Evaluating an Electric Shaver

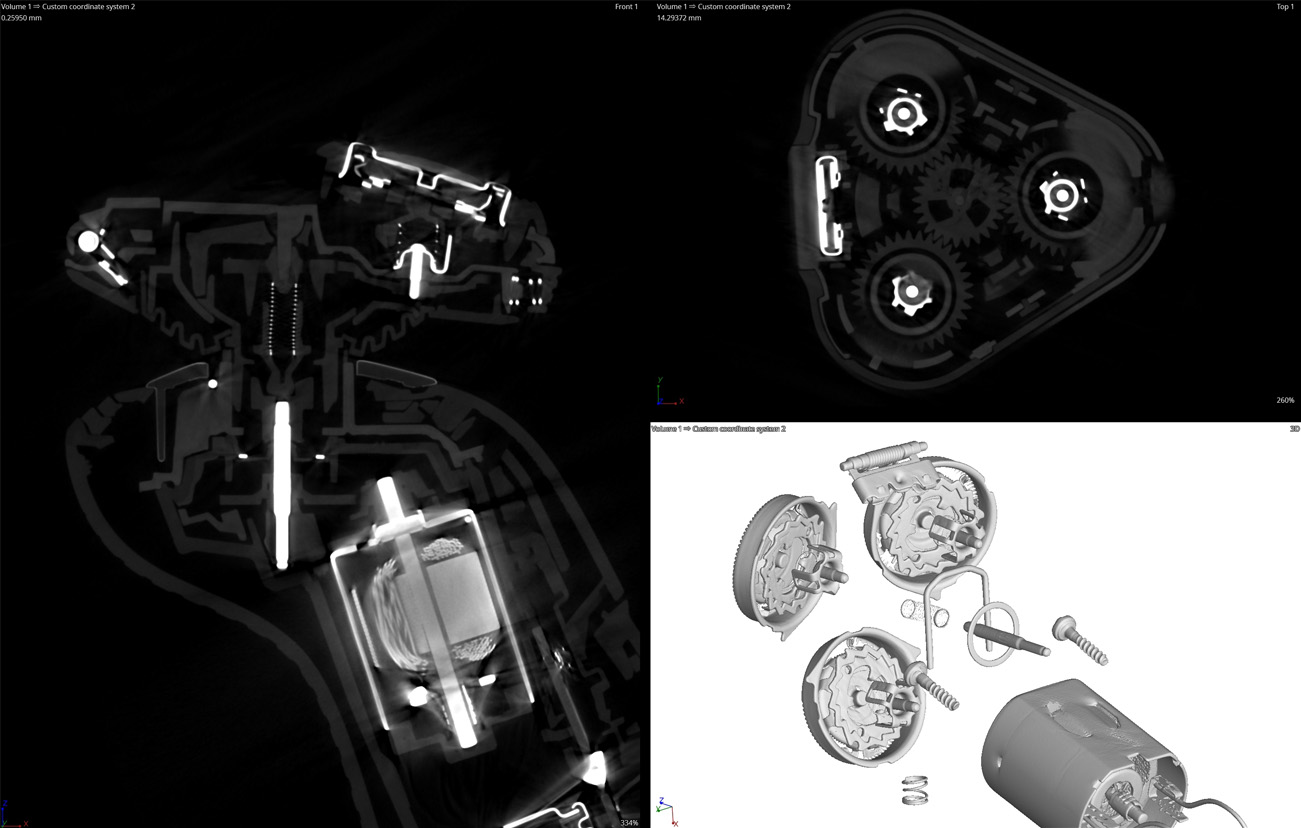

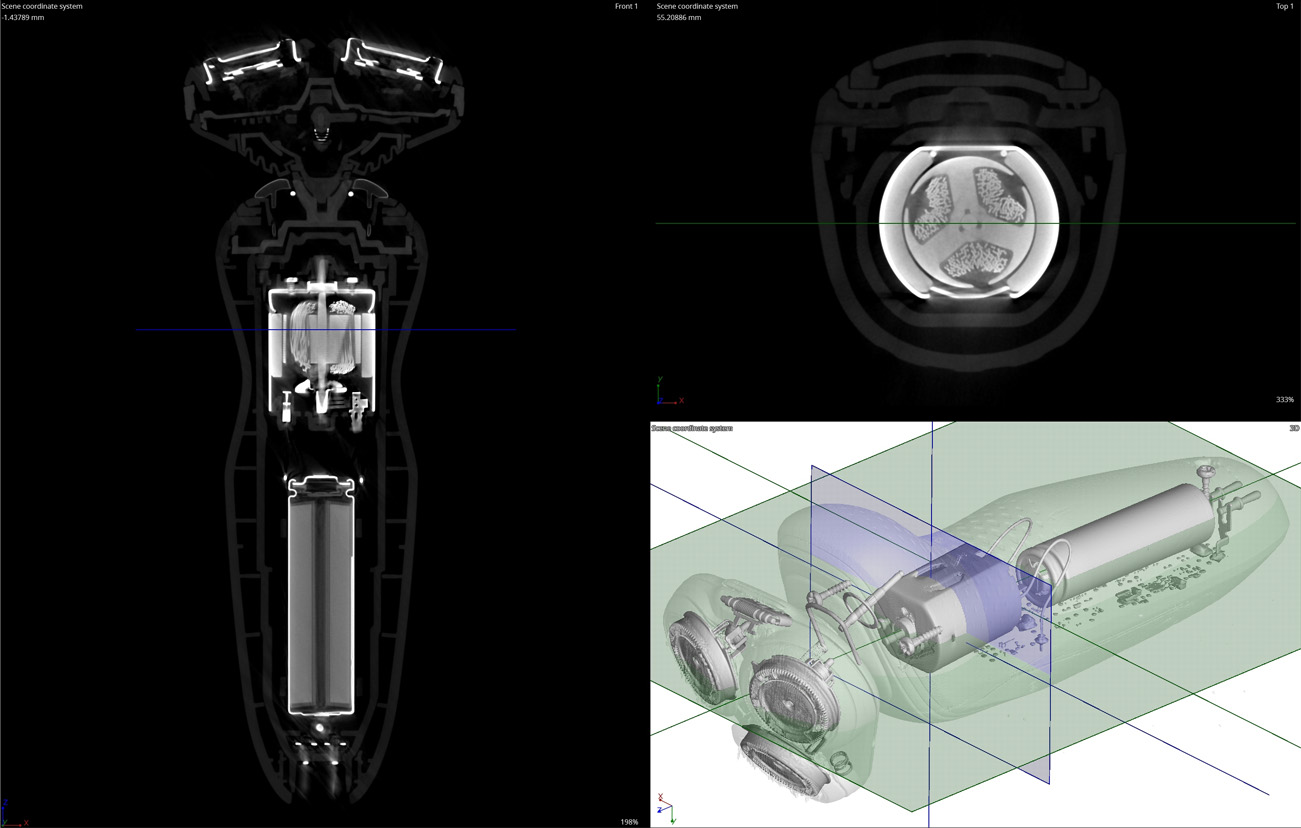

Industrial CT scanning can be used to investigate components and assemblies for proper part placement, failure analysis, and wear. This Norelco shaver is a great demonstration sample because of how complex it is:

