Unlike the medical industry with radiologists receiving years of education and practical training, anyone with enough money can purchase and use industrial x-ray equipment. This is why it’s critical to find a team of radiographers certified under governing bodies and with tenures from the most renowned aerospace and inspection companies.

Our team is led by ASNT / NAS-410 certified staff. Our NAS-410 written practice ensures all staff are current on their practical experience, training, and certifications. Written procedures for each inspection method are used in conjunction with a library of ASTM specifications, IQIs, and reference radiographs.

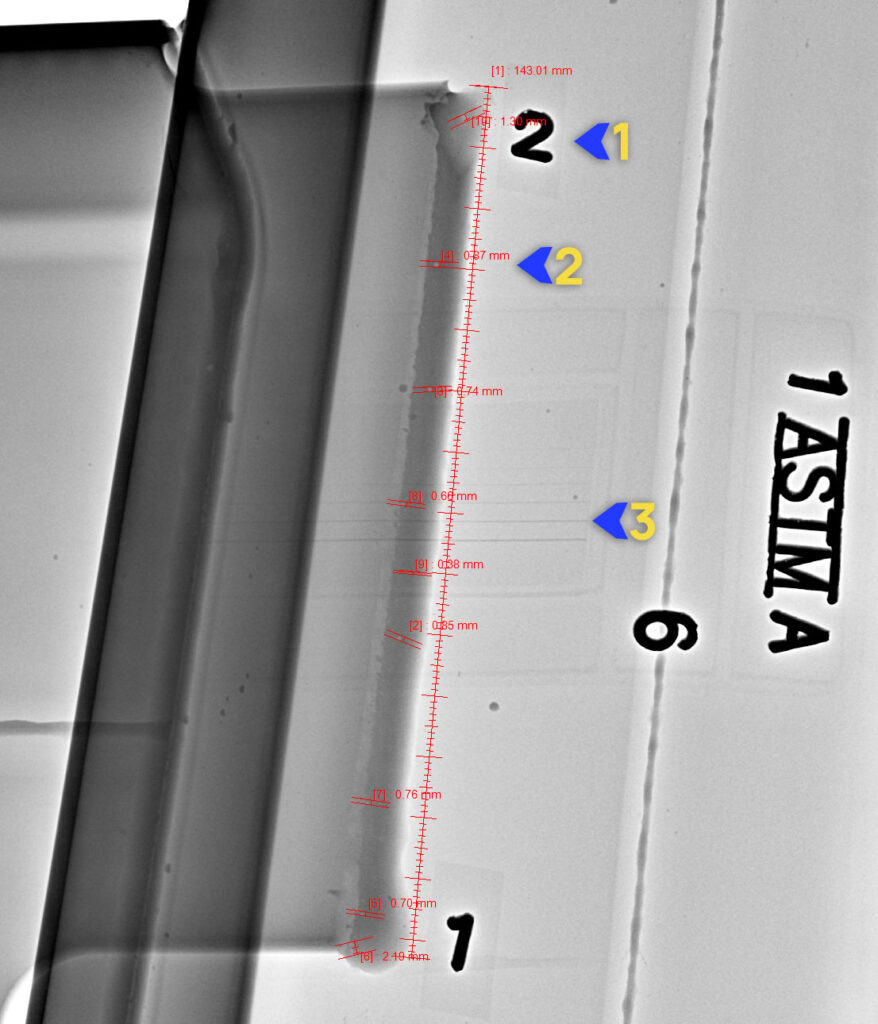

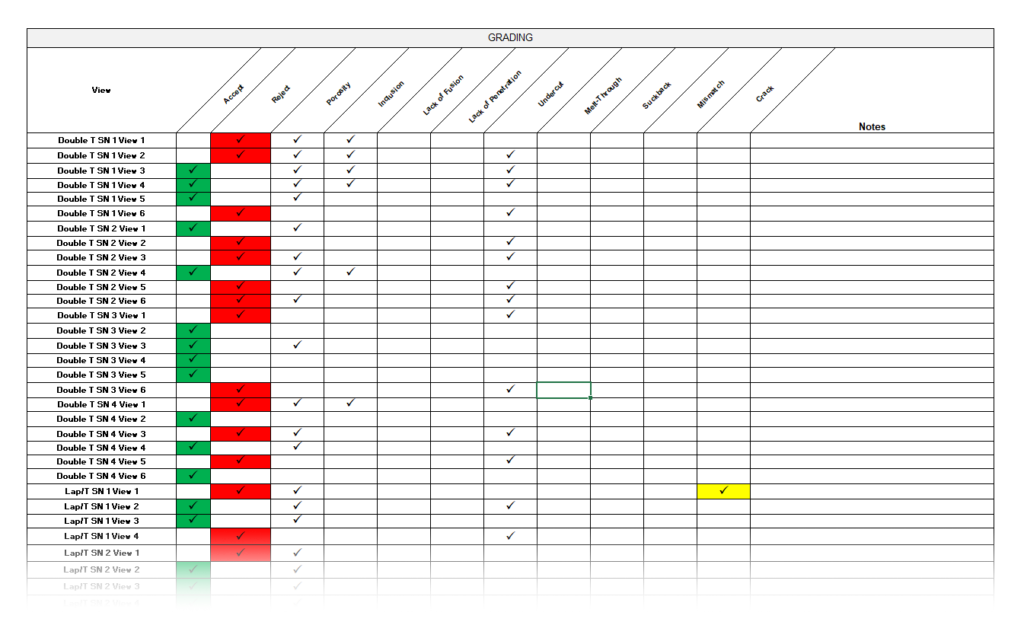

The below image is an indicated digital radiograph of a steel weldment. The weld is x-rayed in accordance with ASTM E2698, graded in accordance to AWS D8.8, and reported with accept / reject for each indication type. Each certified project includes a technique sheet describing all the parameters of the test so it can be duplicated in the future.

- Lead markers – used to define where each weld is in each shot

- Digital indications and measurements are used for precise grading evaluation

- Image Quality Indicators are used to qualify the test method and parameters