THE DEFINITIVE GUIDE TO CT SCANNING BATTERIES

Modern electrification is taking over many industries and battery technology is rapidly evolving to ensure new energy sources have a reliable storage mechanism. Industrial CT imaging, a technology that offers the ability to see inside objects non-destructively, is critical for evaluating manufacturing processes and comparing technology changes.

This case study demonstrates the viability of scanning various battery types from small battery cells to large EV battery modules.

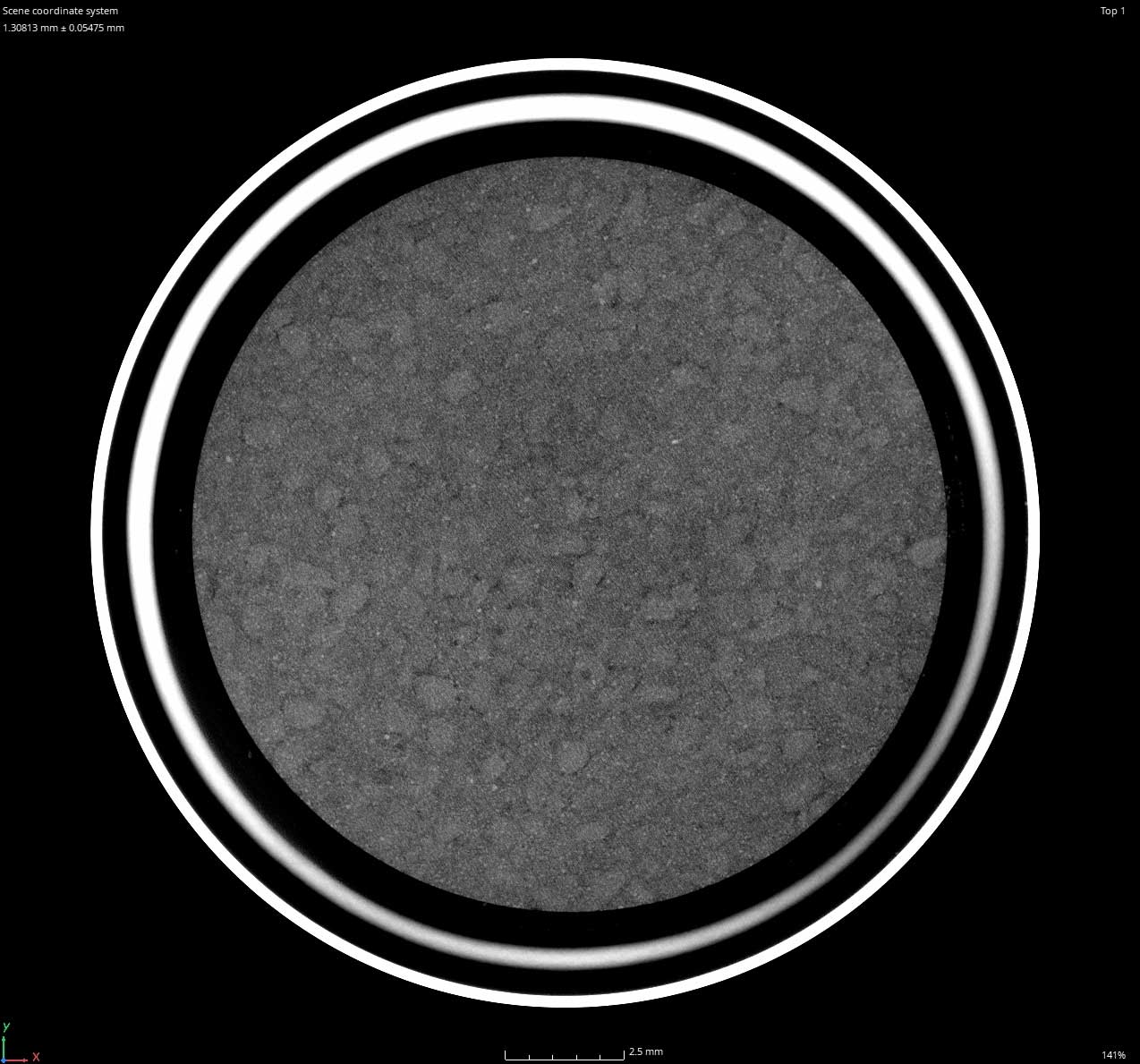

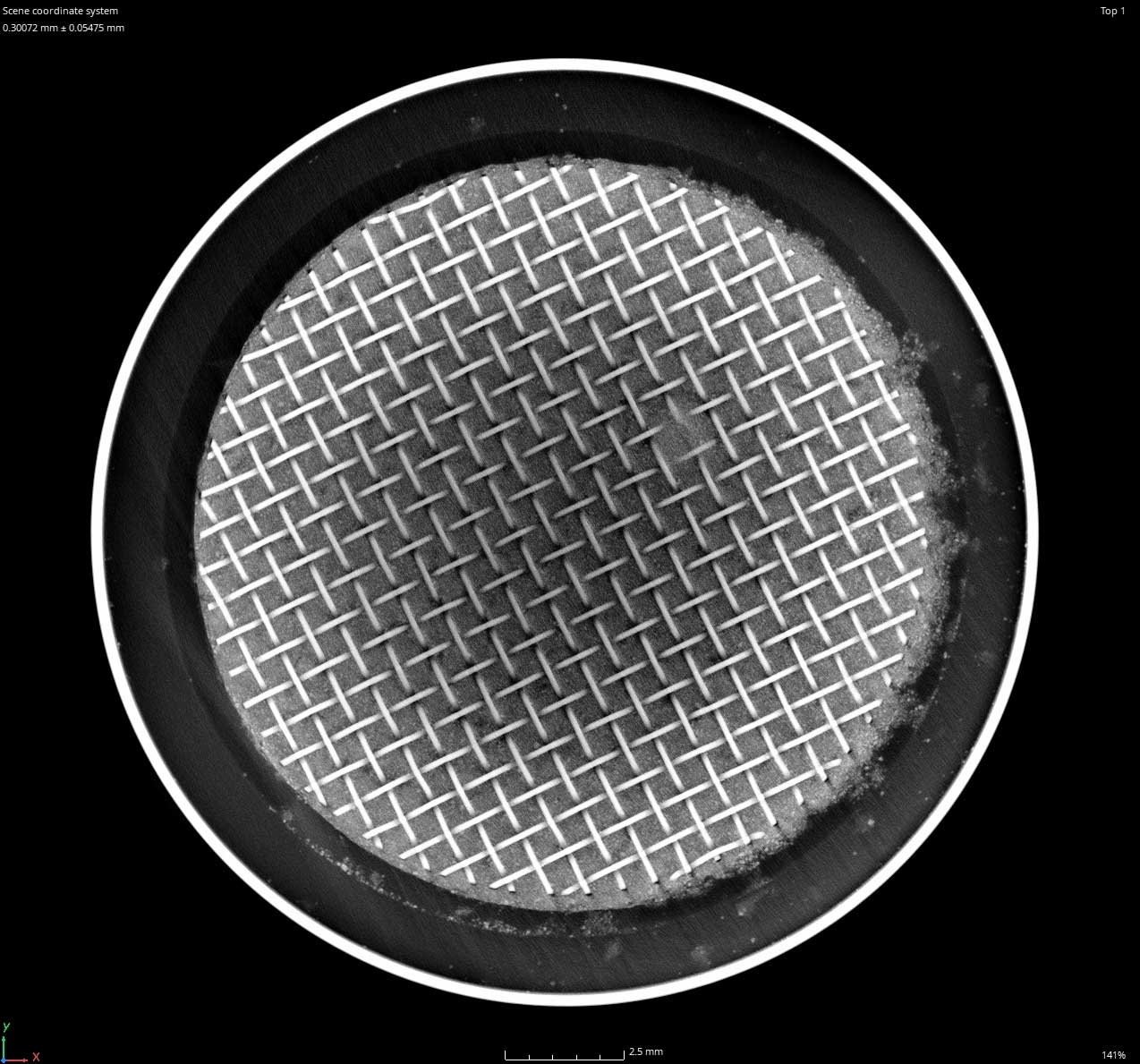

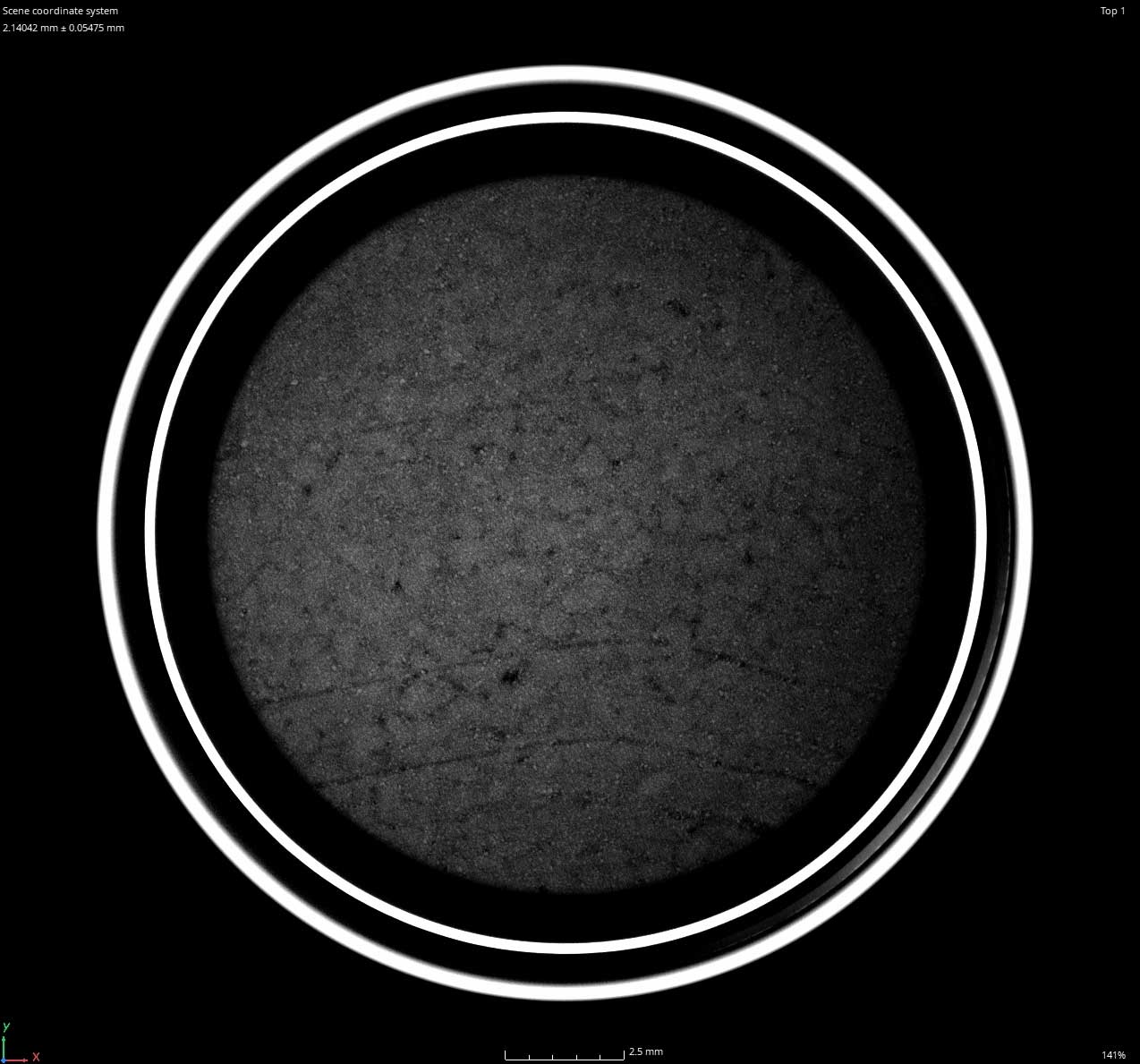

COIN & BUTTON CELL BATTERIES

Micro-CT imaging is a critical tool for characterizing the geometry of small batteries. With variable resolution between 3um and 125um, no battery is too small to be imaged.

CT characterization is used for evaluating new technologies, comparing process changes, and determining points of failure.

