INTERNAL INSPECTION OF ADVANCED MATERIALS

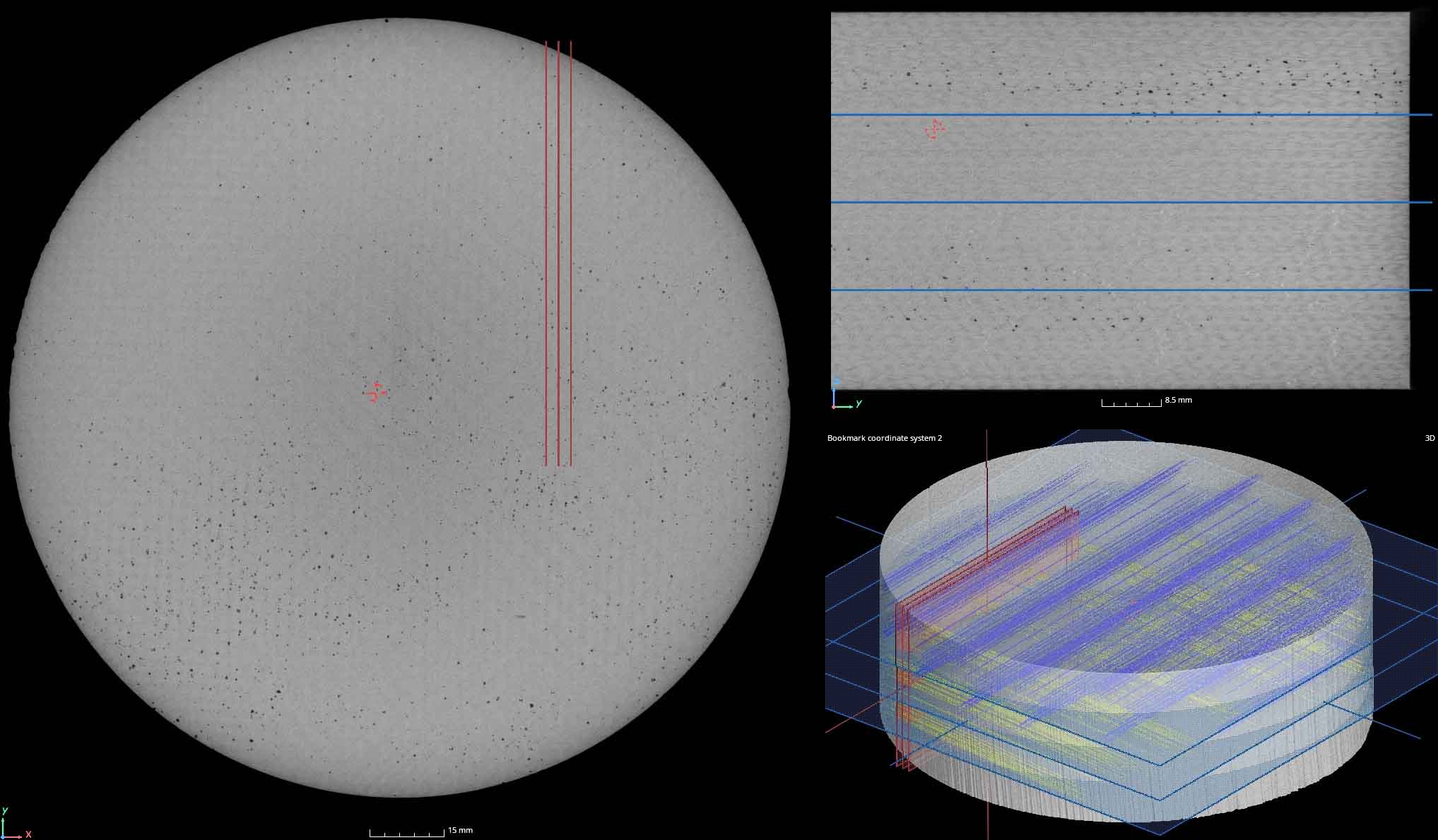

Industrial CT scanning is used to inspect advanced materials for defects like porosity, inclusions, cracks, delaminations, and fiber orientation.

