CT Scanning Bellows

Bellows are a type of expansion joint used in piping applications for a variety of industries like oil & gas, aerospace and defense. Bellows allow complex systems to move according to the forces applied to them (system vibrations, pressure changes, & rapid temperature shifts).

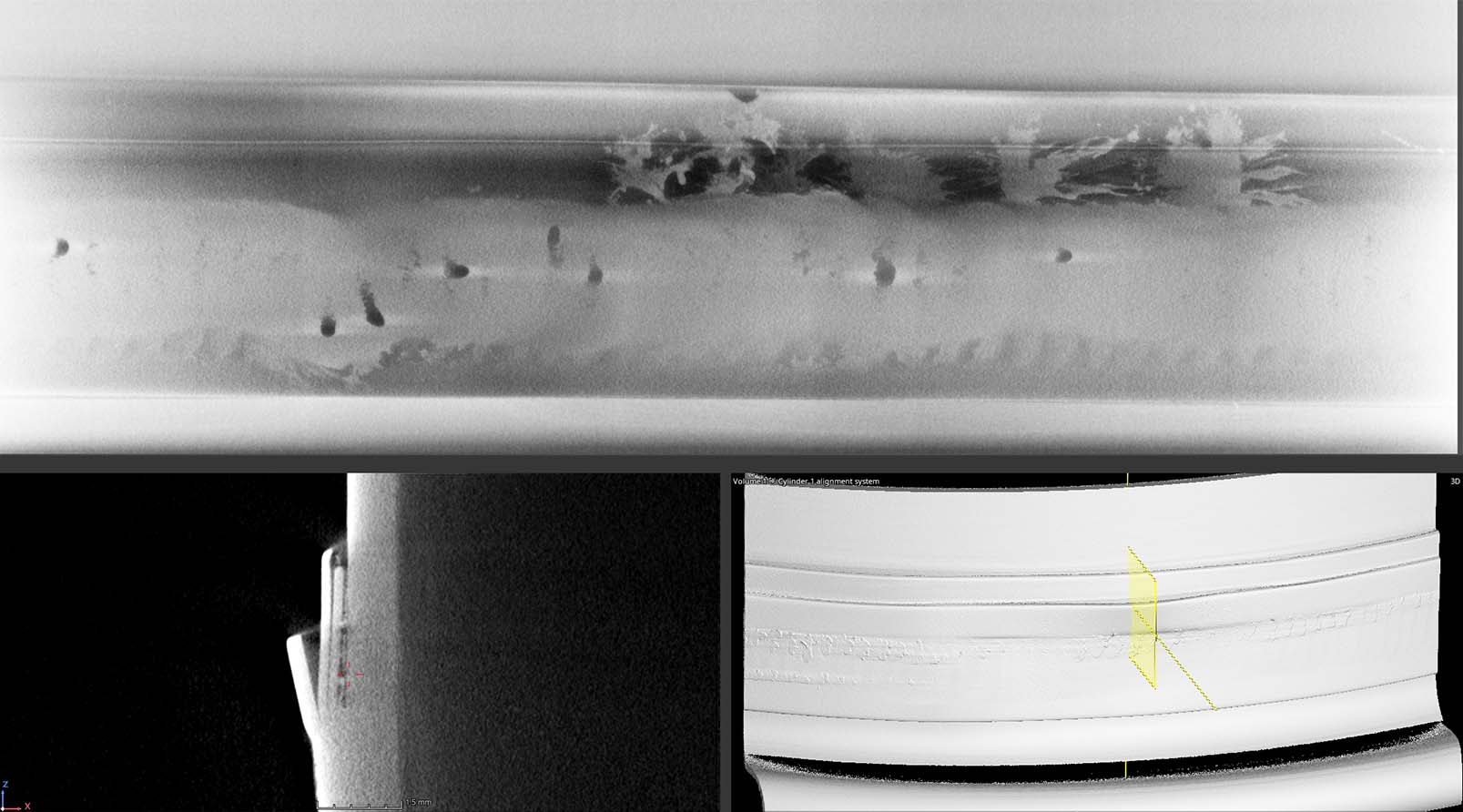

Because bellows are used to sustain a system through the above factors their structural integrity is paramount. This case study demonstrates the method of CT scanning to image and qualify bellows welds and ply separation.