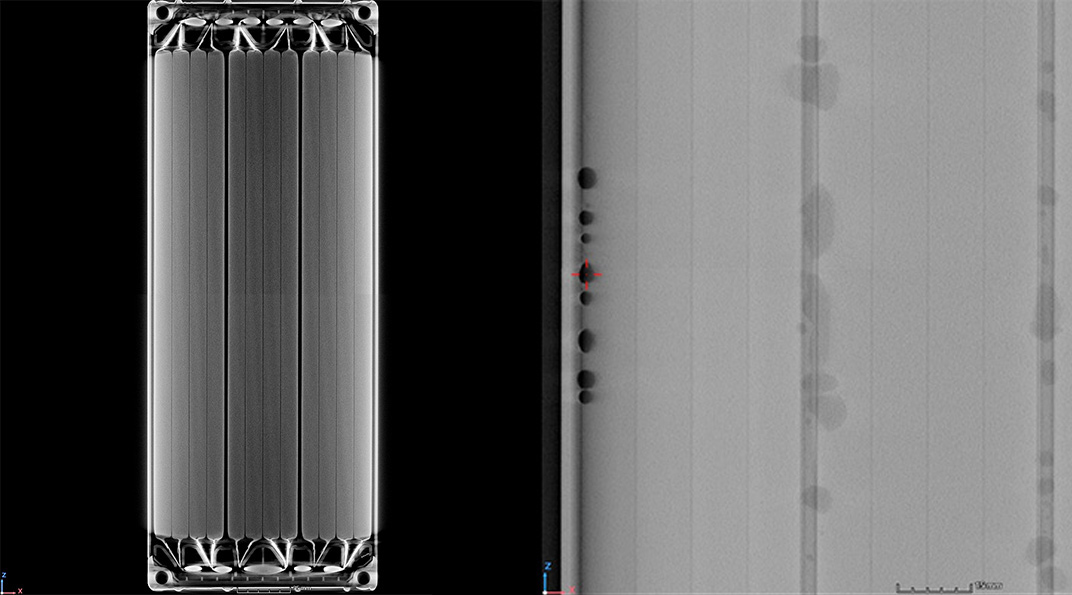

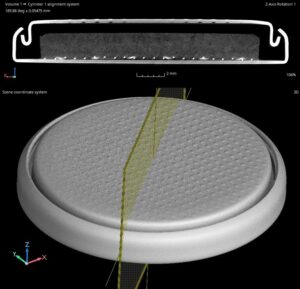

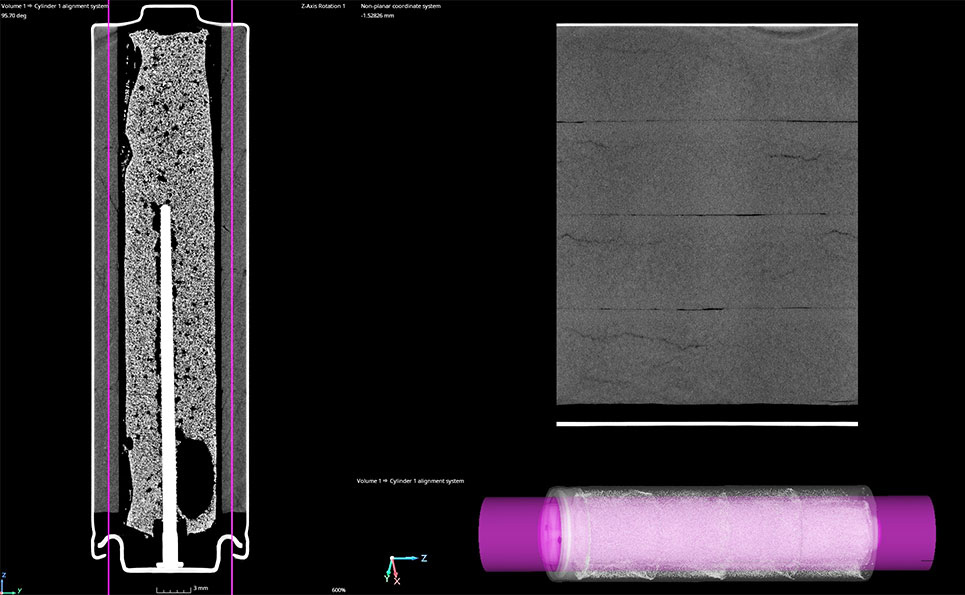

CYLINDRICAL BATTERY CELL (AA)

There are several imaging methods and variables to consider for a given application. When we scan cylindrical cells a useful tool called “Unroll” is often deployed.

Unroll allows the inspector to planarize cylinders. For example, imagine cutting a toilet paper roll and laying it flat on your desk. The digital equivalent allows the inspector to scroll through a planar view at any distance from the specified axis.

The video to the right demonstrates “Unroll.”

