CHARACTERIZING AM COMPONENTS USING INDUSTRIAL CT SCANNING

Industrial CT Scanning is used to characterize 3D Printed / Additively Manufactured components. A strength of these components is the ability to manufacture complex geometries that more traditional manufacturing methods are incapable of producing. However, because of the part complexity more traditional inspection methods like tactile probes and vision system are inadequate. CT scanning can be used to dimensionally inspect and non-destructively evaluate these components for rejectable flaws (porosity, trapped powder, wall thickness, & profile.)

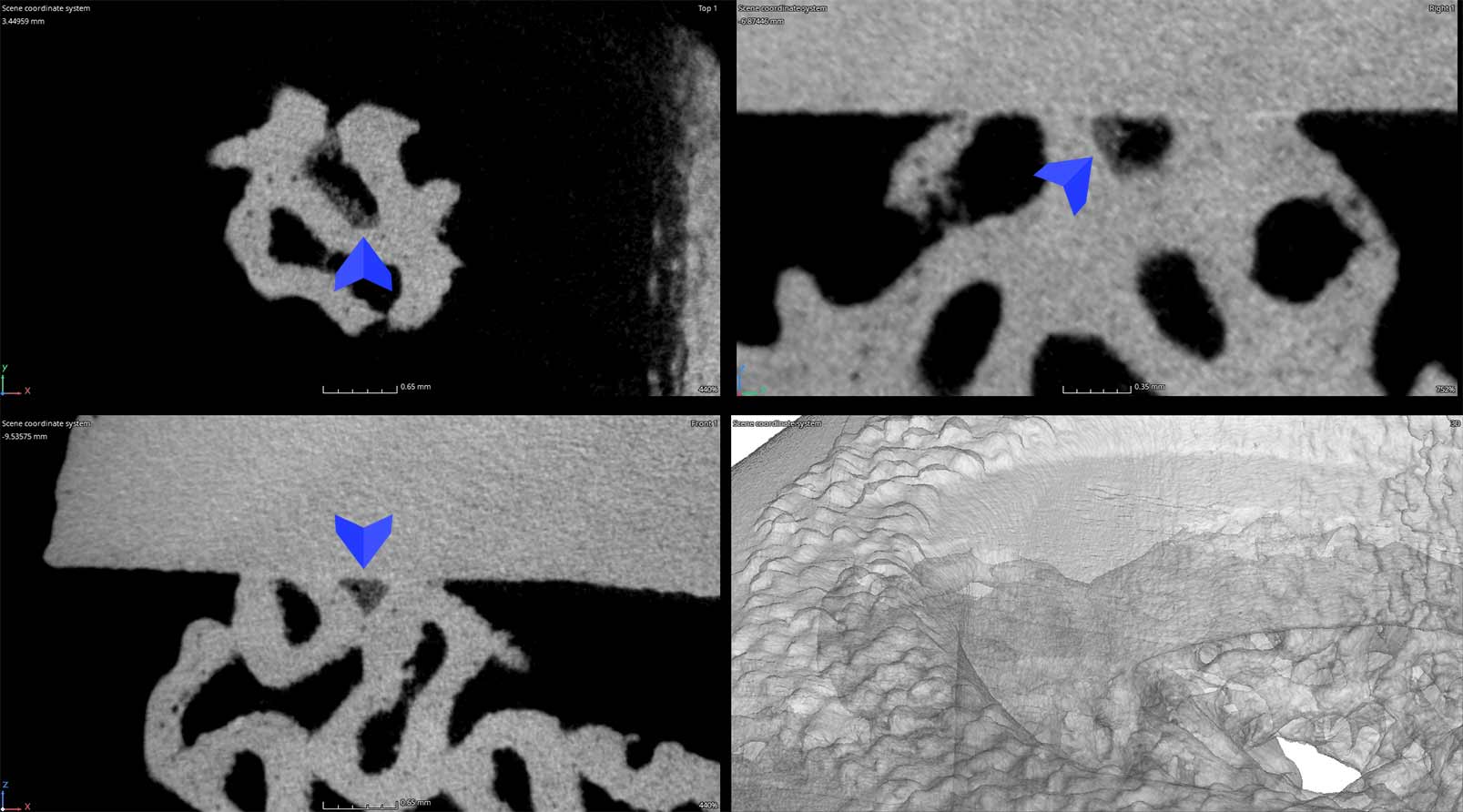

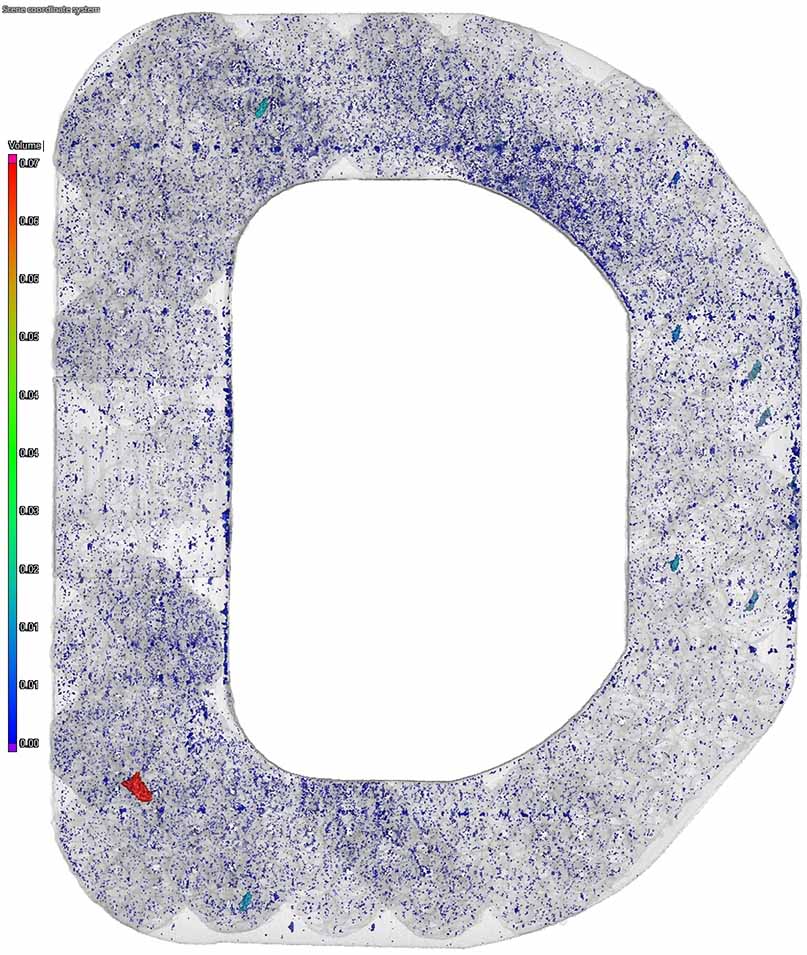

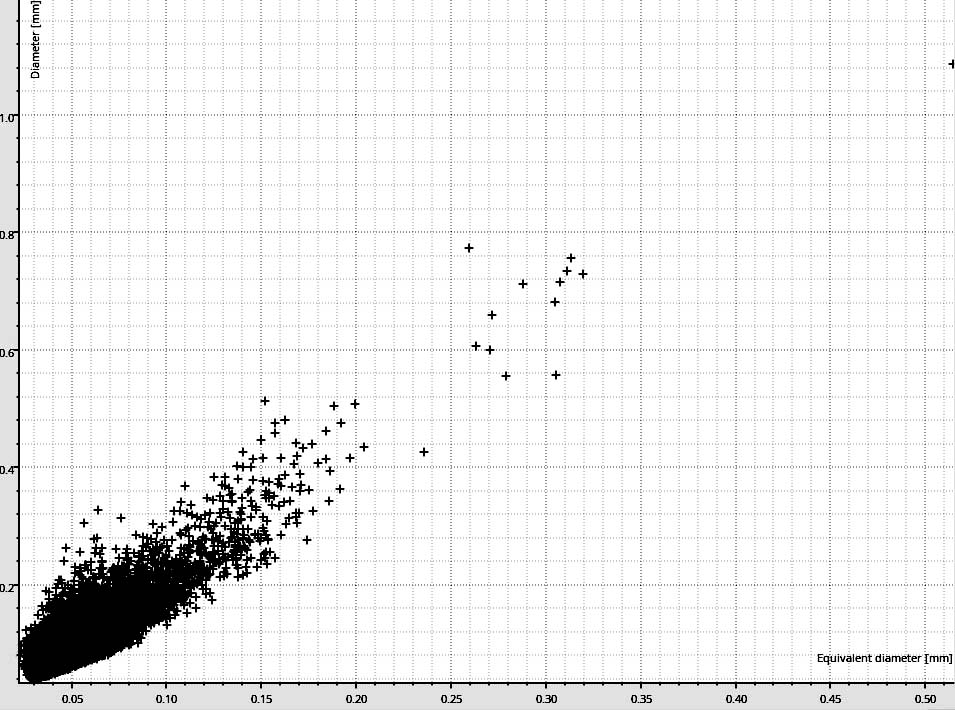

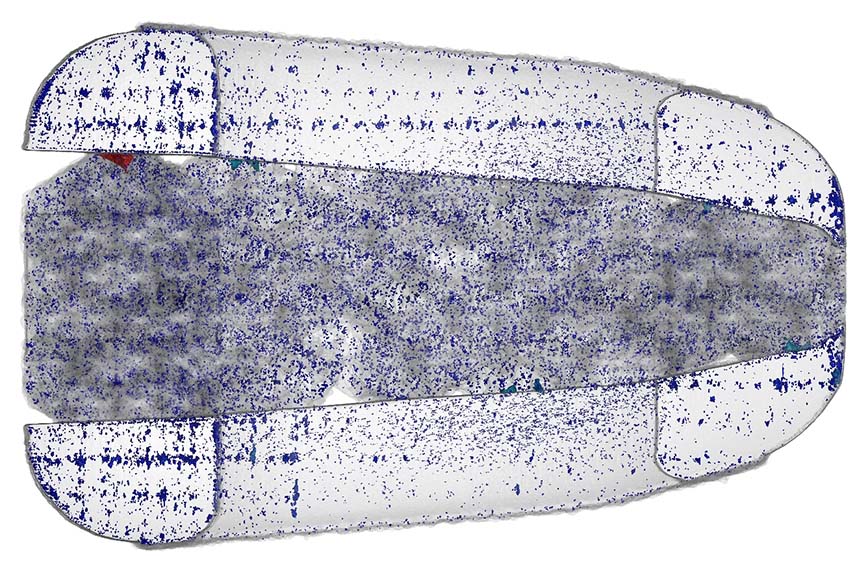

POROSITY ANALYSIS

Porosity can be volumetrically extracted and analyzed for porosity percentage, distribution, 3D rendered for visual comparisons between process changes, or exported to .stl to be used in other software packages.

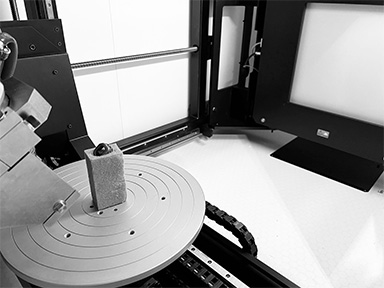

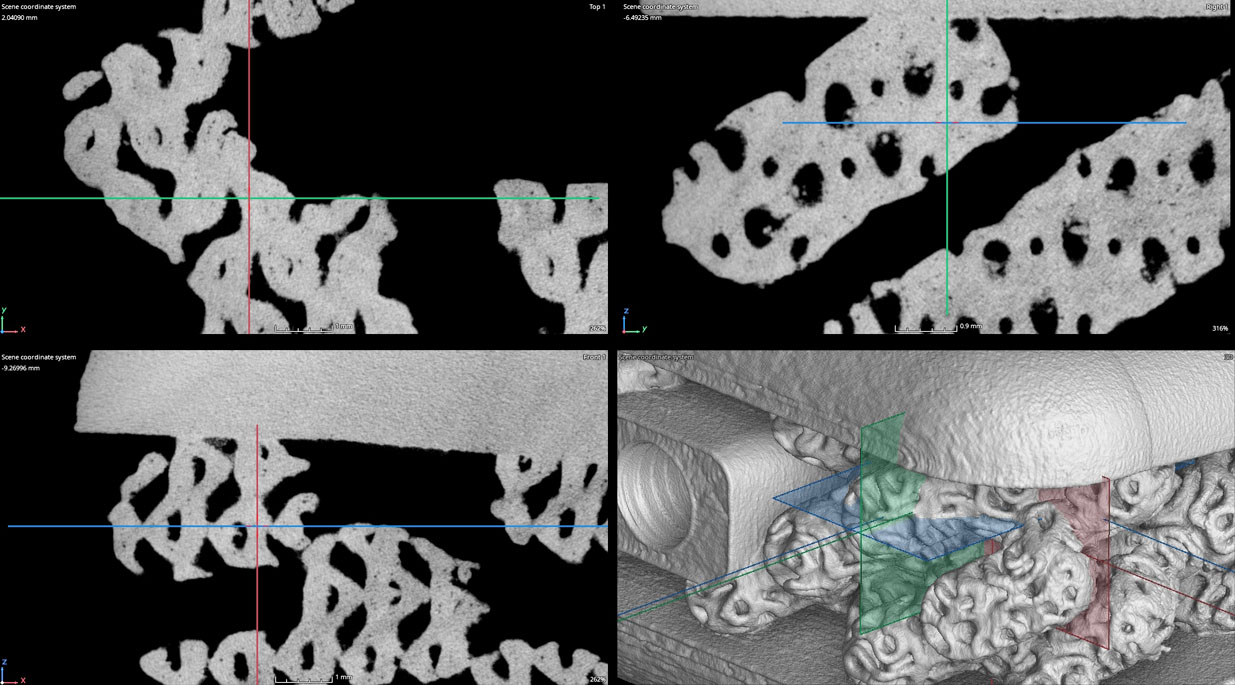

TRAPPED POWDER INSPECTION

Industrial CT scanning is used to analyze additively manufactured products for trapped powder. If trapped powder is not completely removed from products, its release during product service lifetime could cause serious problems. For medical implants with materials that are supposedly biocompatible, metallic powder can cause inflammation and prevent normal blood vessel formation. [Source] The image below shows an area of interest that should be open to the surface but closed during manufacturing. The trapped powder is seen as a slightly lighter shade of gray compared to the neighboring geometry.