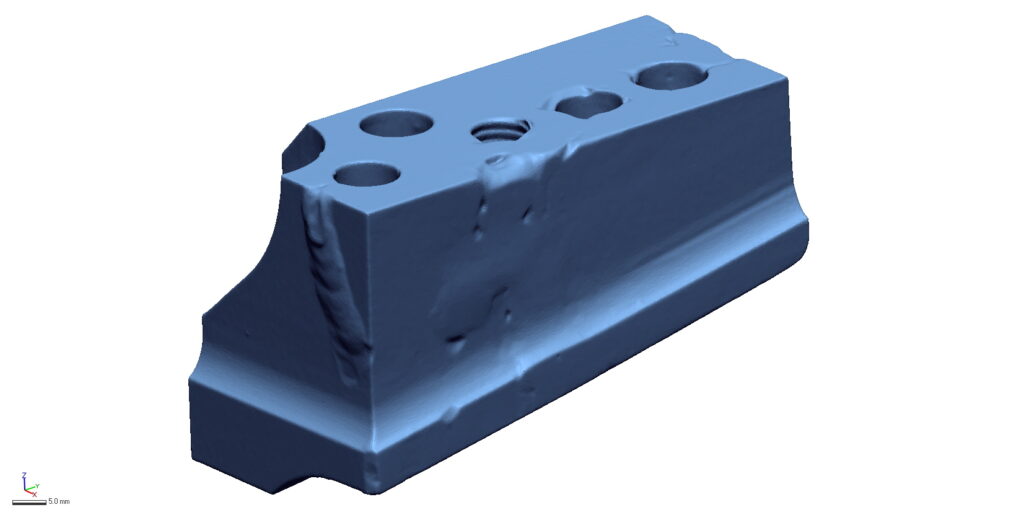

STEP 1 ACQUIRE SCAN DATA

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

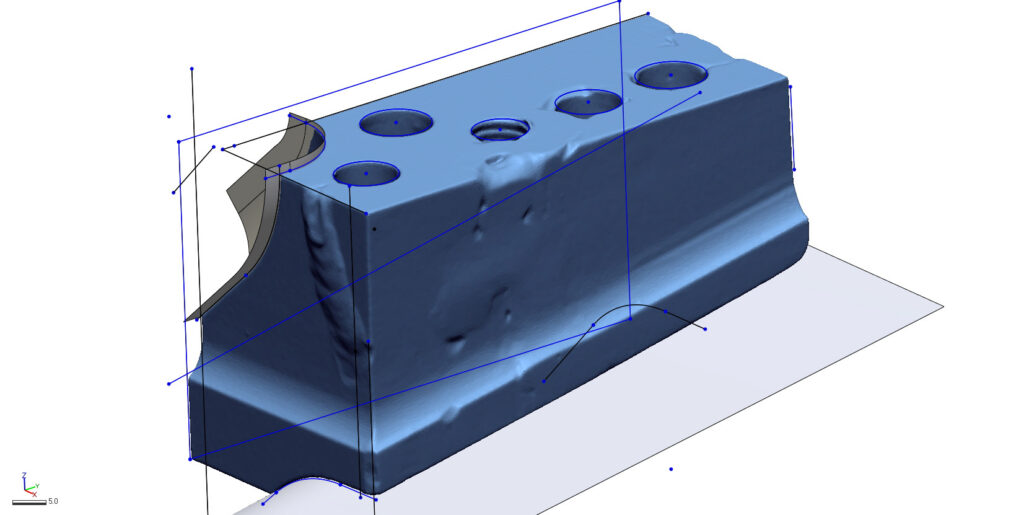

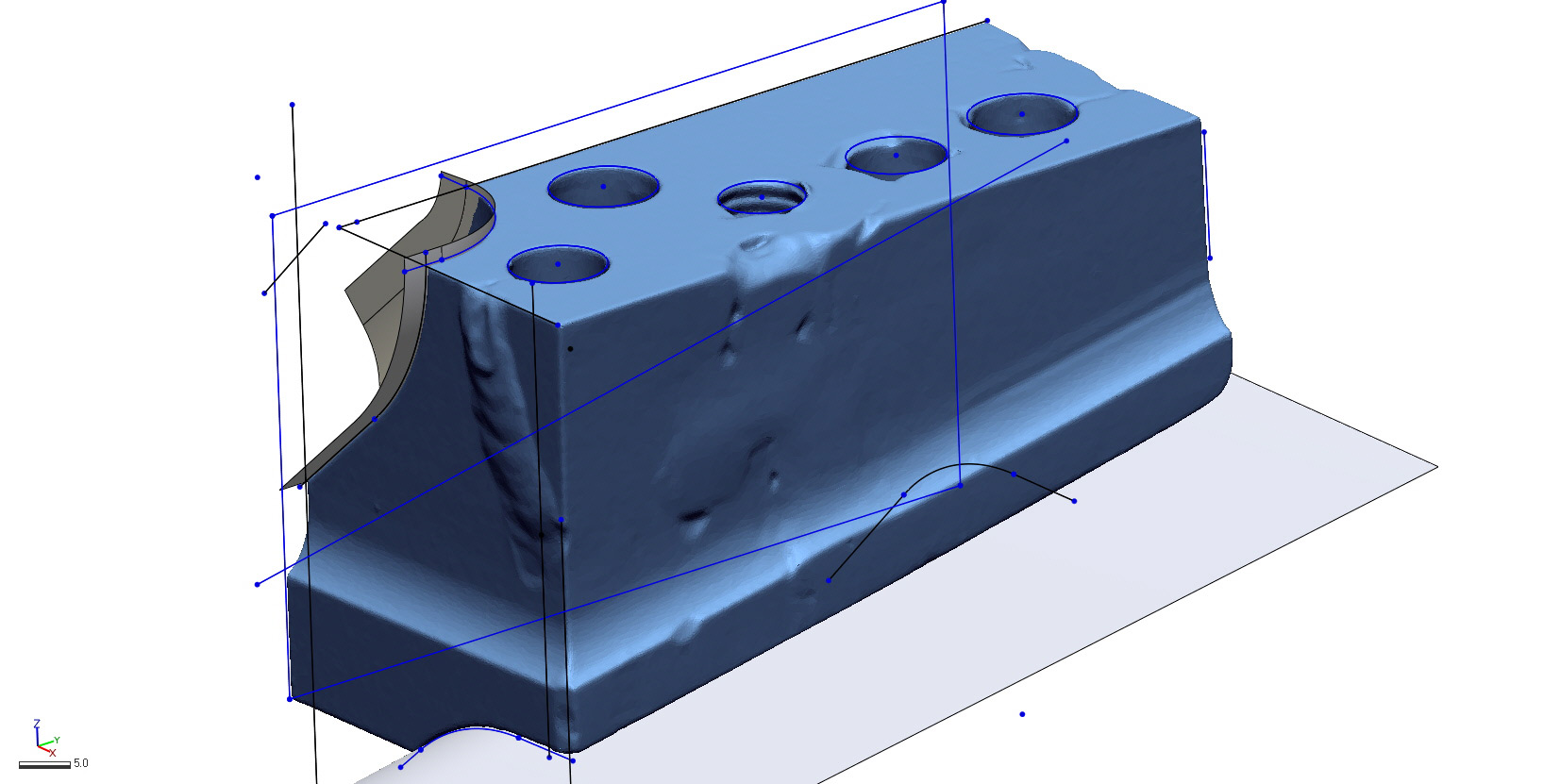

STEP 2 SKETCH THE GEOMETRY

Geomagic Design X offers a large variety of modeling tools like 2D sketching, extrusions, lofting, patterning, and symmetry.

Assets are created and merged into a solid model.