- Multiple materials including plastic & metal

- Intricate gears & interfaces

- Small features like sharp blades

- Motor with copper winding

- Rechargeable cylindrical battery

Blade wear comparison

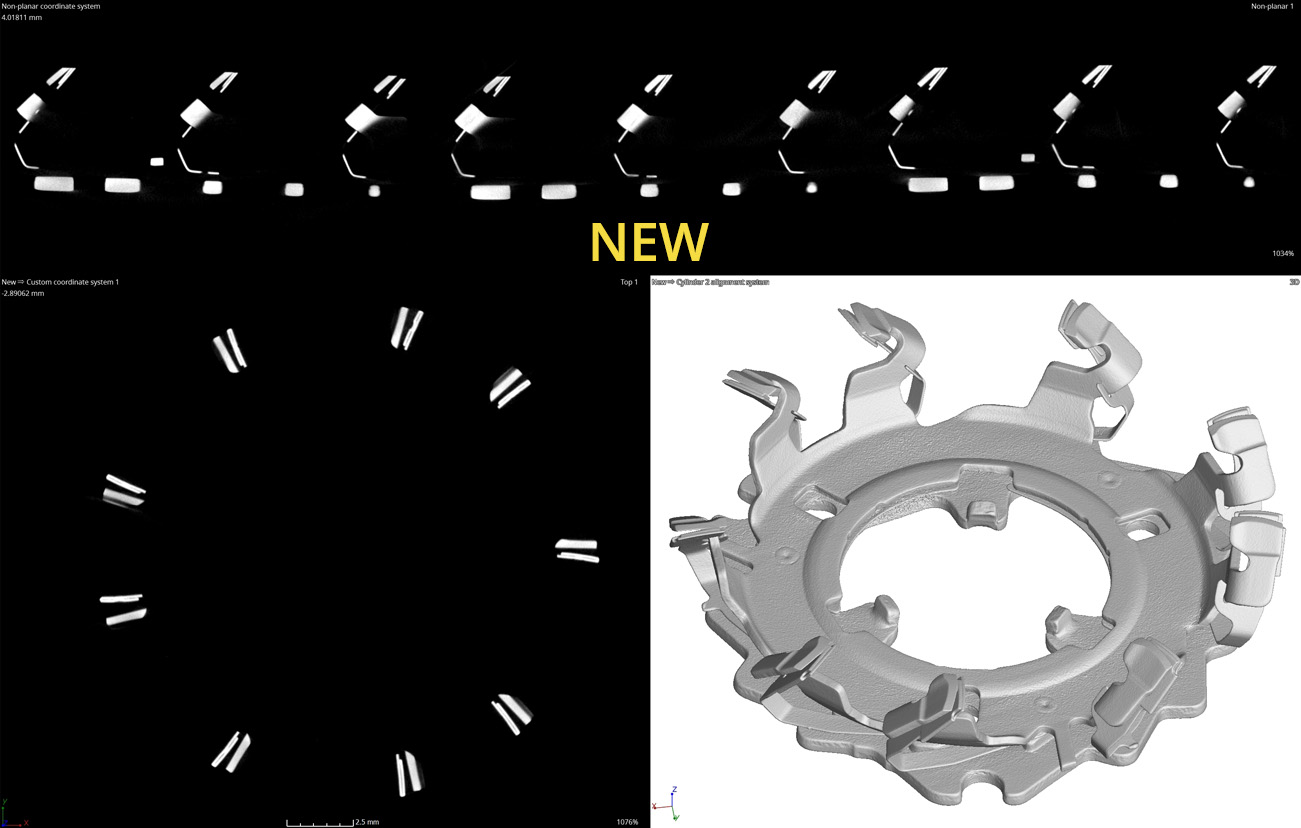

New and used blades were scanned at higher resolution to understand how the part changes and becomes less effective over time. First, the blades were aligned on top of each other for a direct visual comparison.

