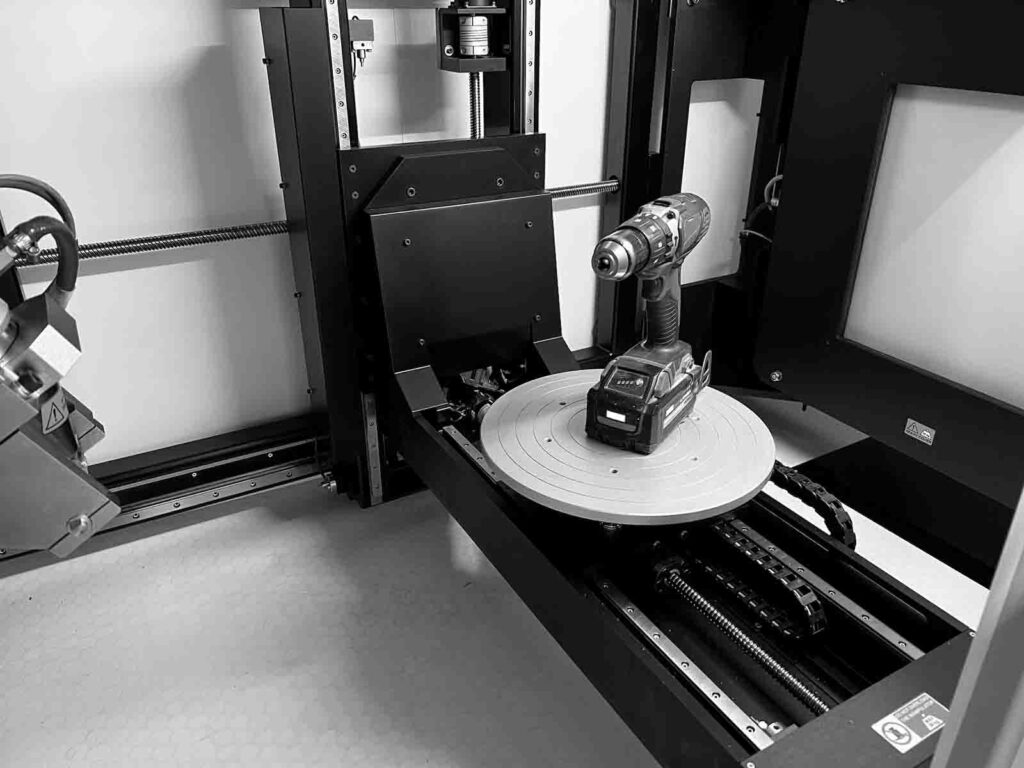

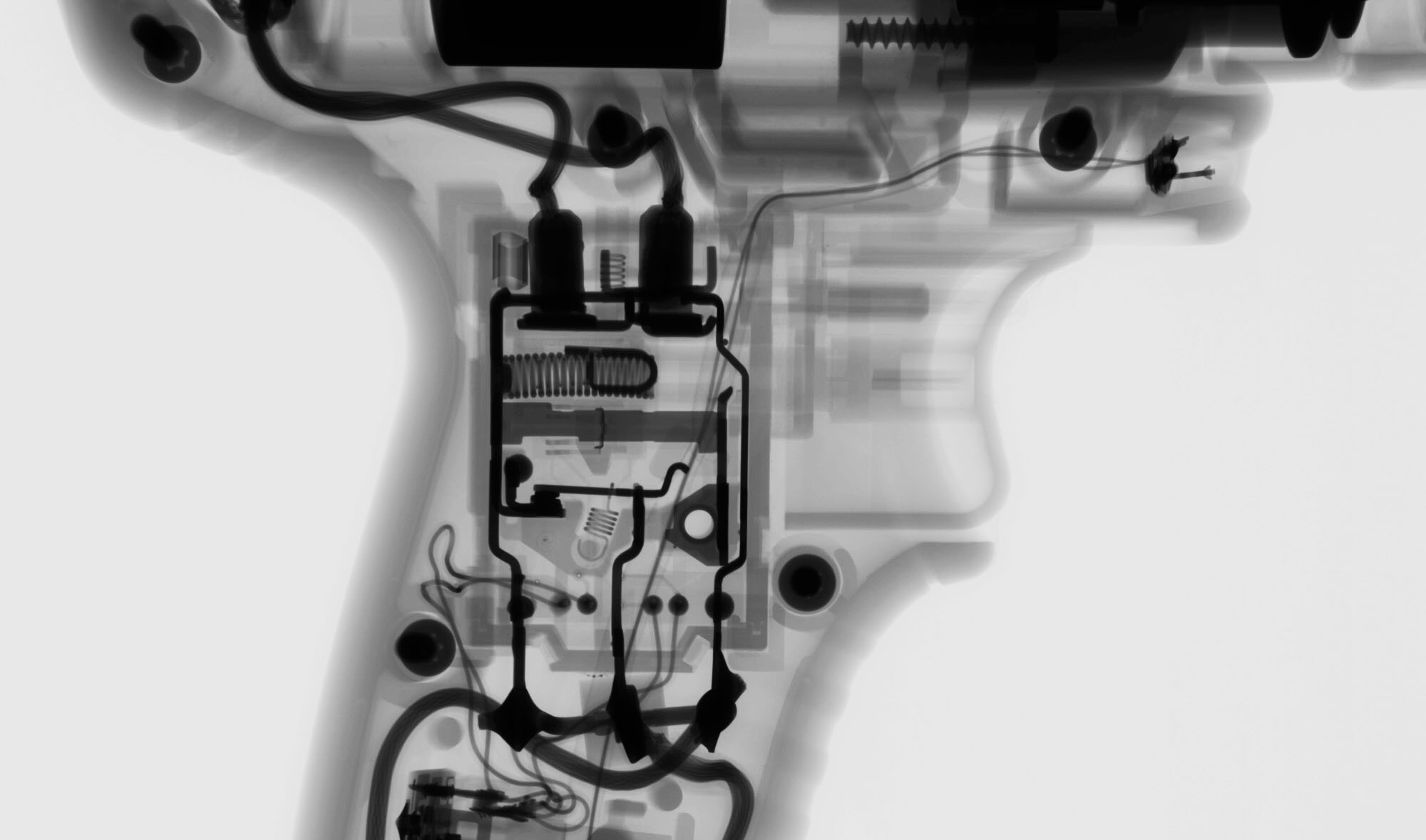

Industrial X-Ray & CT SCANNING OF POWER DRILL

Industrial X-Ray & CT inspection services allow our clients to inspect the internal geometry of their products. This case study explores a power drill. We’ve worked on a variety of home goods like coffee grinders, chainsaw starters, shaver bladers, and mouthwash caps.

High resolution x-ray and CT also allows technicians to measure internal, inaccessible geometry, evaluate fine details like wire bonds and porosity in solder joints, and characterize leak paths in consumables.

