MEASURING SCRATCHES AND VOLUME WITH 3D PROFILOMETER

3D profilometry is commonly used for complex assemblies to assess scratches and surface roughness because it provides high-precision, non-destructive measurements of surface features. Unlike traditional methods like tactile probes, 3D profilometry captures detailed topographical data across a surface, allowing for accurate detection of small imperfections like scratches, dents, or irregularities. This technology is particularly useful in industries where surface quality is critical, such as aerospace or electronics, as it enables thorough analysis and quality control without damaging sensitive components.

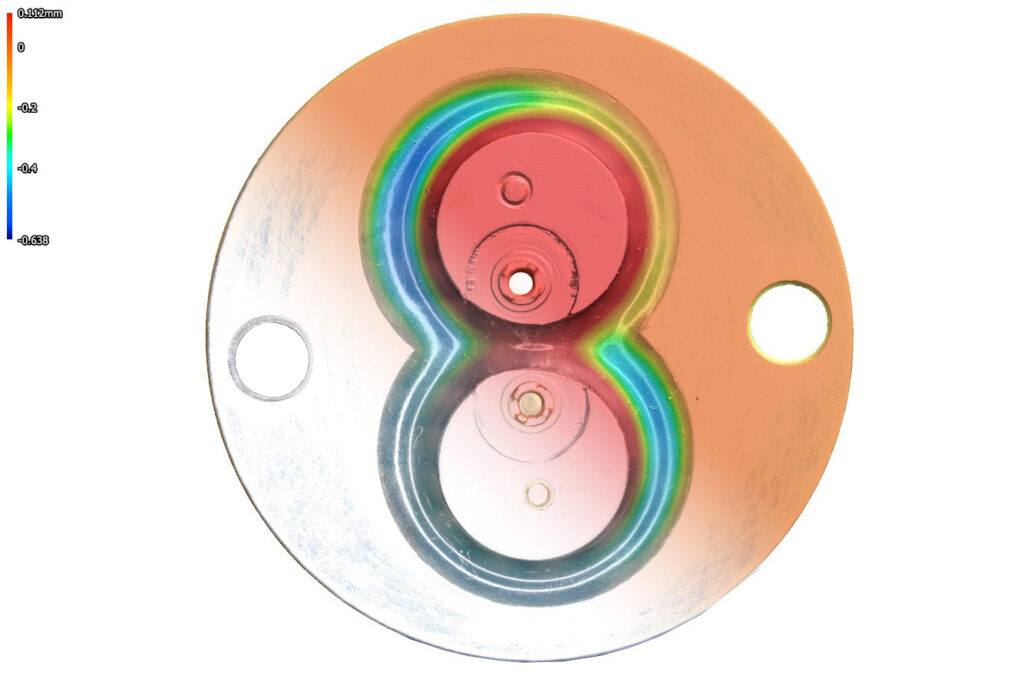

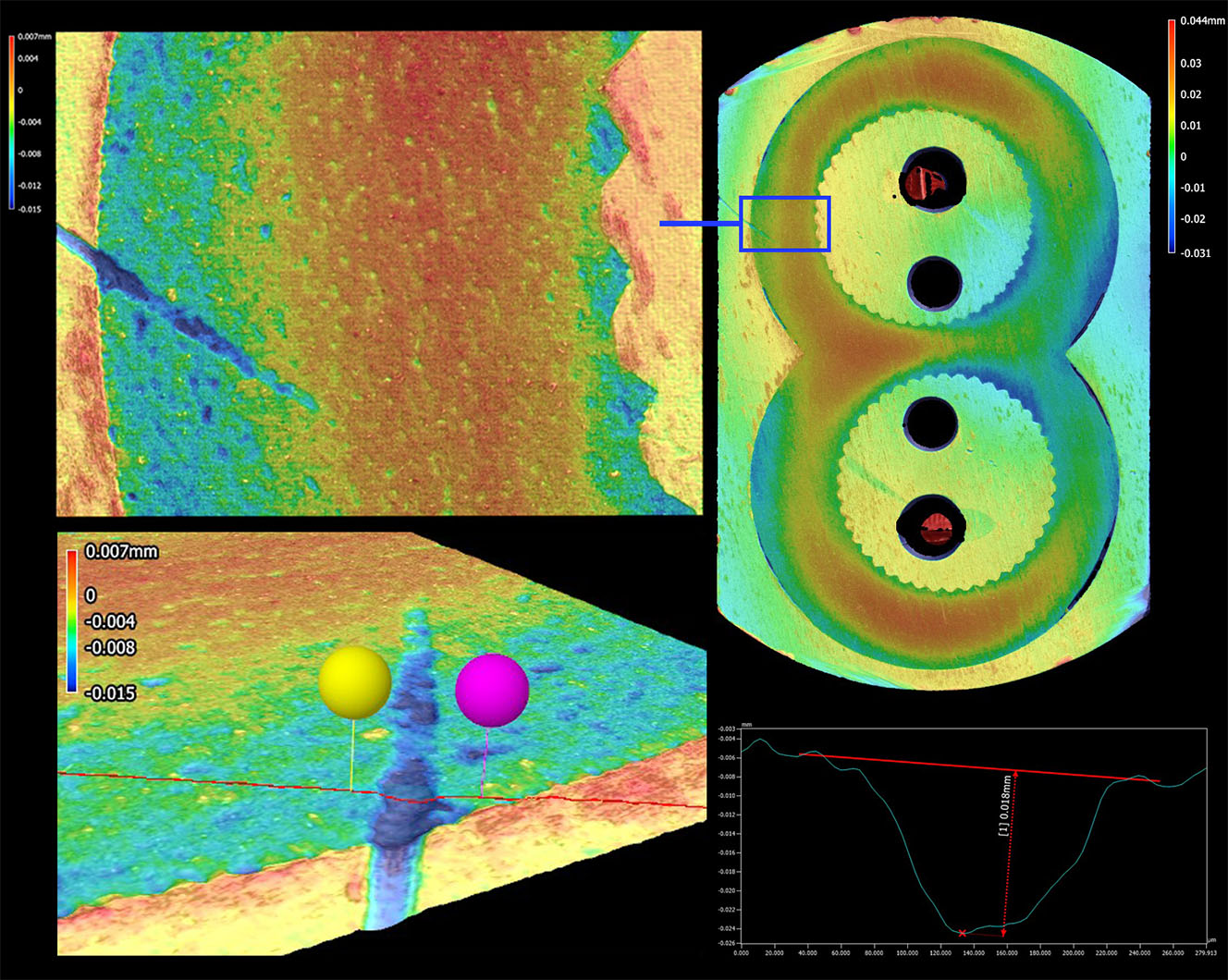

HEIGHT MAPPING FROM DEFINED PLANE

Height mapping, also known as surface profiling, is a technique used to create a detailed deviation map of the surface’s topography by capturing the height variations across a surface. We do this with a variety of systems like our CT scanners, laser scanners, and optical 3D profilometer, which scan the surface and record the height at each point, generating a three-dimensional representation of the surface.

Red areas represent a higher zone, while blue blue represents a lower zone relative to a zero location like the outside, orange flange.

Our Keyence optical profilometer and microscope is capable of 80x magnification and .1 um resolution. This allows us to characterize miniscule features like scratches for depth and origin, as well as surface offsets that should be perfectly level.