The top view shows a cylindrical unroll of the blade. This allows us to simultaneously view all nine blades. From this view we can hypothesize that the lower performance of the used blade is caused by the blades being bent downward over time.

measuring the hypothesis

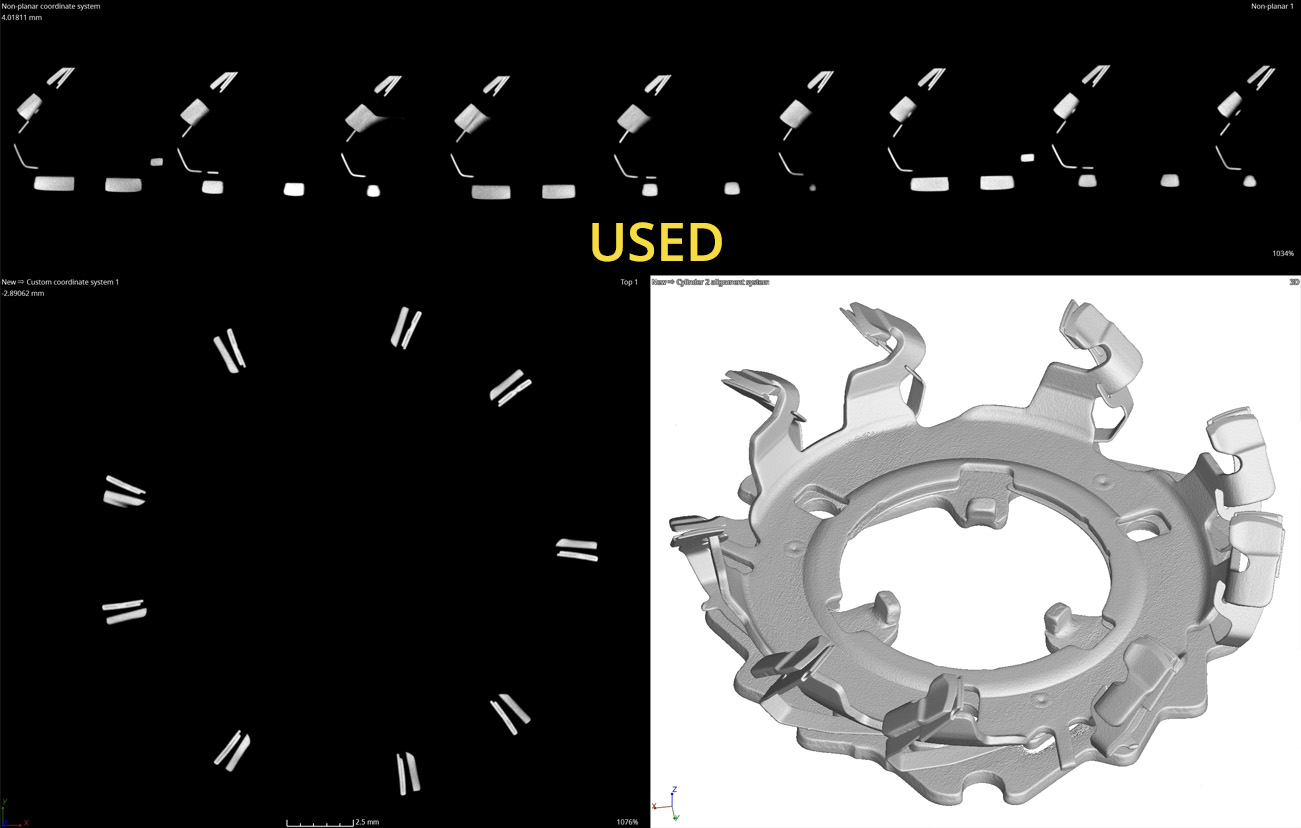

By exporting the blades into .STL scan file format we can use PolyWorks dimensional software to produce a part to part profile comparison. This map confirms that most of the blades are approximately 50 microns lower than the new blade.

