Inspection of Fluid System

Micro Check Valves

Miniature fluid control components are used in every industry – from scientific instruments like respirators, to defense systems like missile seekers, and automotive EV battery heaters and coolers.

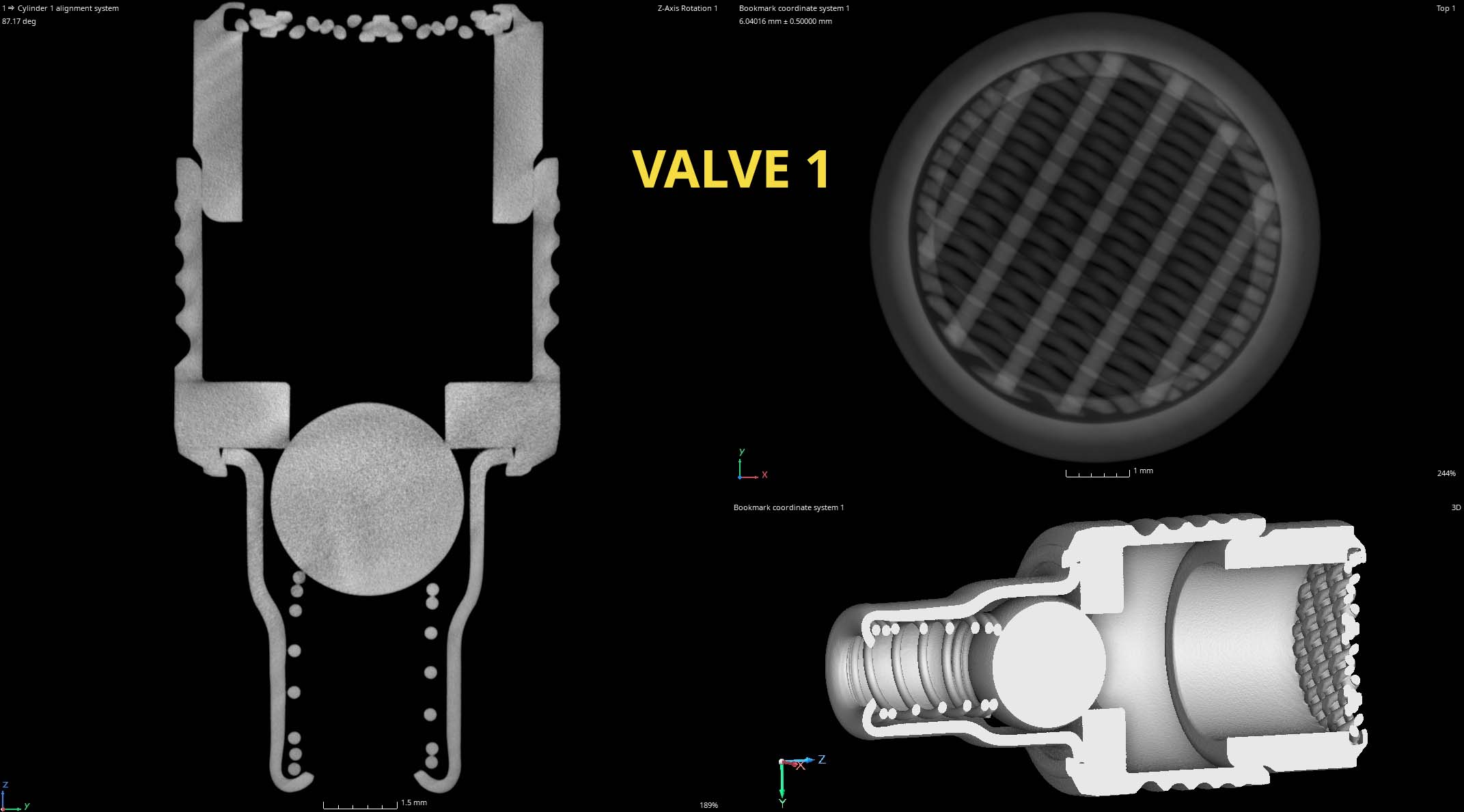

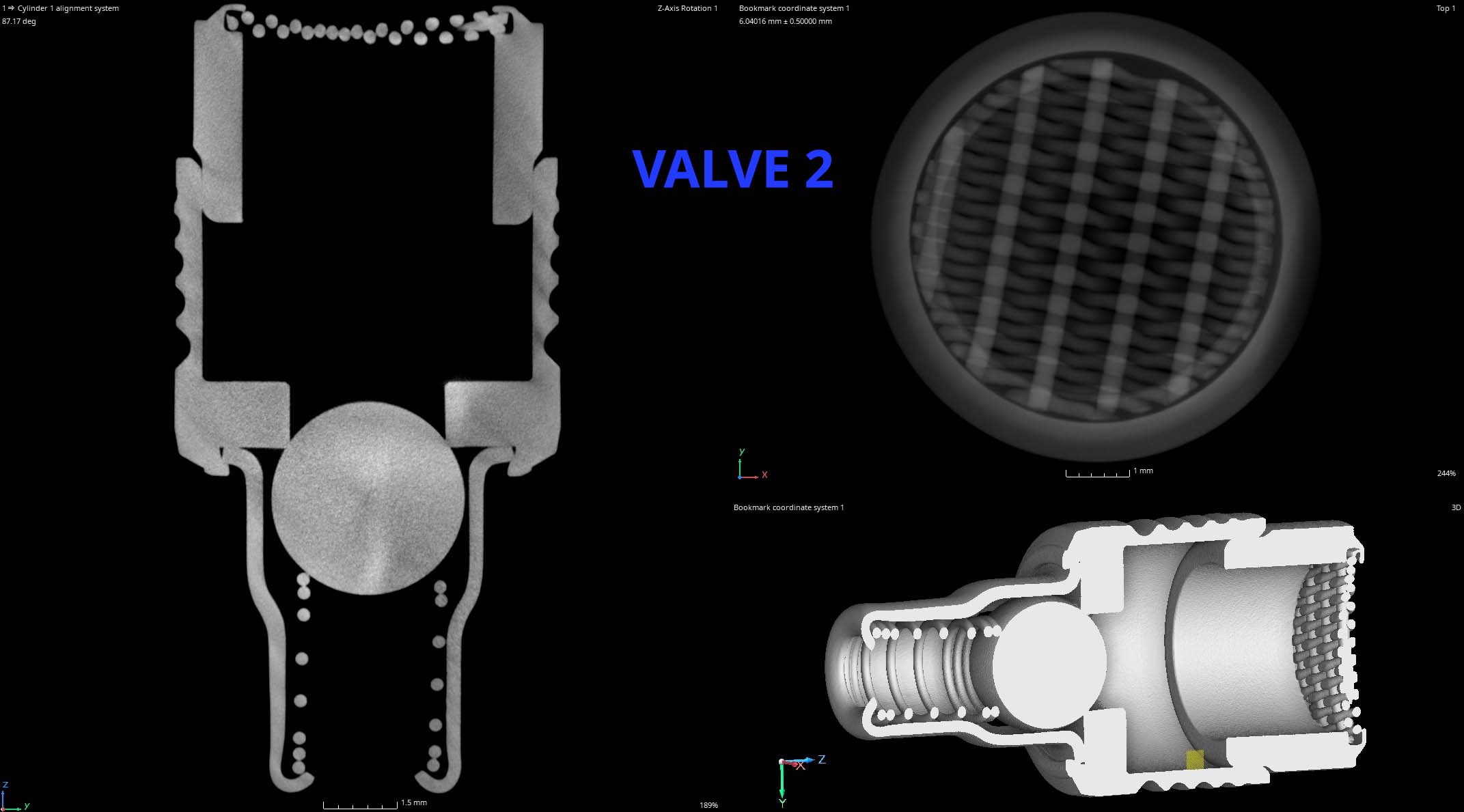

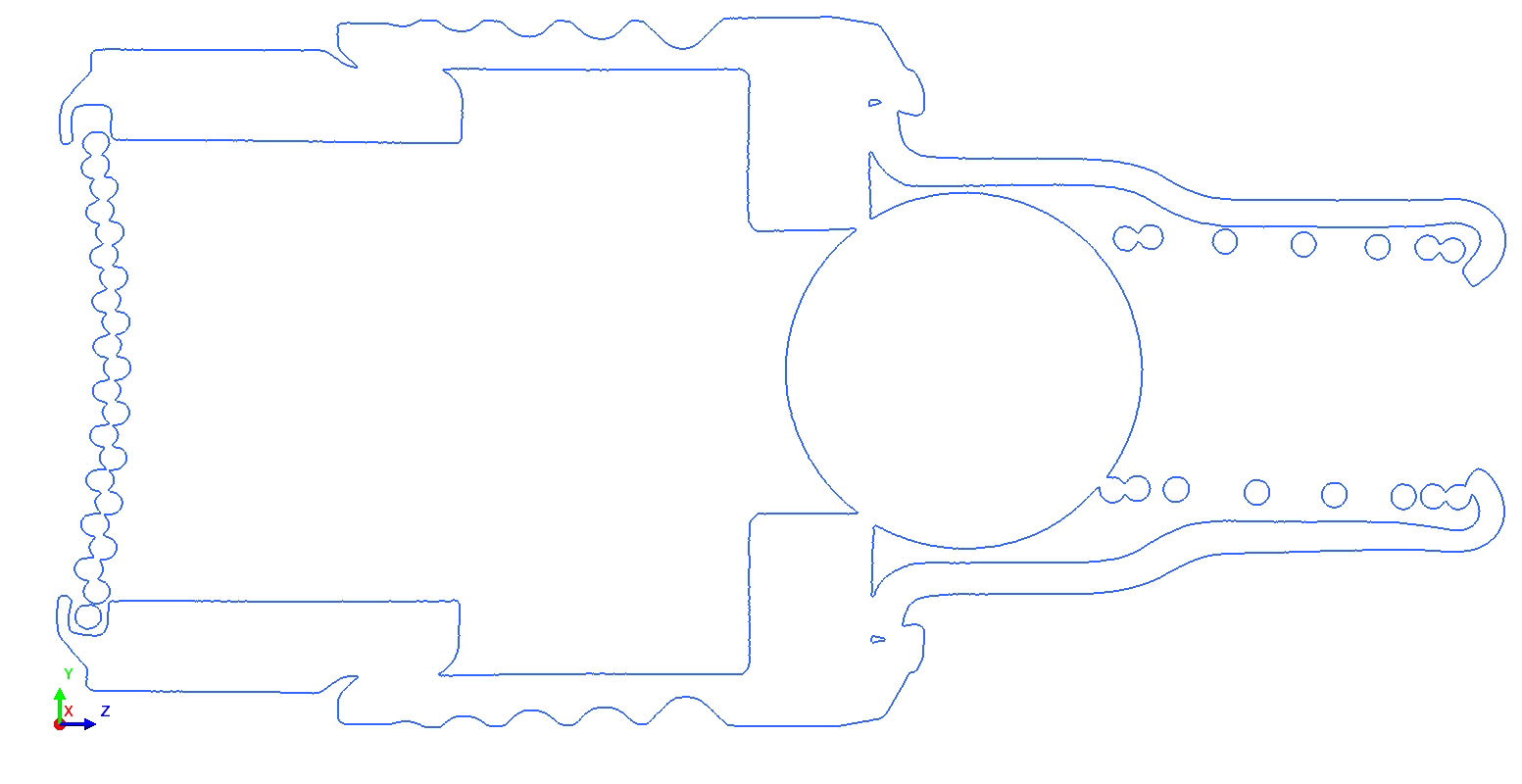