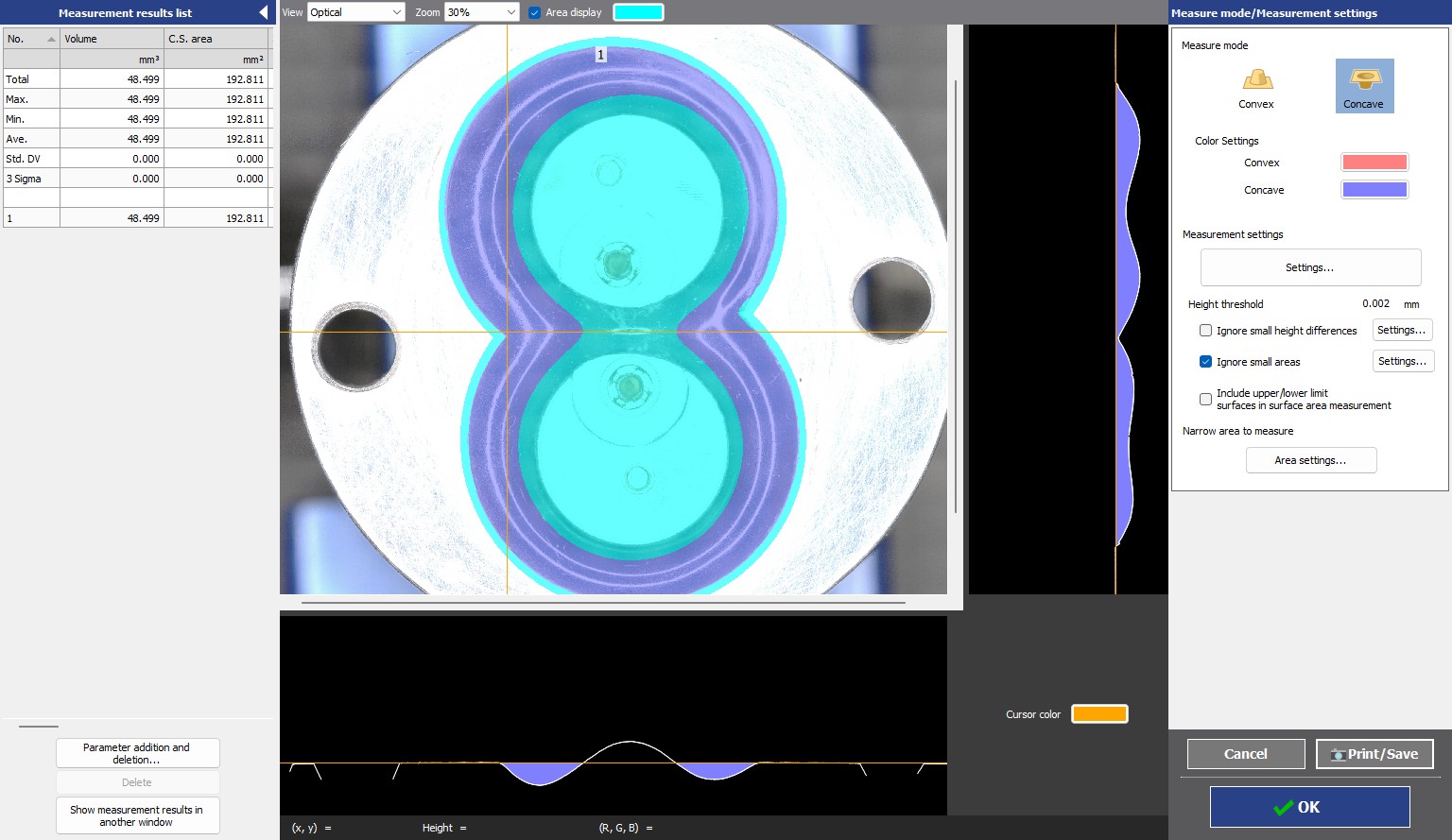

VOLUME & AREA IN CONVEX OR CONCAVE FEATURES

For convex or concave features, such as indentations or depressions, our 3D profilometer captures surface data and detects where the surface raises or drops below a reference plane. The volume is then calculated by determining the difference in height between the surface and the reference.

