PACKAGING inspection using INDUSTRIAL CT SCANNING

We regularly inspect packaging for a variety of goods using industrial radiography and CT scanning. Typical inspections include component presence verification, wall thickness evaluation, and leak path detection. This case study looks at a leaking boxed wine dispenser.

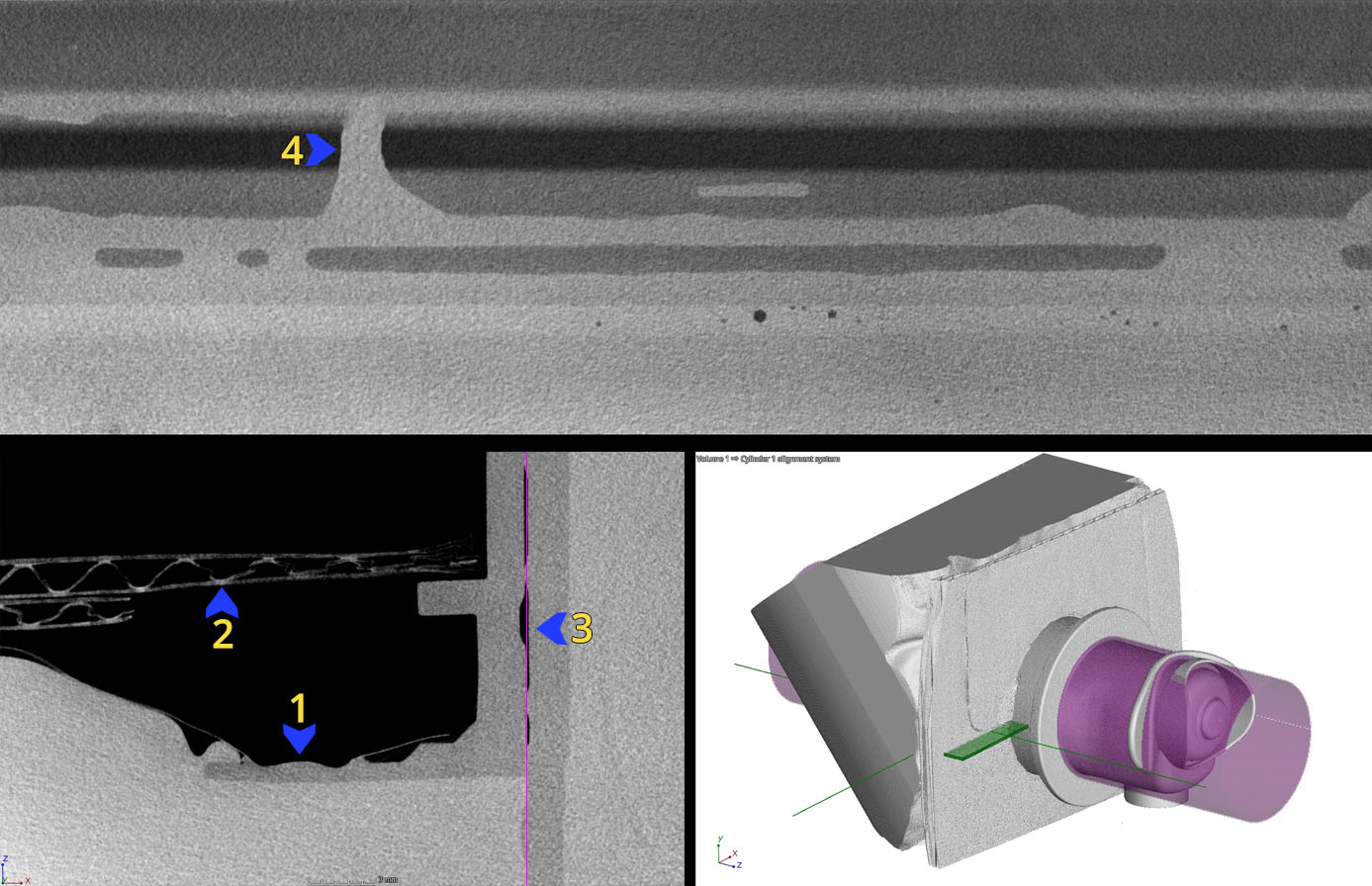

The dispenser itself is very interesting. The image below shows the functional sequence.