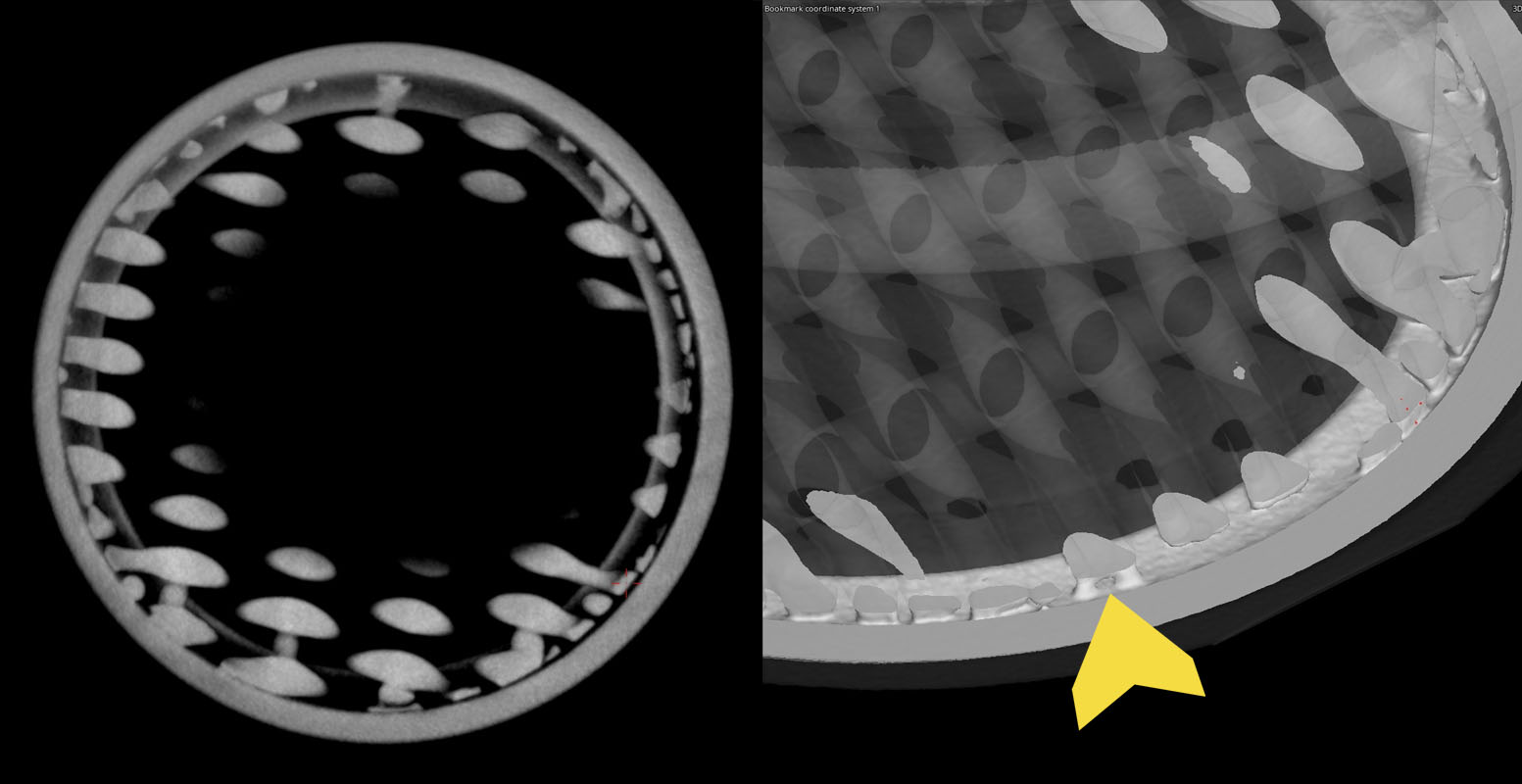

This case study characterizes two stainless steel, mesh screened micro check valves smaller than a dime. We demonstrate CT slice comparisons of the components as well as our measurement capabilities using PolyWorks.

We are able to measure wall thickness, check for component orientation like the spring, ensure the ball seats properly, and image the screen weld.

