CT SCANNING IMPLANT SCREWS FOR INSPECTION & REVERSE ENGINEERING

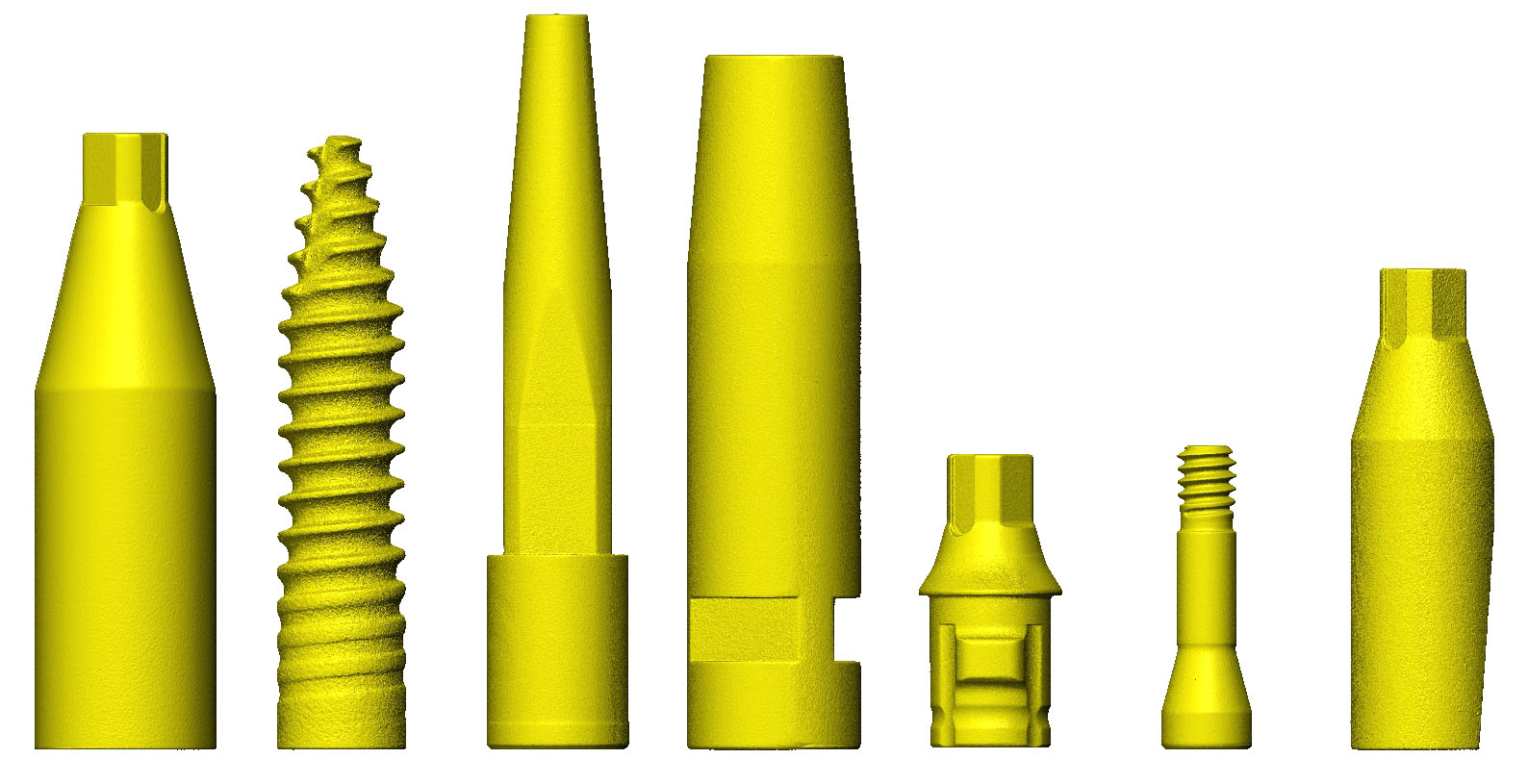

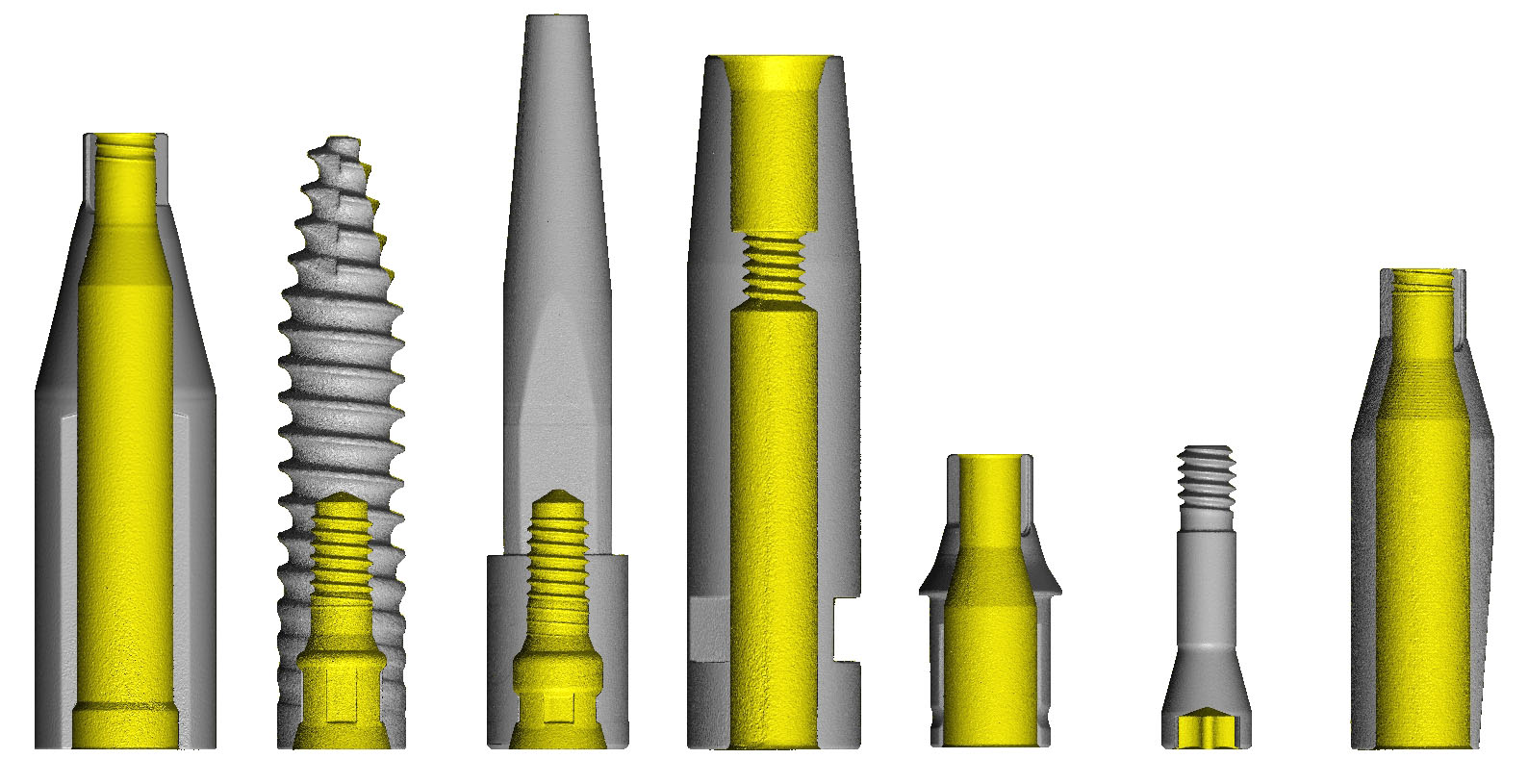

Microfocus CT scanning is used to produce high resolution, water tight scan files of implant screws for a variety of reasons including:

- Non-destructive evaluation – ensuring products are free of contaminants and flaws like cracks

- Dimensional evaluation – ensuring products meet design specifications like profile and concentricity

- Reverse engineering – manufacturers may need accurate models of products to design their own geometry