1

PRESS RUBBER BUTTON2

BUTTON TRAVELS UP RAMP3

RAISED BUTTON LIFTS RUBBER SEAL & COMPRESSES W-SHAPED SPRING4

UPON RELEASE, W-SHAPED SPRING FORCES SEAL BACK TO CLOSED POSITION

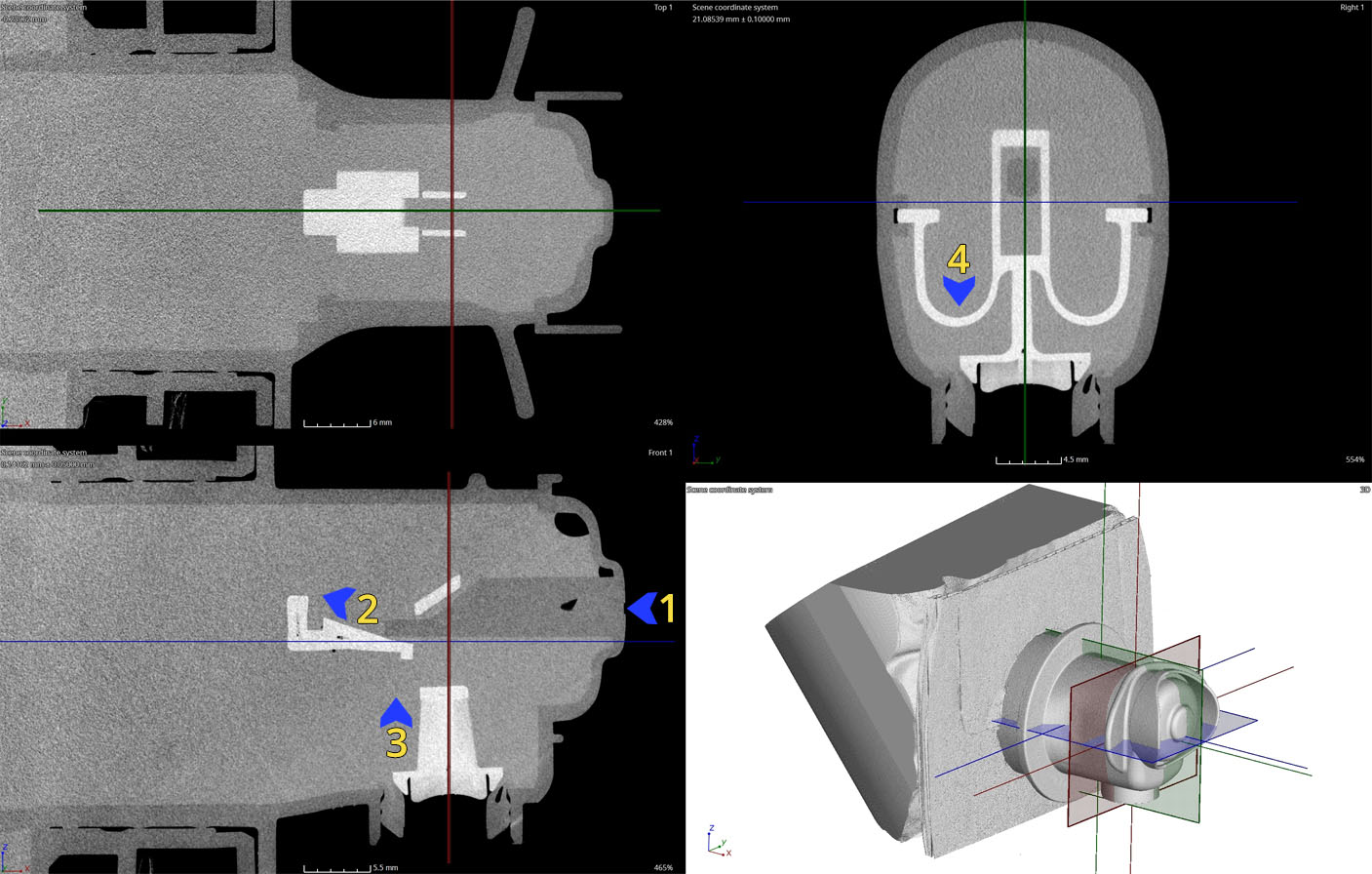

Investigating Leak Point of Origin

1

PLASTIC BAG SEAL - BAG TO DISPENSER BONDED TOGETHER2

CARDBOARD PACKAGING3

UNROLL VIEWING LOCATION - USEFUL FOR VIEWING A CYLINDRICAL FEATURE IN A PLANAR VIEW4

UNROLL VIEW - LEAK PATH - DEFECT OF INTEREST LOCATED