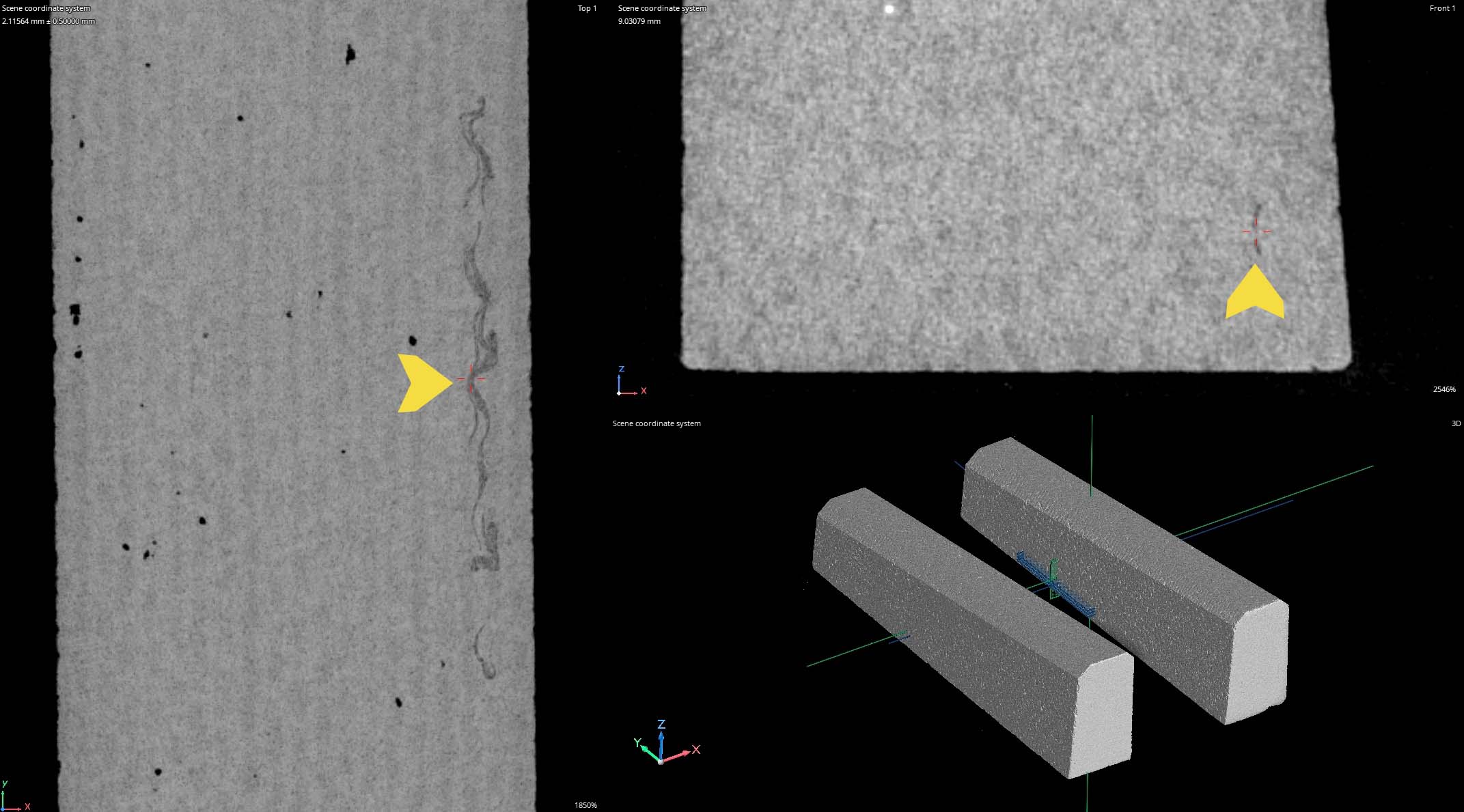

These are aircraft phenolics and their structural integrity is paramount. Pores have been located in proximity to the edge and other indications are characterized throughout the samples.