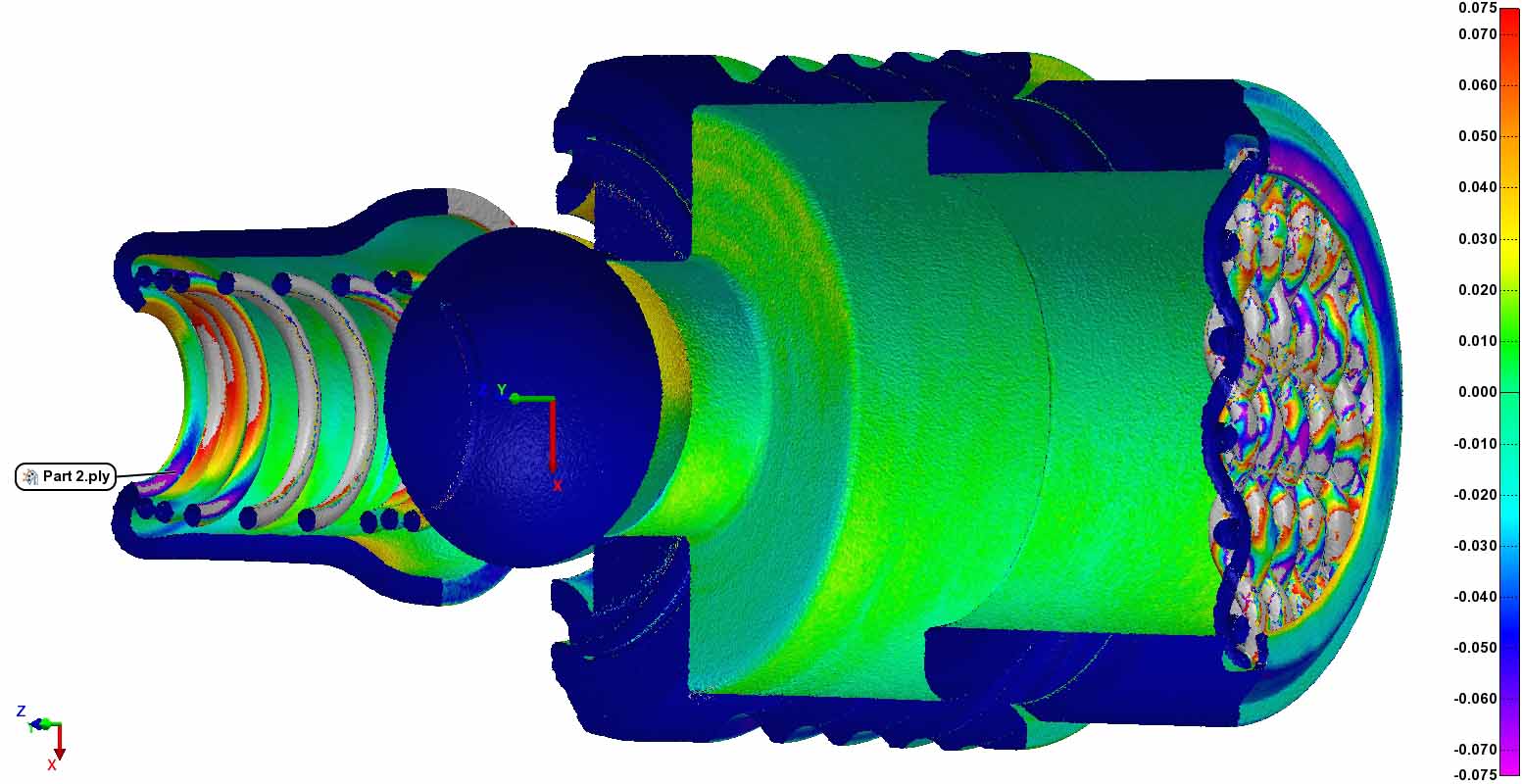

If one part is functioning differently than another we can create a color coded heat map showing the differences.