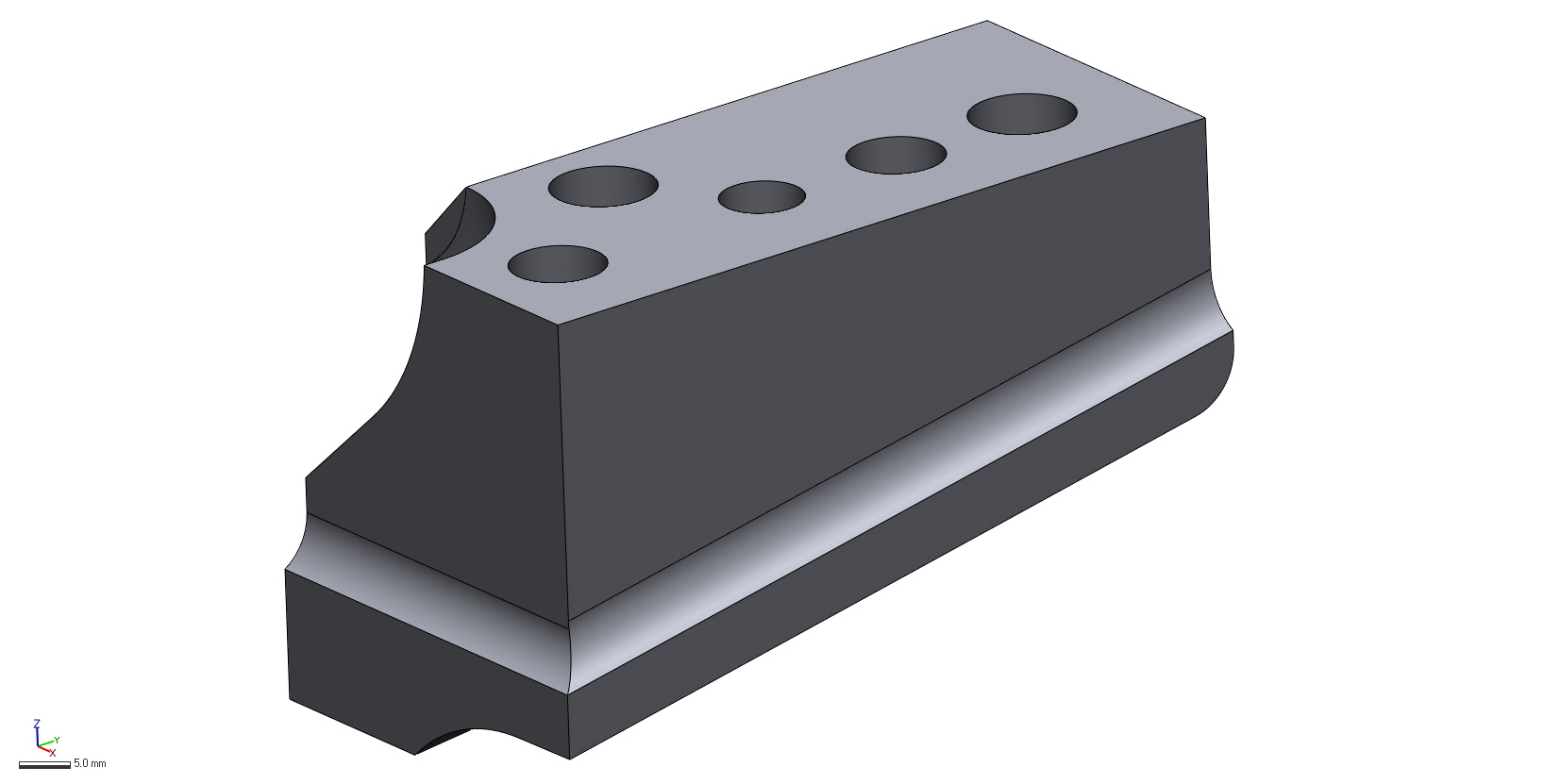

STEP 3 TUNE THE MODEL

After a model is created it is tuned to achieve the minimal amount of deviation. Sometimes surfaces need to be moved or hole sizes adjusted.

STEP 4 REPORT THE DEVIATION

The deliverables for every reverse engineering project include a final .step model as well as a deviation report. This profile heat map shows the areas where the produced model differentiates from the original scan file.

Sometimes deviation is inevitable where a cracked component was stitched back together, while other times a free-form surface cannot be perfectly geometrically replicated.