Characterizing Leak Paths in Brazed Copper Heat Exchangers

Heat exchangers are devices that transfer heat from one medium to another using a network of channeled circuits. We’ve CT scanned most types of heat exchangers including shell & tube to image tube array welds and plate type exchangers to evaluate brazes and leak paths.

This case study uses a common copper plate type heat exchanger which contains a network of channels that fluid passes through.

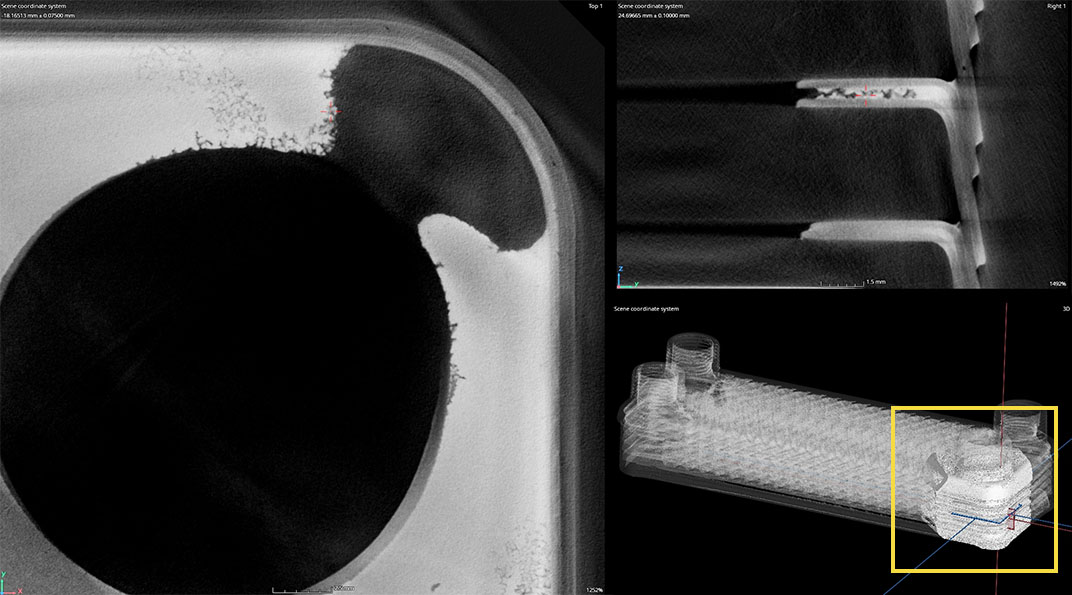

As seen below in the general part scan there are indications of porosity and gaps in the corner and edges which may be causing the part to leak.

Once an area of interest has been determined we can increase resolution to provide better detail of the failure. This partial scan at just the corner reveals that the entire corner is missing brazing material and there are also leak paths in proximity. The customer uses this information to adjust their manufacturing process.