Industrial CT Scanning Battery Cells

In the race towards a sustainable future, battery technologies have emerged as frontrunners, promising cleaner, greener transportation. Central to this revolution are lithium-ion battery cells, the lifeblood of many electronics. Ensuring the safety and reliability of battery cells is paramount, presenting a unique challenge for manufacturers. Enter CT scanning, a game-changing technology offering unprecedented insights into battery cell integrity.

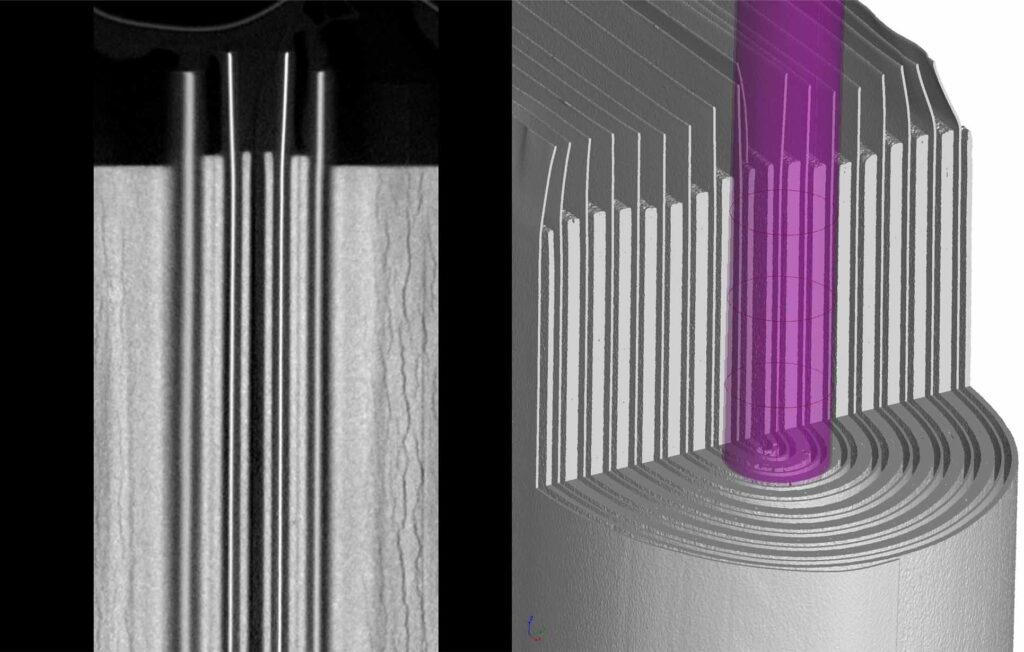