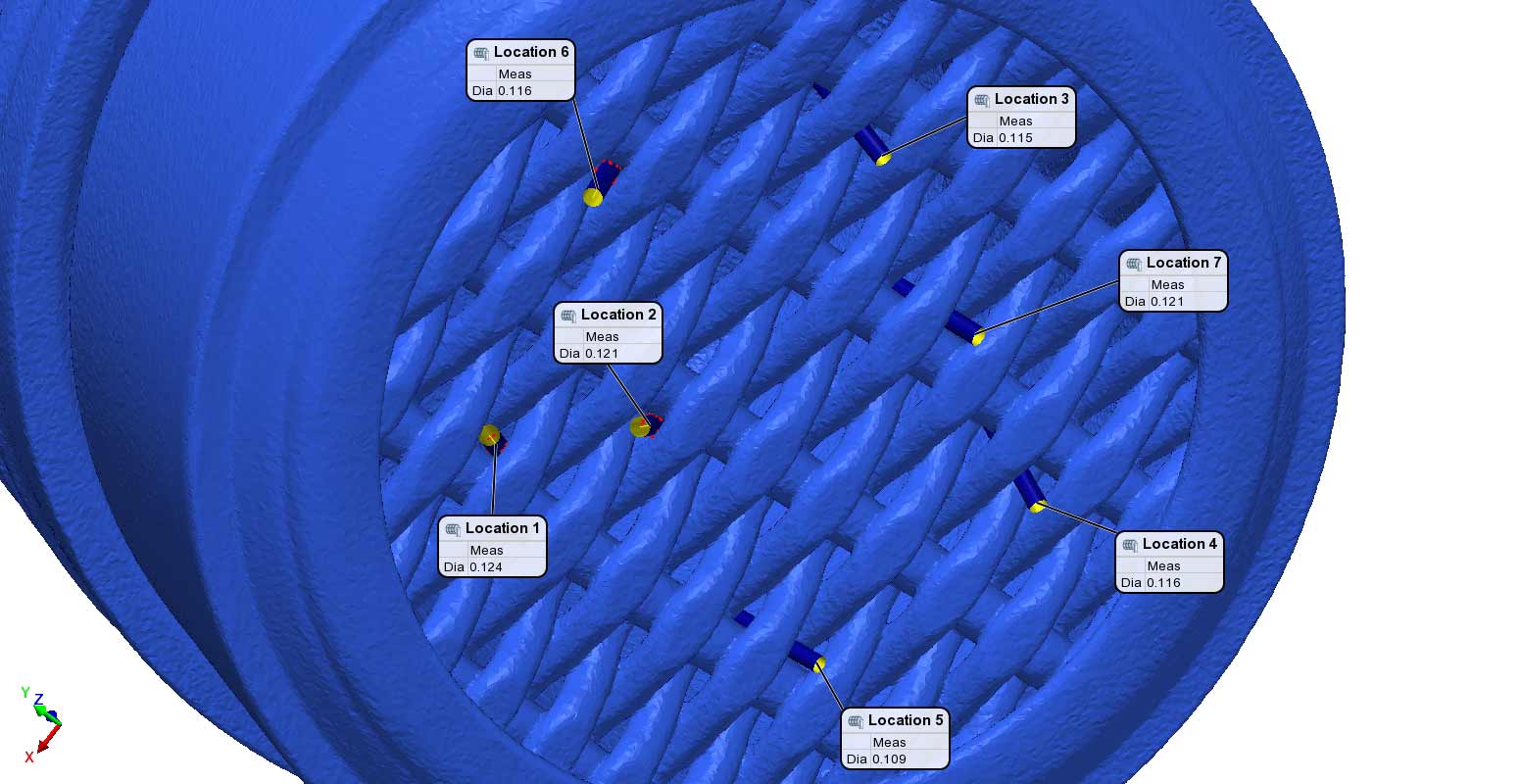

Tangible Measurement of Screen Pore Tolerance

We defined best fit cylinders into the screen gaps to understand the actual diametral width of the screen. We found that the screen, indeed, does not allow any contaminant above 125um diameter through.