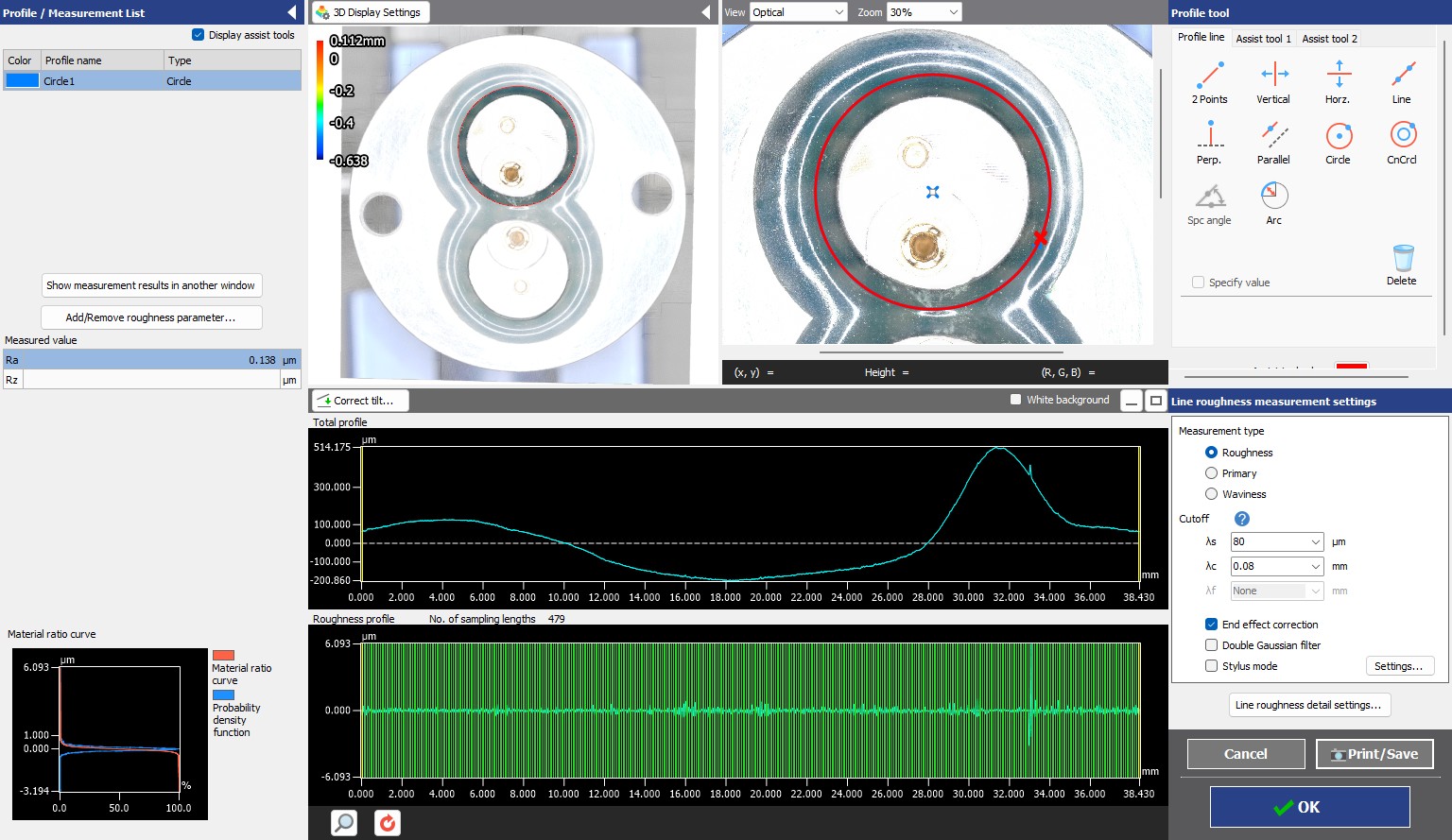

COMPLEX PROFILOMETRY USING EXTRACTED GEOMETRY

Unlike a tactile profilometer, our 3D optical profilometer can measure surface roughness using complex geometric tools. This example shows that we can extract a circle center and then offset a concentric circle to a pre-determined distance to measure a perfectly circular surface roughness result. The profile of a line can also be analyzed.