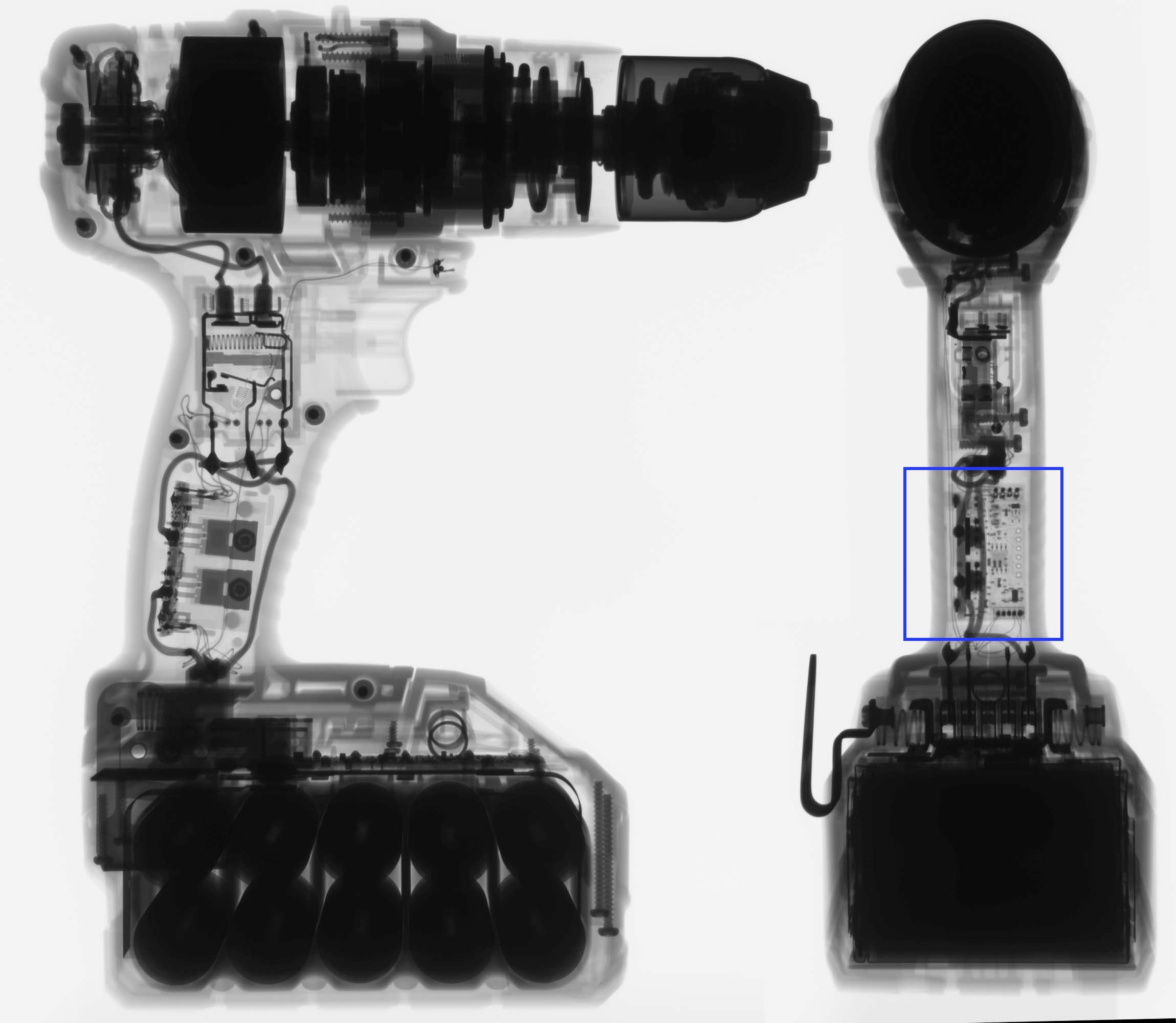

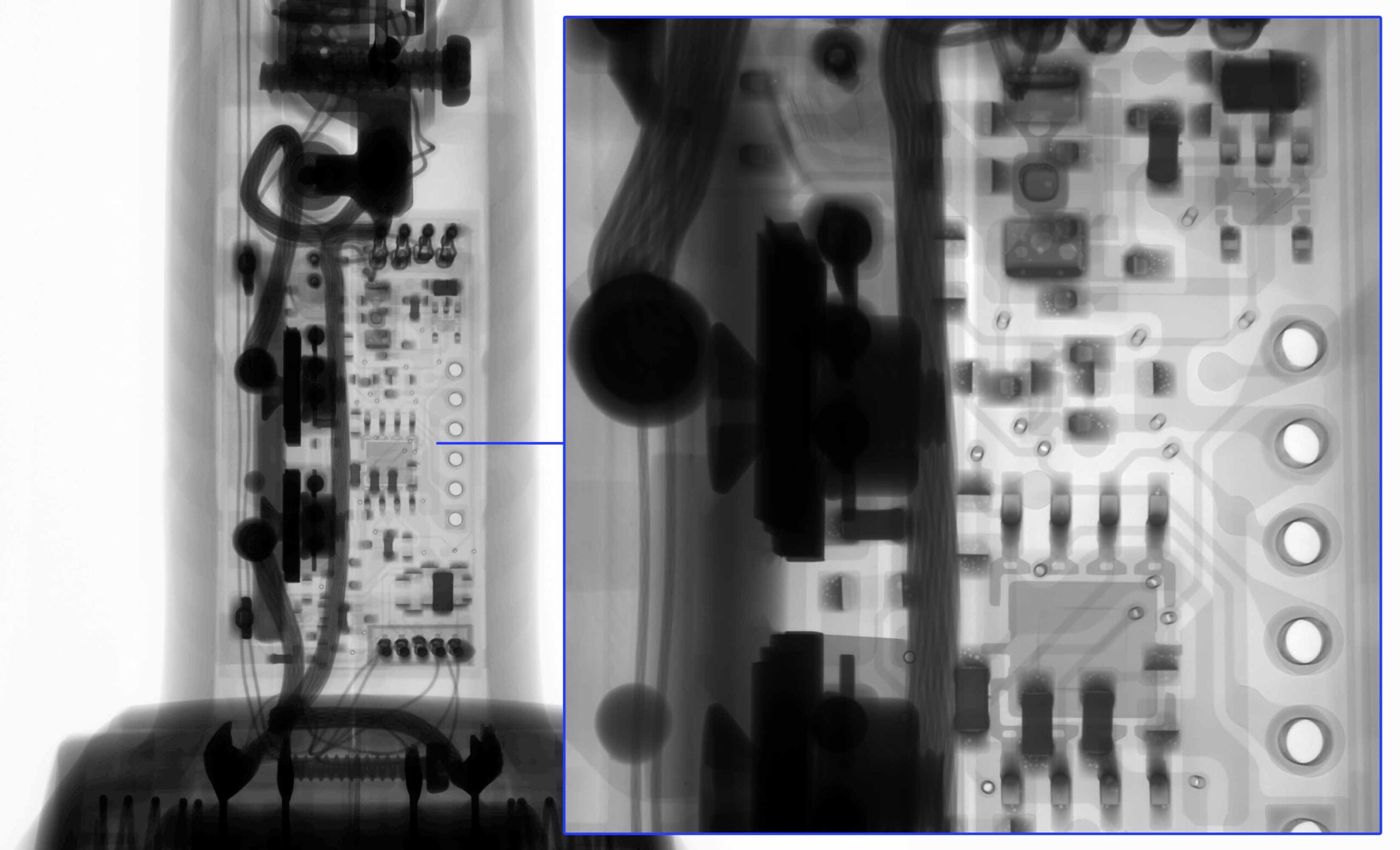

General Digital X-Ray Images of Power Drill

Our digital x-ray systems have variable resolution ranging from 3um to 125um. This allows us to image very small and very large objects. This drill could be imaged at low resolution for general component placement (springs are in position) or at high resolution to detect and calculate porosity in the PCB joints.

Pre-to-Post actuation is useful for understanding the dynamics of a complex assembly. For example, happens when something is powered up? How much clearance is there when a lever is pressed? Fill the blank with your own scenario and consider letting Industrial Inspection quantify it for you.