CT SCANNING FOR REVERSE ENGINEERING

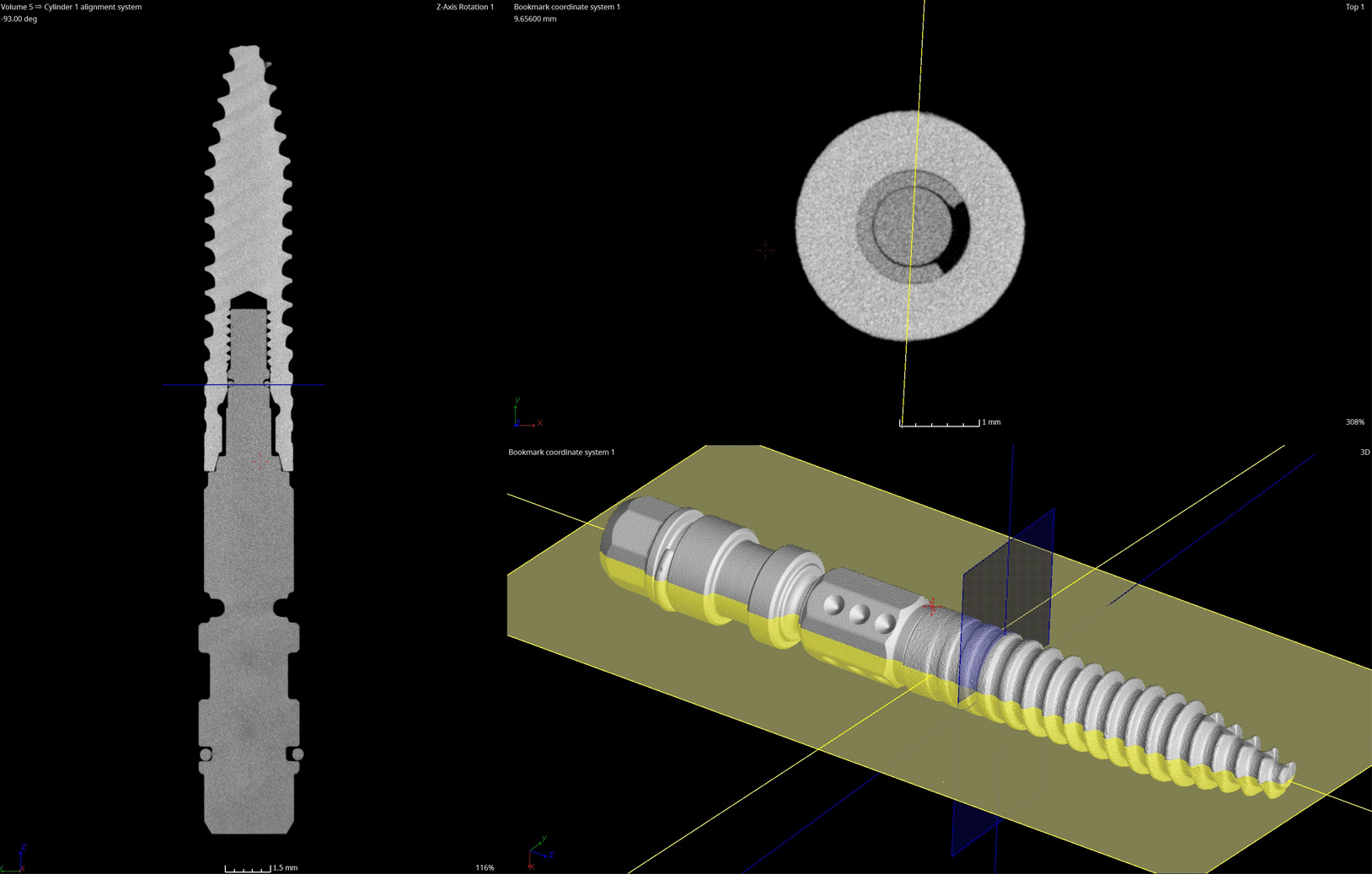

The sample to the left has been reverse engineered to a toolable .STEP model. The screw was CT scanned, exported to .STL, and then modeled in Geomagic Design X.