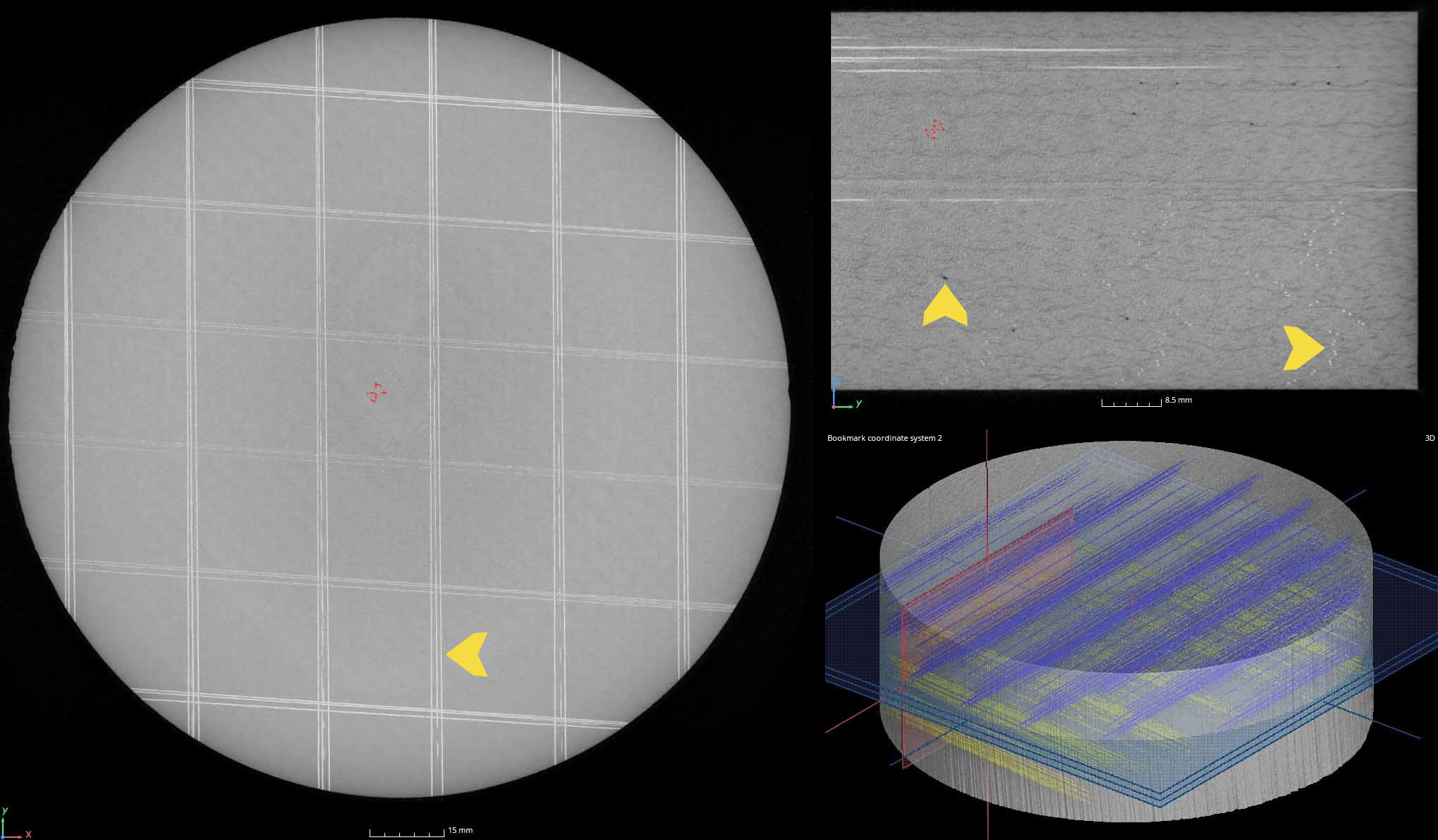

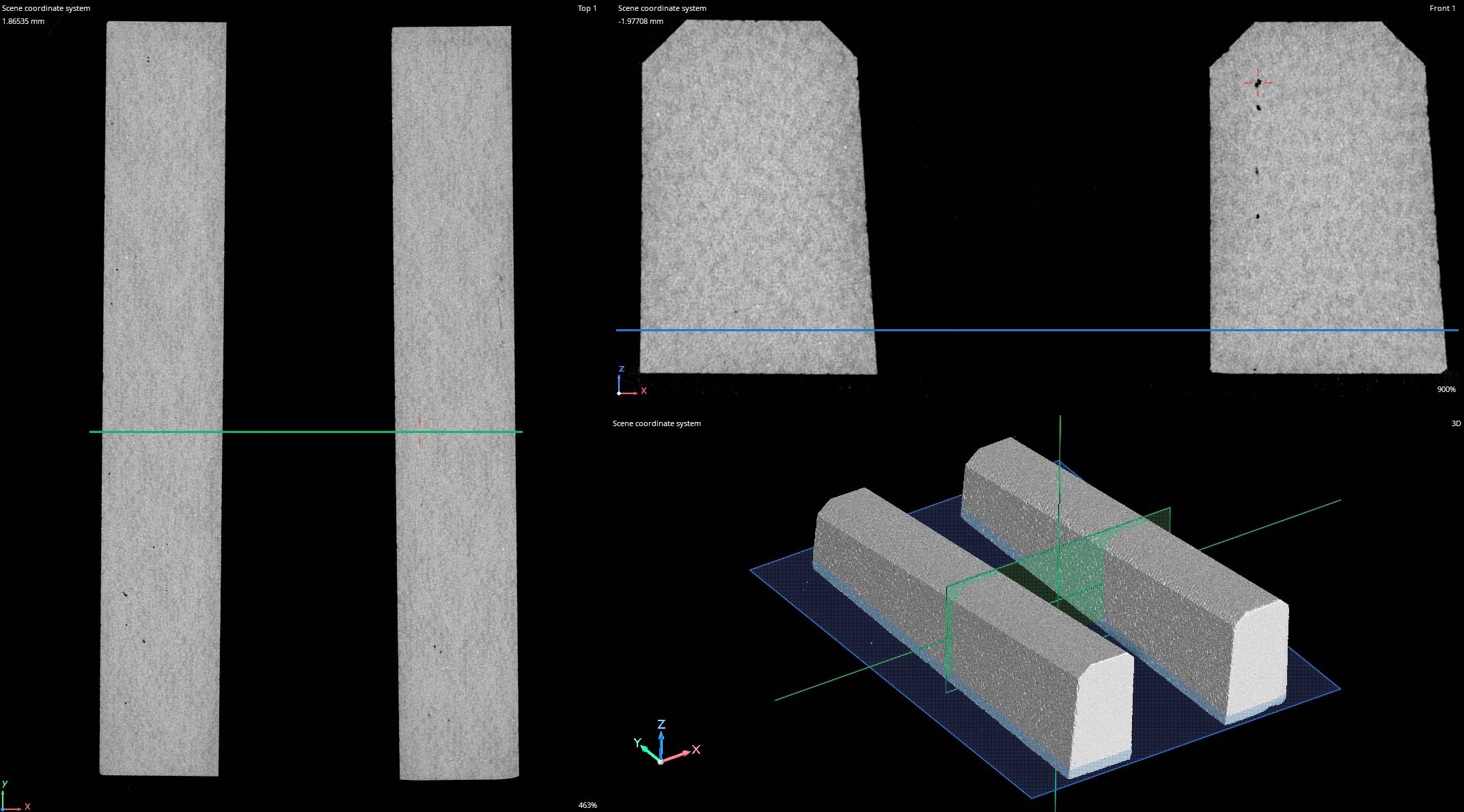

BATCH SCANNING SAVES TIME AND COST

Batch scanning is a technique that can be used to scan several parts at once. This can significantly decrease required scan times and their associated cost. The two samples below were scanned next to each other and separated in Volume Graphics. One drawback to batch scanning is the reduced resolution to fit both samples into the field of view.