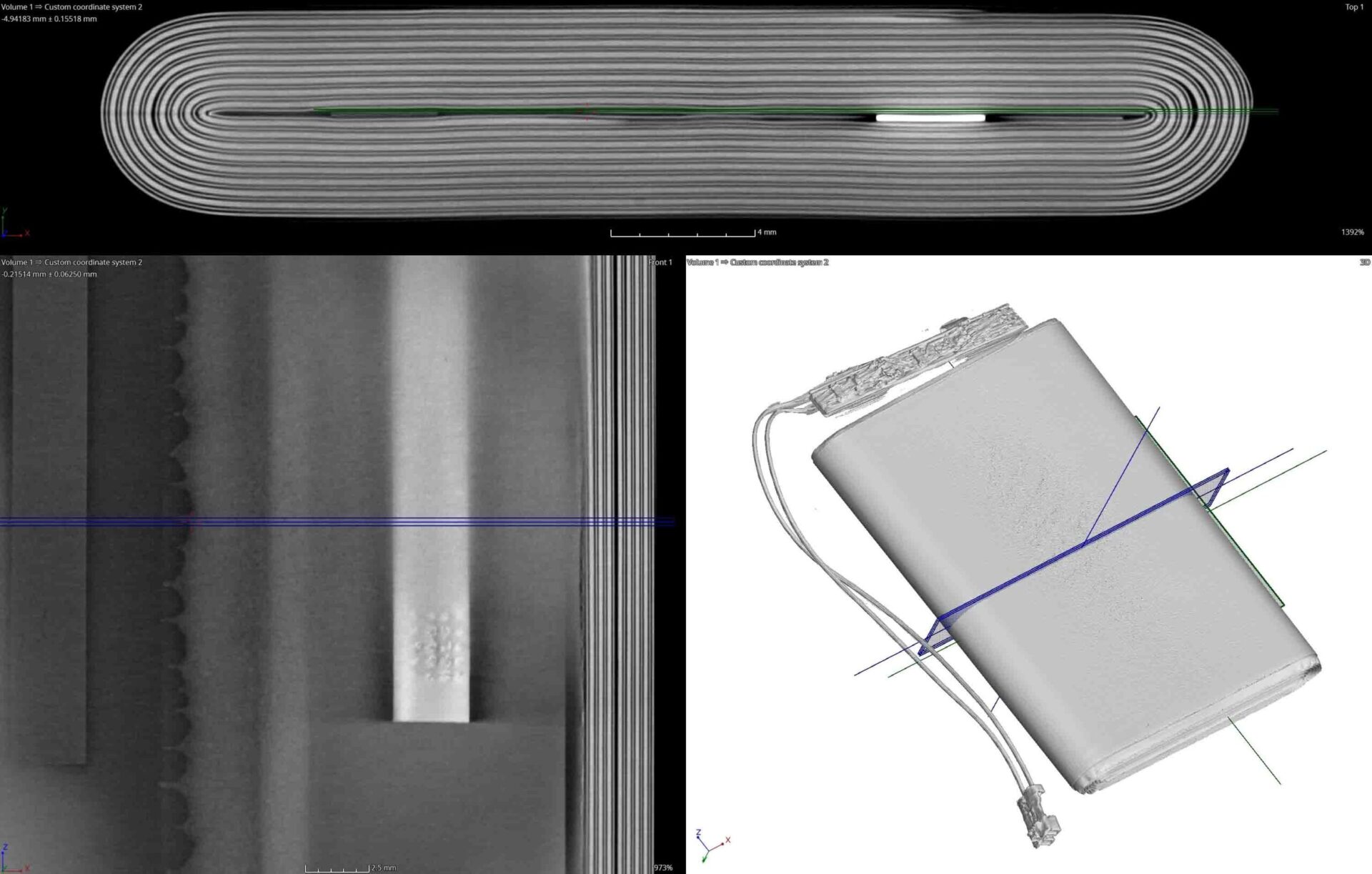

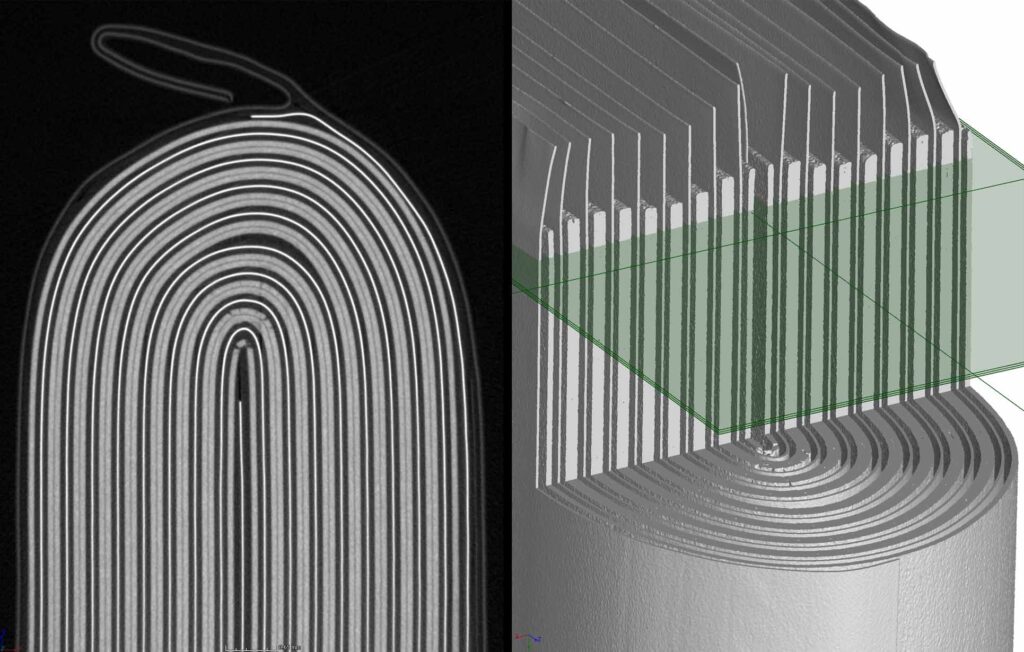

Traditional inspection methods often fall short when it comes to assessing the intricate internal structure of battery cells. However, CT scanning changes the game by providing a non-destructive and highly detailed examination of each cell. With its ability to penetrate solid materials and generate 3D images of internal features, CT scanning offers a comprehensive view of battery cell health.

LOOKING FOR DEFECTS

SORTING CELLS