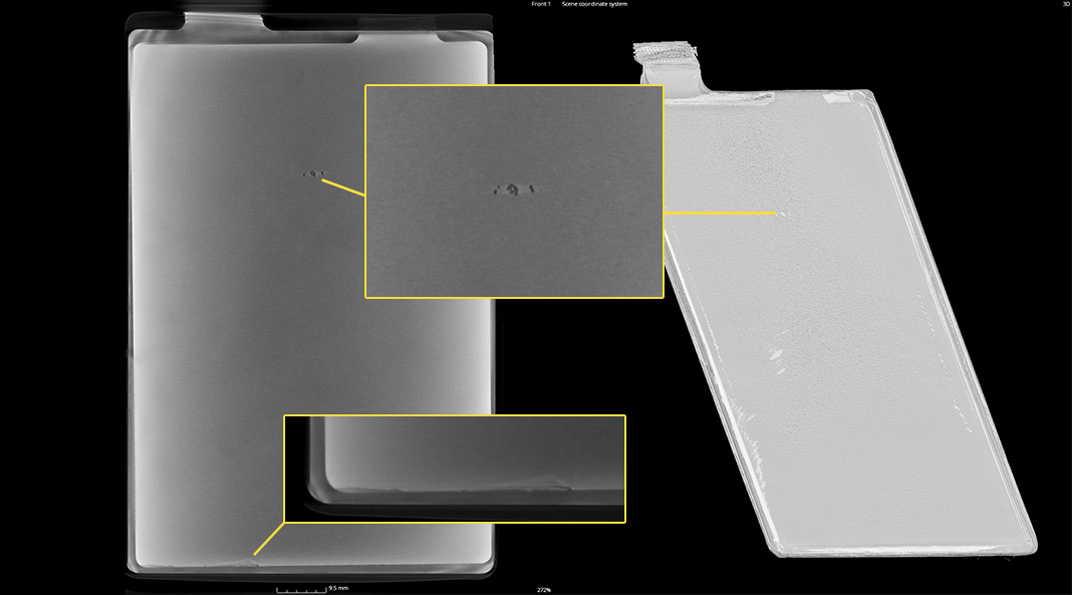

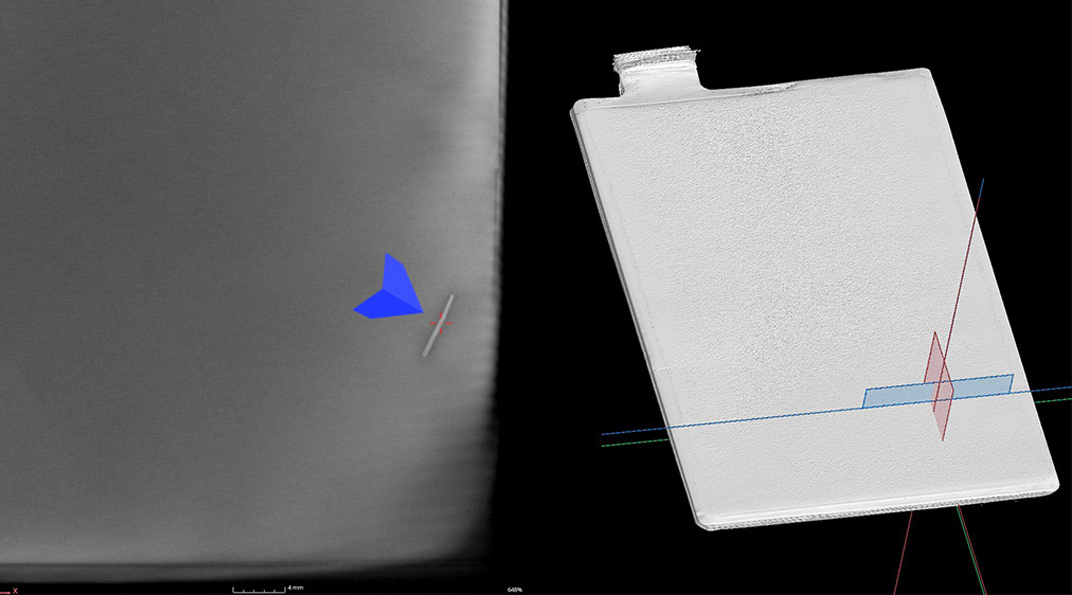

POUCH & PRISMATIC CELLS

Foreign object debris is one of the primary causes of battery thermal runaway resulting in increased temperatures, destruction of the battery, and fires.

Reliable detection of foreign objects is critical for the safe manufacture, storage, and long term use of battery cells. If there is a manufacturing failure it is best to inspect cells before assembling them into full battery modules. Because cells are smaller and easier to handle resolution and x-ray penetration can be improved.

BATTERY MODULES

Industrial Inspection staff has CT scanned thousands of battery modules. Customized criteria are used for each project with regard to what the issue may be. Some typical rejectable indications include:

> Foreign Object Debris

> WELD DEFECTS

> ANODE AND CATHODE ALIGNMENTS

> CELL TEARS & LEAKS