CROSS SECTION COMPARISON

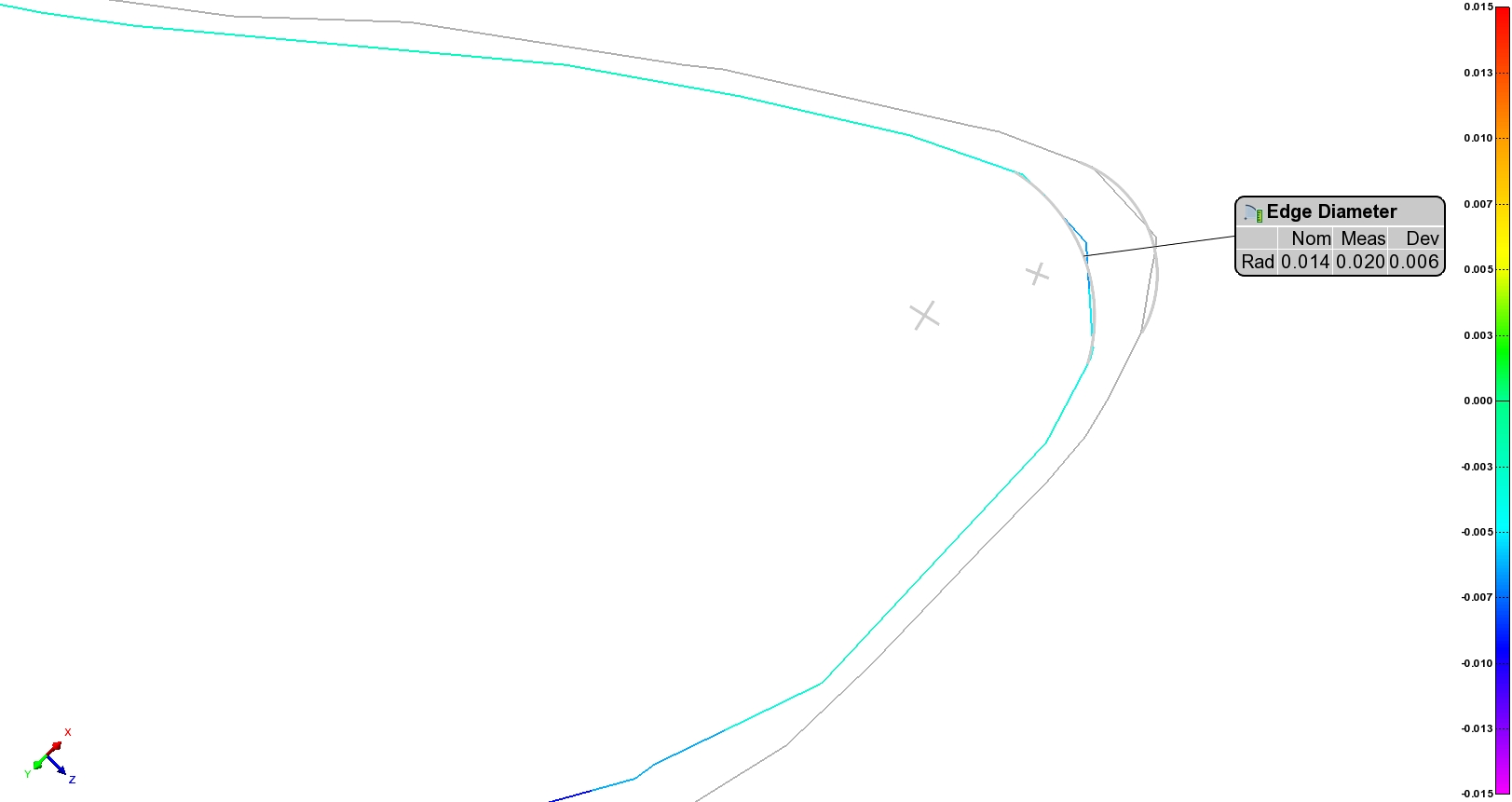

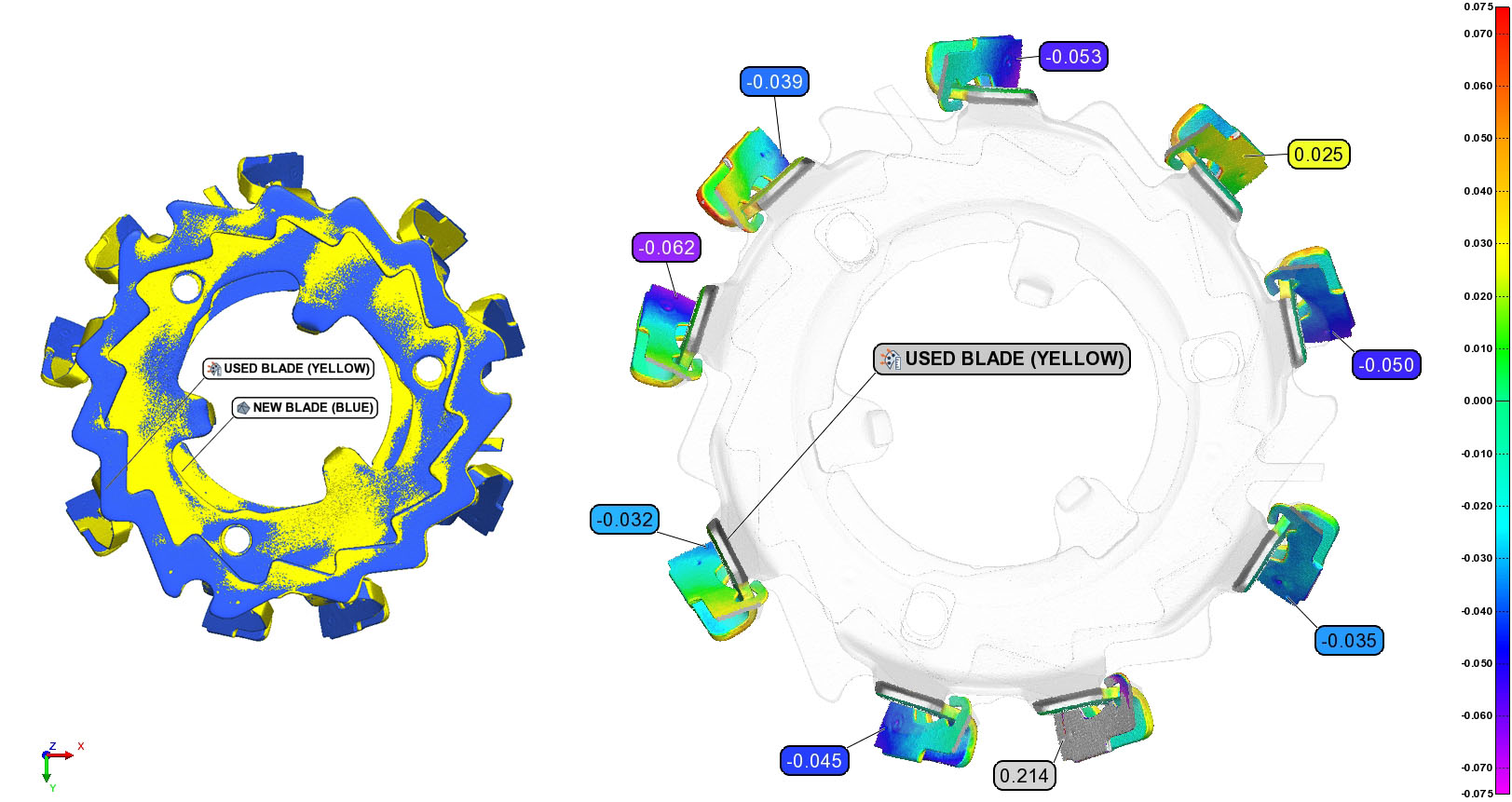

A 2D cross-section is placed across “best-fit” aligned blades. The used blade was then manually shifted to the left to help visualize the samples. Then, arcs were defined on each blade with an approximate deviation of .006mm between nominal (new blade) to measured (used blade.)