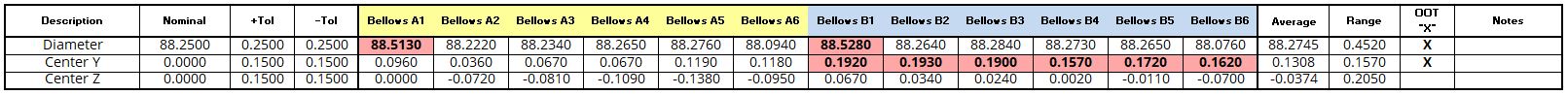

UNROLL METHOD

The “Unroll” technique offers a planar viewing method for cylindrical features or parts. Below is an unrolled, higher zoom view of the weld, porosity, and sleeve seam.

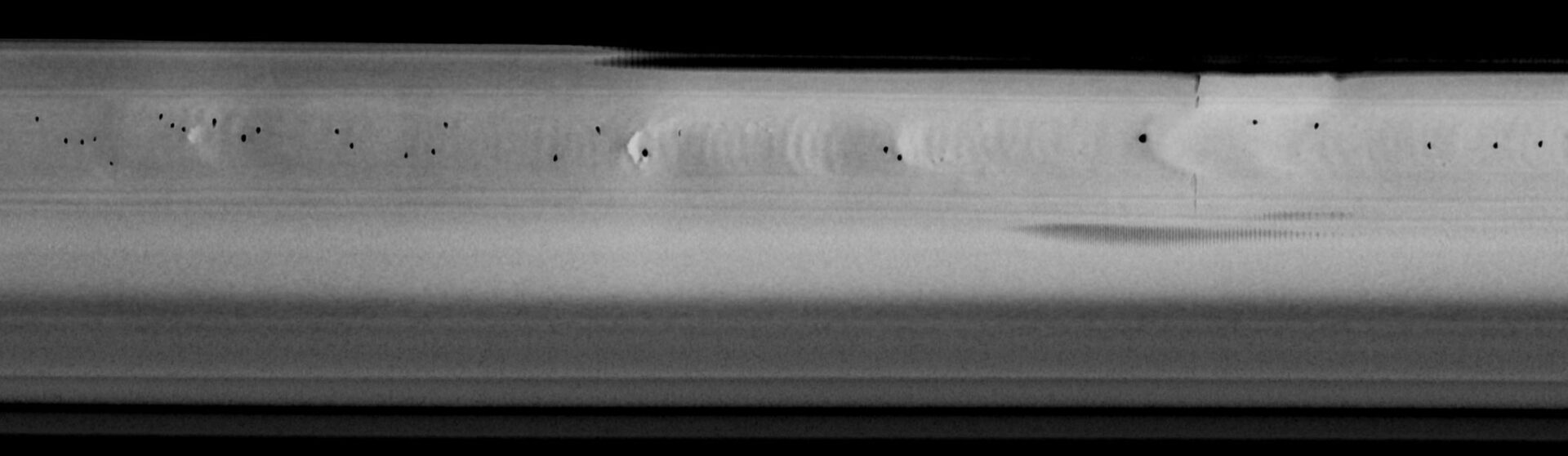

FOCUS SCAN (20um RESOLUTION)

During process development engineers often request the highest possible resolution of an area of interest. This characterization helps inform the engineer for process changes and product viability.

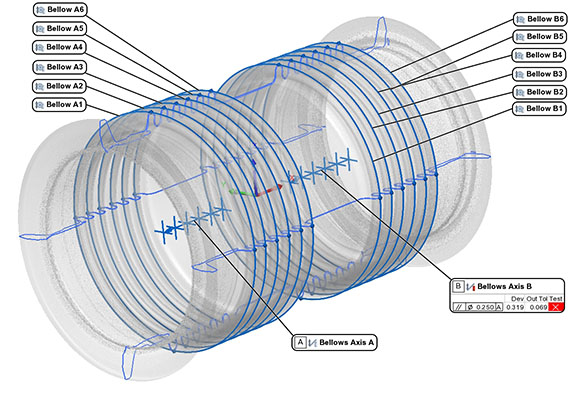

DIMENSIONAL INSPECTION

Industrial CT data, and surface data acquired using laser scanning (click here to learn more), is exported to .stl for dimensional inspection. We are able to inspect complex, inaccessible geometries that more conventional systems cannot reach. For example, we measured ID axis perpendicularity and inside ply diameter centerpoints of each bellow and found this bellow consistently deviates in +Y.