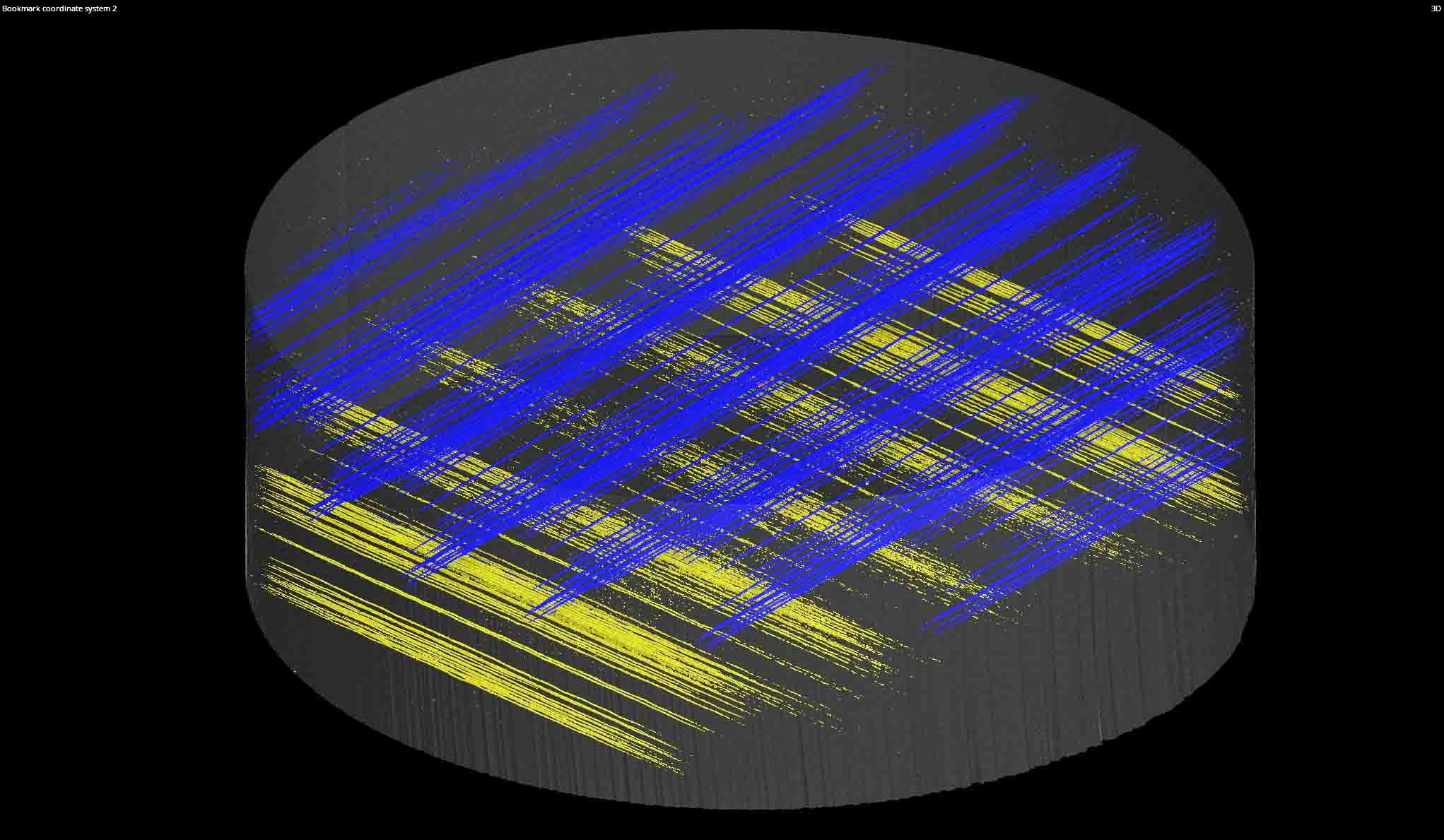

Seen below is a significant linear indication found along the length of one of the samples.

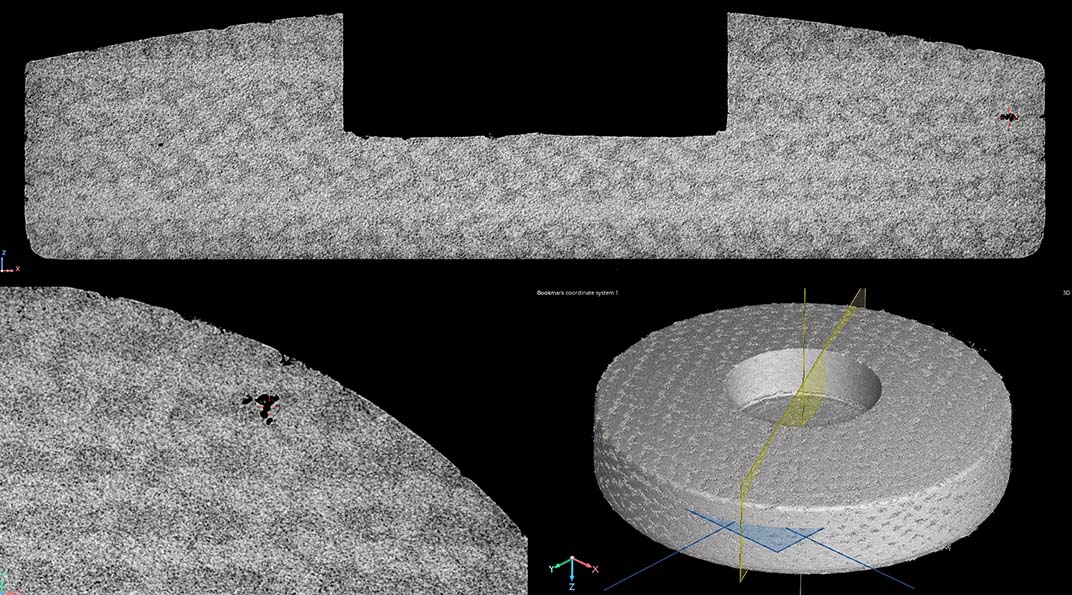

CORE SAMPLE ANALYSIS

Due to penetration and volume limitations of CT scanning, core sampling is used to test a batch of much larger parts to characterize their quality. Clients may section material out of an area of interest (a functionally critical zone or area that is more prone to manufacturing flaws). These core samples are then used to qualify batches of product or compare different vendor processes or lots.

This carbon fiber sample demonstrates porosity, inclusions, and fiber orientation.