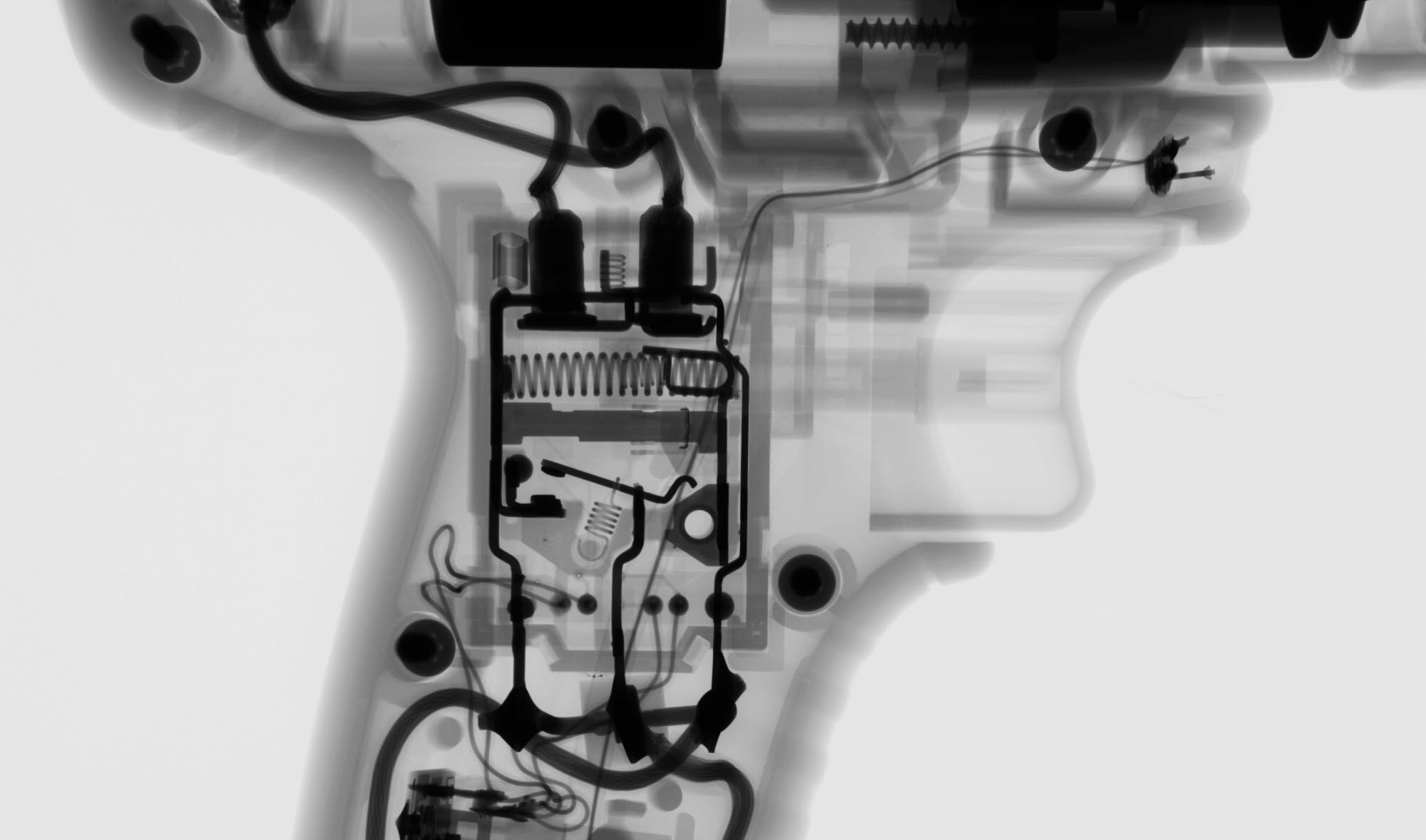

INDUSTRIAL CT SCAN OF POWER DRILL

2D Digital radiography is great for a general understanding of components. However, 3D CT scanning allows inspectors to produce tangible, complex measurements of devices. For example, we could measure the concentricity the chuck components, the profile of the handle, or the depth wires are placed into a connector.